Continuous casting production molding method of hollow fiber membrane module

A molding method and fiber membrane technology, which is applied in the field of continuous casting and molding of hollow fiber membrane modules, can solve problems such as root protection of membrane filaments, increased cost investment, and tediousness, and achieve high economic benefits, market promotion value, and labor saving and time cost, and the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The continuous casting method is produced according to the manufacturing method of the hollow fiber membrane module, but adopts the method of continuous casting from the bottom. The sequence of continuous casting is to pour the soft epoxy resin first, and then pour the hard epoxy resin. The density before curing is 1.05g / cm3 (25°C), and the density of hard epoxy resin before curing is 1.15g / cm3 (25°C).

Embodiment 2

[0018] The continuous casting method is produced in accordance with the manufacturing method of the hollow fiber membrane module. The hollow fiber membrane with a water content of less than 10% is used. According to the method of continuous casting from the bottom, the sequence of continuous casting is to cast polyurethane first, and then cast hard epoxy resin. .

[0019] The control group 1 adopts the secondary casting method and is produced according to the manufacturing method of the hollow fiber membrane module, using the method of casting hard epoxy resin at the bottom and casting polyurethane at the side port.

[0020] The control group 2 adopts the secondary casting method, and is produced according to the manufacturing method of the hollow fiber membrane module.

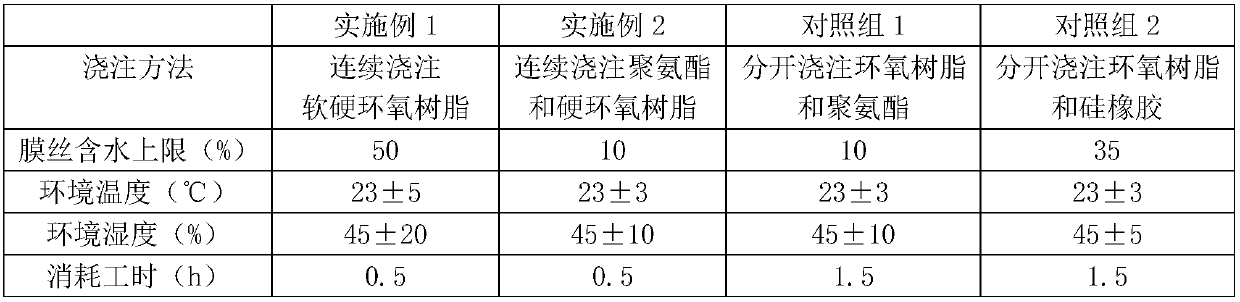

[0021] The above methods are summarized in the following table based on factors such as the casting environment, membrane moisture content and cost consumption in the preparation process of the hollow fiber m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com