Double-needle cup seaming machine

A technology of overlock sewing machine and sewing machine, which is applied in the direction of sewing machine components, sewing machine housing, mechanism for cutting thread in sewing machine, etc., which can solve the problems of not being able to handle cloth with two hands and rising costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

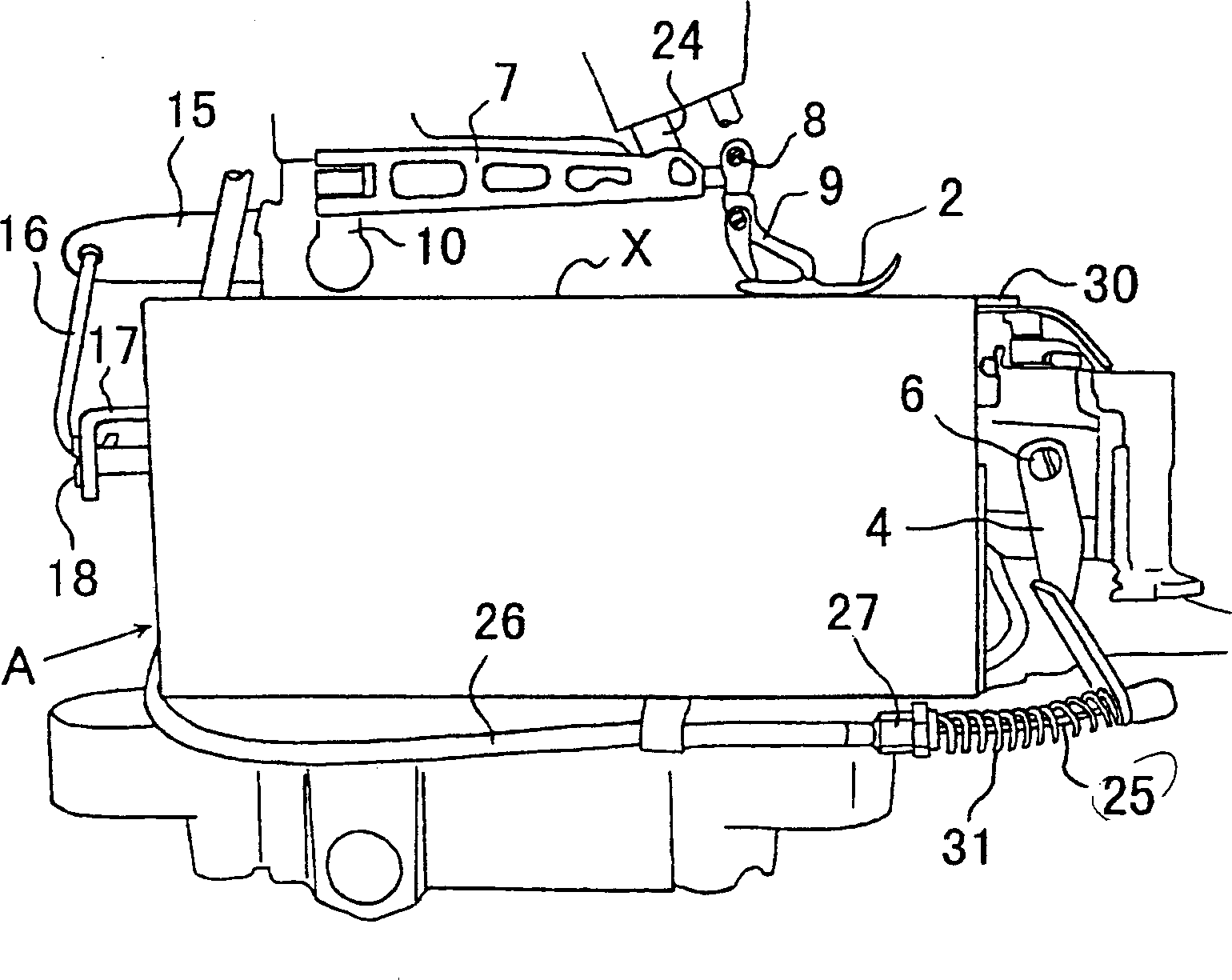

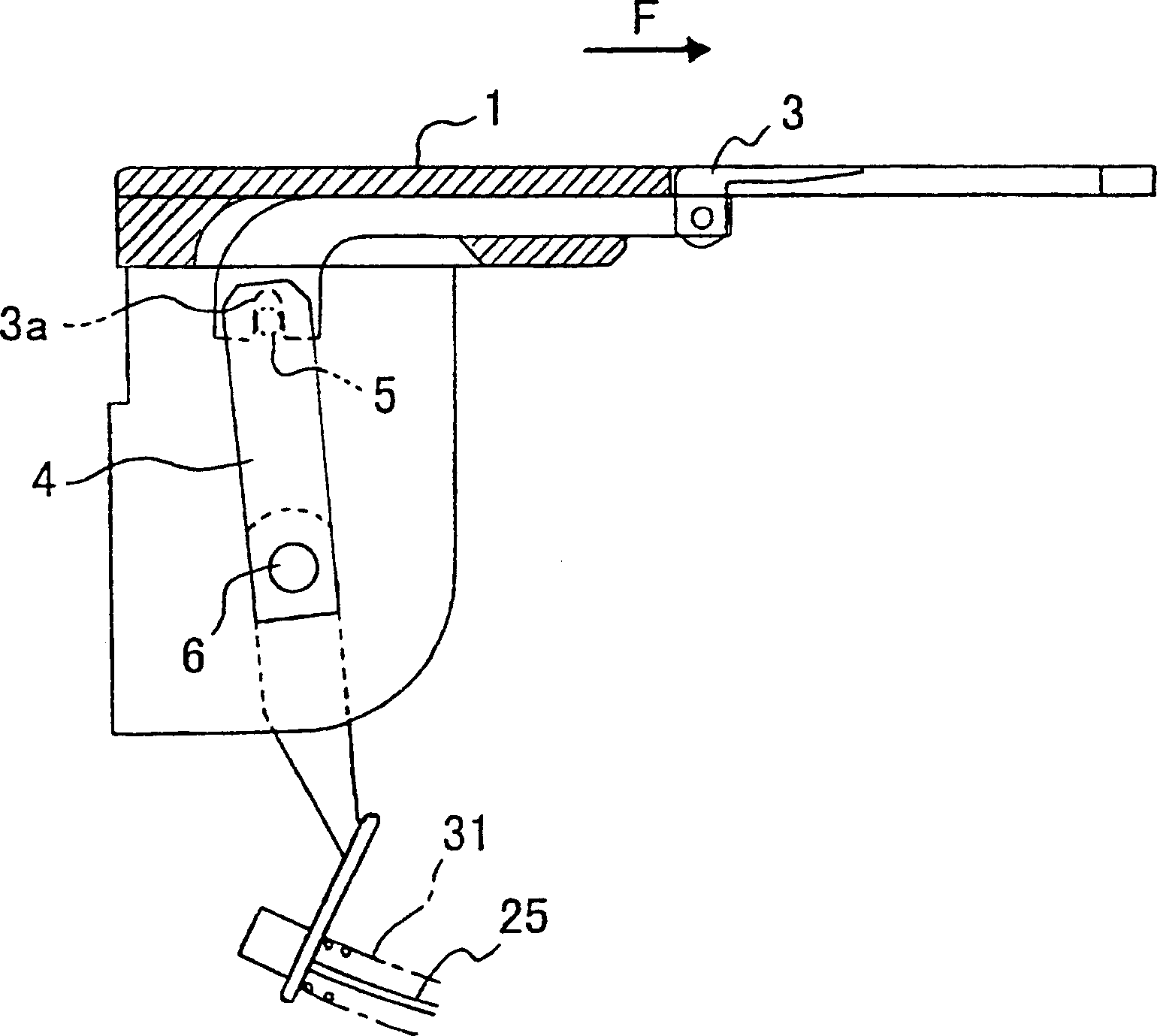

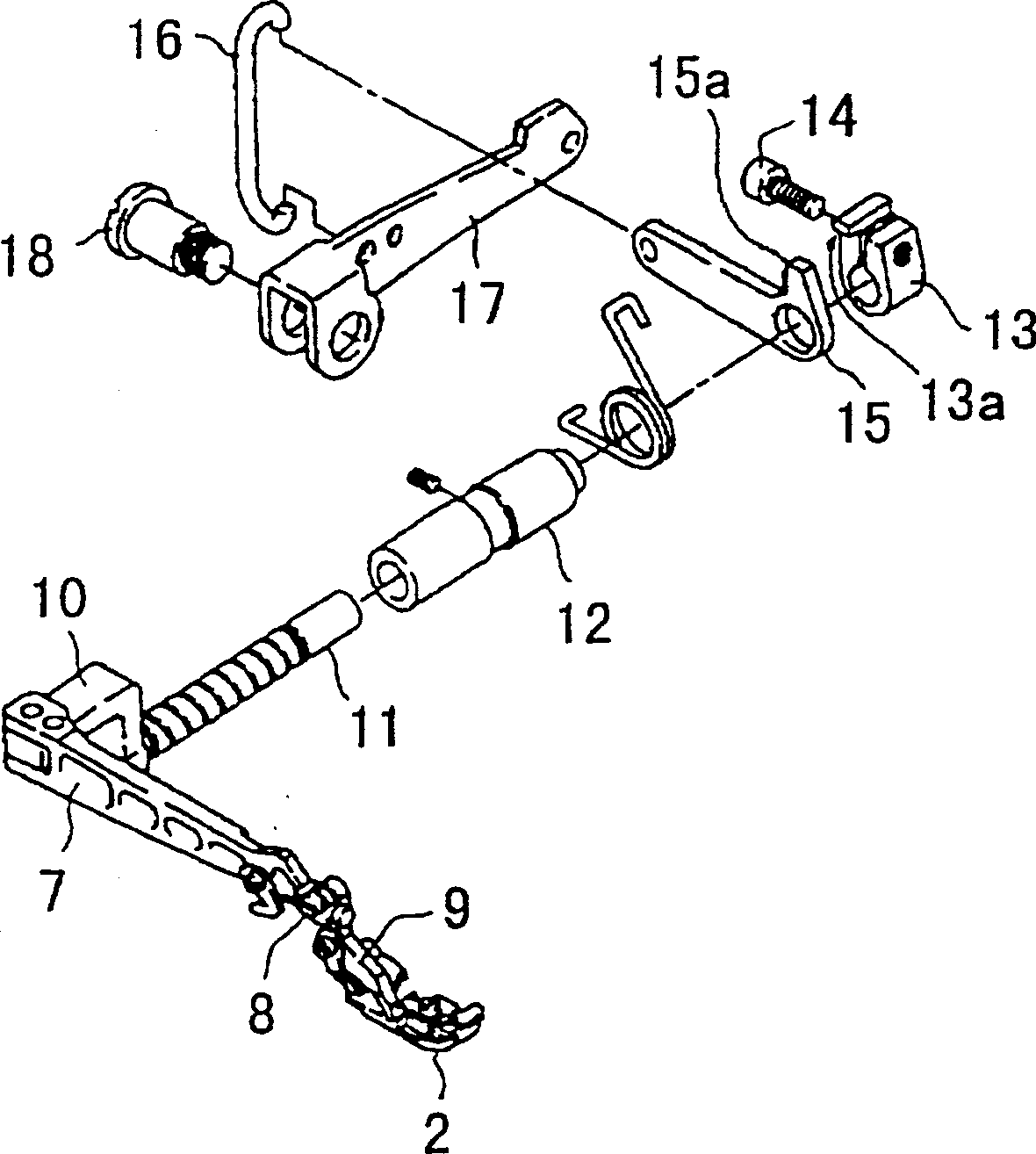

[0014] Next, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a side view showing the main part of the double-needle overlock sewing machine of the present invention. Working face X has needle plate 1 (refer to Figure 6 ), a part of the needle plate 1 forms the outer claw 1a. The needle plate 1 has grooves (not shown) for feed dogs, and is fixed with screws 1b. Such as Figure 6 As shown, the outer claw 1a is extended along the feed direction F with the adjacent portion of the needle entry points N1 and N2 as a starting point. The middle claw 3 is arranged parallel to the outer claw 1a. The middle claw 3 is slidably arranged along the extension direction of the outer claw 1 a, and can enter and exit the open needle hole of the needle plate 1 . The base end portion 3a of the middle claw 3 is constituted by a recessed portion, such as figure 2 As shown, the recess engages with a pin 5 formed on the support piece 4 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com