Module of agitation fan in microwave oven

A technology of microwave ovens and components, which is applied in the direction of household stoves/stoves, household heating, lighting and heating equipment, etc., can solve the problems of increasing the types of components and the number of assembly processes, reducing the processing technology, and difficult to process, so as to reduce the types and The number of assembly processes, the improvement of processing manufacturability, and the effect of reducing assembly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

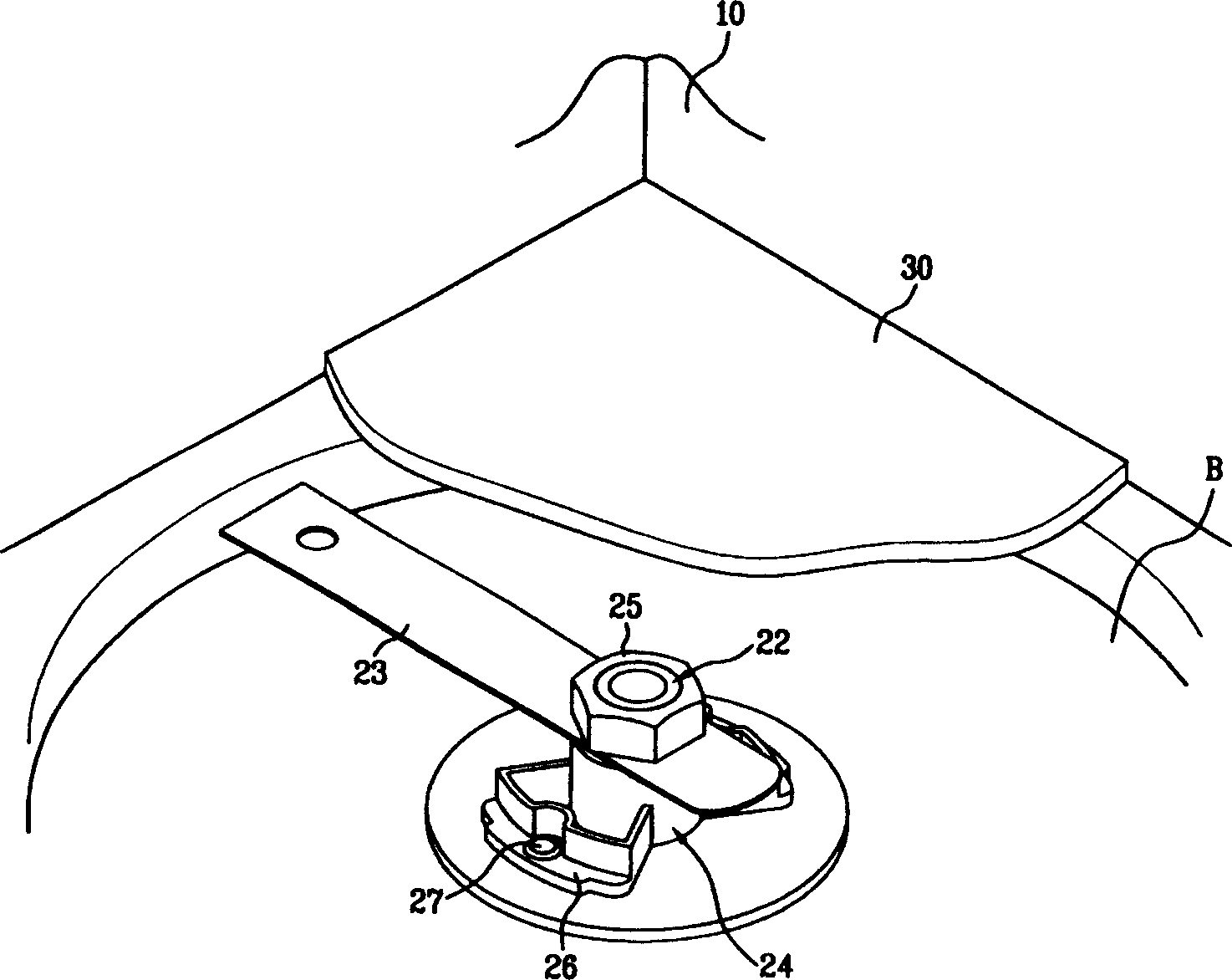

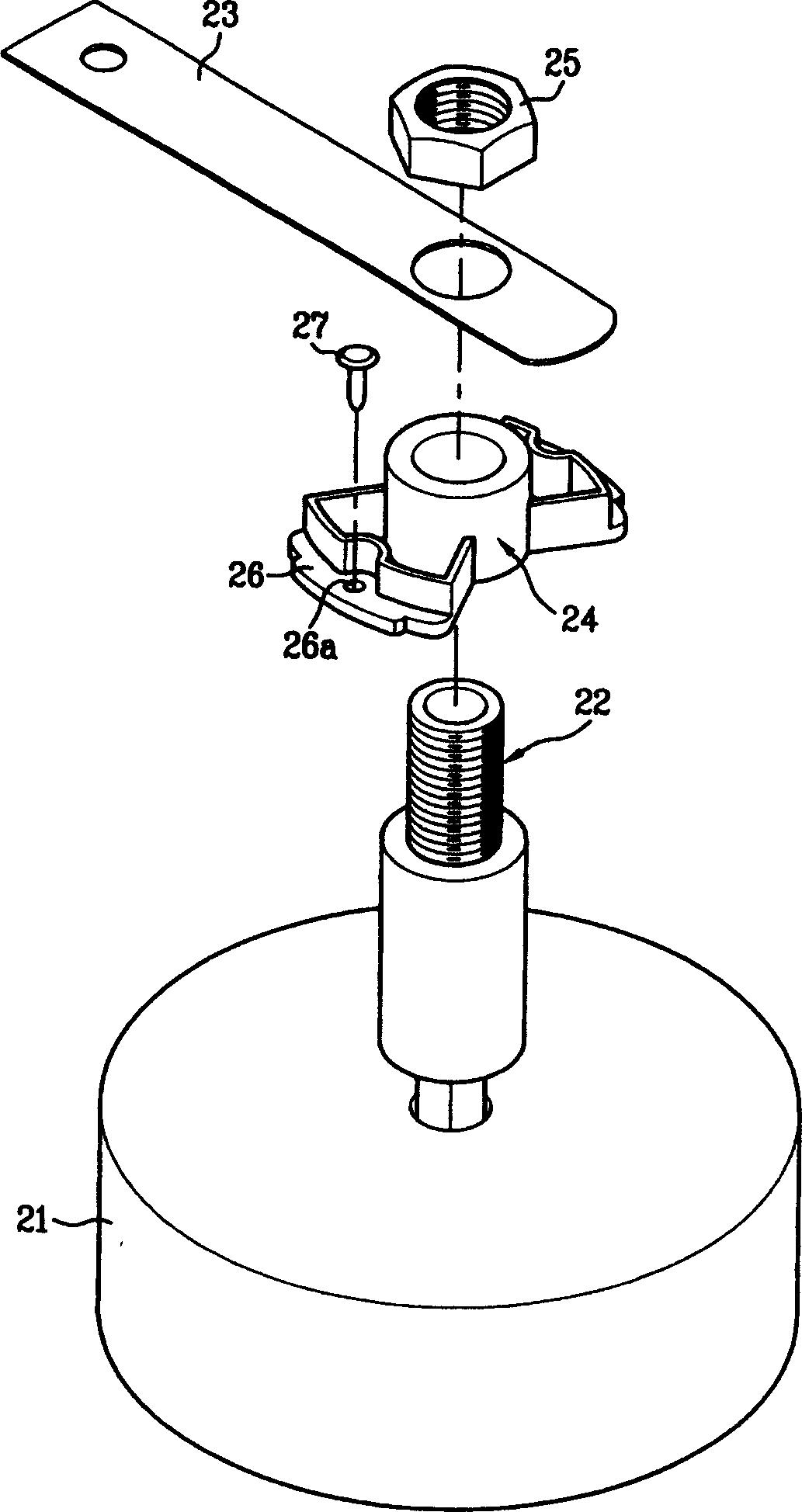

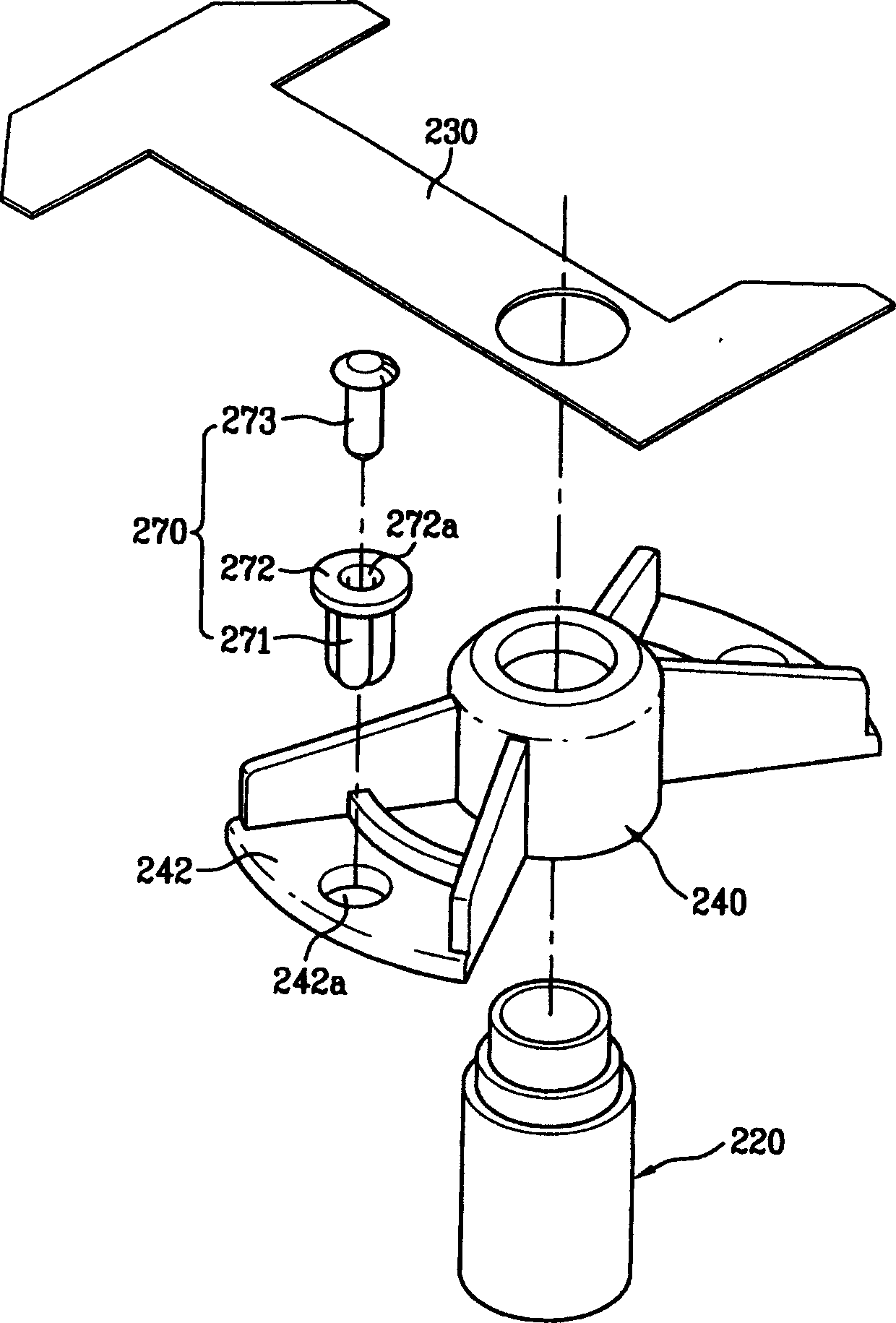

[0011] Such as image 3 As shown, the stirring fan assembly of the microwave oven provided by the present invention mainly includes a supporter 220 , a bracket 240 , a stirring fan 230 and a rivet 270 . Supporter 220 is hollow tubular, and its bottom endoporus is connected on the axle 211 of the rotary motor 210 that runs through furnace chamber 100 bottom surface, and the diameter of its upper end endoporus is larger than the diameter of its lower end endoporus. In addition, the upper end of the supporter 220 has such a thickness that its outer wall can be bent outward by a pressing process. A central hole 241 that can be inserted into and combined with the upper end of the holder 220 is formed through the central part of the bracket 240 , and assembling parts 242 are formed on both sides of the central hole 241 . The inner diameter of the lower end of the central hole 241 is substantially the same as the outer diameter of the lower end of the holder 220, that is, the inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com