Machine head and machine base split type pattern sewing machine

A pattern sewing machine, split-type technology, applied in the field of sewing machines, can solve the problems of reduced work efficiency, poor stability, small sewing area, etc., and achieve the effects of improved production efficiency, convenient operation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

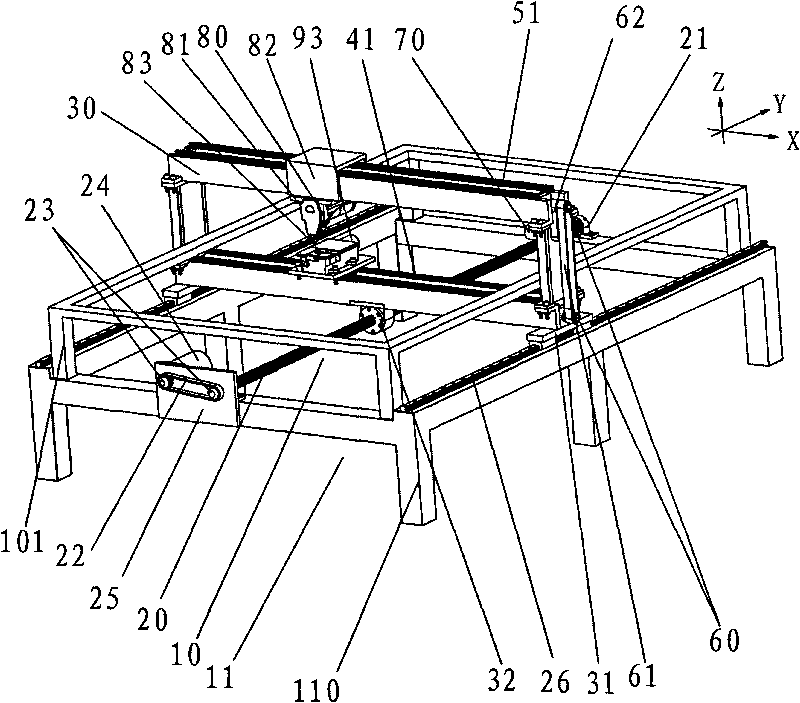

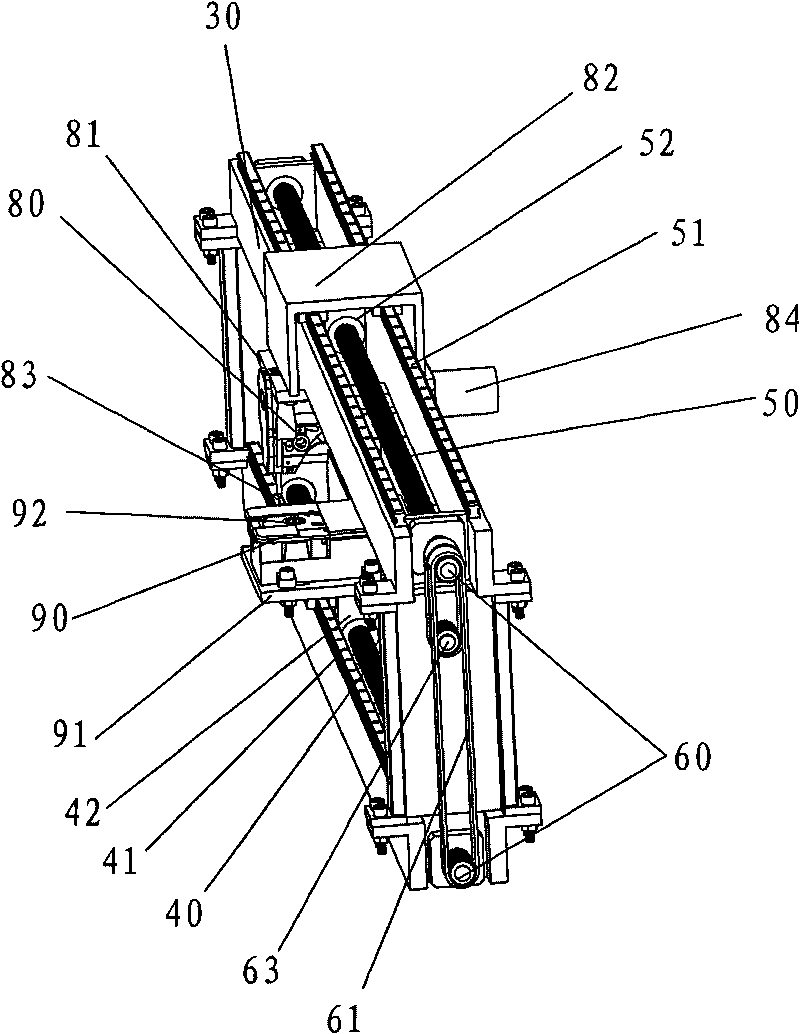

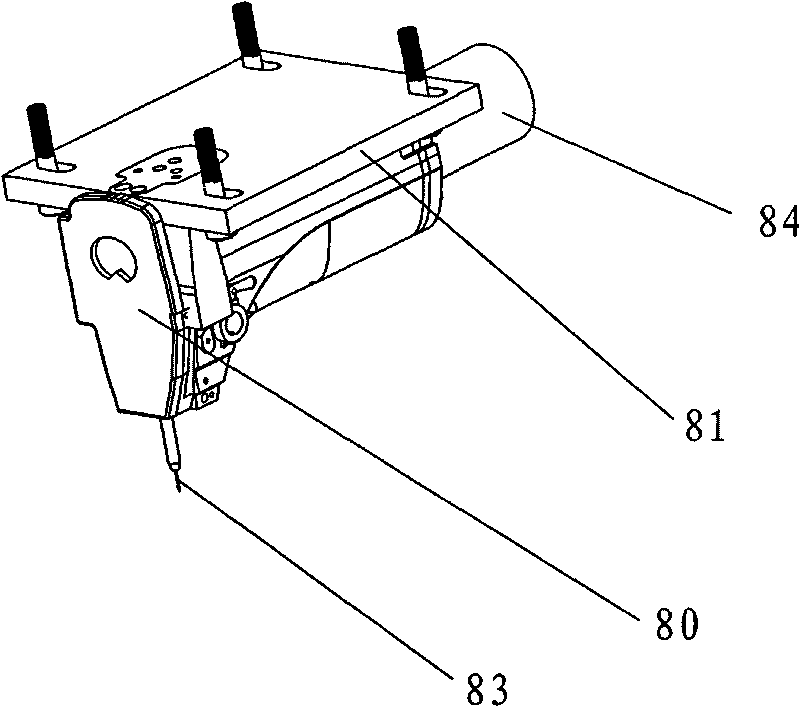

[0023] The present invention will be further described below with specific embodiments in conjunction with the drawings, see Figure 1-4 :

[0024] Separated pattern sewing machine with head and base, including:

[0025] Frame: It is composed of a lower frame 11 and an upper frame 10. Both the upper frame 10 and the lower frame 11 are provided with support legs 101 and 110 downward on a rectangular frame, and the support leg 101 of the upper frame 10 is installed On the upper surface of the rectangular frame of the lower frame 11;

[0026] Y-direction feeding device: two ends of a ball screw 20 are respectively provided with bearing seat assemblies 21, the bearing seat assemblies 21 are respectively fixed on the front and rear frames of the lower frame 11, the front end of the ball screw 20 passes through the belt 22 and the pulley 23 Connected to the main shaft of the servo motor 24, the belt 22 and the pulley 23 and the servo motor 24 are separately arranged on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com