Sewing machine presser foot

A sewing machine and presser foot technology, which is applied in the field of sewing machine presser feet, can solve problems such as difficulty in obtaining good-quality sewing products, impossible to deal with, and reduced operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

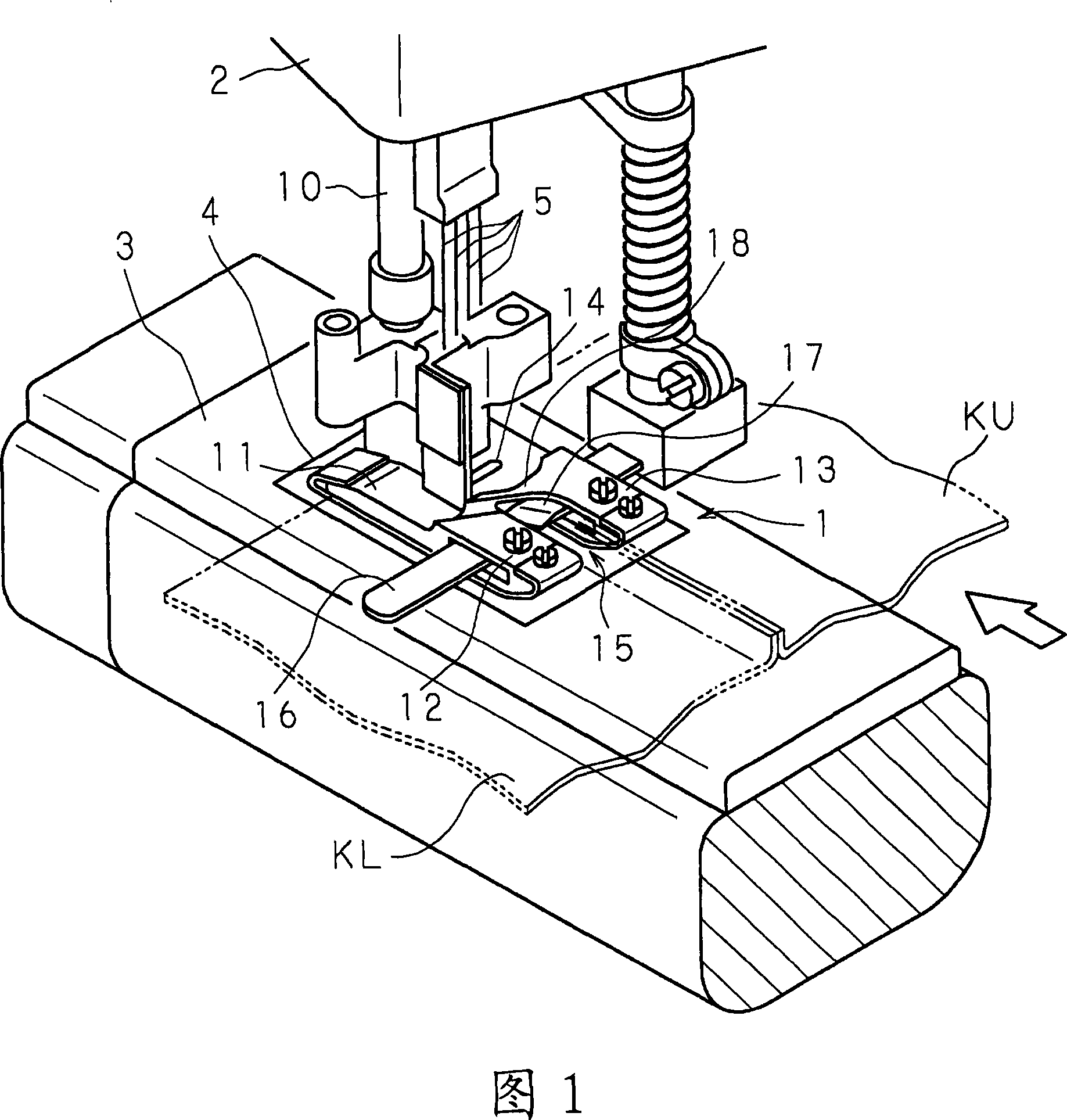

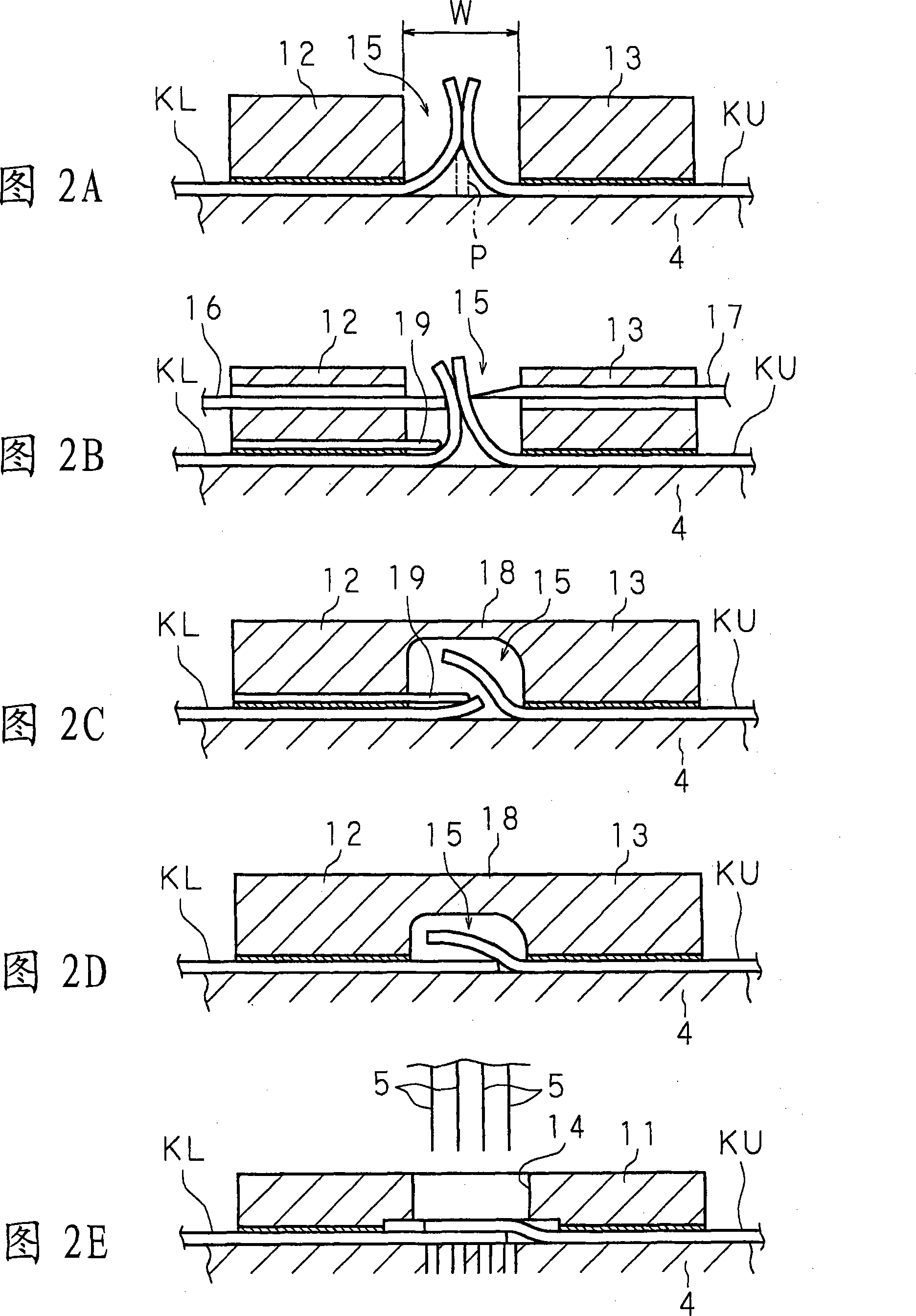

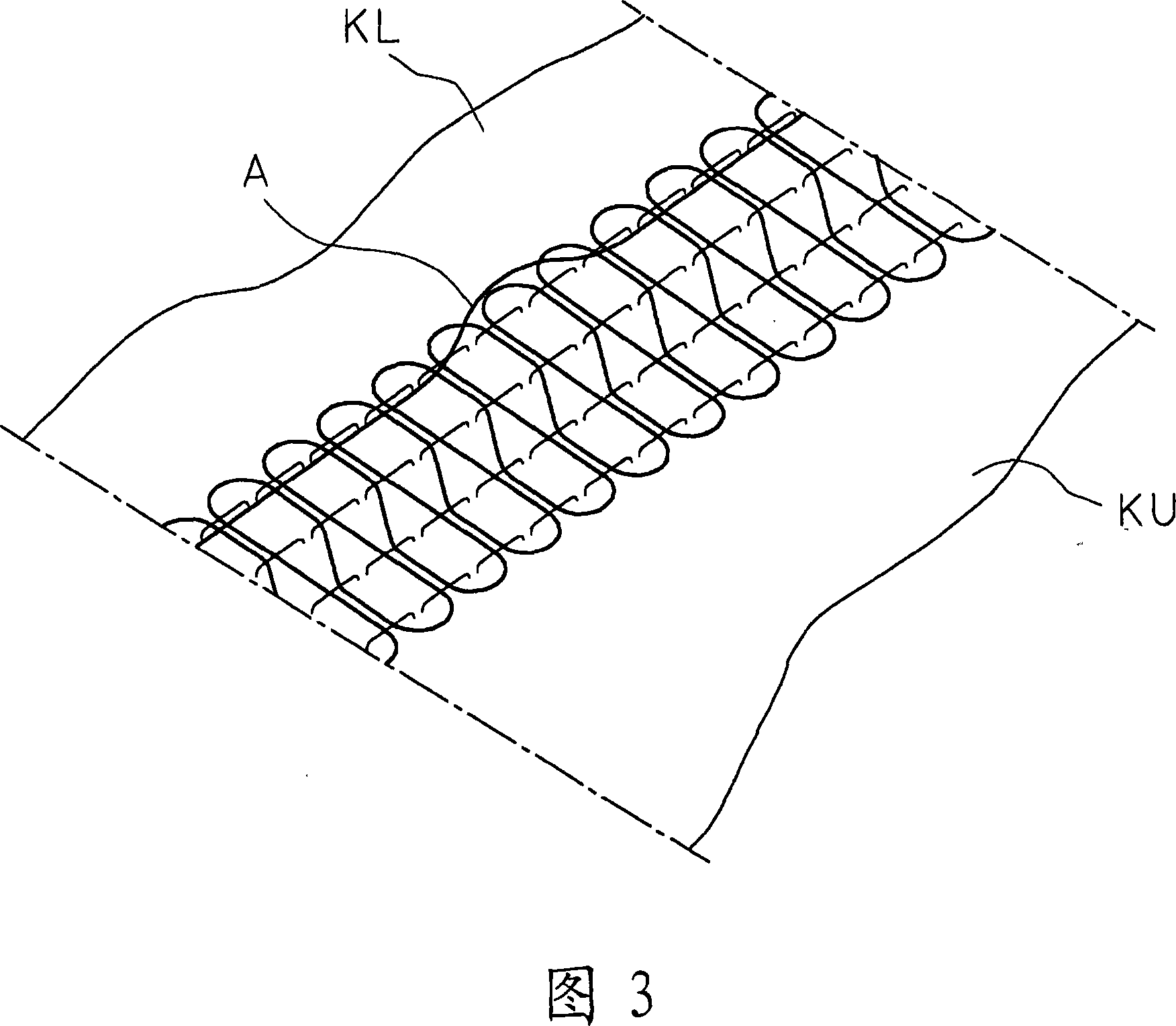

[0033] Hereinafter, the present invention will be described in detail based on the drawings showing preferred embodiments. 4 is an exploded perspective view of the presser foot of the sewing machine according to the present invention.

[0034] The presser foot 1 according to the present invention has a presser foot main body 11 with a needle drop position 14 provided at the approximate center thereof, and two presser claws 12 and 13 provided at the front of the presser foot main body 11 and parallel to each other Extend forward. The presser foot main body 11 has an upright support leg 11a at the rear, and is inserted into and fixed to the lower end of the presser bar 10 indicated by the double-dot chain line in FIG. Like the conventional presser foot 1 , as shown in FIG. 1 , the presser foot main body 11 is supported on the lower portion of the front end of the sewing machine arm 2 .

[0035] As shown in FIG. 1 , the presser foot 1 is a needle that is lowered onto the sewing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com