Patents

Literature

47results about "Loop holders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

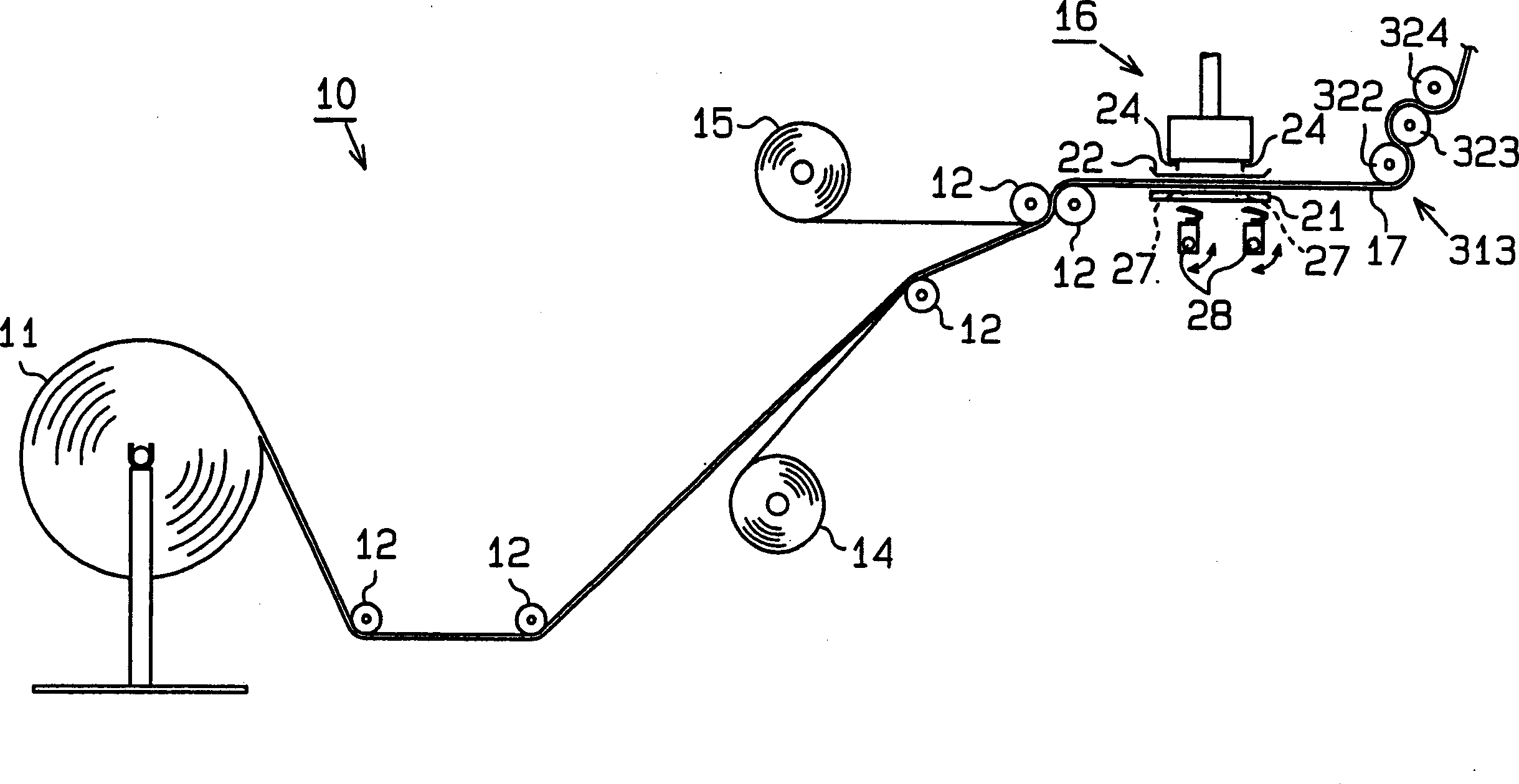

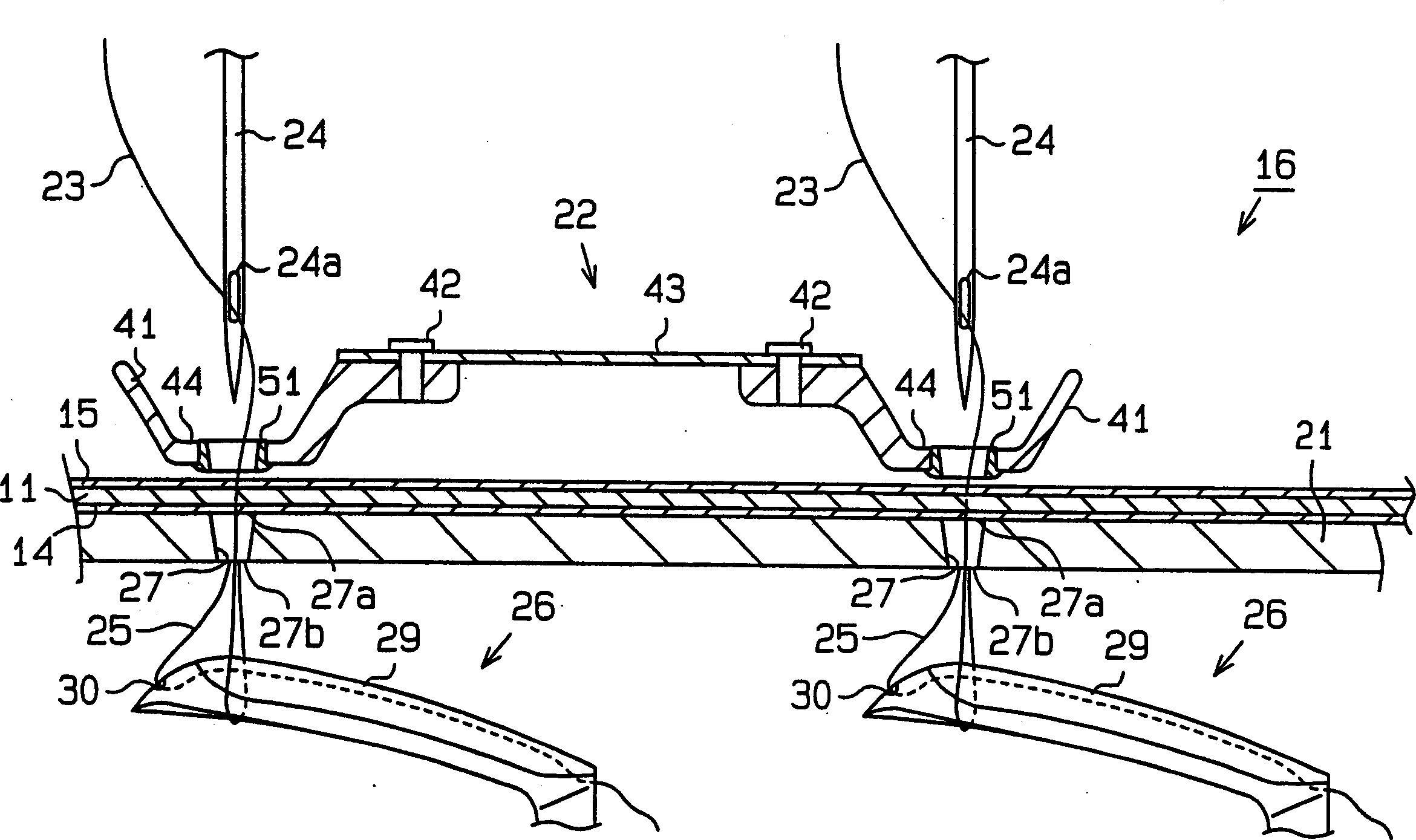

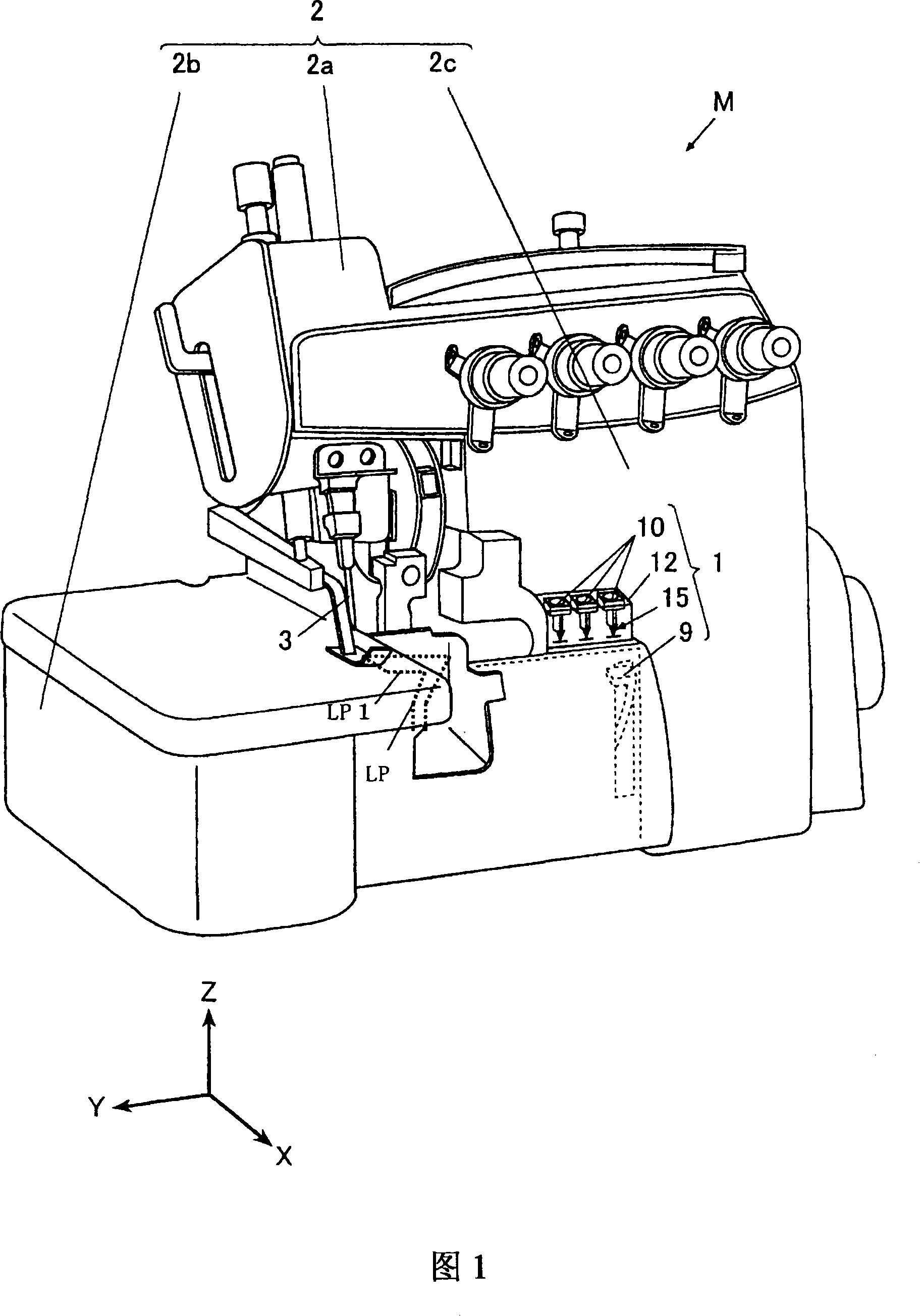

Method and apparatus for preventing a seam from raveling in double chain stitch sewing machine

InactiveUS6119613APreventing a seam from ravelingNeedle severing devicesLoop holdersEngineeringDouble chain

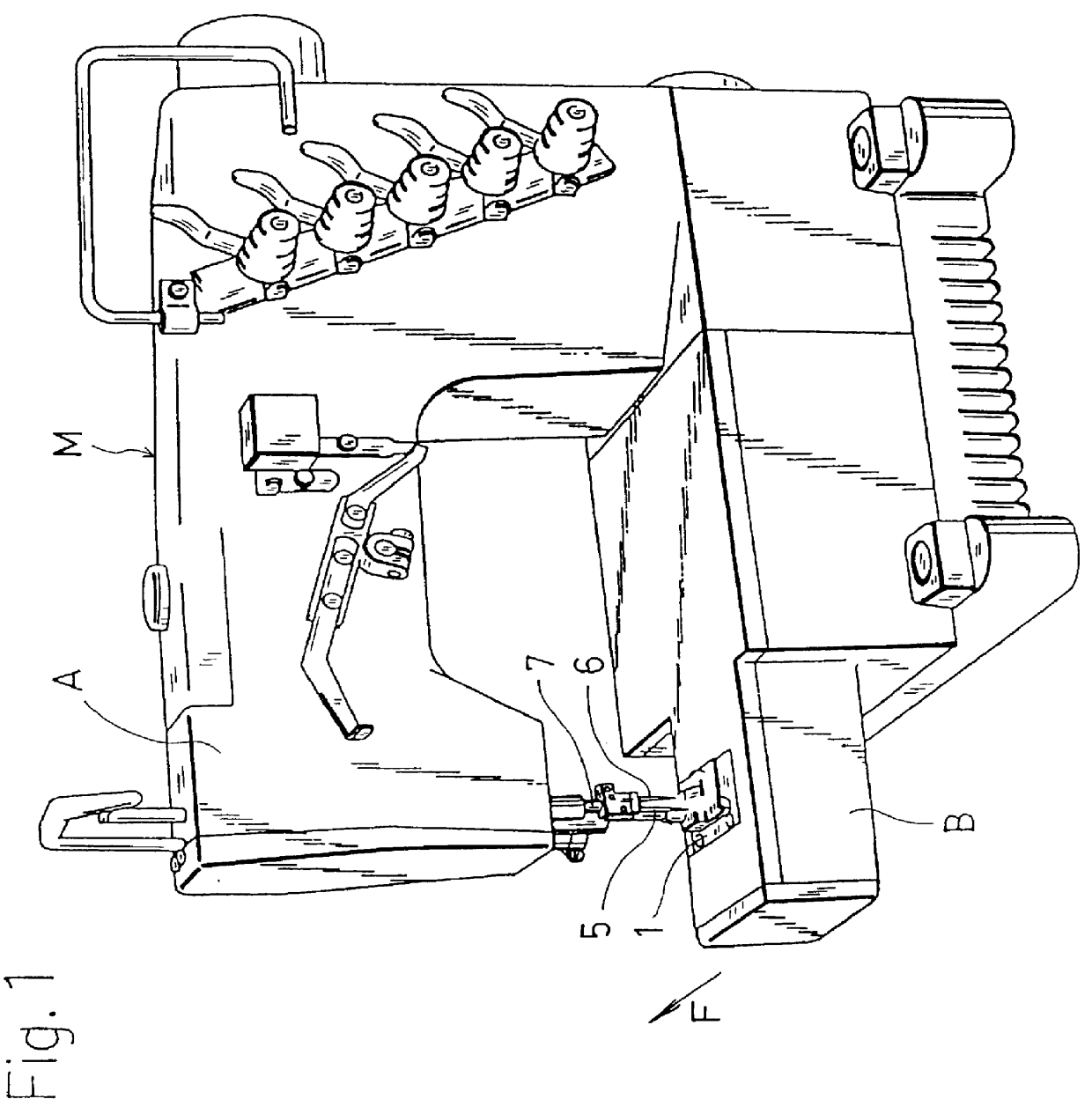

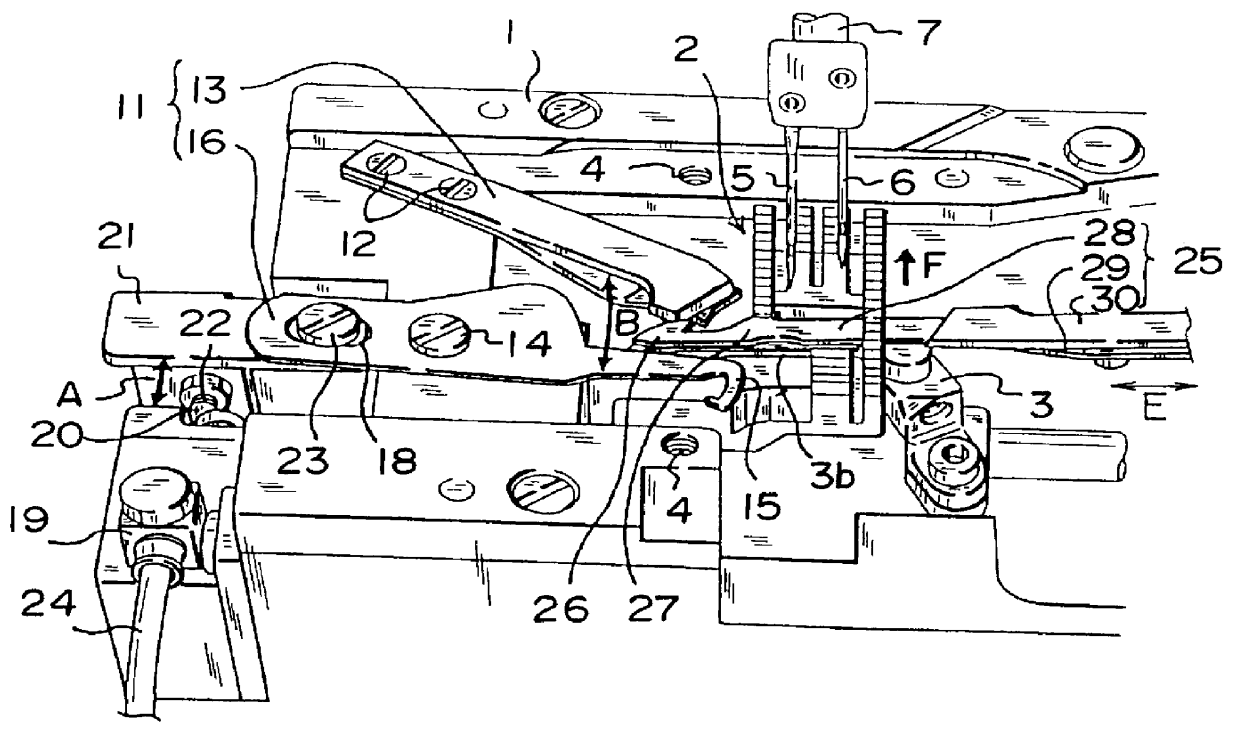

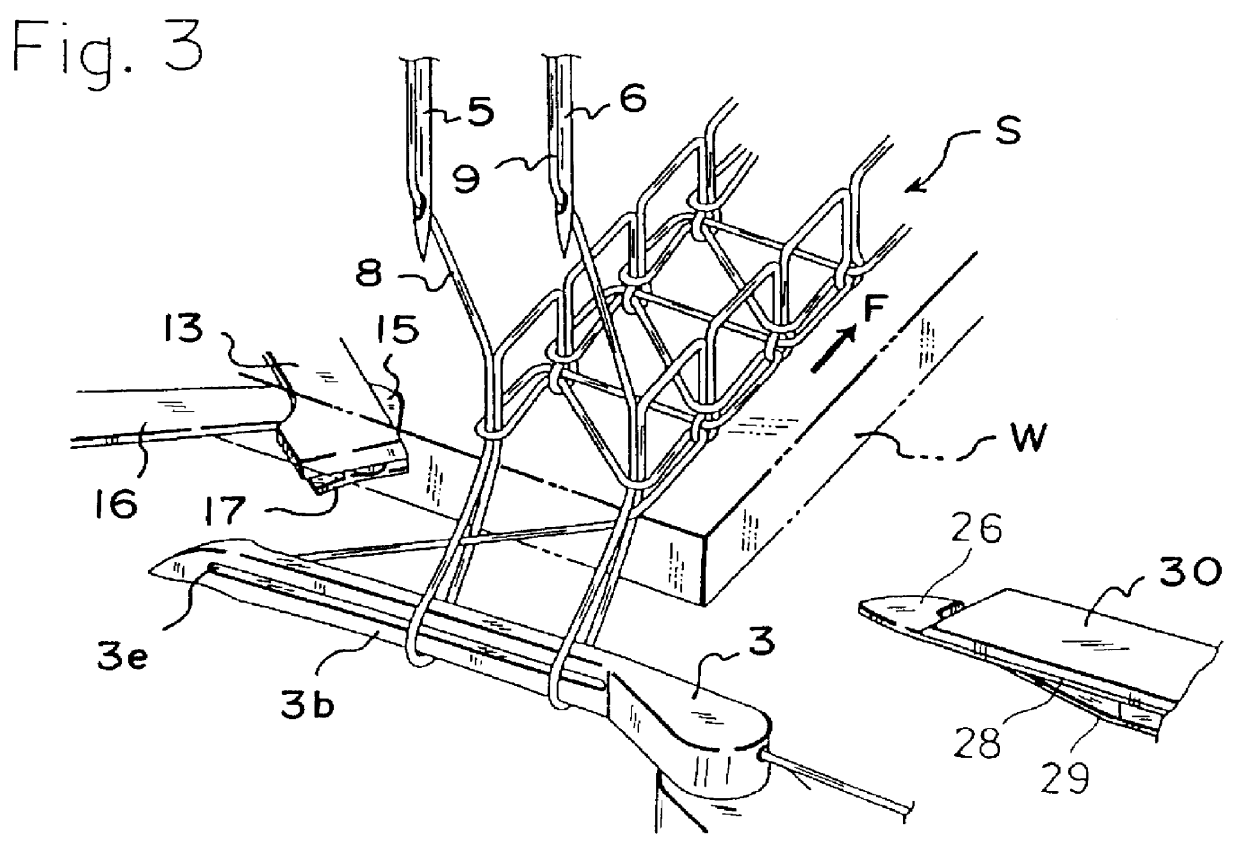

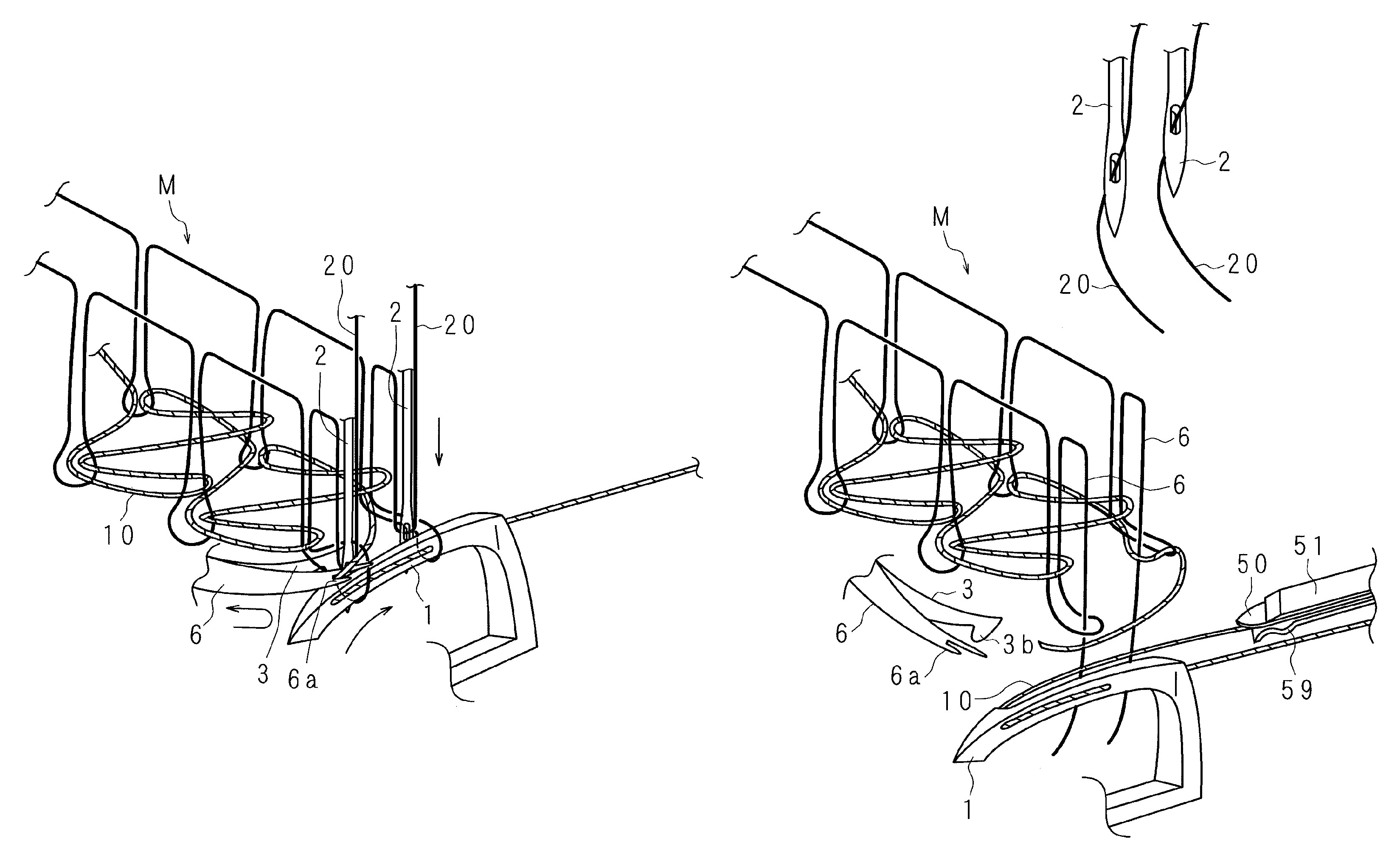

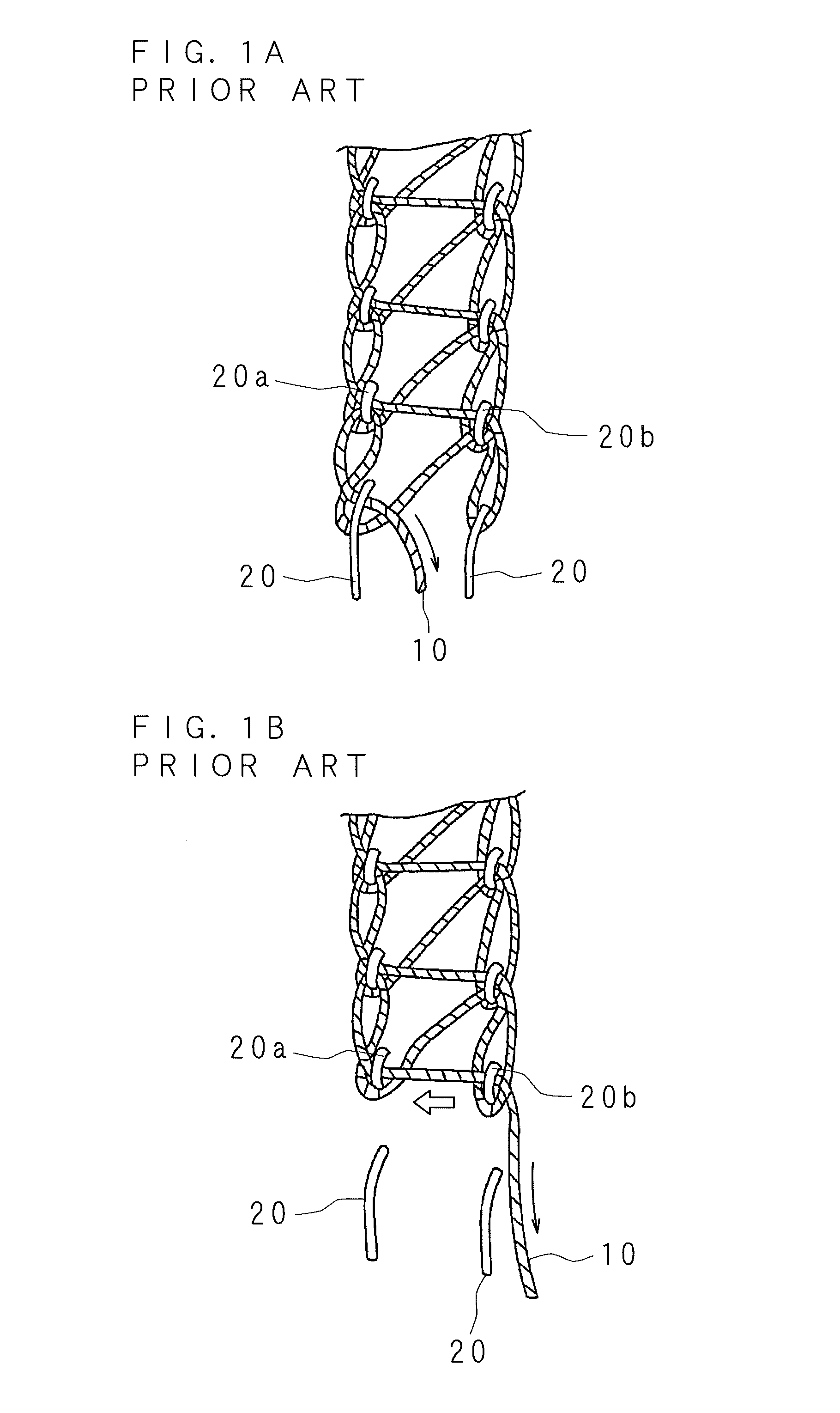

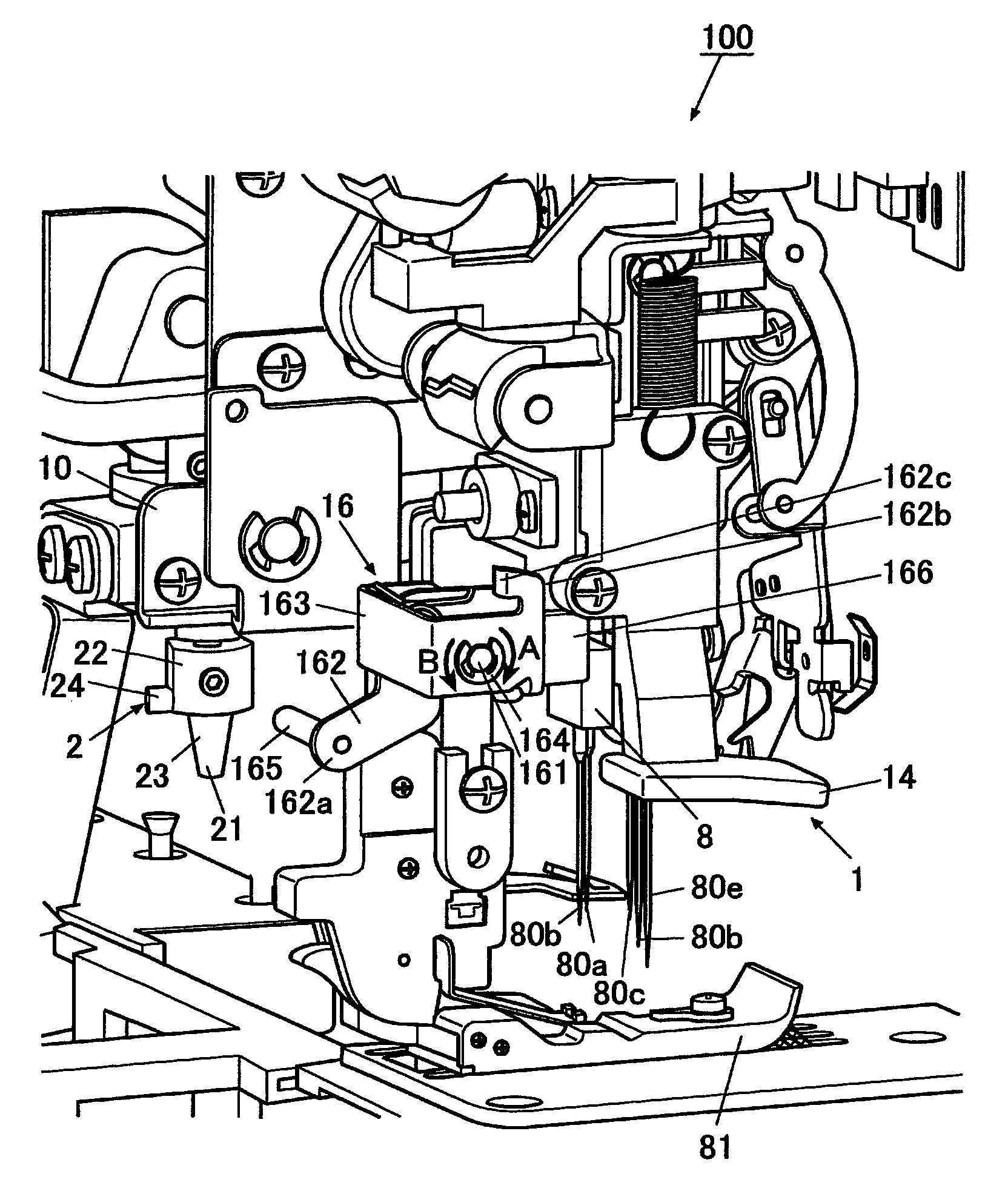

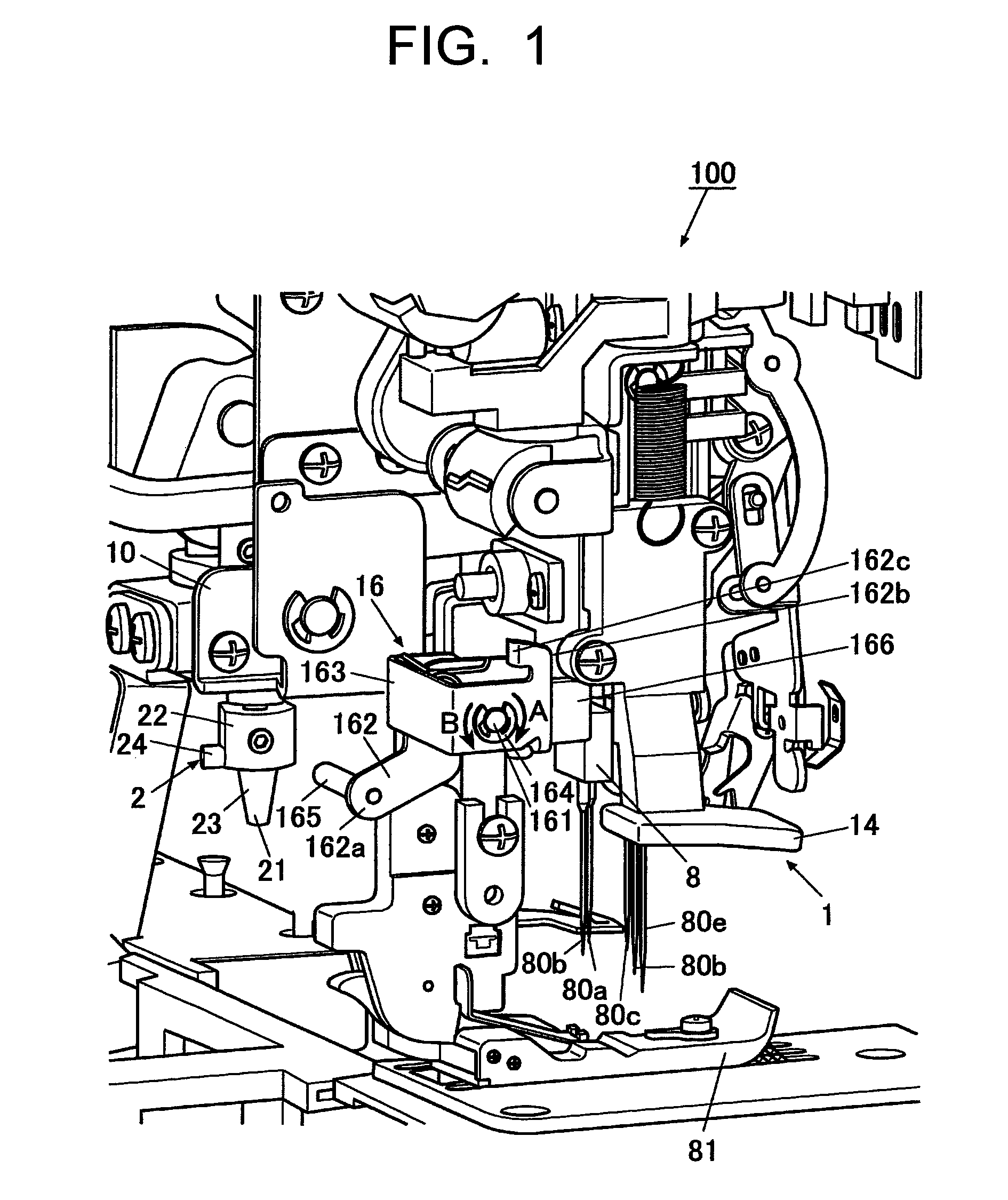

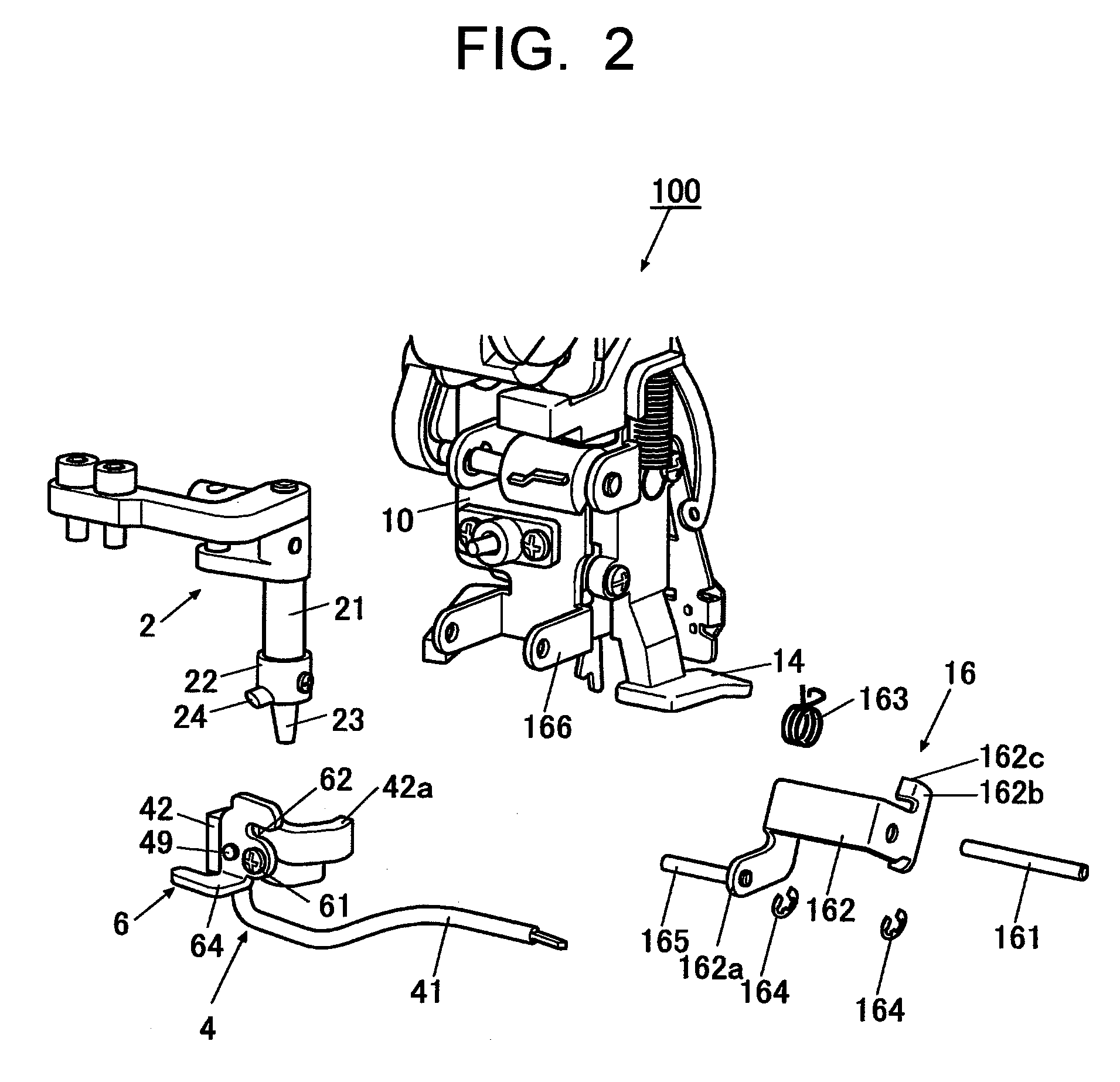

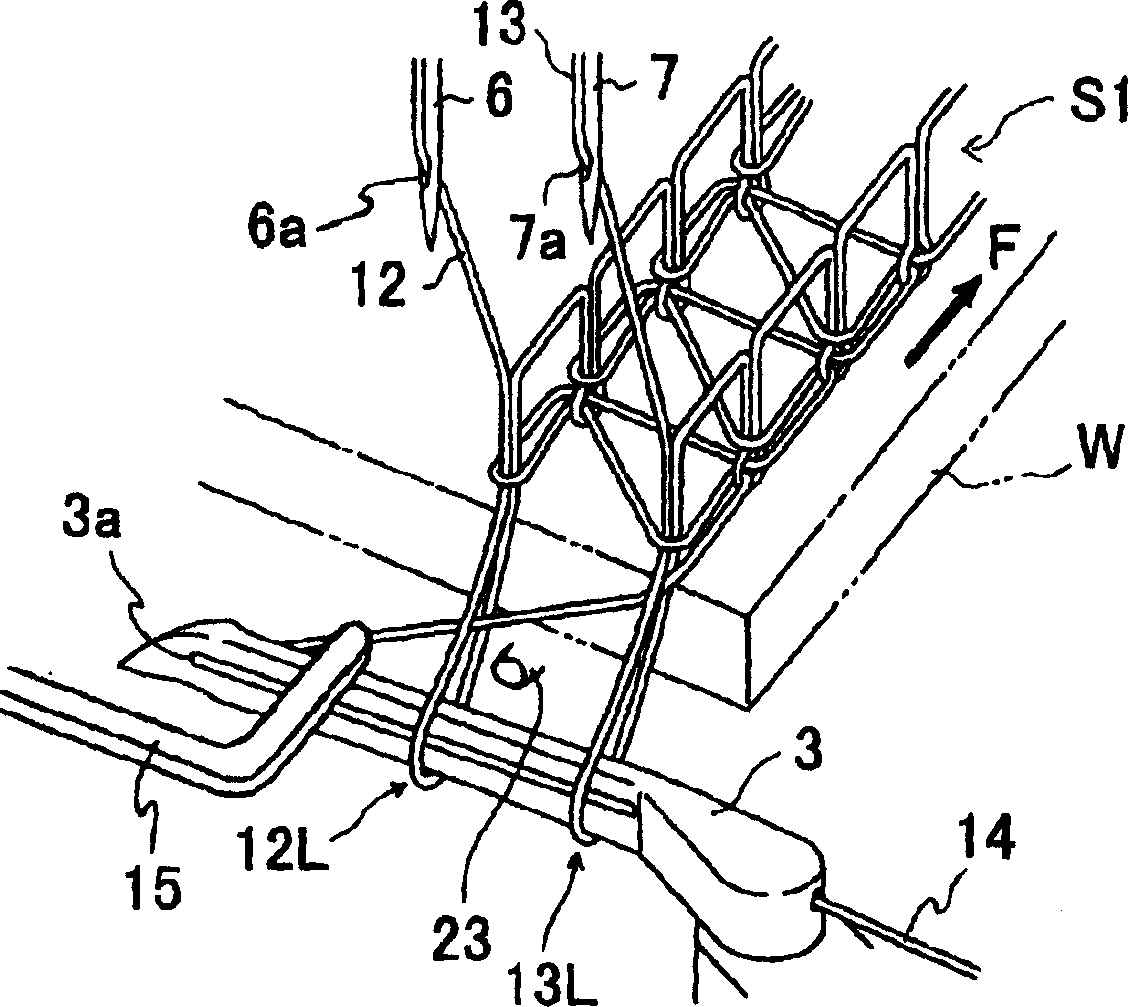

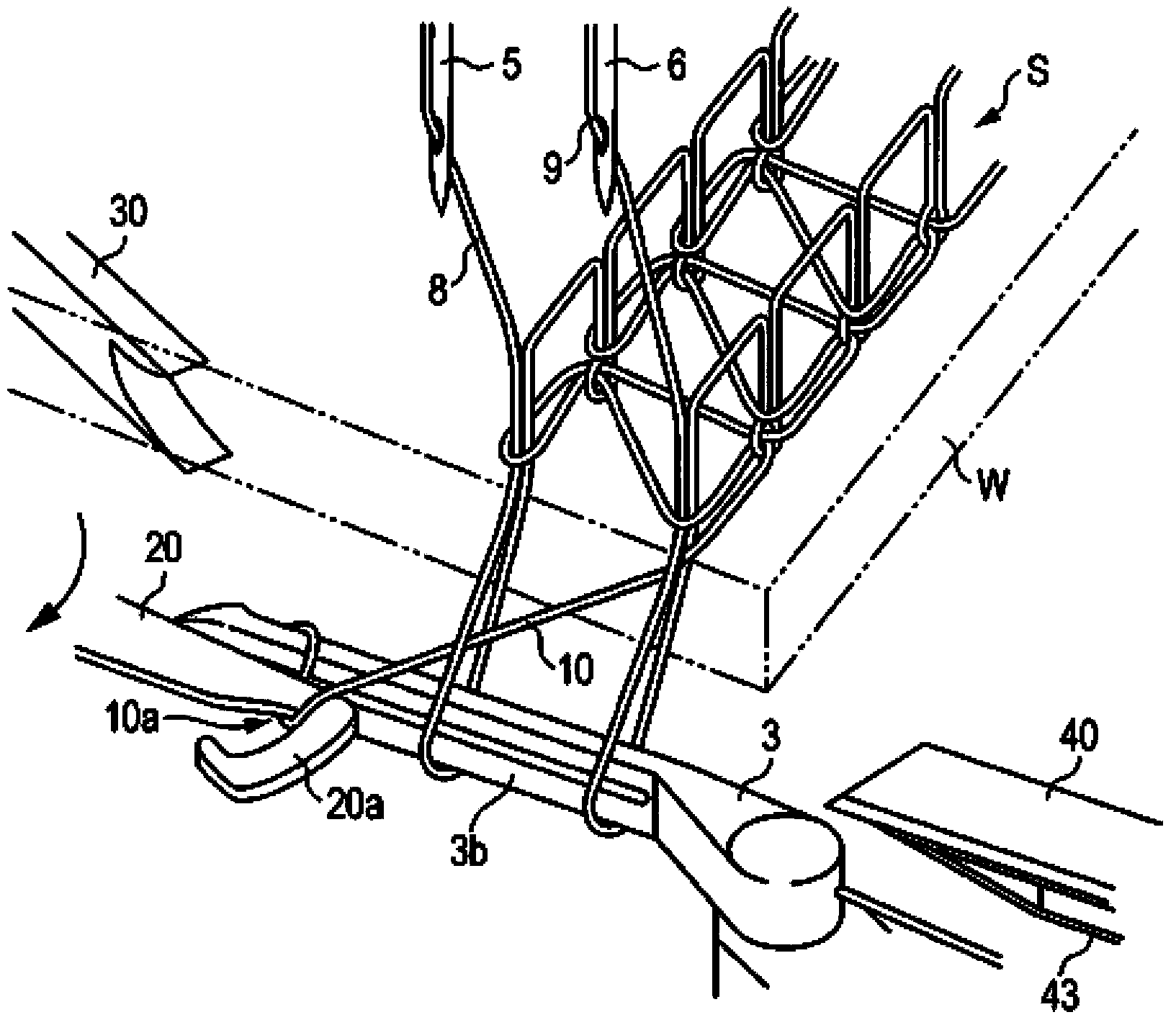

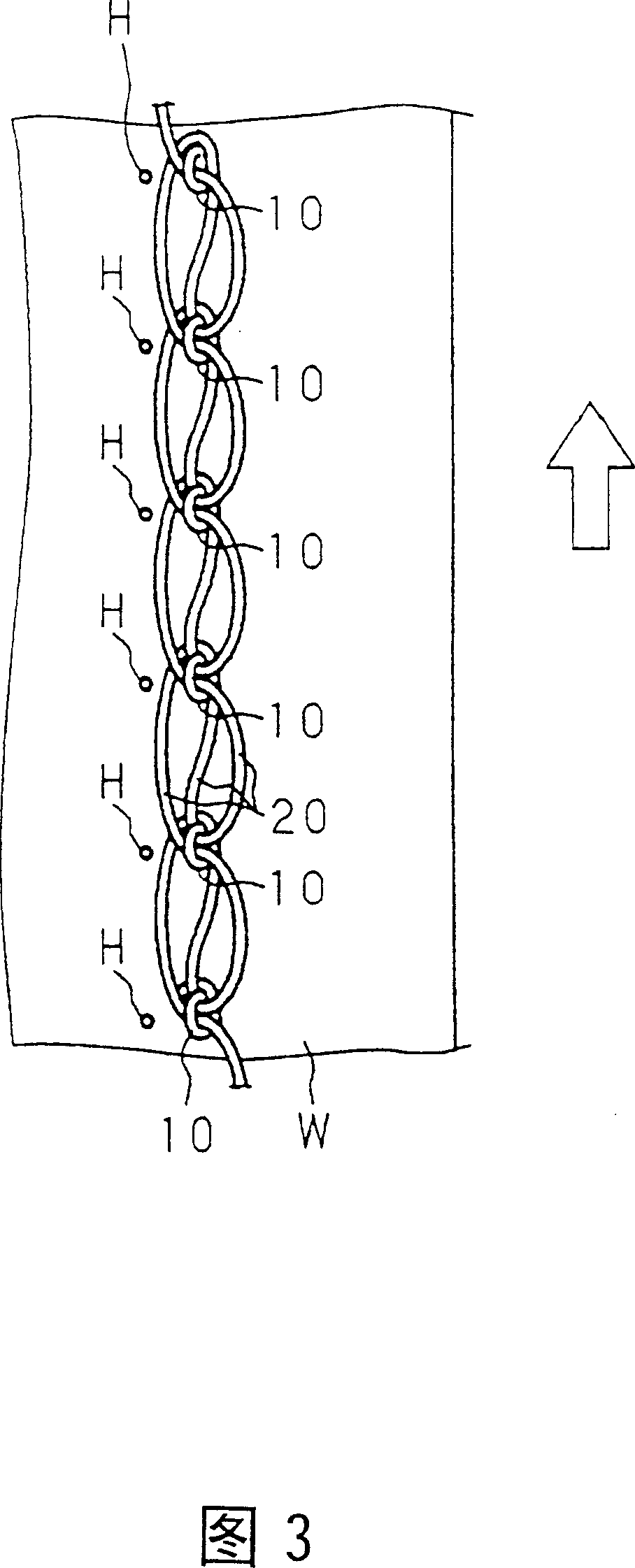

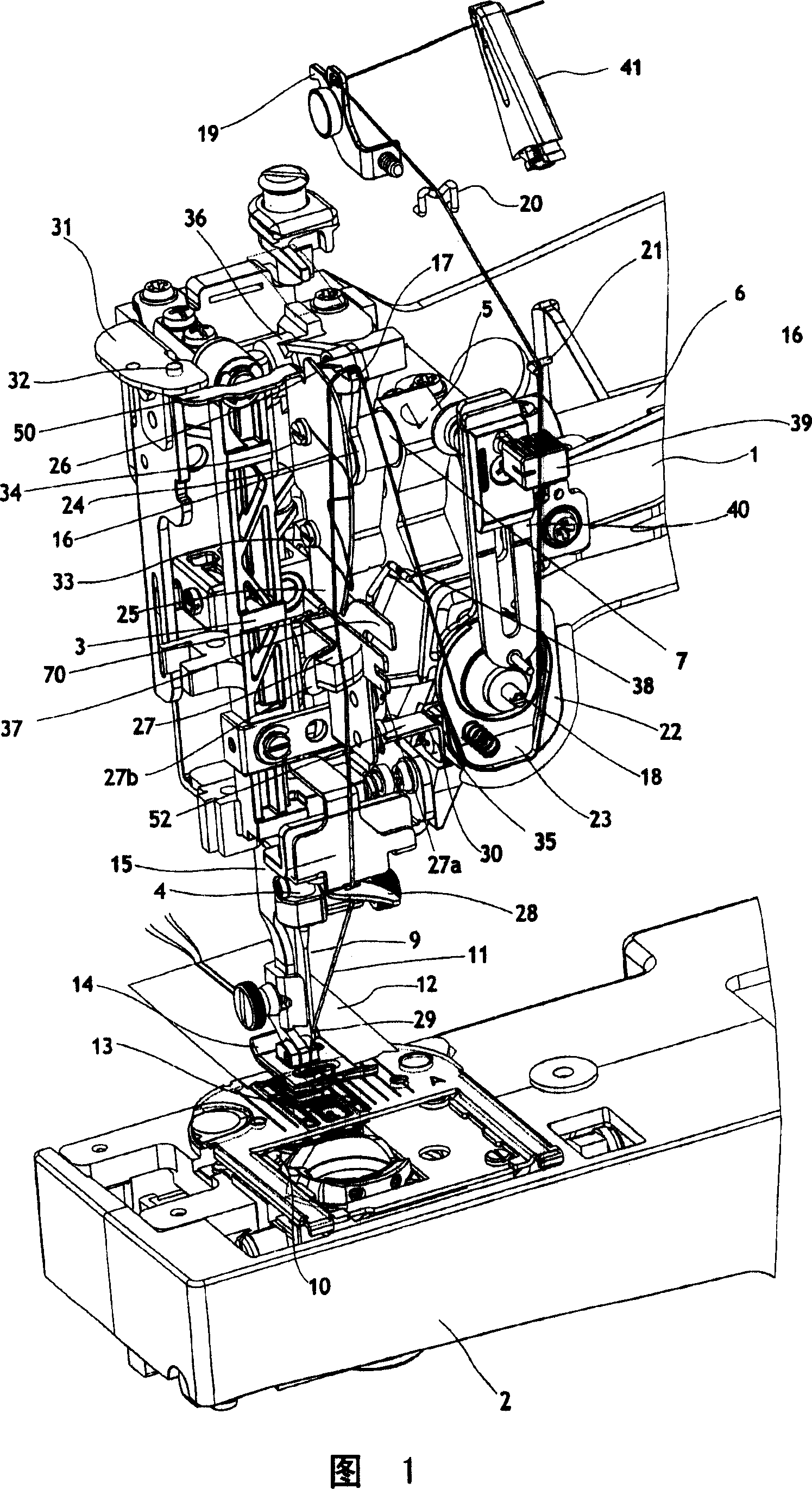

A method and apparatus for preventing a seam from raveling in a double chain stitch sewing machine according to the present invention are applied to sewing of cloth by a double chain stitch sewing machine. Near the sewing end point for forming a double chain stitch by collaboration of a plurality of needles and a looper, the looper thread consecutive to the looper from the cloth is hooked and engaged on the hook at the left side of the needles. After driving the sewing machine for a half stitch or one stitch in this state, the looper thread hooked on the hook is cut off. Simultaneously with this cutting or before or after the cutting, the needle thread loop consecutive to the needles from the sewing end of the cloth through the looper is cut off between the looper and the cloth. Further, capturing the cut looper thread consecutive to the looper from the cloth, the end of the cut looper thread is pulled out from the final needle thread loop at the end of sewing. Therefore, raveling of thread from the sewing end point is prevented, and the length of the thread end consecutive to the sewing end point is short, so that sewn products of good appearance may be obtained.

Owner:PEGASUS SEWING MACHINE MFG

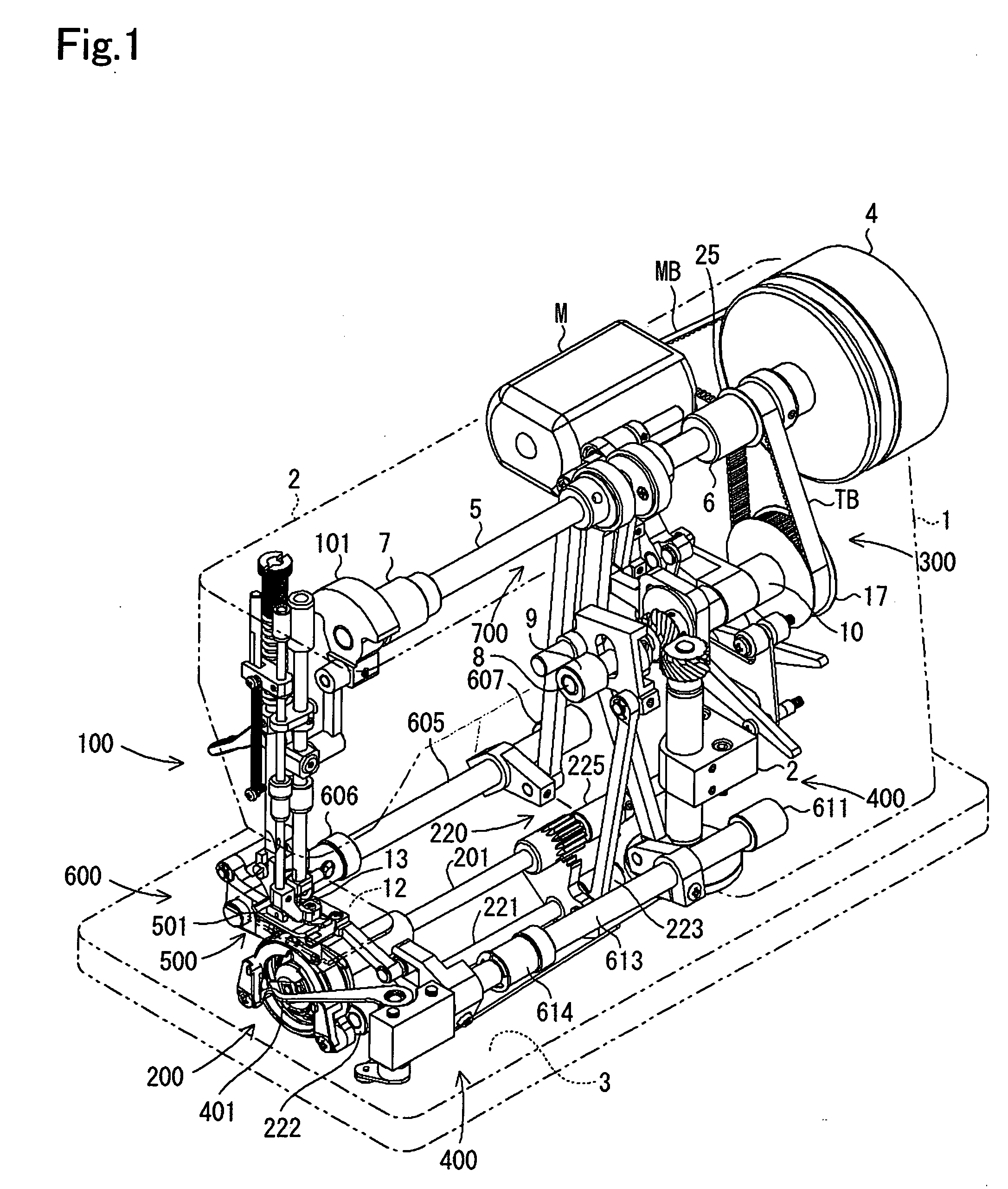

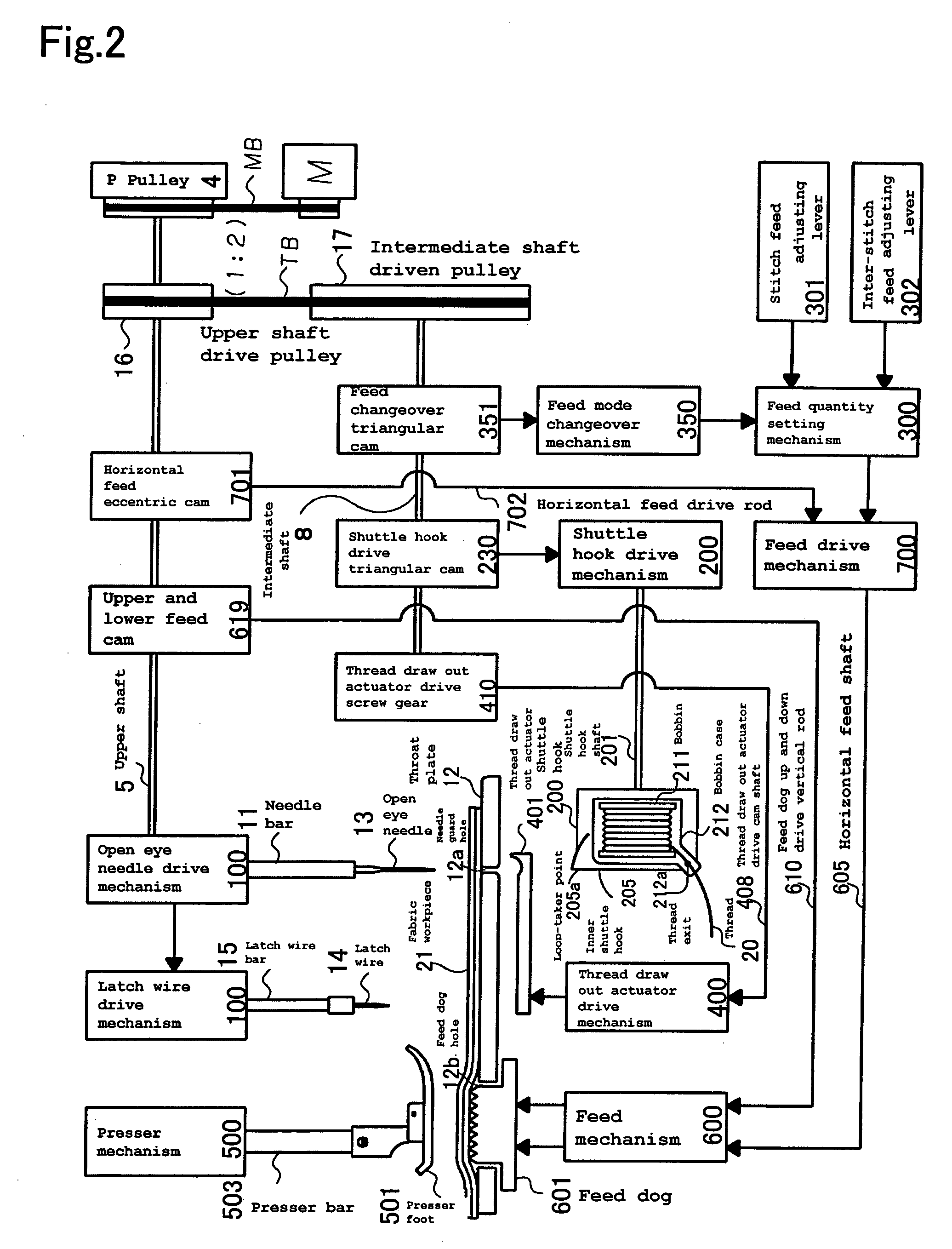

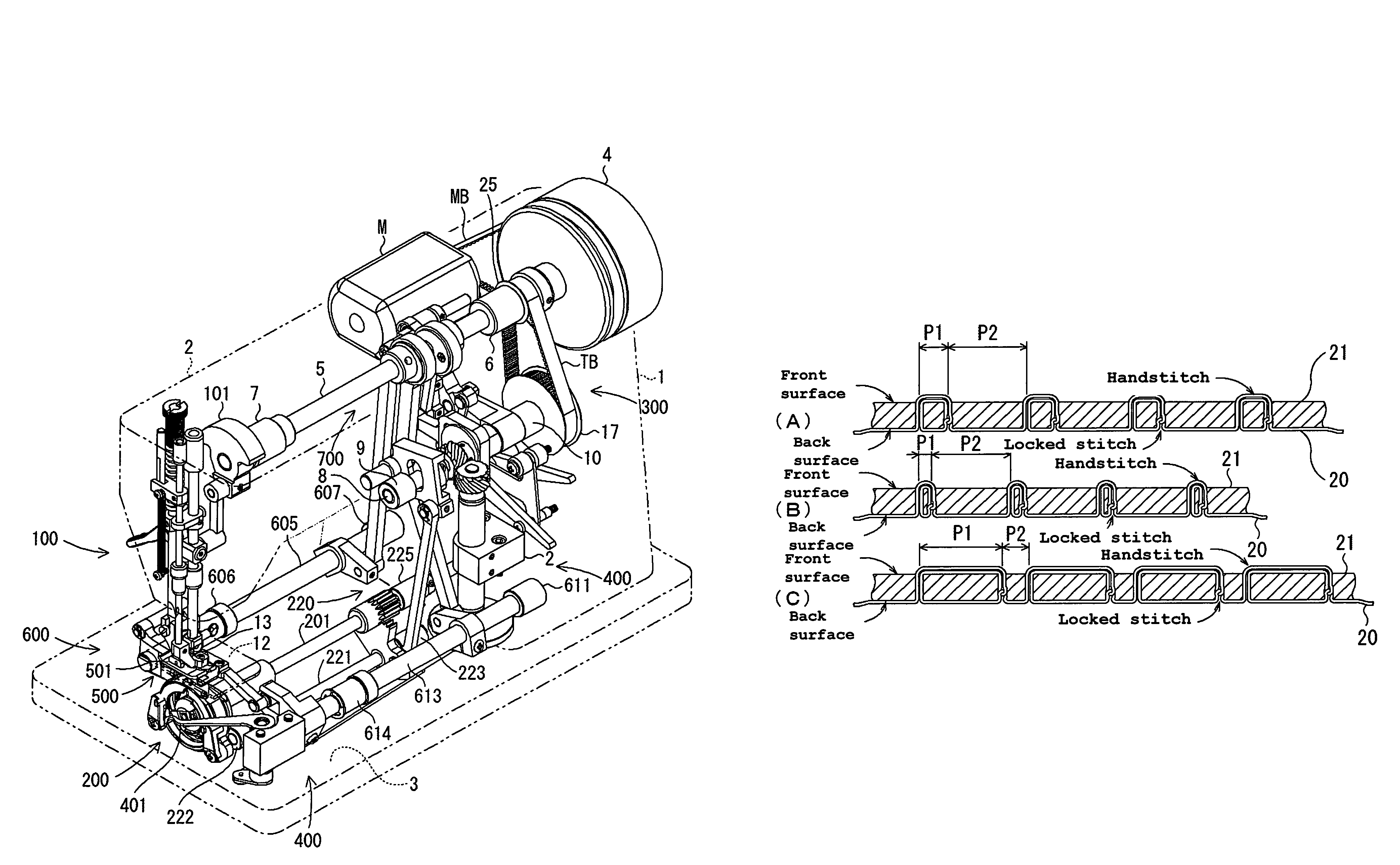

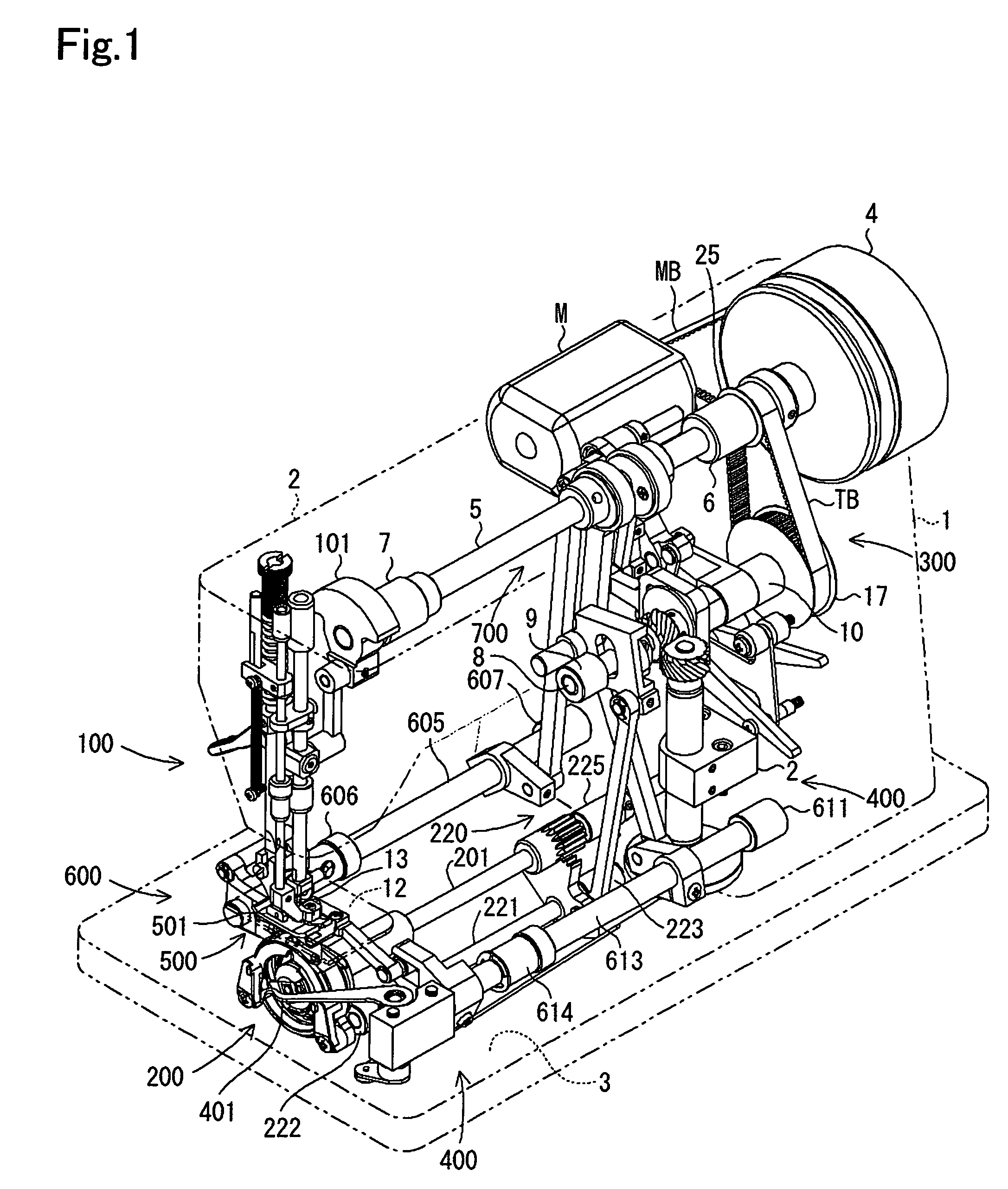

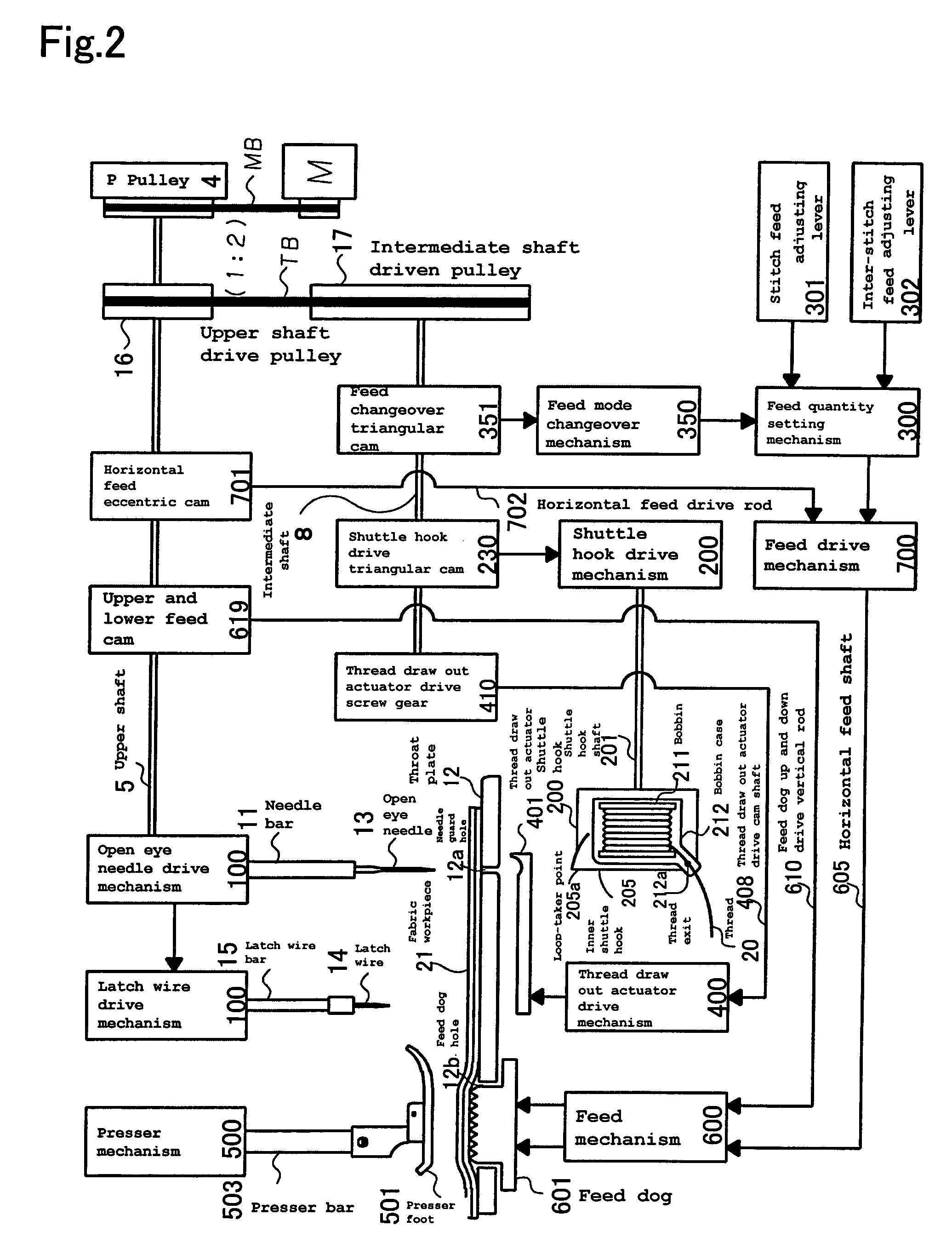

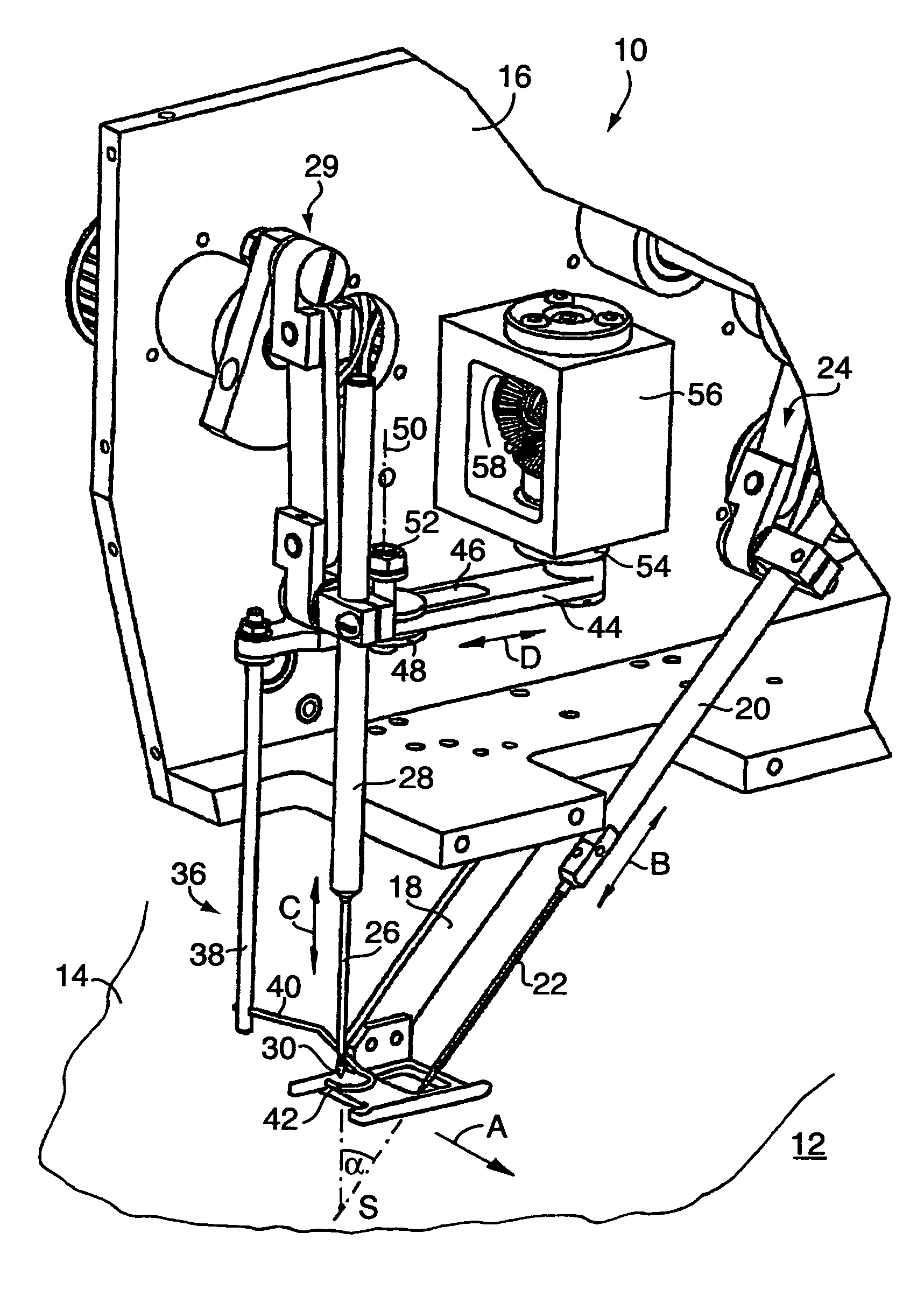

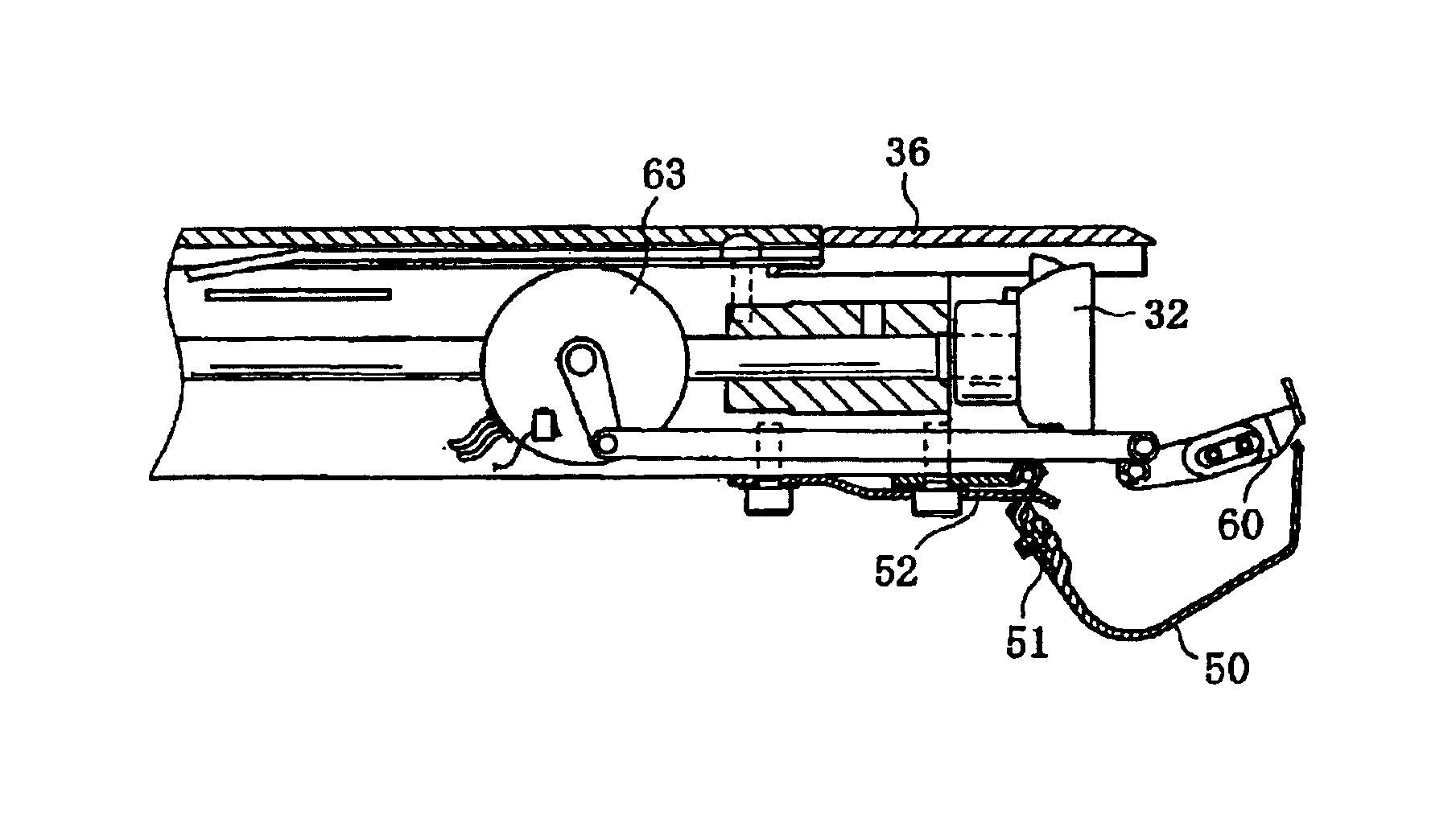

Method and Sewing Machine for Forming Single-Thread Locked Handstitches

ActiveUS20090007830A1Confirm positionAccurate sewingProgramme-controlled sewing machinesWork-feeding meansEye needlesEngineering

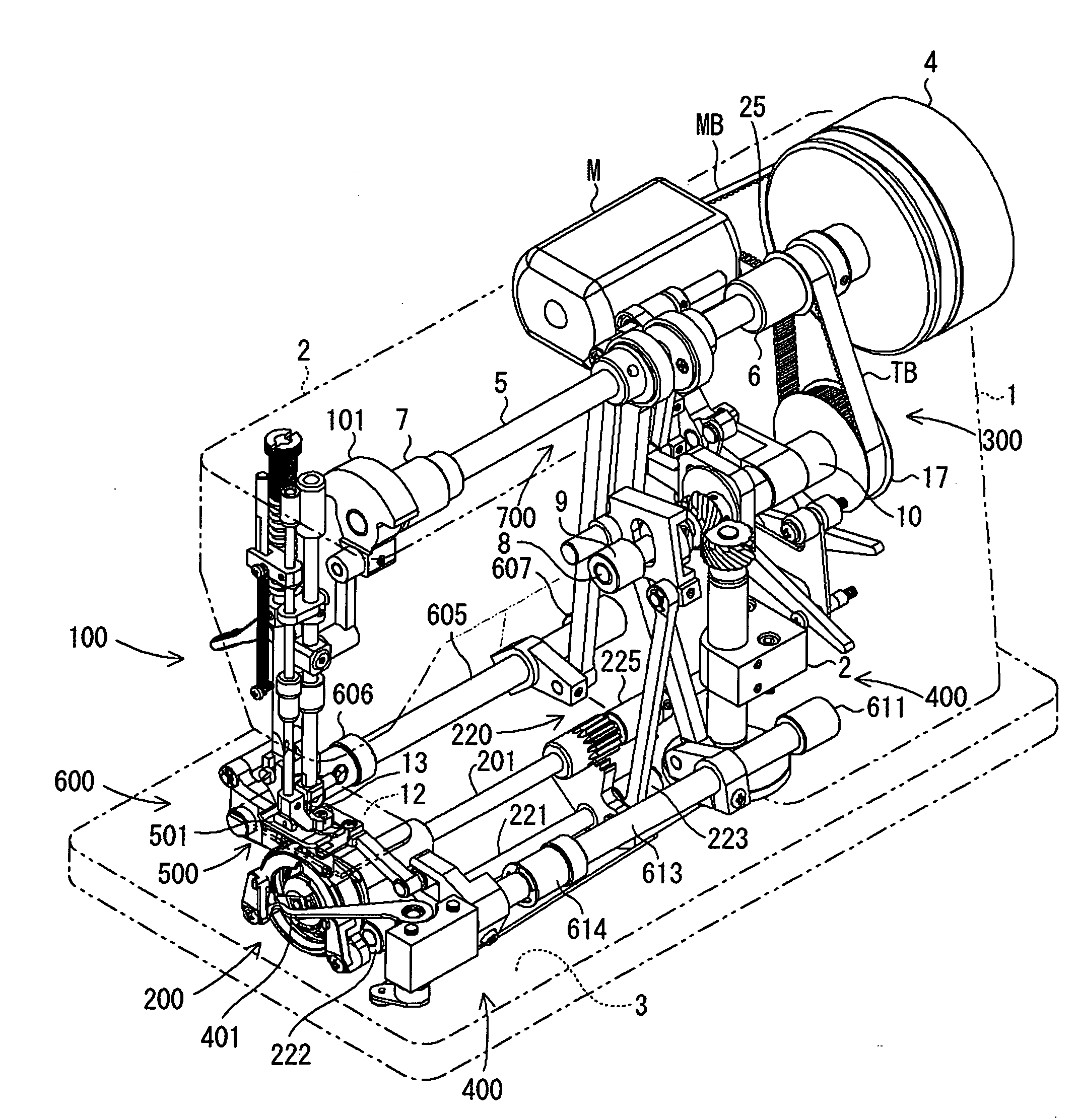

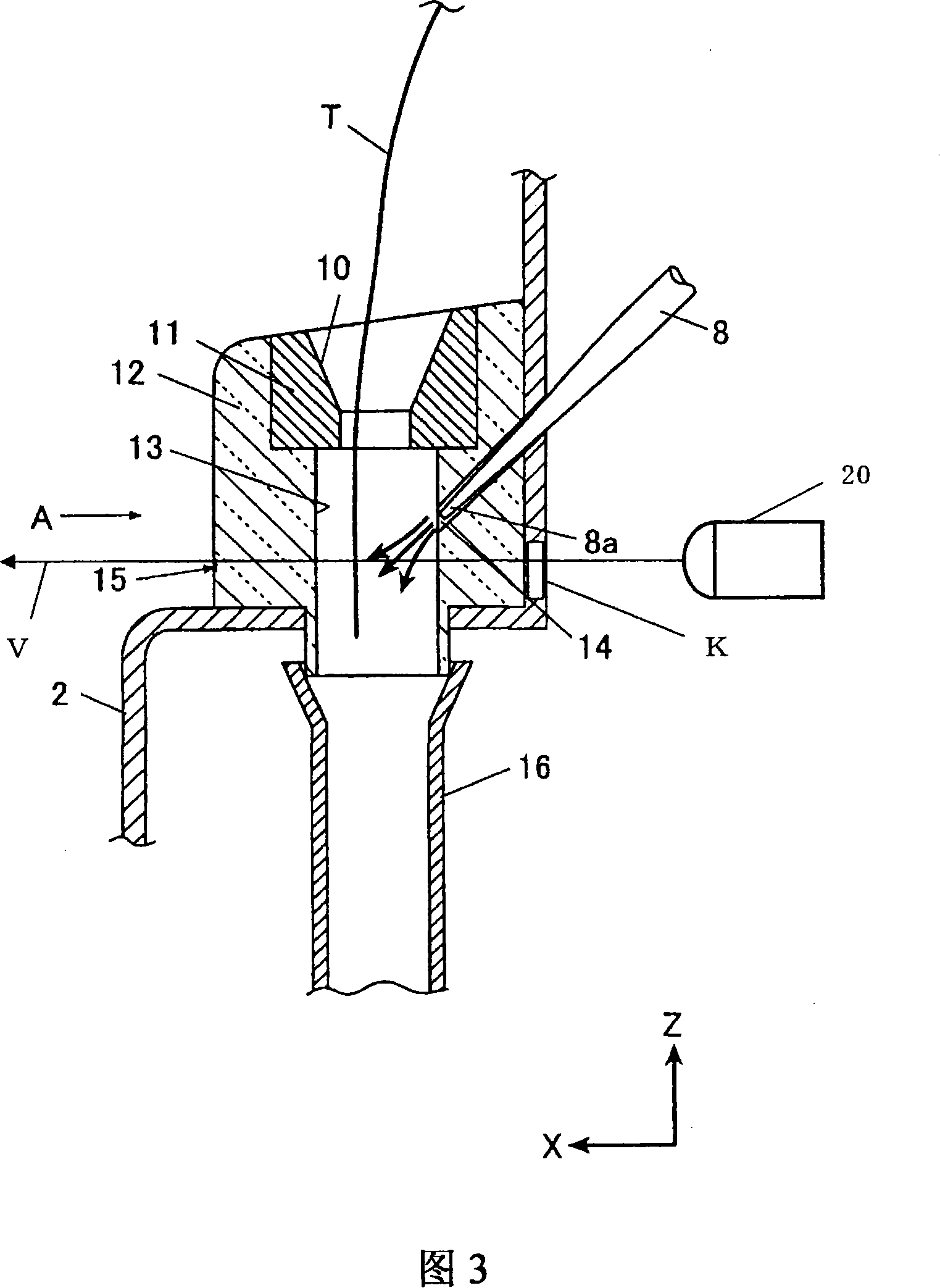

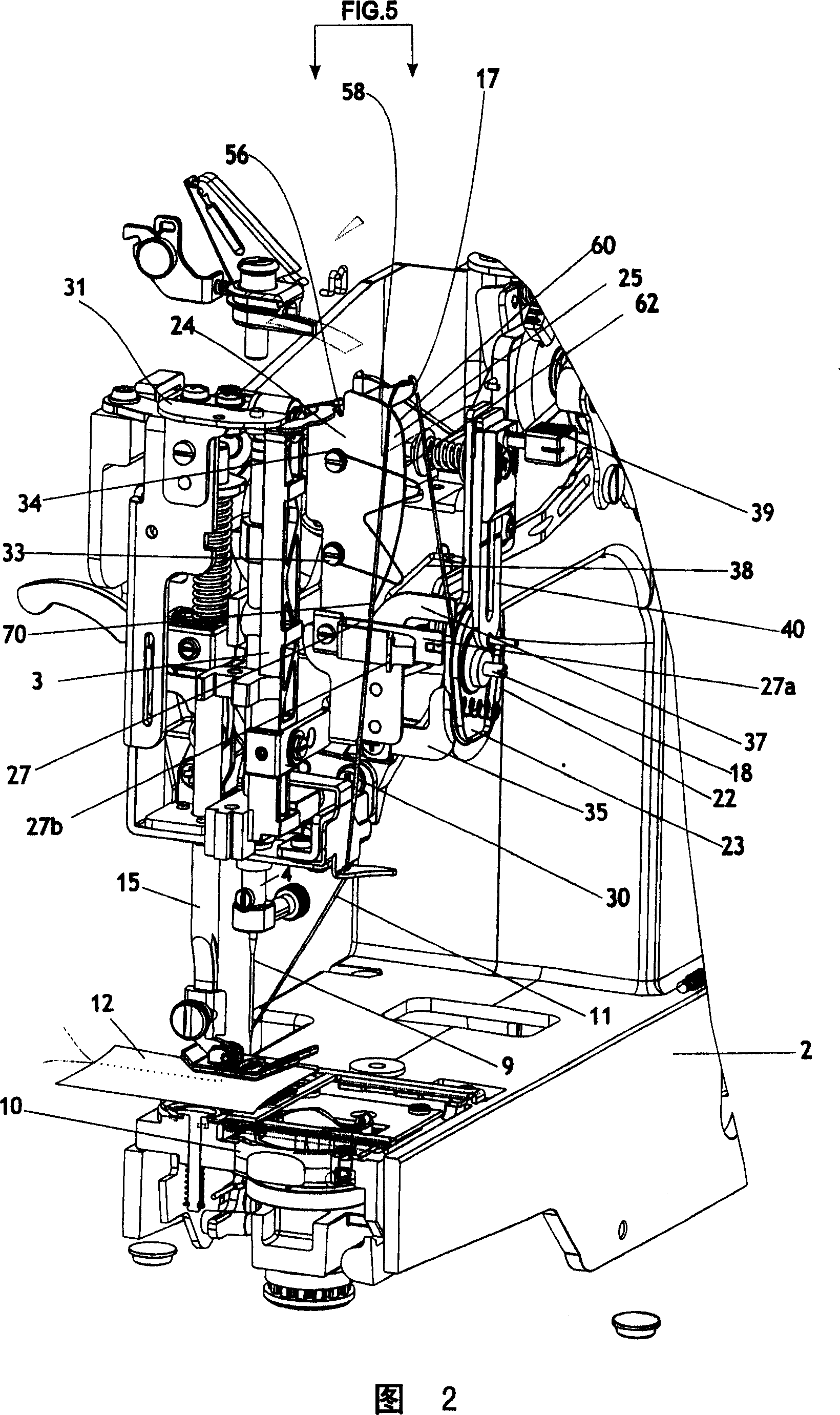

A sewing thread (20) can be captured certainly with a thread capturing open eye (13a) of an open eye needle (13) and the stitches are formed in the inner space of a sewing machine bed (3). A handstitch and a locked stitch are formed, respectively, on the front surface and the back surface of a fabric workpiece (21) as a skip stitch set through cooperation of the open eye needle (13), a shuttle hook (200) and a thread draw out actuator (401). A feed dog (601) feeds the fabric workpiece by a stitch length (P1) for handstitch during a first stroke of the open eye needle (13), and feeds the fabric workpiece by an inter-stitch pitch (P2) between the handstitches during a second stroke of the open eye needle (13).

Owner:SUZUKI MFG CO LTD

Sewing machine

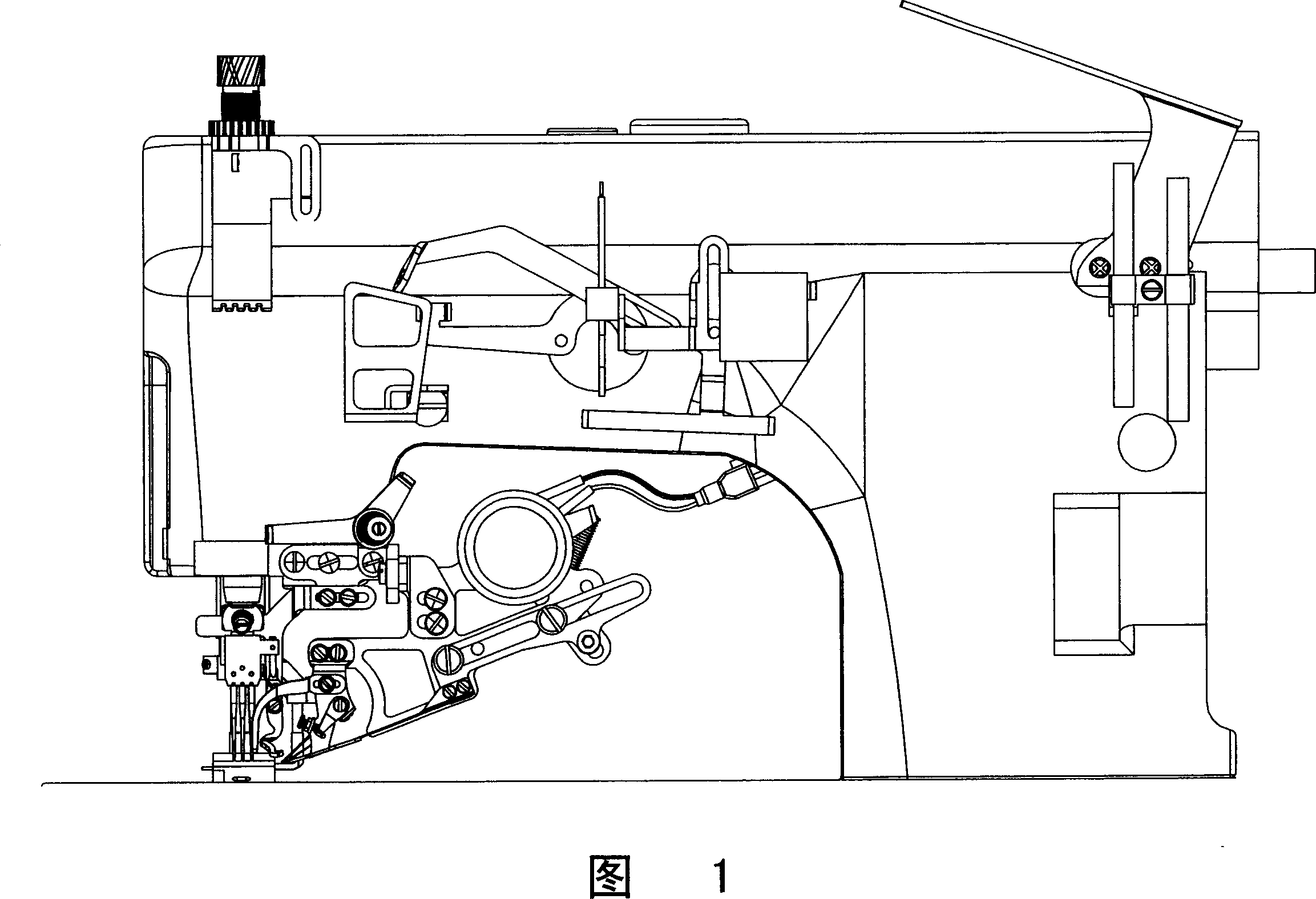

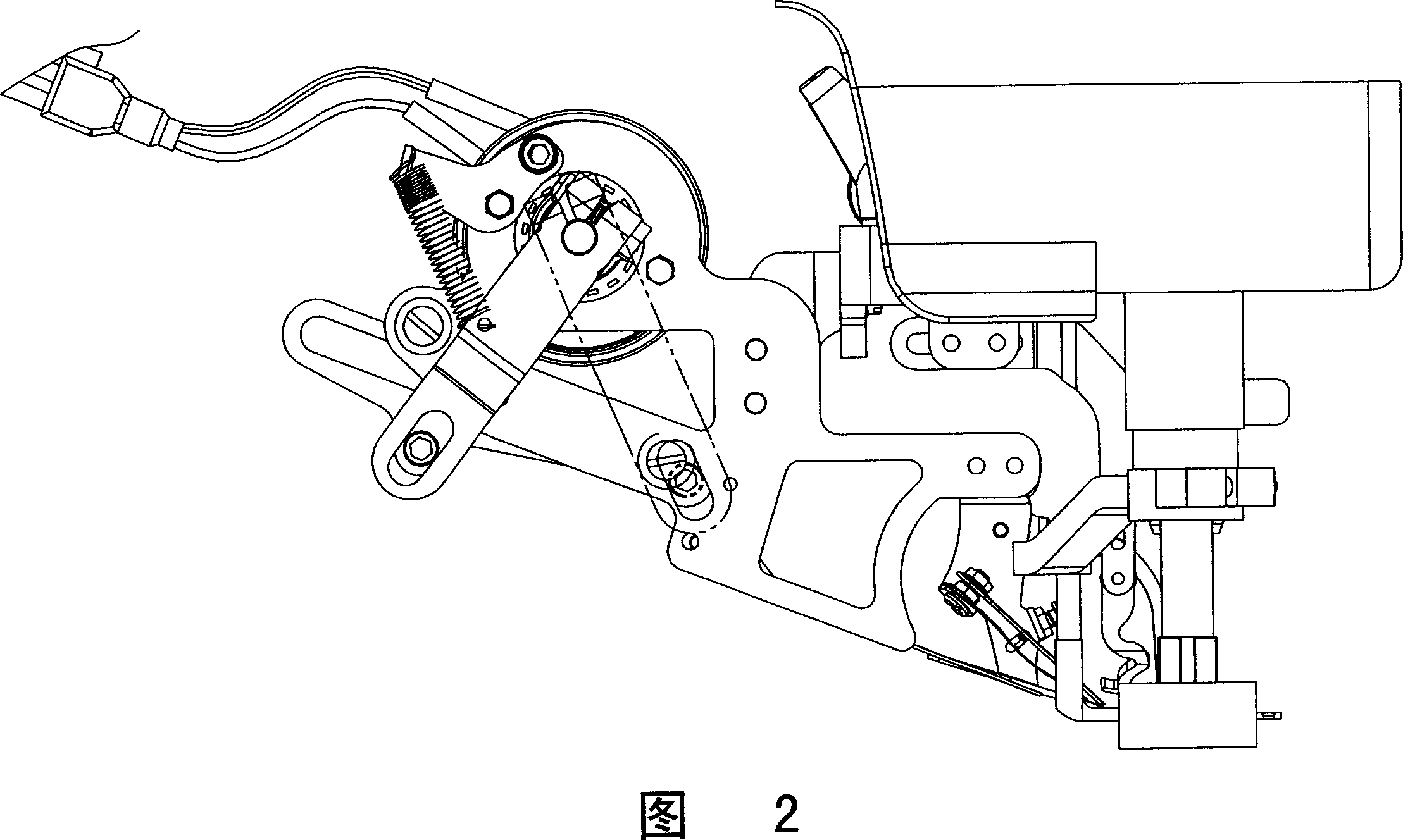

InactiveCN1485488ASewing-machine casingsNeedle severing devicesTop dead centerBiomedical engineering

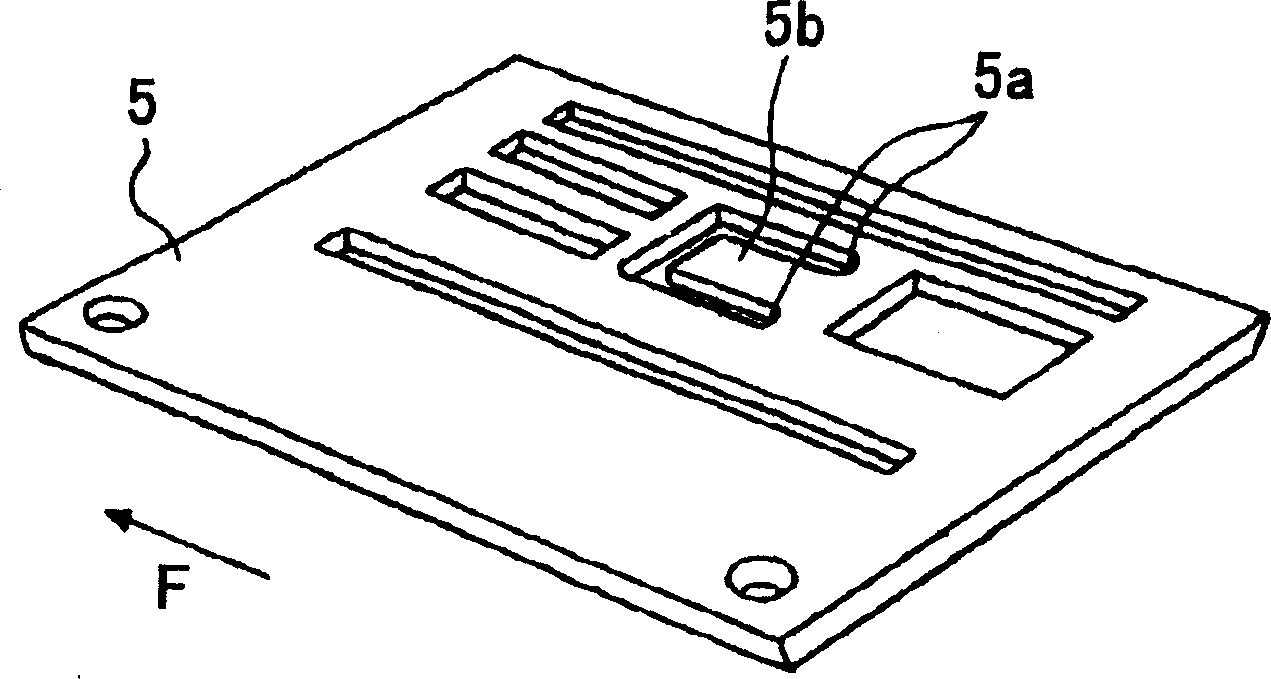

A sewing machine includes a supporting plate portion and a needle. The supporting plate portion contacts sewing fabric that is moved in a predetermined direction during a sewing operation. The needle is vertically moved between a top dead center above the supporting plate portion and a bottom dead center below the supporting plate portion. The supporting plate portion has a needle hole through which the needle passes. The lower end opening of the needle hole is larger than the upper end opening.

Owner:HASHIMA

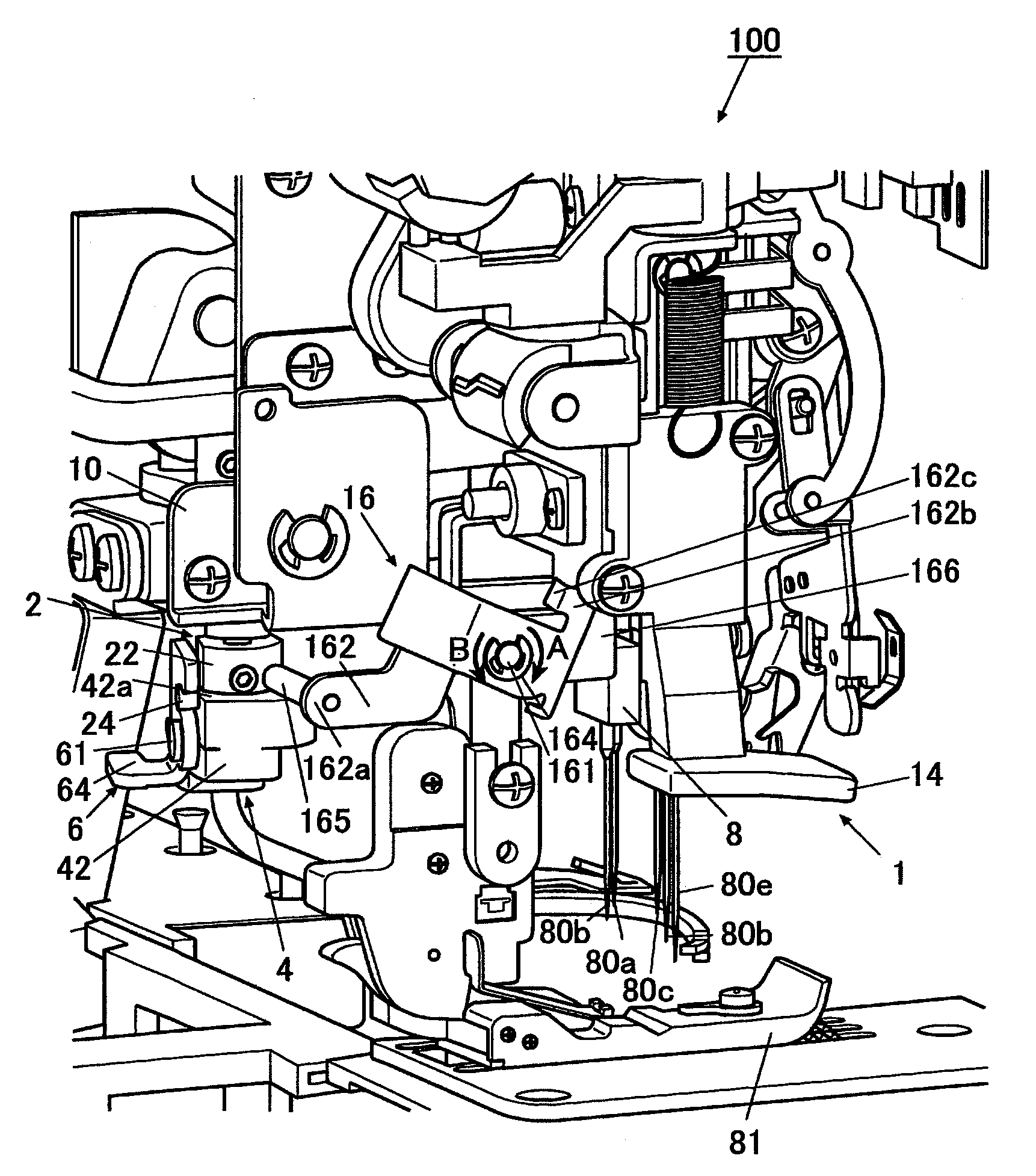

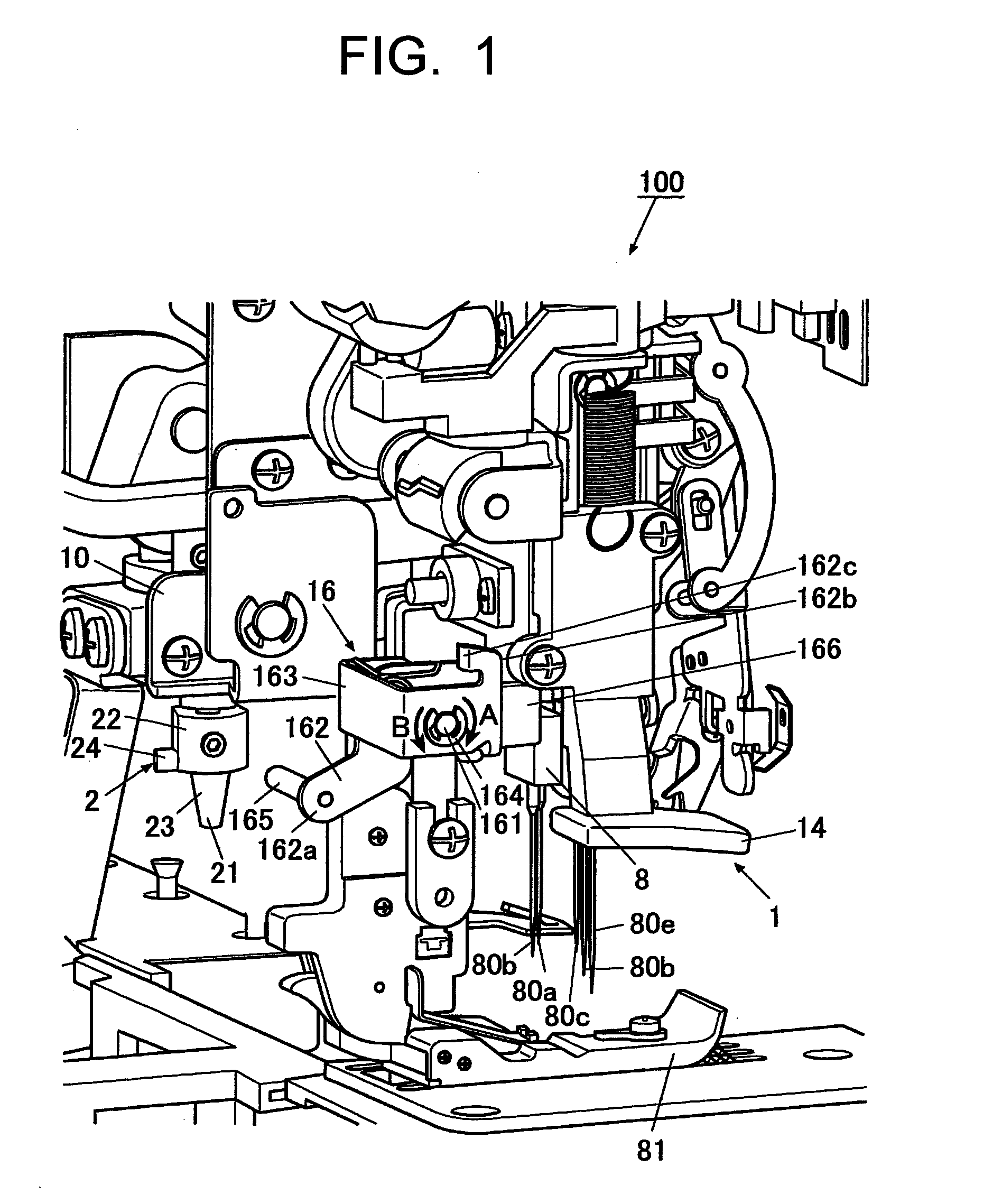

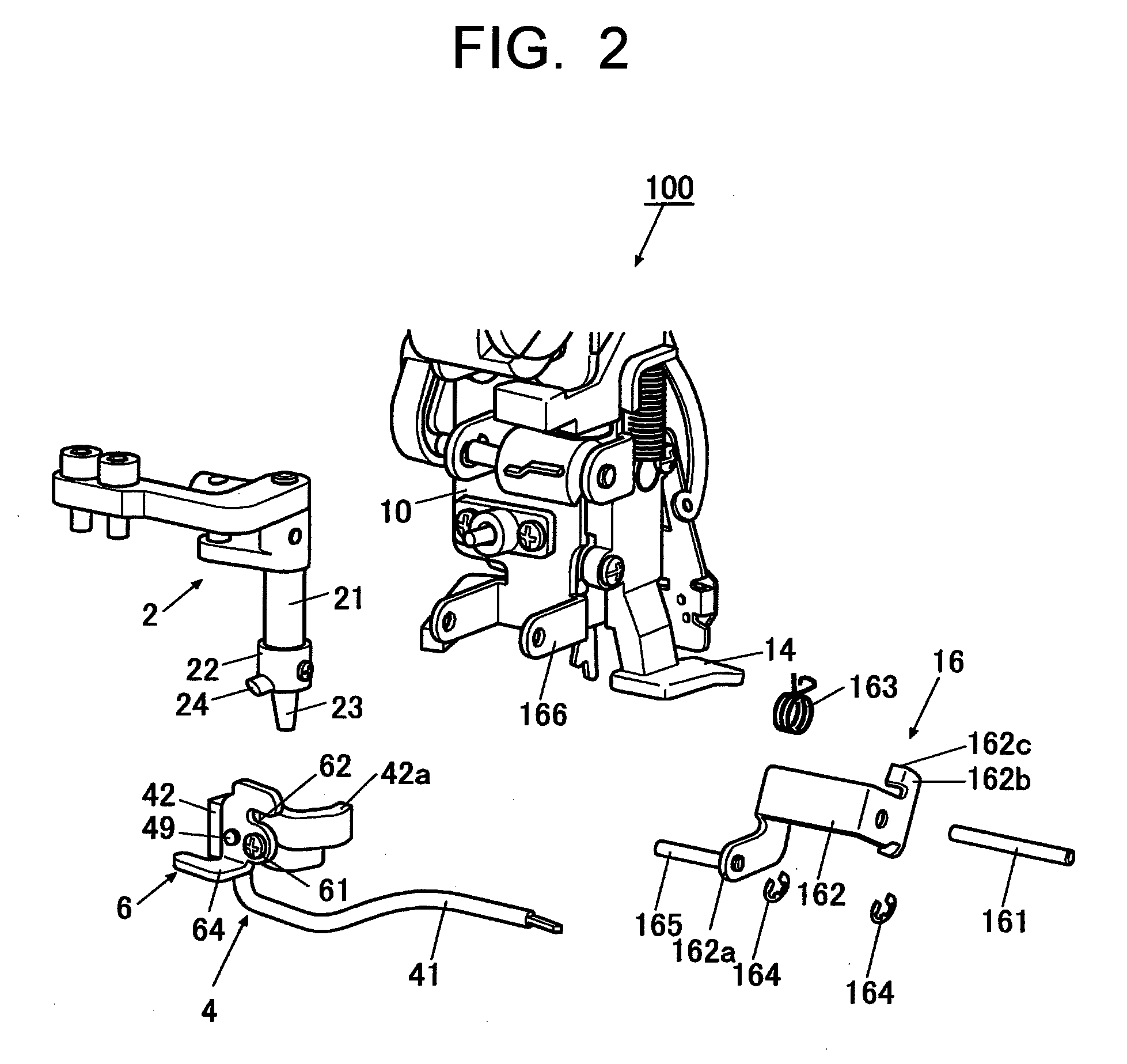

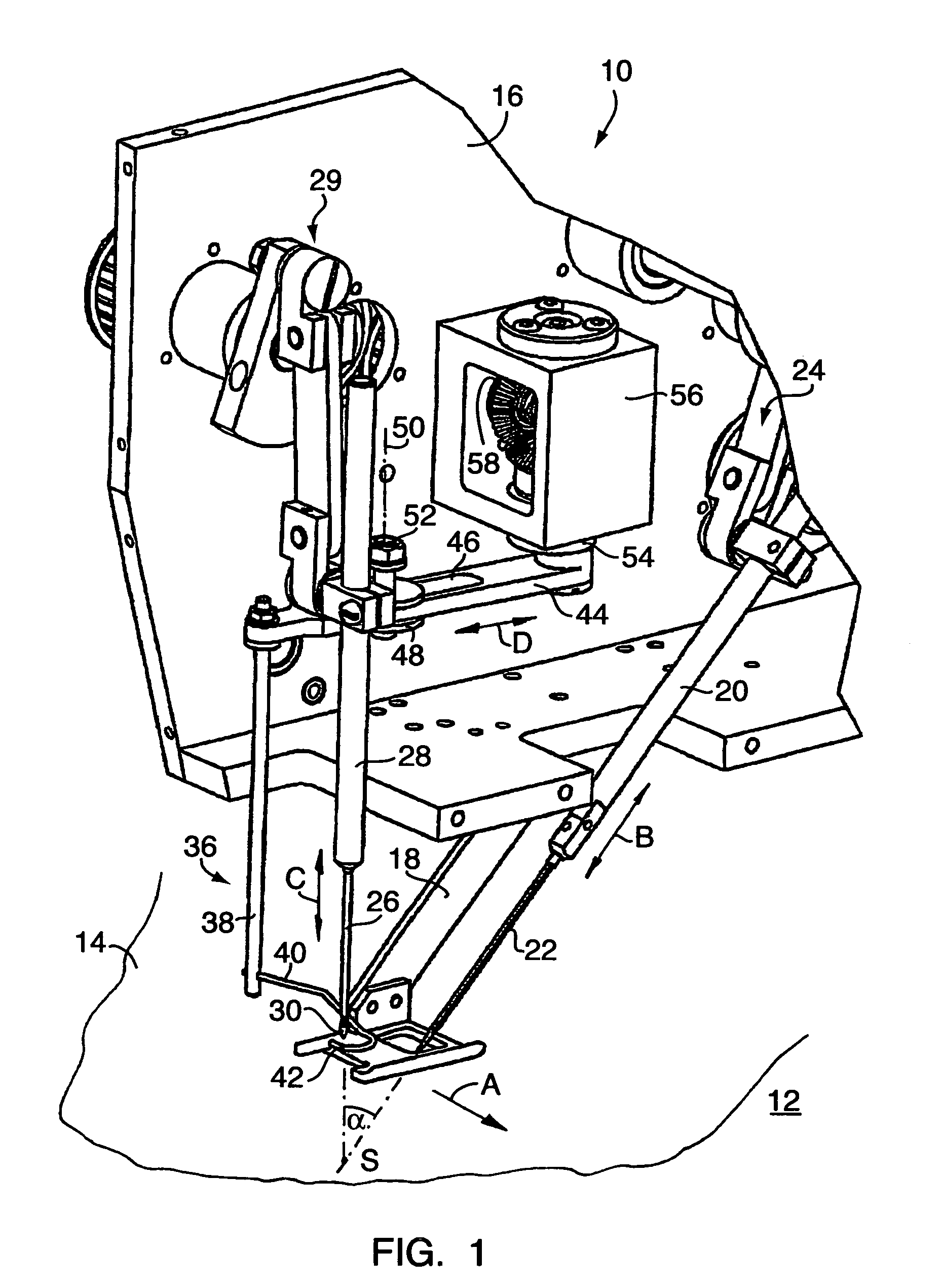

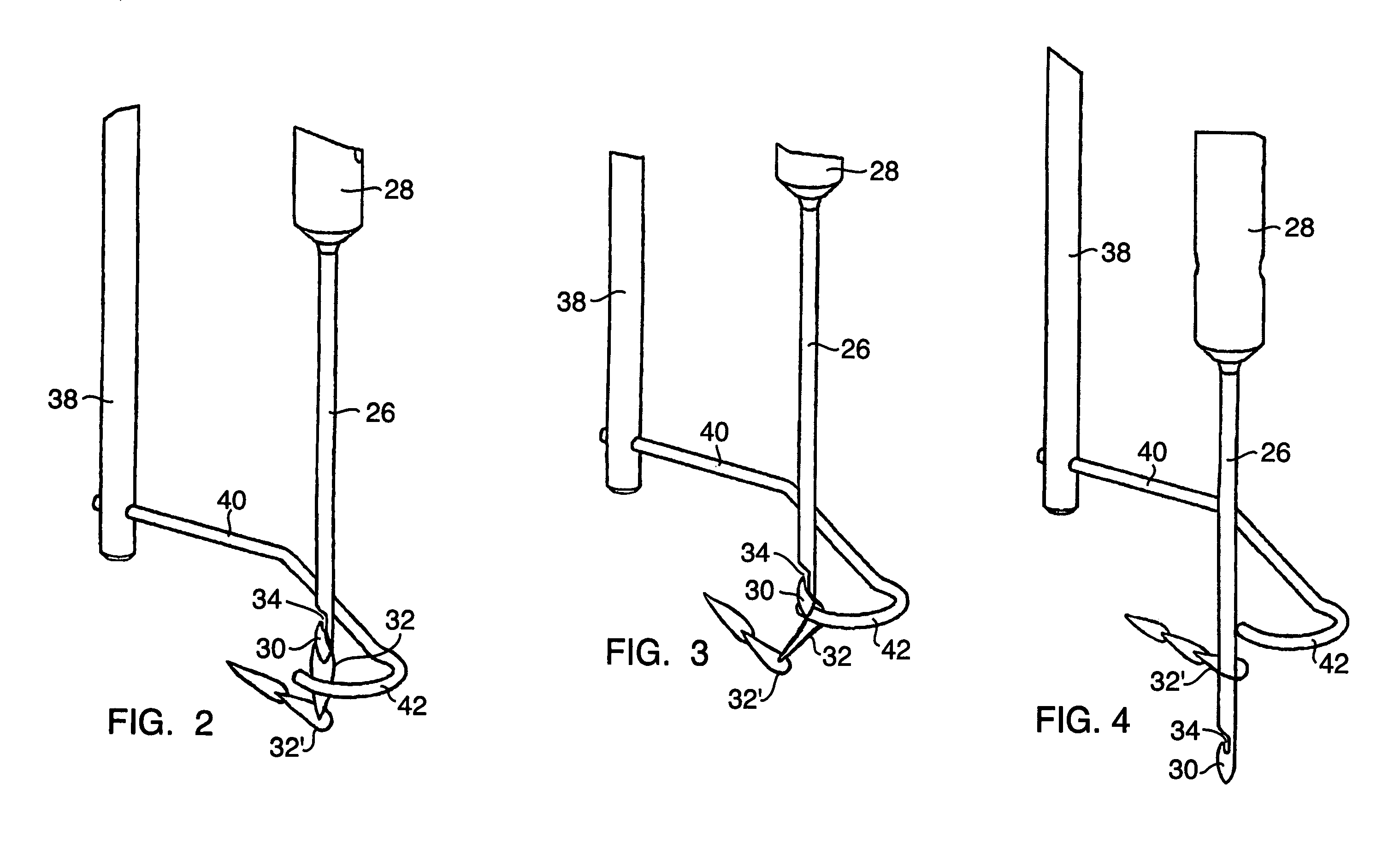

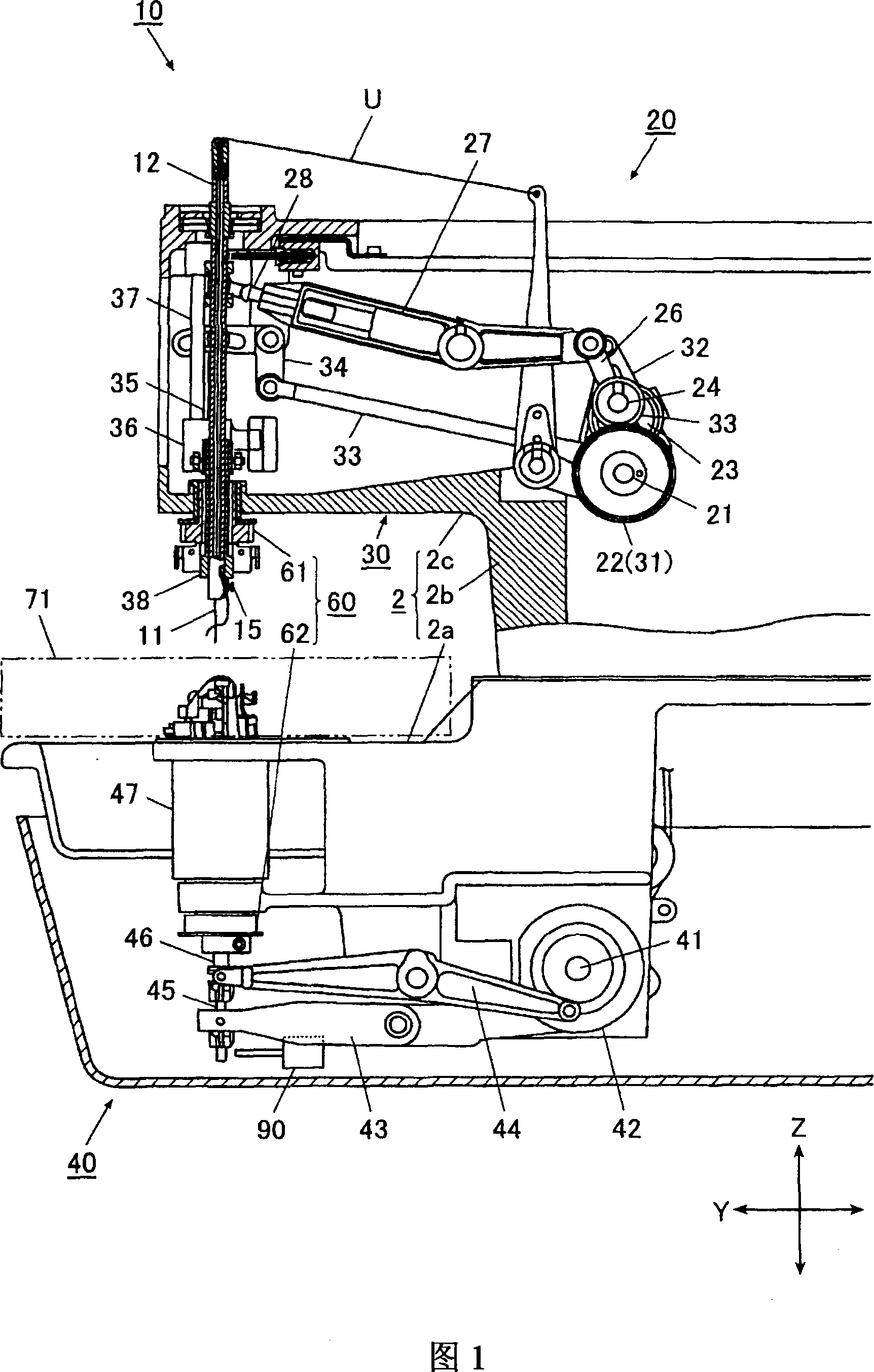

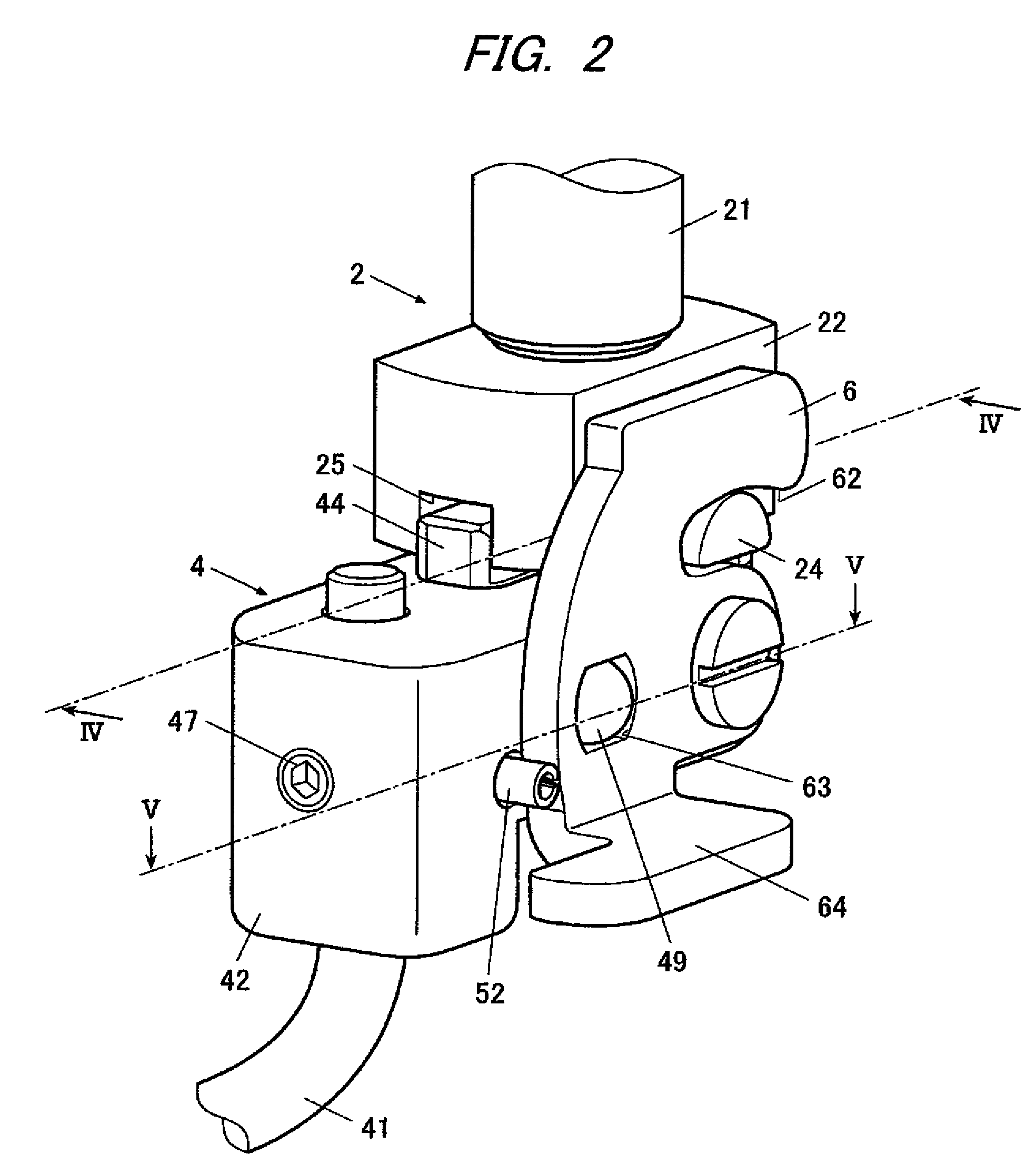

Apparatus for preventing stitching from raveling

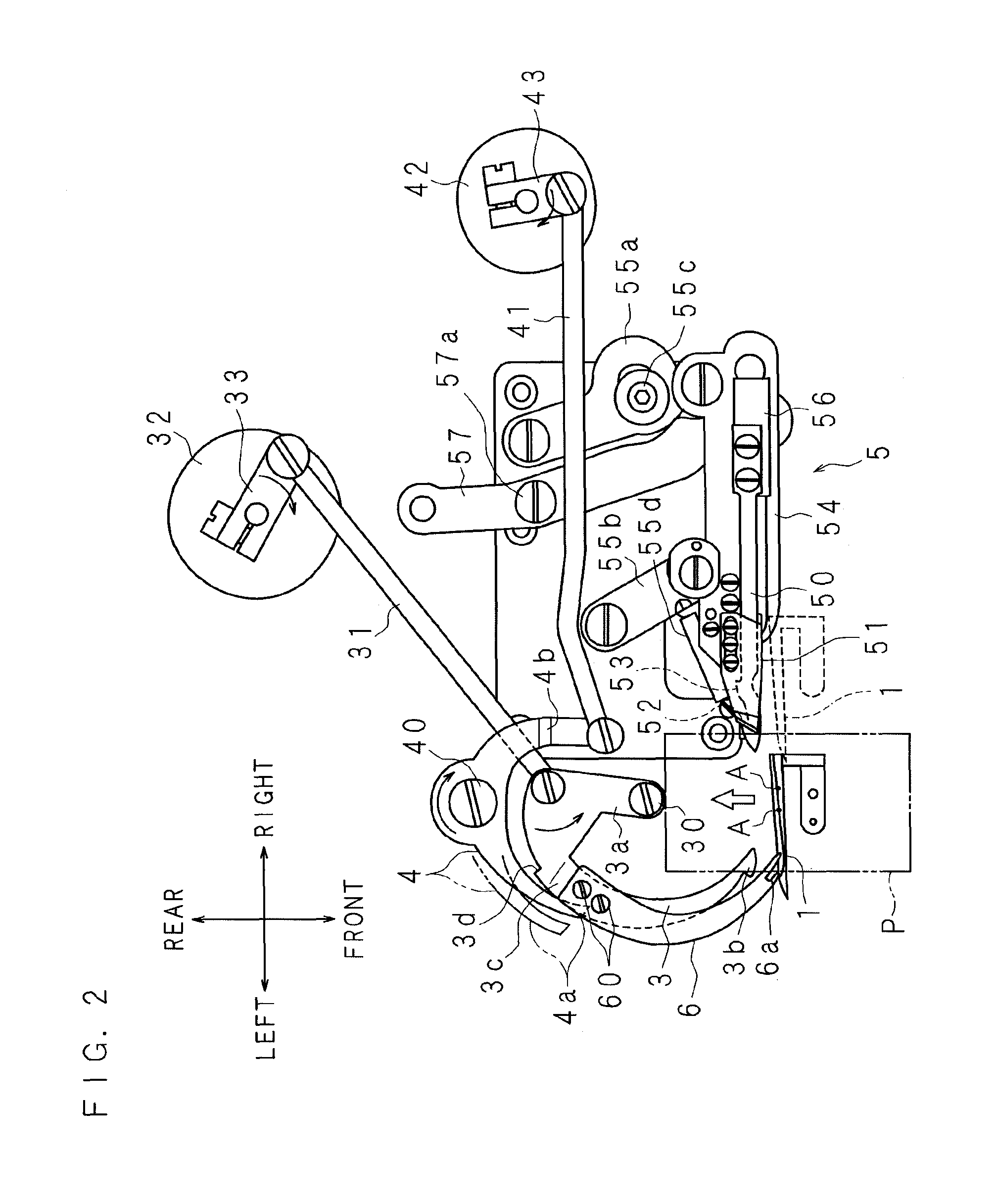

The present invention relates to an apparatus for preventing a double chain stitching from raveling. Looper thread engaging structure engages with the looper thread consecutive to the looper from the cloth by moving when the looper is at the forward position and forms a looper thread loop consecutive from the cloth at the engaged portion by driving a sewing machine in the engaged state. A looper thread cutter cuts the looper thread loop at the engaged portion and a thread cutter cuts the loop-shaped needle thread consecutive to the needle via the looper from the cloth and the looper thread consecutive to the looper from the cloth between the cloth and the looper. Therefore, it is able to prevent a double chain stitching from raveling from the stitching end side. Further, defining structure is provided to define the moving distance of the looper thread engaging structure. The length of the looper thread loop is changed by definition of the moving distance of the looper thread engaging structure by the defining structure. Therefore, the thread of the thread end left over in the cloth by the looper thread cutter can be varied. By varying the length of the thread end consecutive to the sewn end side, a good-looking sewn product is obtained.

Owner:PEGASUS SEWING MACHINE MFG

Method and sewing machine for forming single-thread locked handstitches

ActiveUS7891307B2Confirm positionAccurate sewingProgramme-controlled sewing machinesWork-feeding meansEye needlesEngineering

A sewing thread (20) can be captured certainly with a thread capturing open eye (13a) of an open eye needle (13) and the stitches are formed in the inner space of a sewing machine bed (3). A handstitch and a locked stitch are formed, respectively, on the front surface and the back surface of a fabric workpiece (21) as a skip stitch set through cooperation of the open eye needle (13), a shuttle hook (200) and a thread draw out actuator (401). A feed dog (601) feeds the fabric workpiece by a stitch length (P1) for handstitch during a first stroke of the open eye needle (13), and feeds the fabric workpiece by an inter-stitch pitch (P2) between the handstitches during a second stroke of the open eye needle (13).

Owner:SUZUKI MFG CO LTD

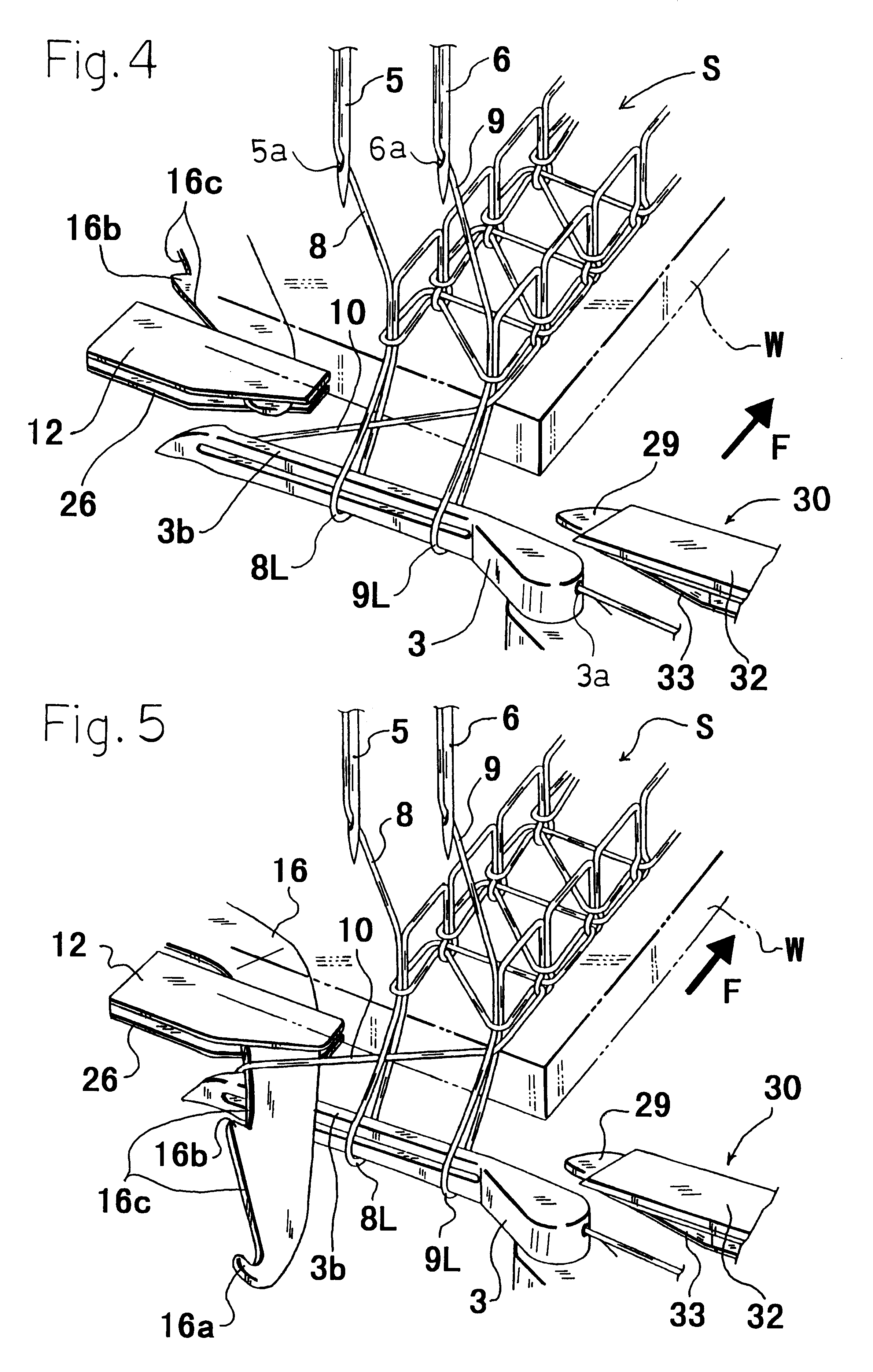

Seam ravel preventing method, seam ravel preventing apparatus and seam structure

ActiveUS8943985B2Avoid it happening againGood effectNeedle severing devicesLoop holdersEngineeringBiomedical engineering

A thread hook and a looper thread holder are arranged on a rear side of a needle drop position of a sewing machine. When usual sewing is completed, the thread hook and the looper thread holder swing and move close to a looper. A hook part provided at a tip end of the thread hook holds a needle thread loop caught by the looper and positions it on an advance end side of the looper away from the needle drop position, and a thread receiving part provided at a tip end of the looper thread holder holds a looper thread extending from the looper to cloths and positions it on the front side away from the needle drop position. The sewing machine performs sewing for at least one stitch while maintaining positions of the needle thread loop and the looper thread.

Owner:YAMATO SEWING MASCH MFG CO LTD

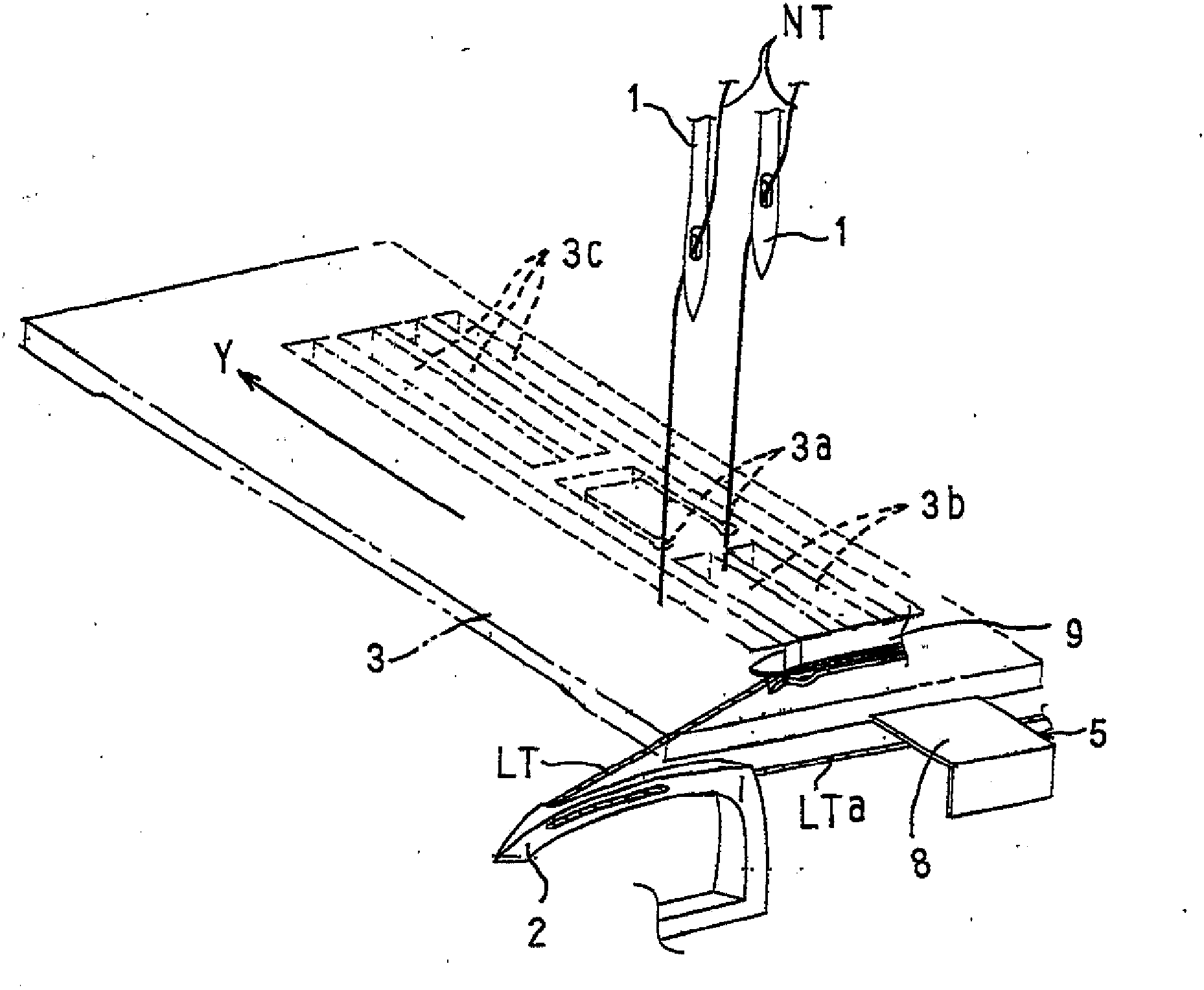

Sewing method of cloth and double-chain-ring sewing machine

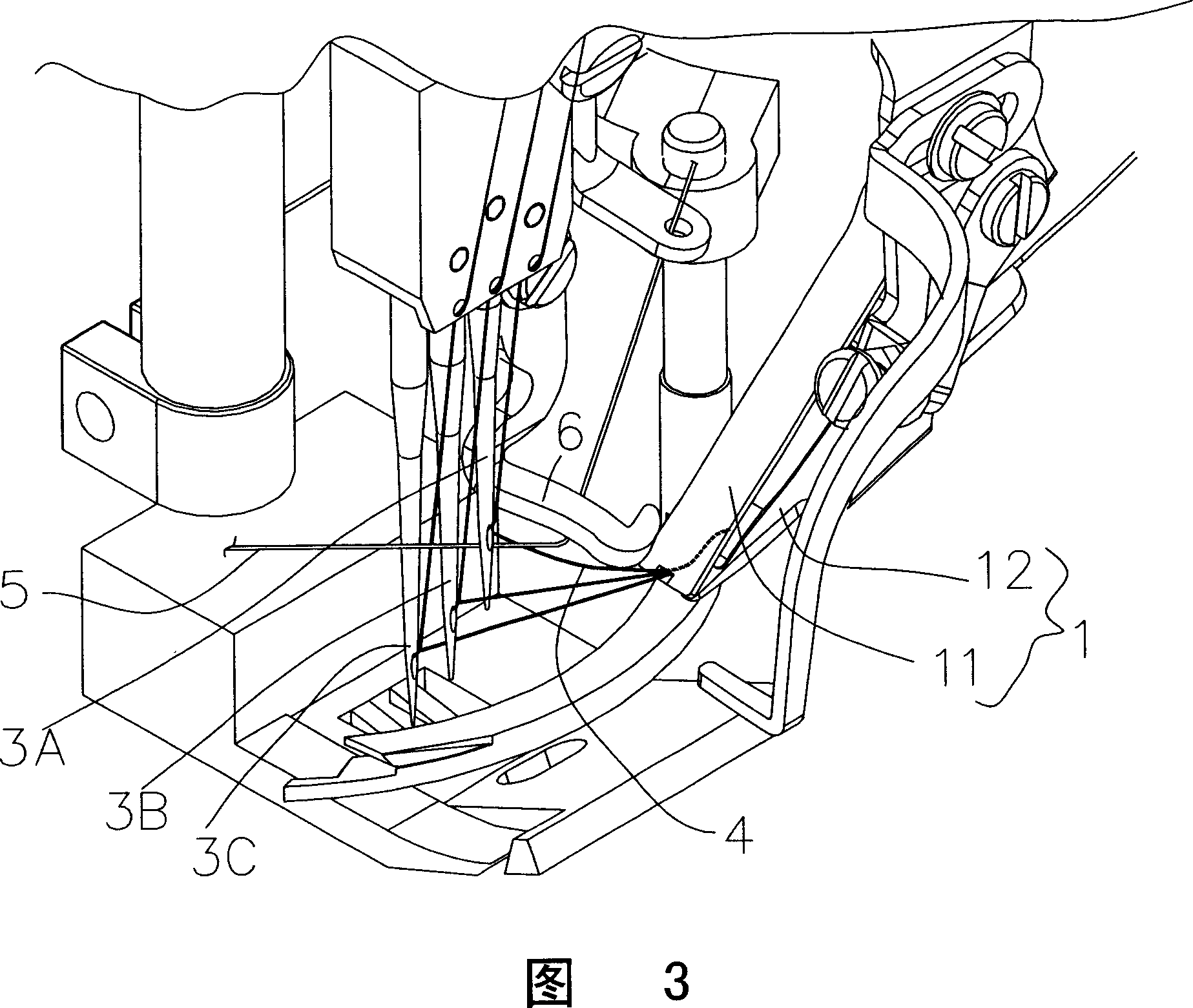

ActiveCN103361889AEasy to operateWon't hurtSewing-machine casingsWork-feeding meansOperabilityEngineering

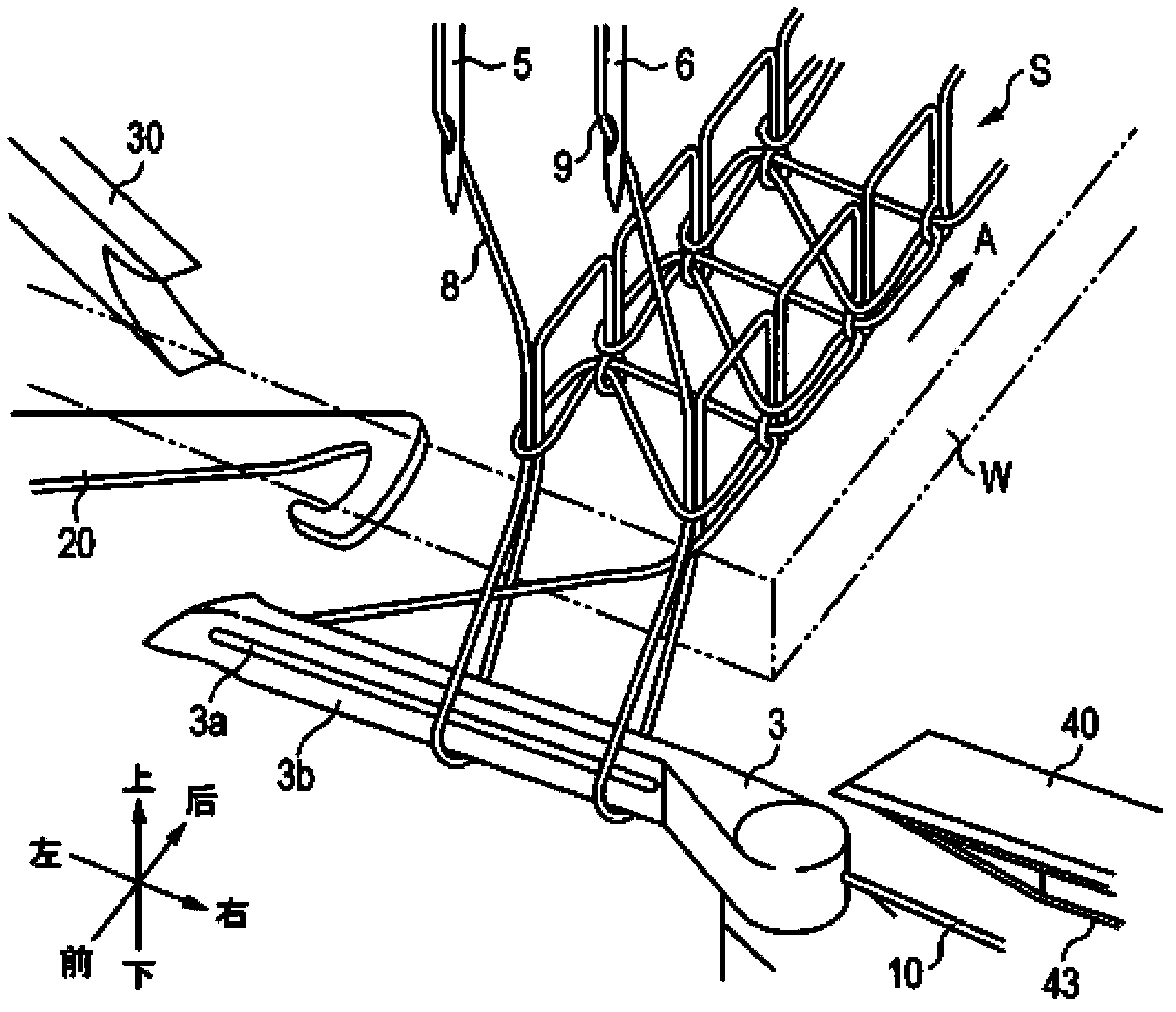

A sewing method of cloth and a double-chain-ring sewing machine transfer the cloth towards a specified sewing advancing direction along an upper surface of a needle plate, and form a stitch ring at a lower side of the needle plate by utilizing two needles which keep stitching and move up and down, and catch the stitch ring through advancing of a curved needle which can advance and retreat in a direction approximately orthogonal to an up-down moving path of the needle, and utilize a looper thread maintained by the curved needle to wind the caught stitch ring, so that double-chain-ring stitch is formed on the cloth, at the moment, a movement guiding stitch diagonal member is utilized to perform movement guide to a stitch end part which is protruded onto a surface of the cloth when the stitch of the first needle begins, so as to form a state of falling and tilting towards a downstream side of the sewing advancing direction, thereby sewing and processing the stitch end part into the double-chain-ring stitch. Therefore, cut processing for the stitch end part does not cost time, thereby realizing labor saving, raising the efficiency of sewing operation and operability of the cloth, and preventing damages to the cloth.

Owner:YAMATO SEWING MASCH MFG CO LTD

Seam ravel preventing method, seam ravel preventing apparatus and seam structure

ActiveUS20140076222A1Reduction in feed pitchFeeding is stoppedNeedle severing devicesLoop holdersBiomedical engineeringCotton material

A thread hook and a looper thread holder are arranged on a rear side of a needle drop position of a sewing machine. When usual sewing is completed, the thread hook and the looper thread holder swing and move close to a looper. A hook part provided at a tip end of the thread hook holds a needle thread loop caught by the looper and positions it on an advance end side of the looper away from the needle drop position, and a thread receiving part provided at a tip end of the looper thread holder holds a looper thread extending from the looper to cloths and positions it on the front side away from the needle drop position. The sewing machine performs sewing for at least one stitch while maintaining positions of the needle thread loop and the looper thread.

Owner:YAMATO SEWING MASCH MFG CO LTD

Threading device of sewing machine

InactiveUS20090064914A1Avoid breakingAvoid collisionThread-laying mechanismsNeedle-threading devicesEngineeringMotion transfer

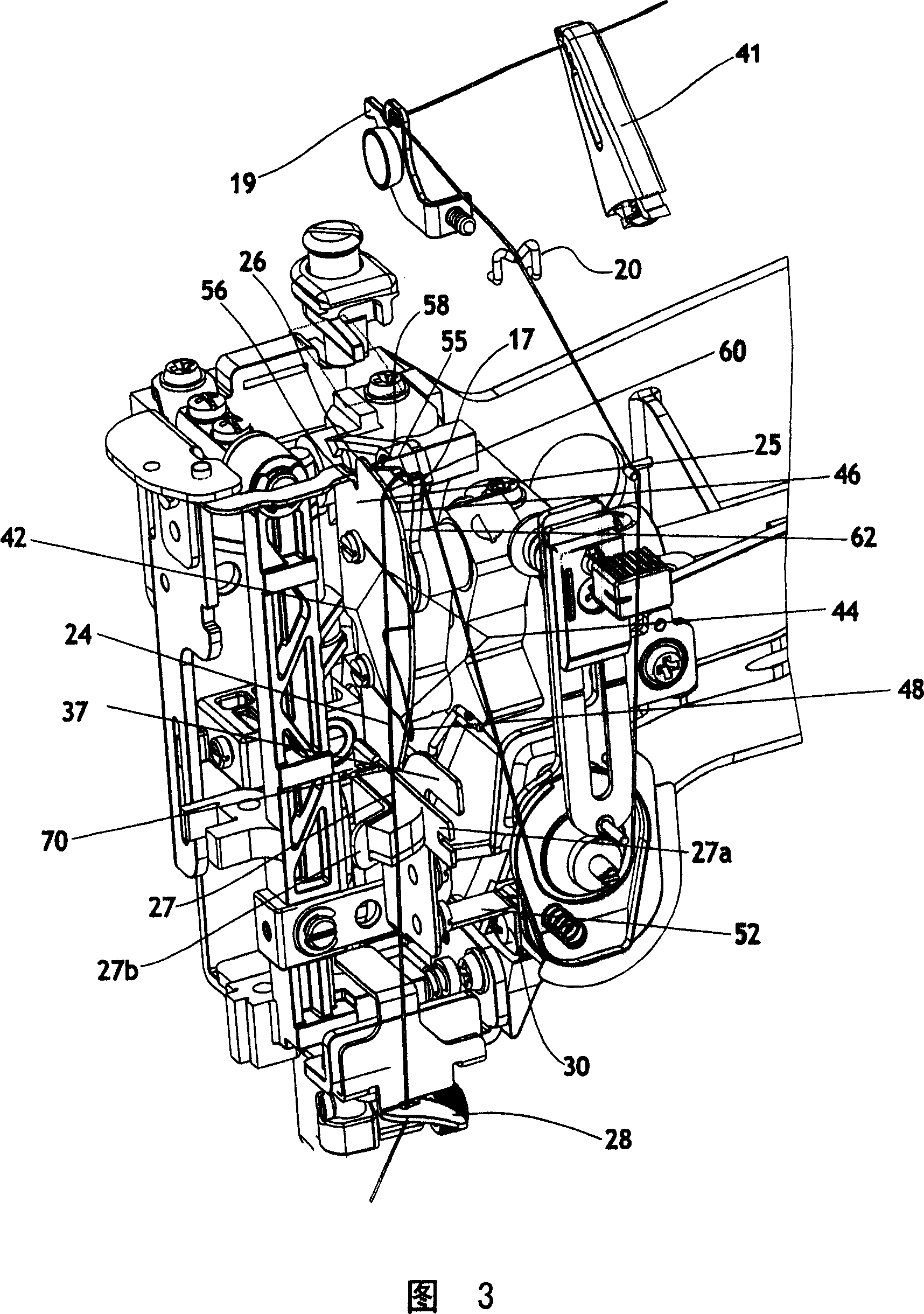

A threading device of a sewing machine is provided. The threading device includes a threading hook which moves forward to enter an eye of a needle to catch a needle thread, and moves rearward with the needle thread being caught to insert the needle thread through the eye, a threading shaft which holds the threading hook, an operating member which is operated to move the threading shaft, a threading operation mechanism which transmits the movement of the threading shaft to the threading hook to move the threading hook back and forth, and a restricting device which makes the threading operation mechanism inoperable when the spreader mechanism is attached to the sewing machine main body, and makes the threading operation mechanism operable when the spreader mechanism is detached from the sewing machine main body.

Owner:JUKI CORP

Chain stitch sewing mechanism

ActiveUS6973887B2Easy constructionReliable functionSewing-machine control devicesSewing needlesReciprocating motionSharp angle

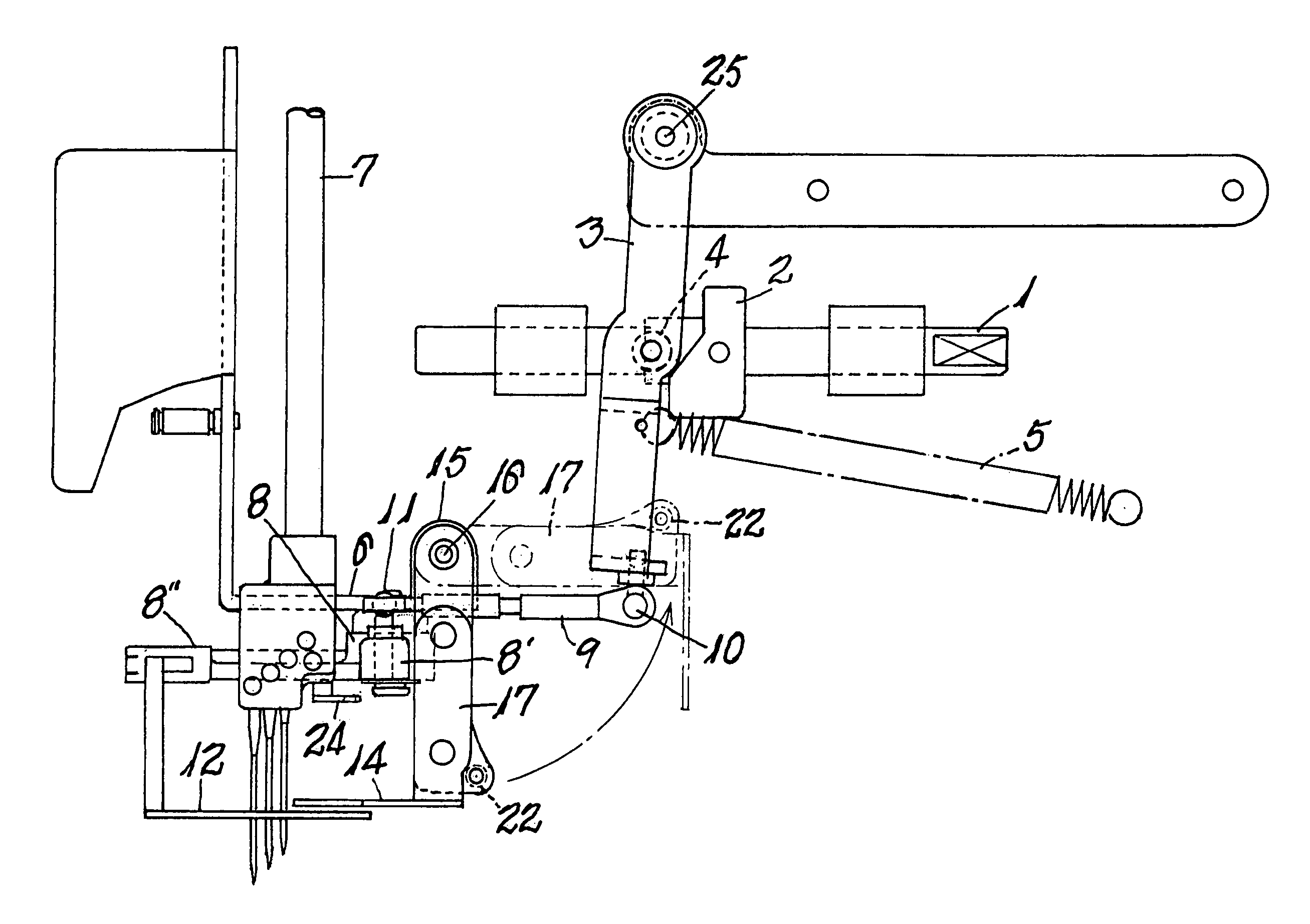

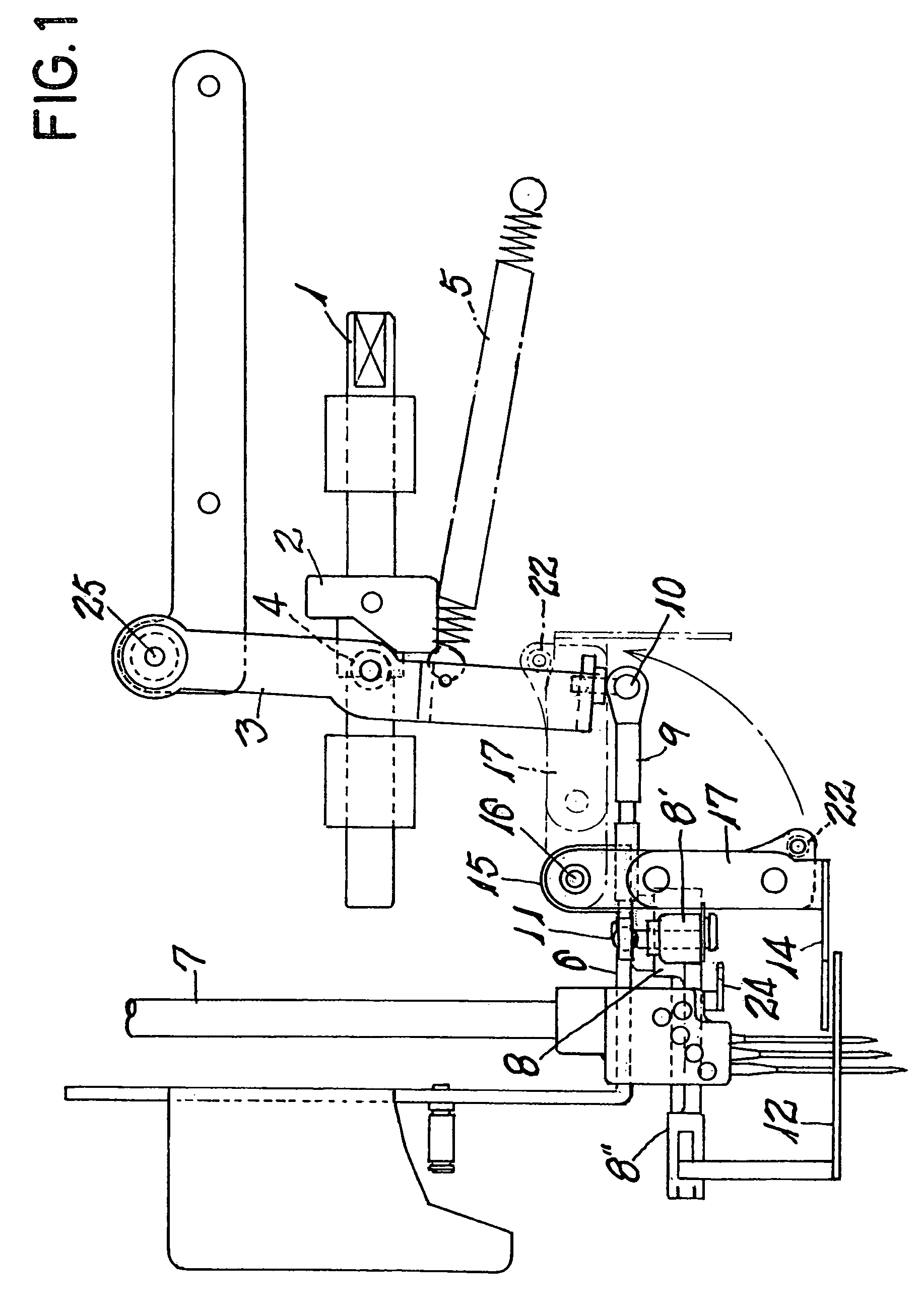

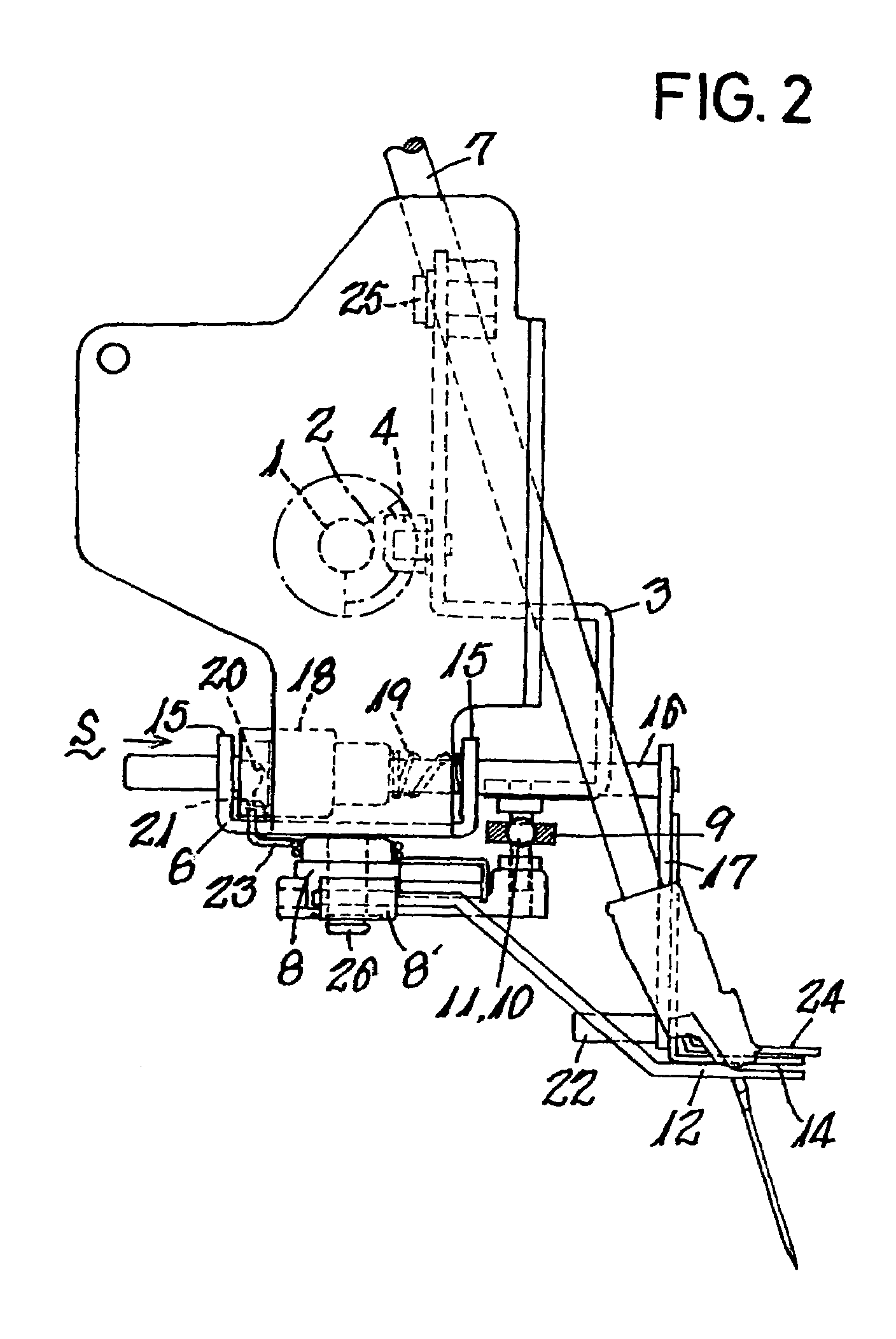

In a chain stitch sewing mechanism with a sewing head movable parallel to the sewn material plane, including a needle rod with a needle drive for reciprocating a thread carrying needle, a catcher drive for reciprocating a needle shaped thread catcher with an open catching hook. The needle and thread catcher have movement paths forming a sharp angle with one another whose apex lies beneath the sewn material plane and the needle and catcher being so controlled such that a loop formed by the withdrawal of the needle is caught by the thread catcher and pulled through the material. A thread puller on a movable thread arm is moved towards the thread catcher and cooperates with the thread catcher for deflecting the loop hanging off the thread catcher at an angle to the movement path of the thread catcher toward the side opposite to that of the hook opening.

Owner:PFAFF INDUSTRIESYSTEME & MASCH GMBH

Thread-through device for sewing machine

ActiveCN101168889AEasy to identifyEasy threading workLightening equipmentNeedle-threading devicesEngineeringTread

Owner:JUKI CORP

Upper decorative stitching device

ActiveUS7107919B2Simple structurePromote conversionSewing-machine control devicesFilament handlingSpherical bearingReciprocating motion

An upper decorative stitching device is designed to make it possible to precisely transmit the swing movement of a first lever which is capable of swing movements widthwise in a pendulum manner to horizontal reciprocating motion of a second lever, which is provided with a spreader. The device facilitates the operation of switching between an upper decorative stitching and no upper decorative stitching. A connecting rod (9) is provided at both ends with spherical bearings (10, 11) to provide a connection between the first lever (3) and the second lever (8), thereby converting the rotation of the upper shaft into the reciprocal movement of the spreader.

Owner:JANOME CORP

Threading device of sewing machine

InactiveUS7918171B2Avoid collisionThread-laying mechanismsNeedle-threading devicesEngineeringMotion transfer

A threading device of a sewing machine is provided. The threading device includes a threading hook which moves forward to enter an eye of a needle to catch a needle thread, and moves rearward with the needle thread being caught to insert the needle thread through the eye, a threading shaft which holds the threading hook, an operating member which is operated to move the threading shaft, a threading operation mechanism which transmits the movement of the threading shaft to the threading hook to move the threading hook back and forth, and a restricting device which makes the threading operation mechanism inoperable when the spreader mechanism is attached to the sewing machine main body, and makes the threading operation mechanism operable when the spreader mechanism is detached from the sewing machine main body.

Owner:JUKI CORP

2 needle sewing machine for angular seam

To provide a twin needle sewing machine for corner sewing capable of sewing without generating a crossing thread on an upper face of a fabric. The fabric is turned at the time of pausing of sewing by using right and left needles and a looper. When the fabric is sewed again after turning, a corner sewing is applied to the fabric. The twin needle sewing machine for corner sewing has an air blower which blows air to thread loops in a needle rear part so that the thread loops are separated from a looper orbit, and a hook for sliding the thread loops caught by the looper toward a looper base side. When the fabric is turned clockwise, the thread loops in a rear part of the right needle are separated from the looper orbit in a range from several stitches before turning of the fabric to several stitches after turning of the fabric. When the fabric is turned counterclockwise, the hook is advanced by several stitches before turning of the fabric, and the thread loops of the left needle caught by the looper are slid toward the looper base side and the thread loops of the left needle are caught by the right needle. The thread loops of the rear part of the left needle are separated from the looper orbit by several stitches after the turning of the fabric.

Owner:PEGASUS SEWING MACHINE MFG

Stitch opening preventing device

InactiveCN103572515ANo cutting requiredNeedle severing devicesLoop holdersEngineeringMechanical engineering

Disclosed is a stitch opening preventing device which is capable of shortening thread ends so as to avoid cutting off of the thread ends. The stitch opening preventing device comprises a hook piece, a first cutter and a second cutter; the hook piece hooks a part of a looper thread connected to a looper from fabric when a terminal is finished and the looper is at an advancing position; the first cutter and the second cutter cut off threads and the looper thread. By the stitch opening preventing device, when the looper thread is hooked by the hook piece and after needles and the looper are driven by a stitch, parts of the threads, namely thread loops, connected to the needle from the fabric via the looper and the part of the looper thread connected to the looper from the fabric are cut off between the fabric and the lopper through the second cutter; the first cutter cuts off a thread loop, between the fabric and the hook piece, of the looper thread hooked between the fabric and the hook piece through advancing.

Owner:JUKI CORP

Method for sewing machine to prevent miss-sewing

The method for sewing machine to prevent miss-sewing is to limit the distance for the string hooking grip to move the hooked string in the place corresponding to the first needle, so that the string hooking grip hooks only the string penetrating the first needle reliably. The method can prevent miss sewing reliably.

Owner:顾飞龙

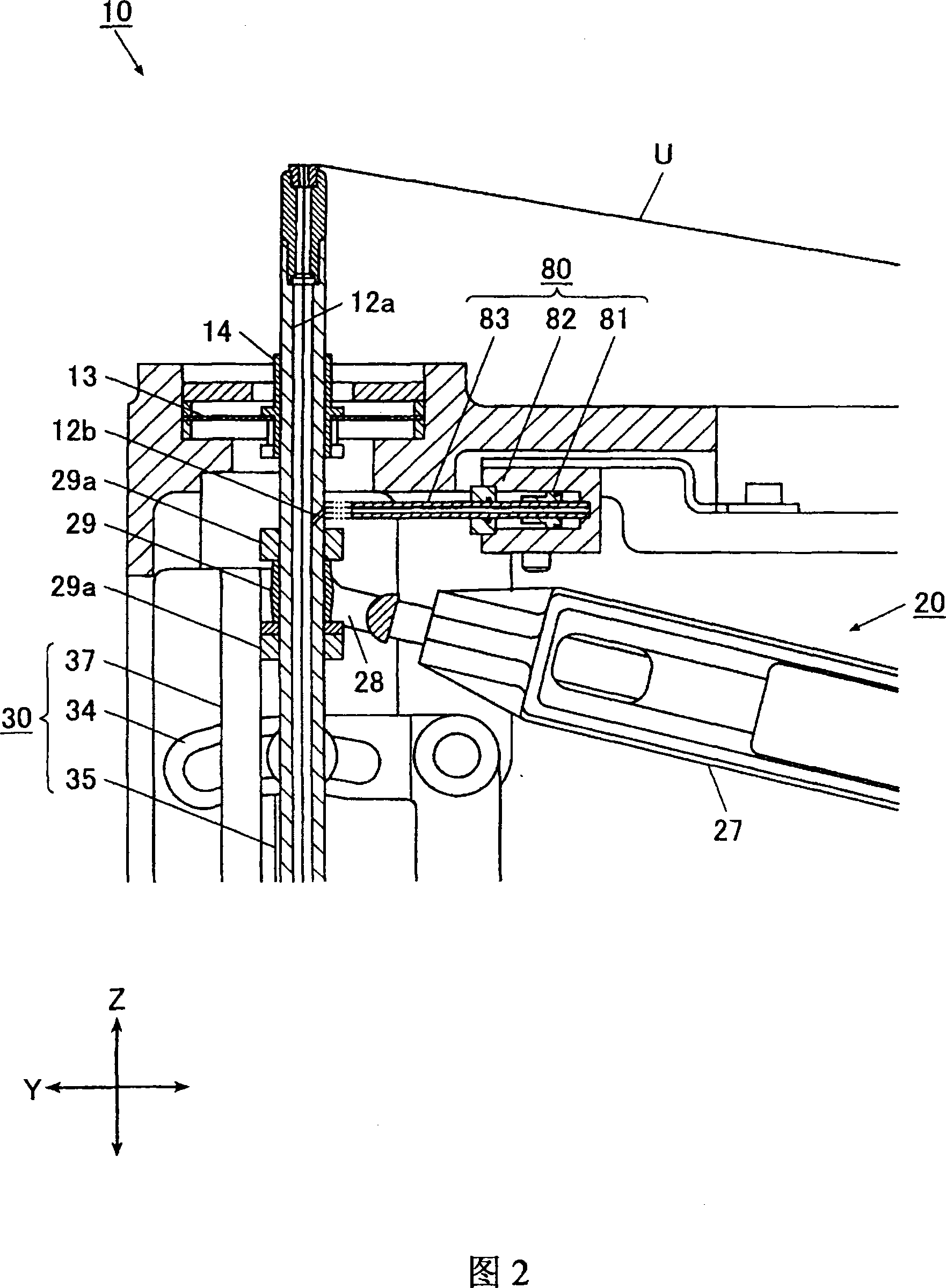

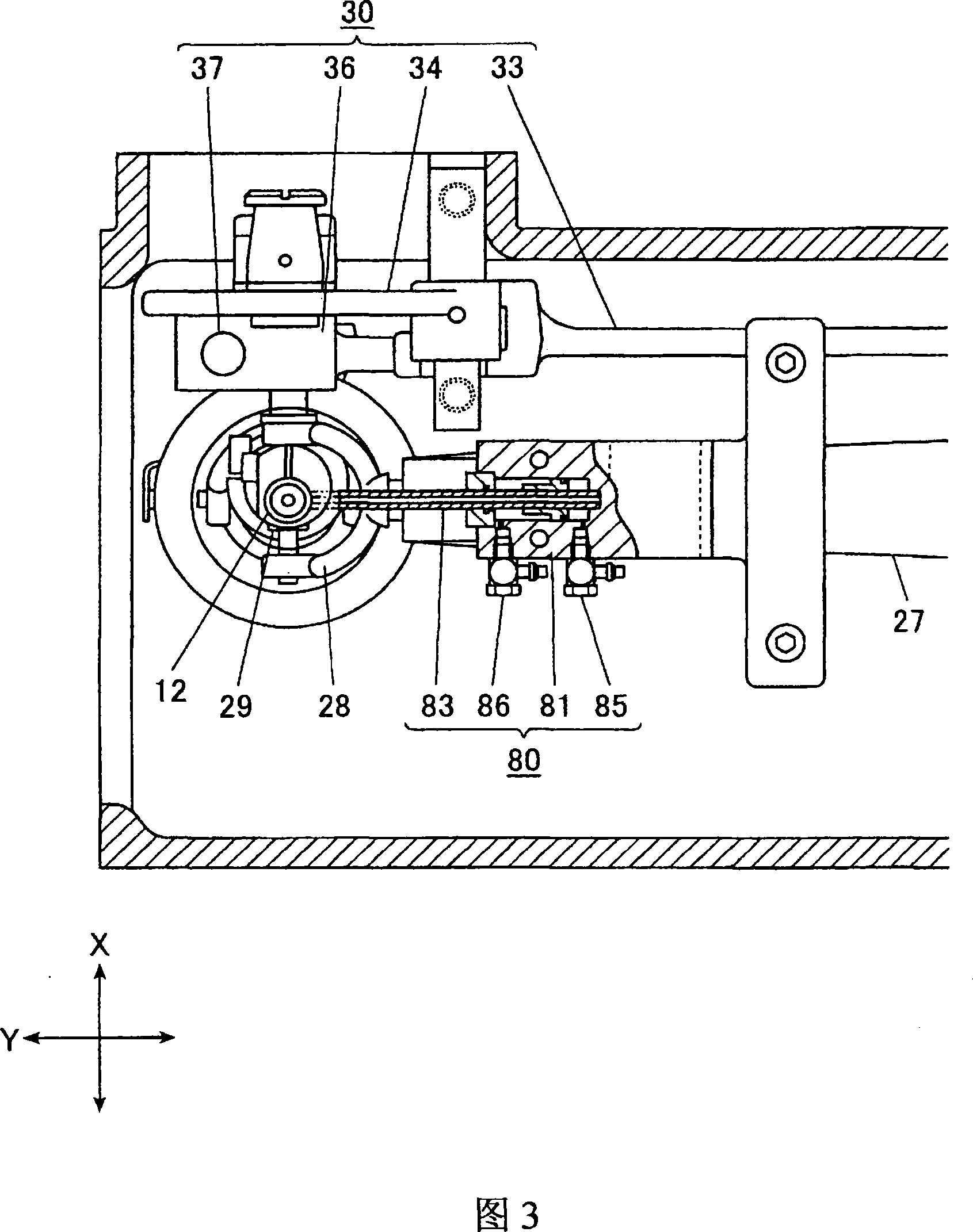

Button keyhole sewing machine

InactiveCN101173425AInterfering with sewing actionAvoid getting in the wayThread-laying mechanismsNeedle-threading devicesEngineeringKeyhole

According to the invention, the needle thread can be pulled through eyelet simply. The sewing machine of the invention is provided with a needle bar (12) having a thread guiding part (12a) passing through upper end to the lower end; a vertical motion mechanism (20) of needle bar; a needle-swinging mechanism (30) which enables the needle bar to swing; a looper mechanism (40); a turning mechanism (60) which enables the needle bar and looper mechanism base to rotate; and a motion mechanism which enables the process cloth to move, and forms an inclined needle-bar opening (12b) at the needle bar for blowing of air into needle thread eyelet. Also is provided with an air nozzle for feeding thread mounted on the side of the needle bar; and a controller for controlling the vertical motion mechanism, needle-swinging mechanism and rotation mechanism, which enables the needle-bar opening to align with the air jet hole of the air nozzle.

Owner:JUKI CORP

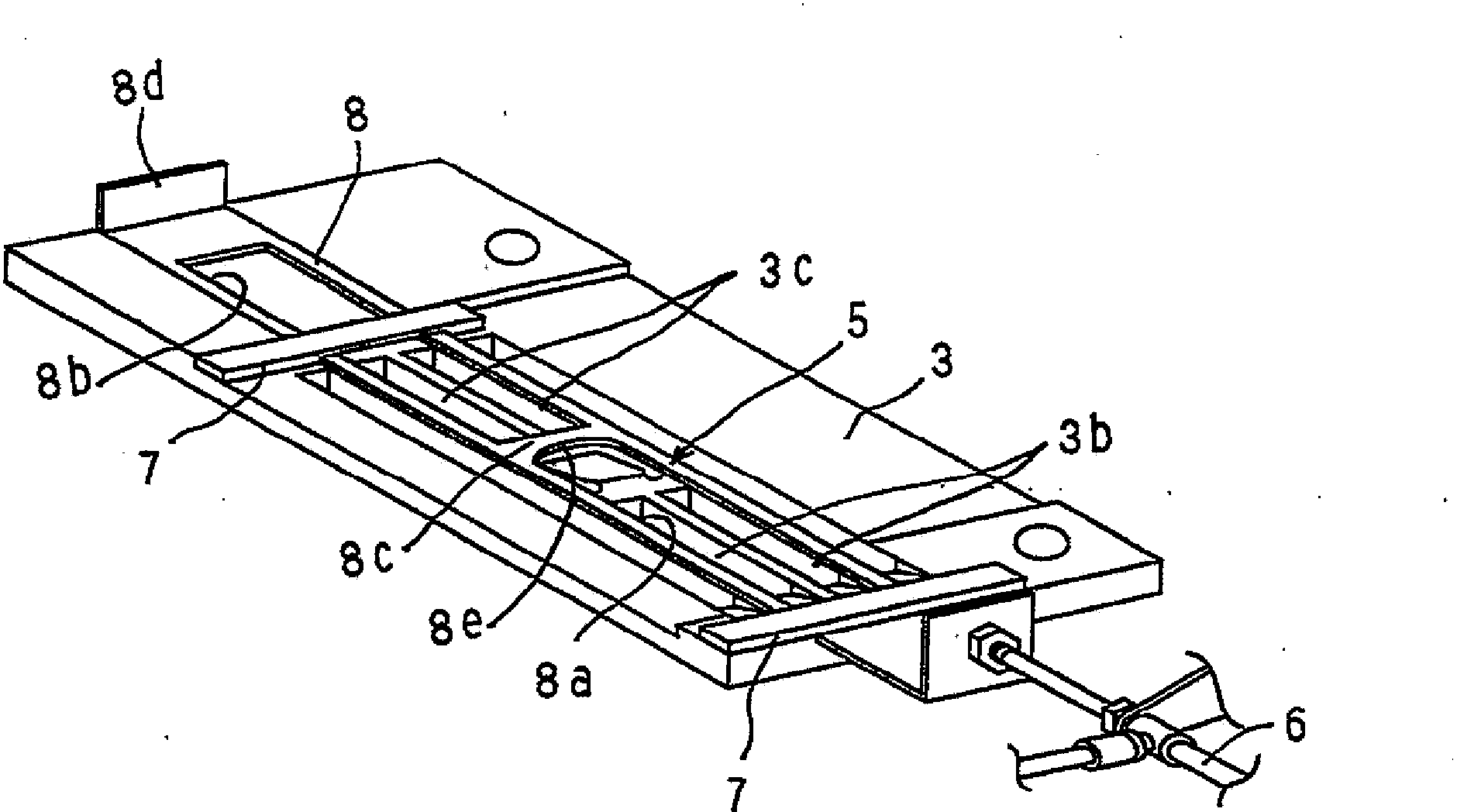

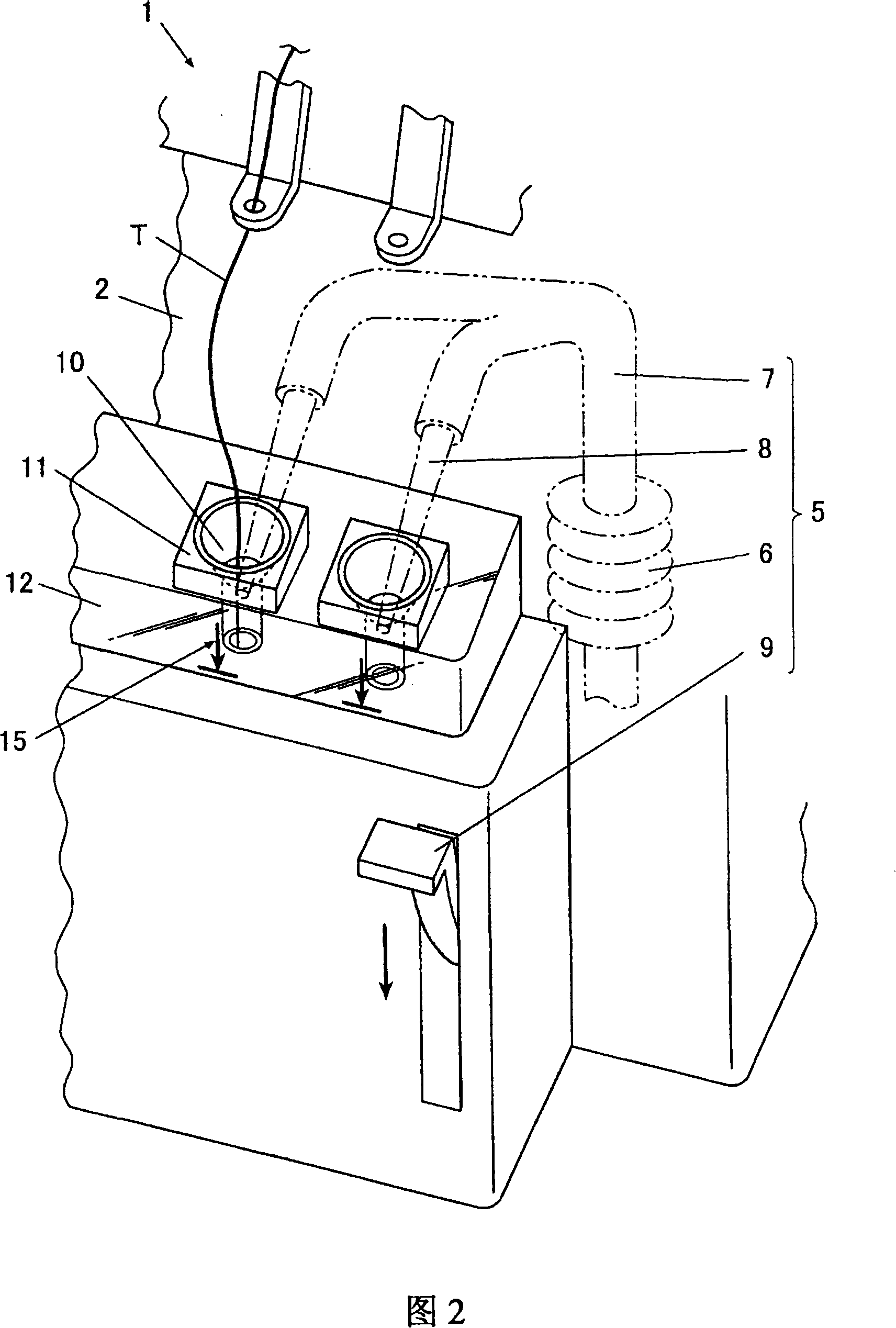

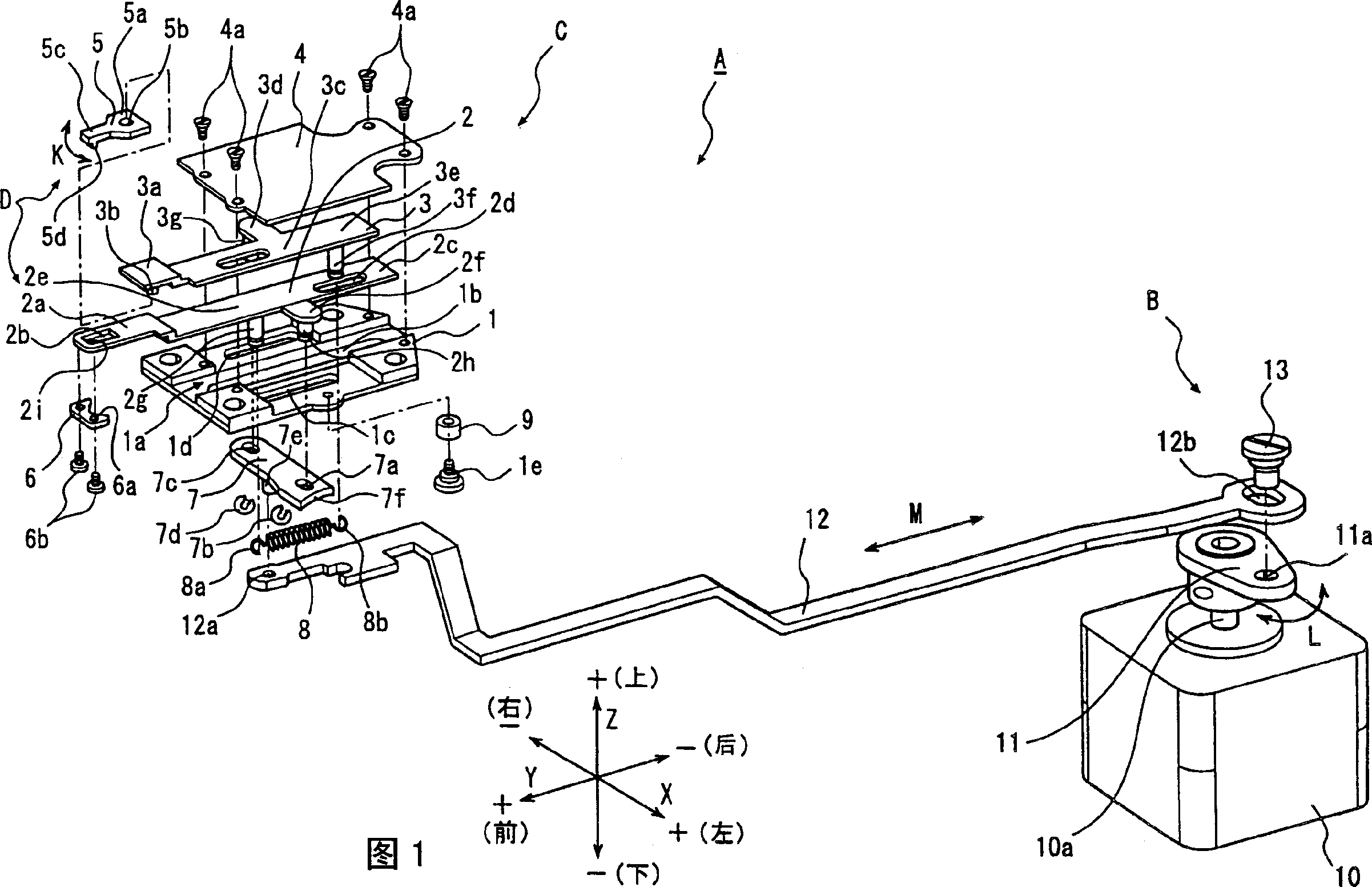

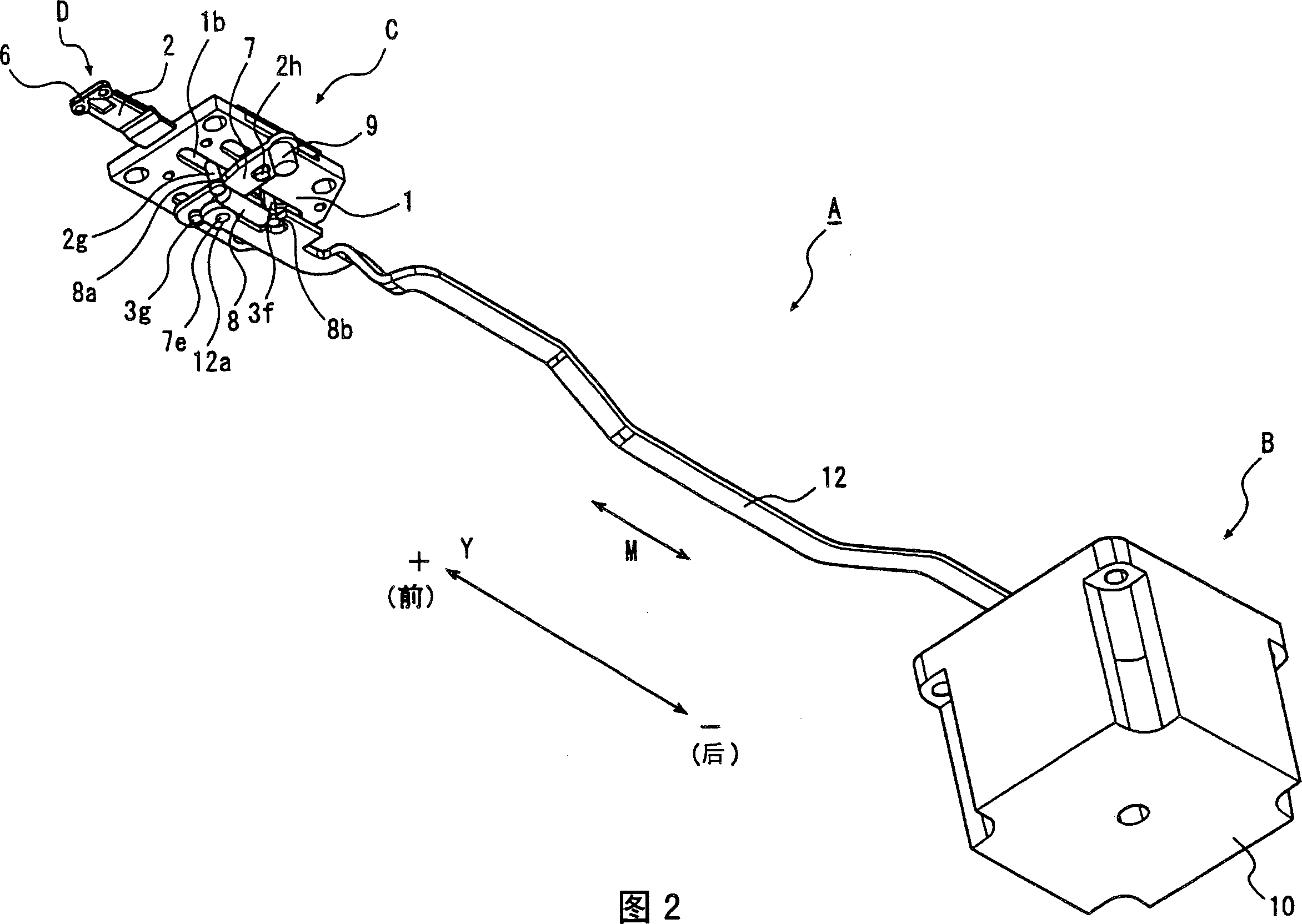

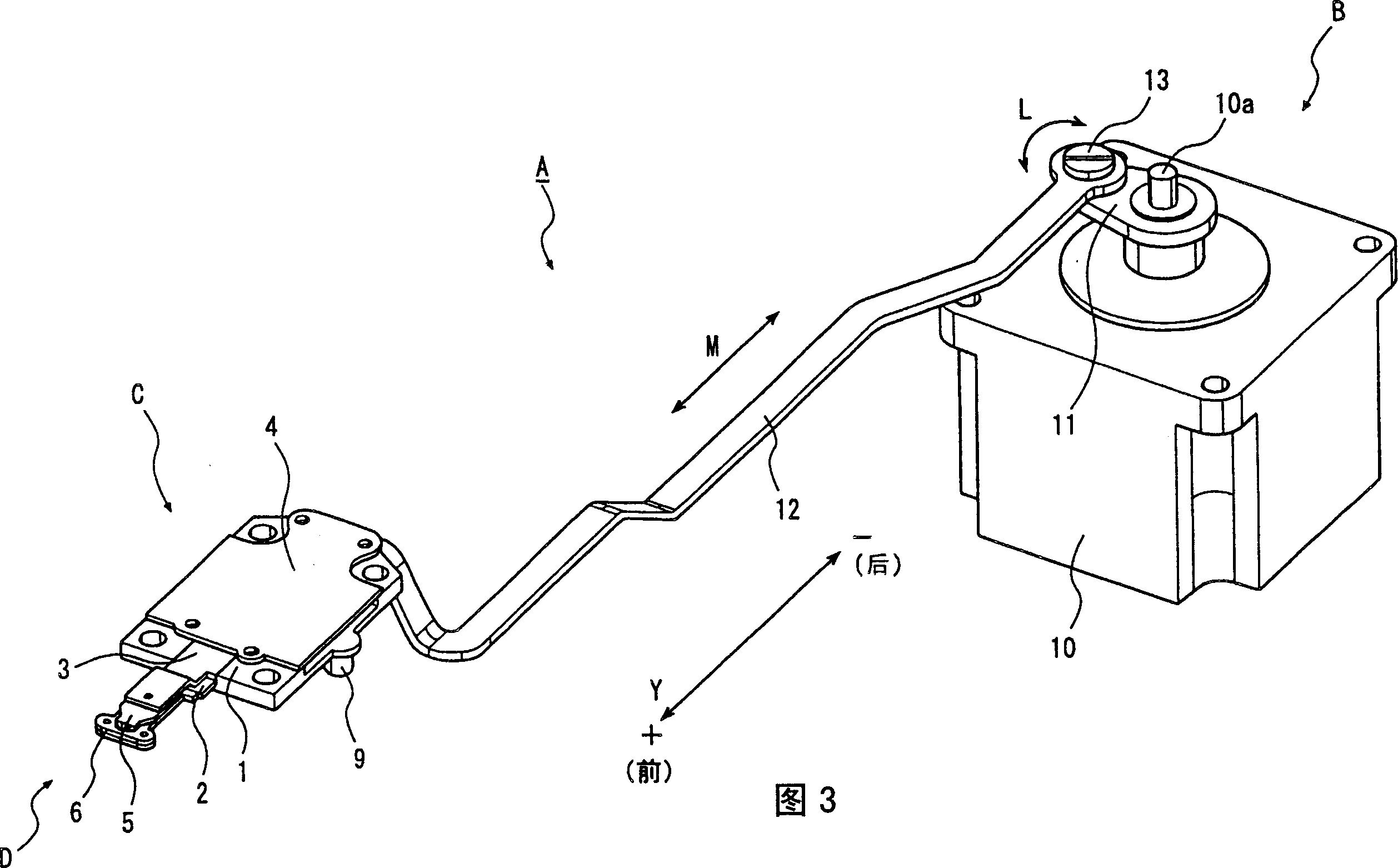

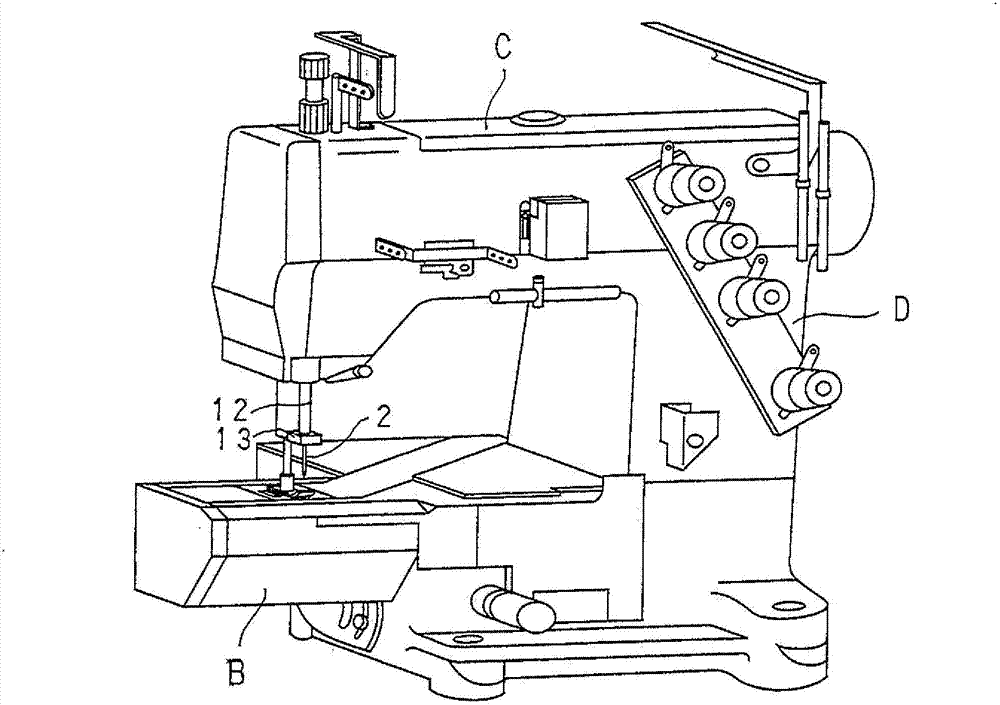

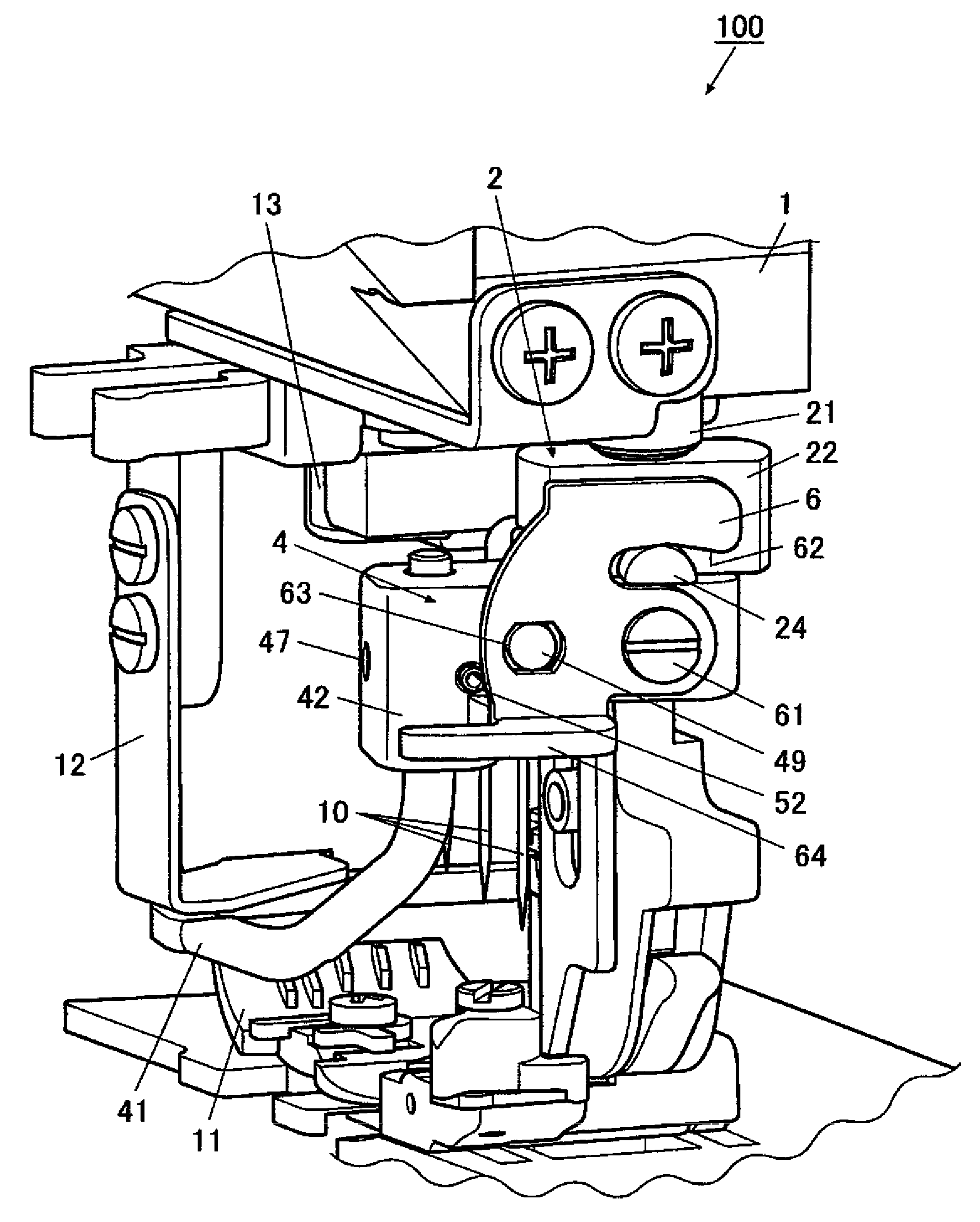

Face yarn holder for sewing machine

InactiveCN1450219AGuaranteed driving forceAvoid interferenceSewing-machine casingsNeedle severing devicesYarnEngineering

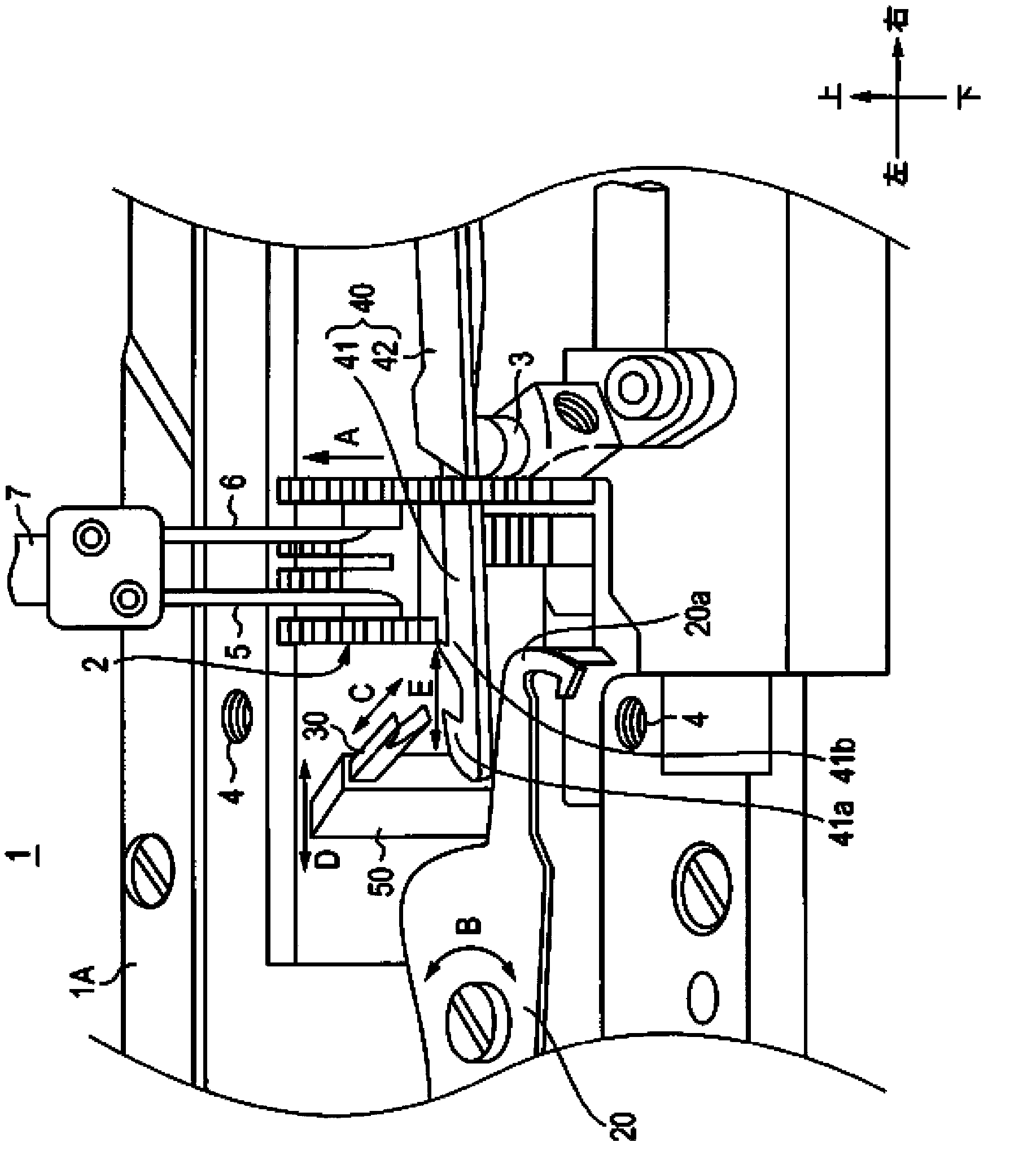

The present invention relates to a needle thread holding device for sewing machine. The needle thread holding device A is provided with: an insert- holding means D for insert-holding the end of the needle thread; a stepping motor 10 which serves as a single actuator; a related operation means C provided with the insert-holding means D at a front end part; and a connection means 12 for connecting the motor 10 with the related operation means C. When the motor 10 is operated, the connection member 12 is moved forward and backward to transmit the operation of the motor 10 to the related operation means C. Then, the lower thread grasping plate 2 and an upper thread grasping plate 3 of the related operation means C are moved relatively, and the protrusion part 5d of an insert-holding member 5 and the front wall 2i of a through- hole 2b formed at the lower thread grasping plate 2 are abutted on each other to insert-hold the end of the needle thread put through the through hole 2b. Thus, by using the motor 10 which serves as a single actuator, the end of the needle thread is insert-held (held).

Owner:JUKI CORP

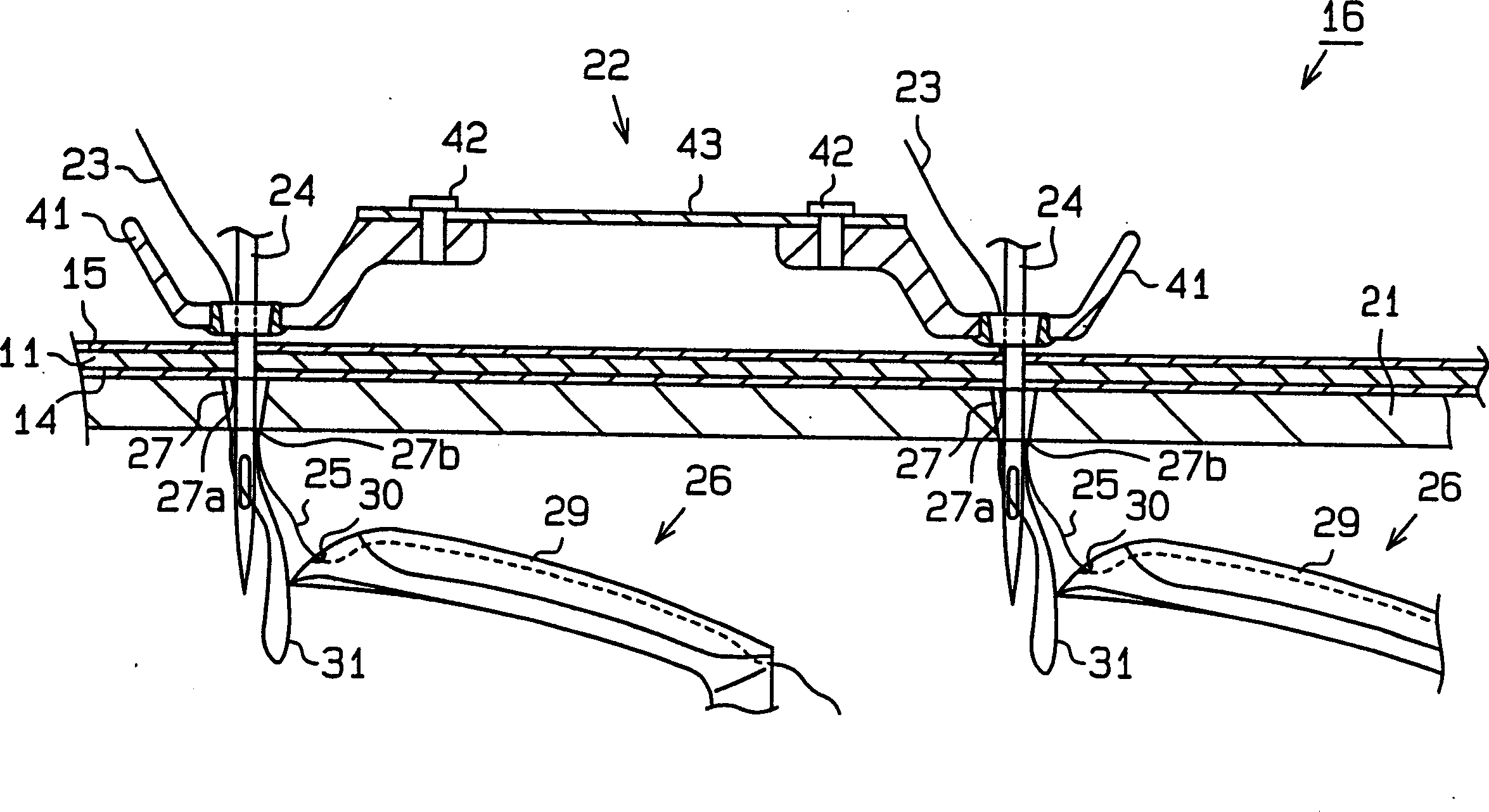

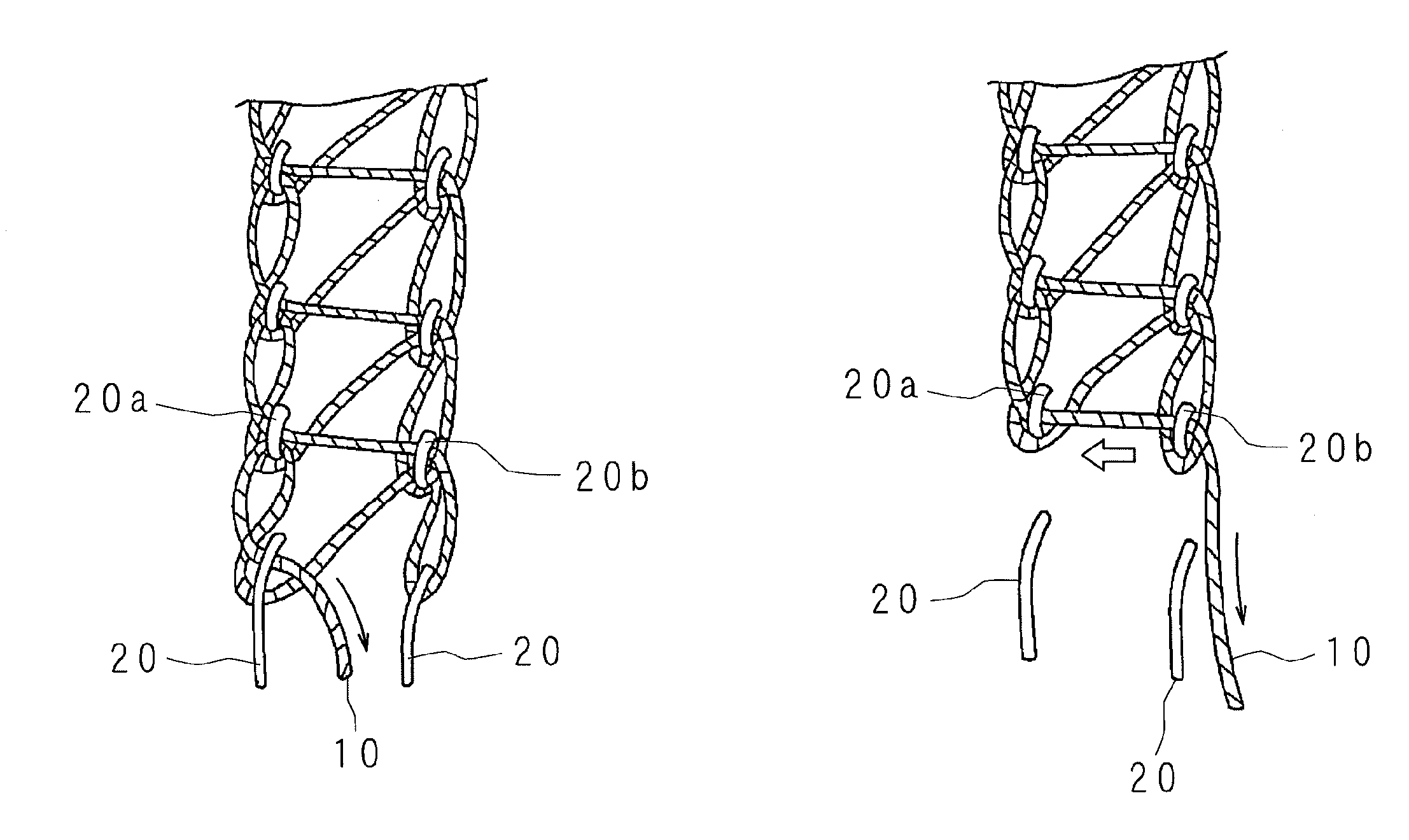

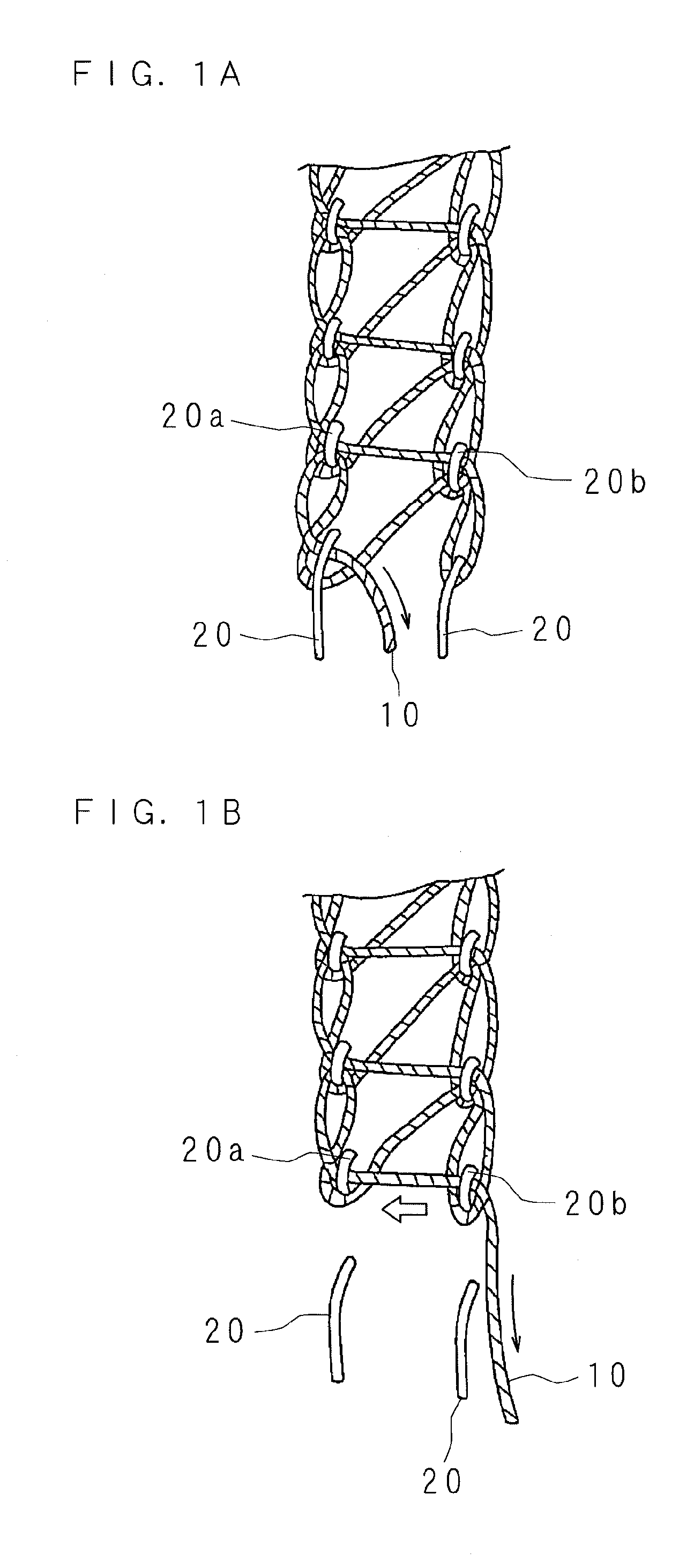

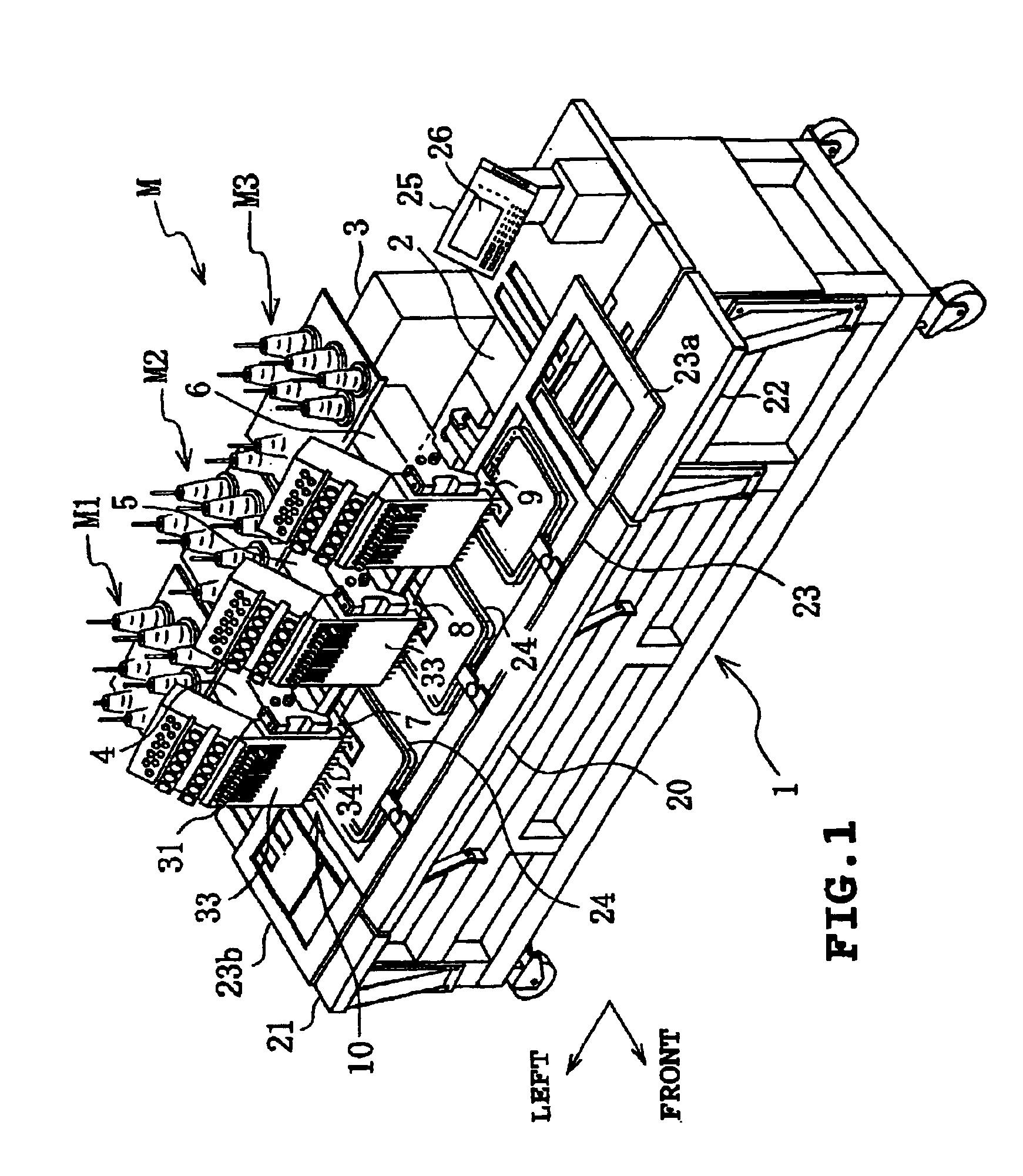

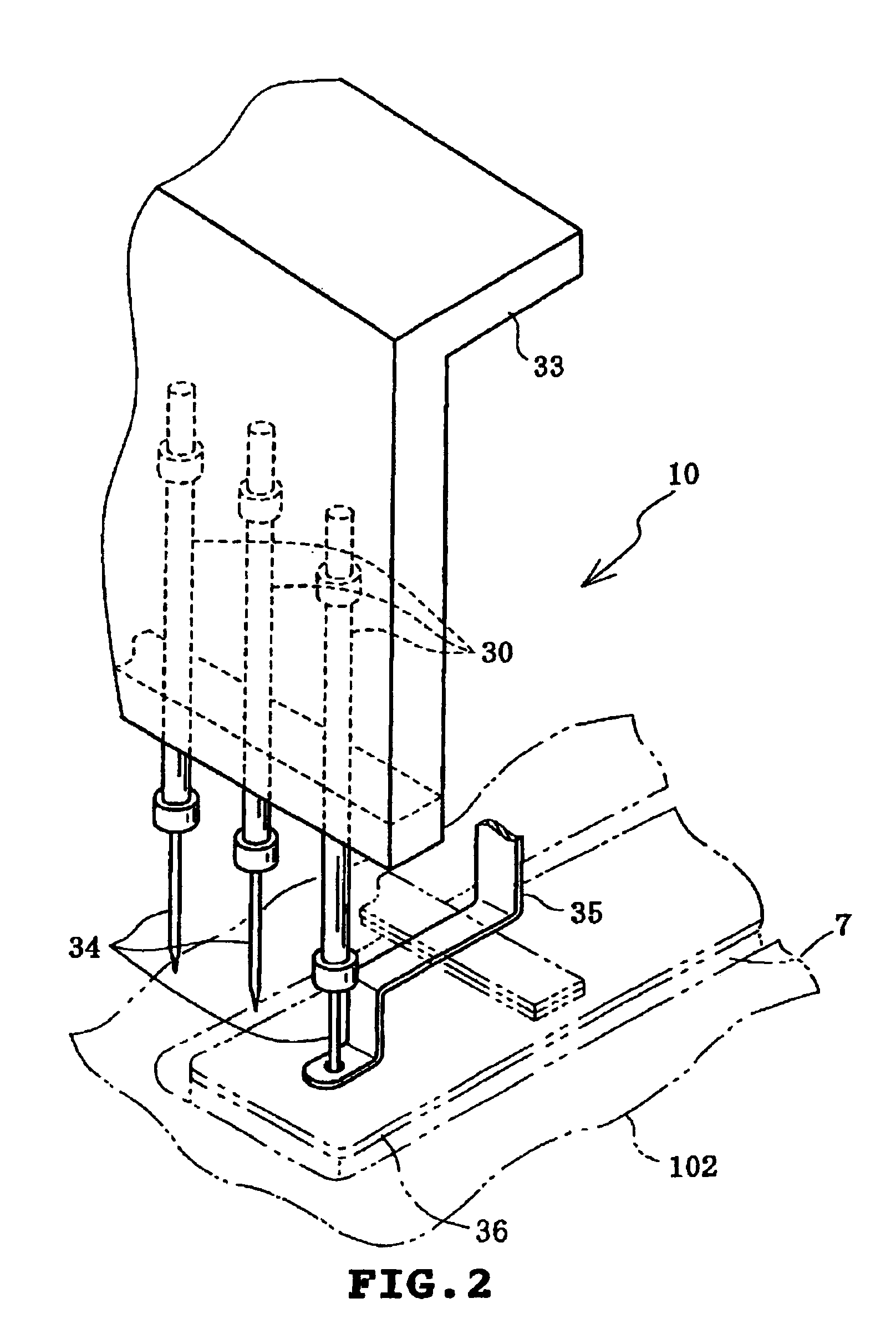

Method for preventing seam ravel of multi-thread chain stitches, seam ravel preventing apparatus for multi-thread chain stitch sewing machine, and multi-thread chain stitch seam structure

InactiveCN102995300APrevent open wirePrevent pulling outWork-feeding meansNeedle severing devicesStructural engineeringIndustrial engineering

Owner:YAMATO SEWING MASCH MFG CO LTD

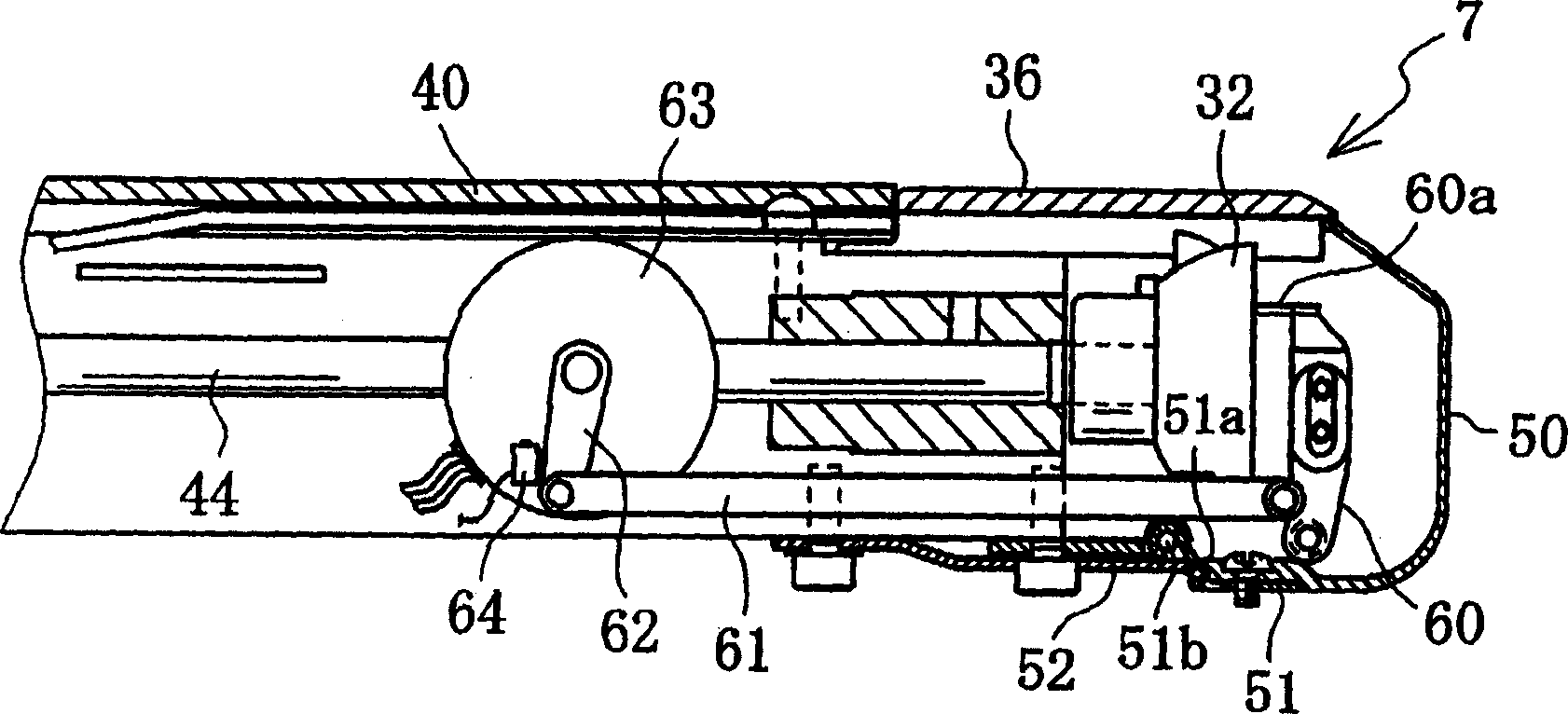

Sewing machine with picker and picker control program therefor

ActiveUS6860213B2Easy to implementSewing-machine casingsNeedle severing devicesSewing needleBiomedical engineering

A sewing machine includes a sewing mechanism including a needle bar, a thread take-up lever and a shuttle, a picker capable of holding a needle thread extending from an eye of a sewing needle near the shuttle located below a needle plate, and a picker driver driving the picker between a first stop position where the picker is capable of holding the needle thread and a second stop position spaced farther away from the shuttle than the first position. The picker is movable to a third position spaced farther away from the shuttle than the second position.

Owner:BROTHER KOGYO KK

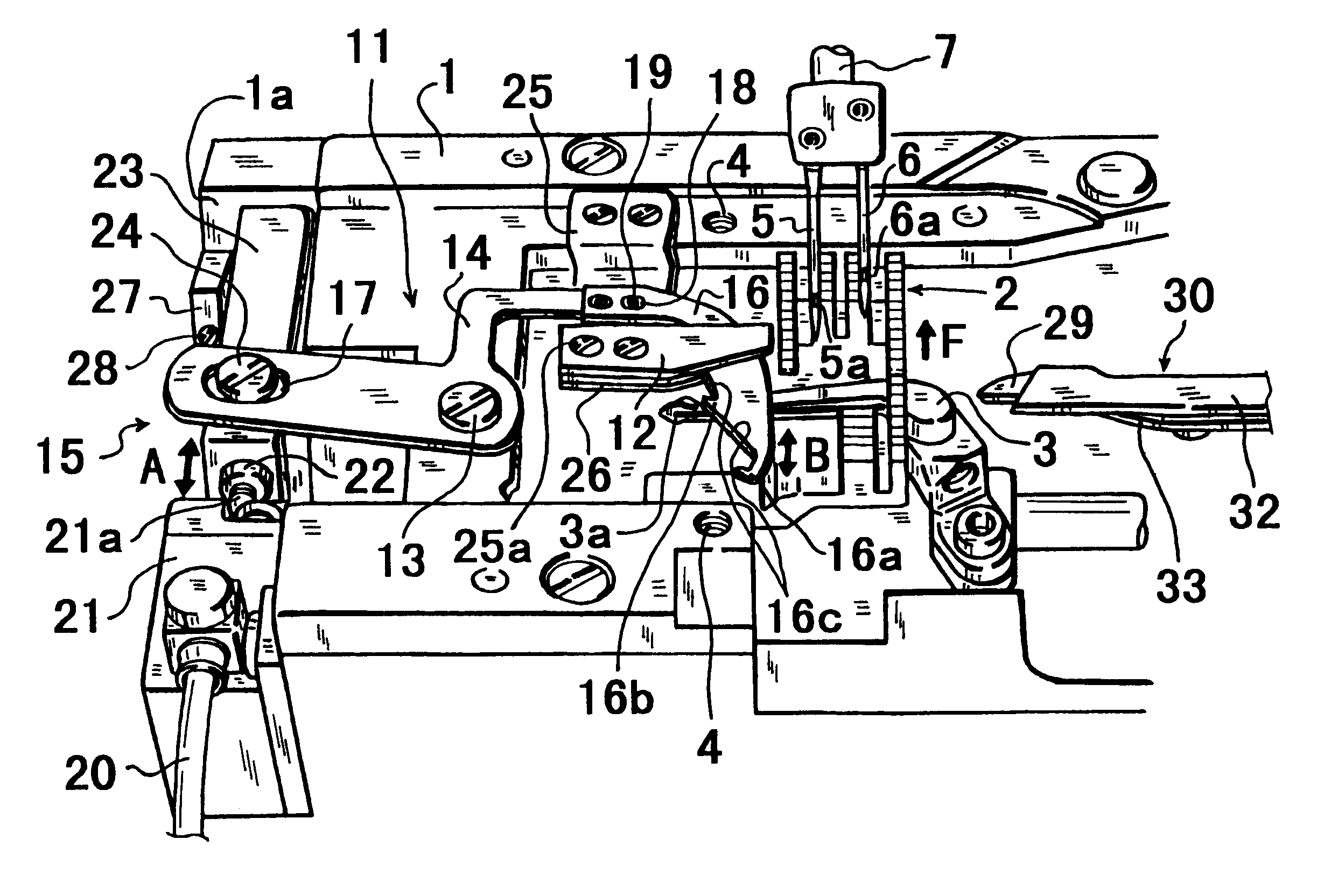

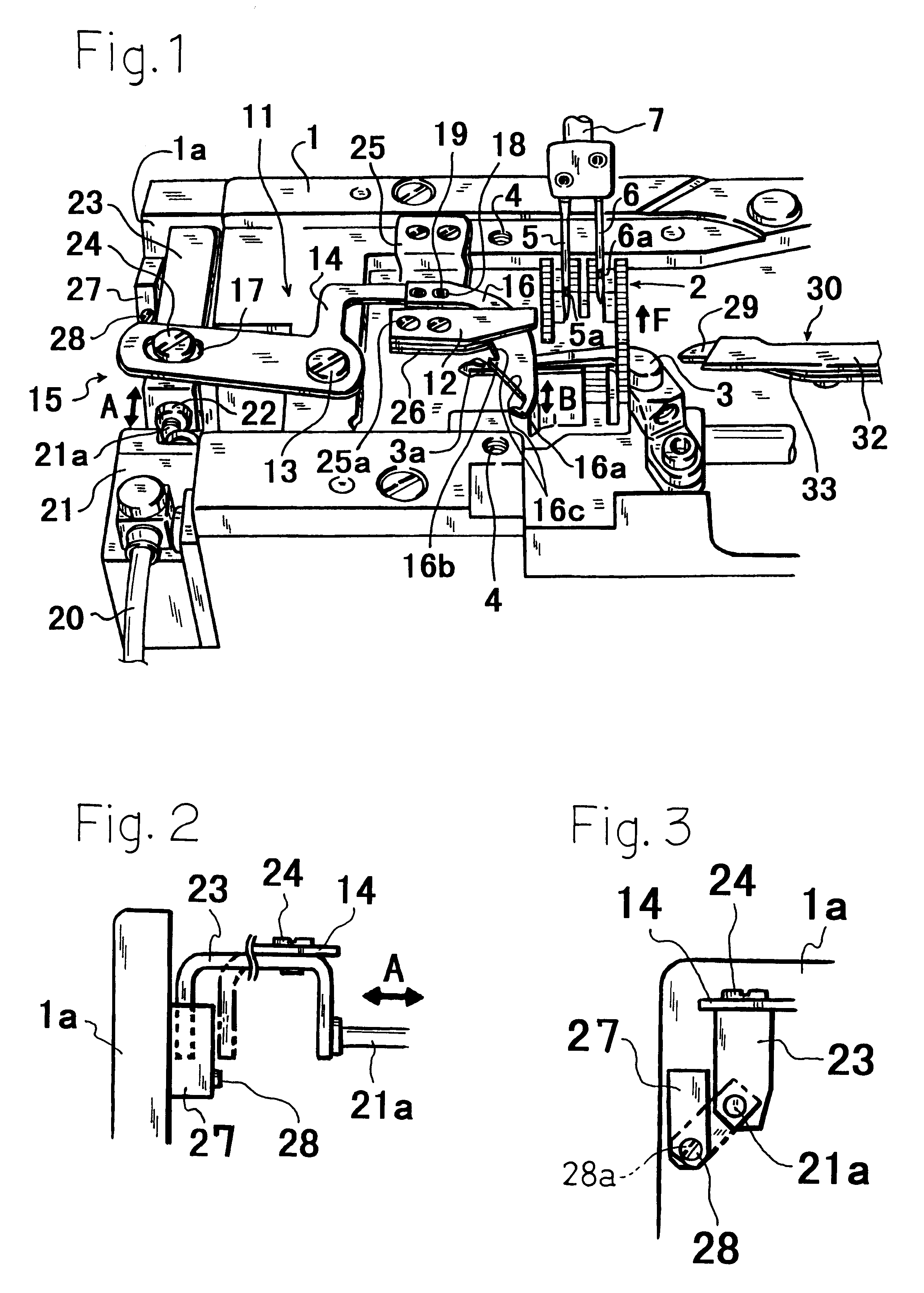

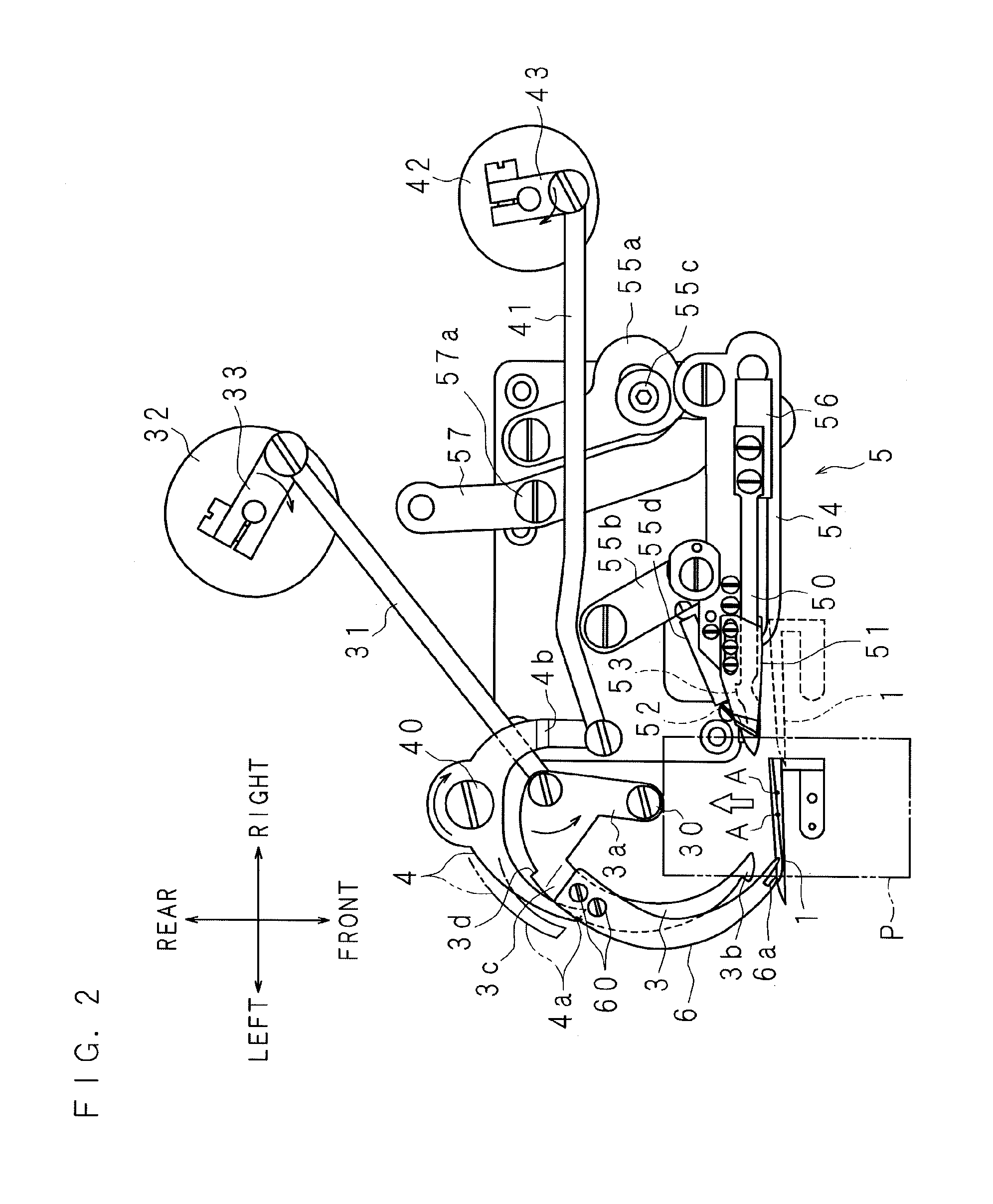

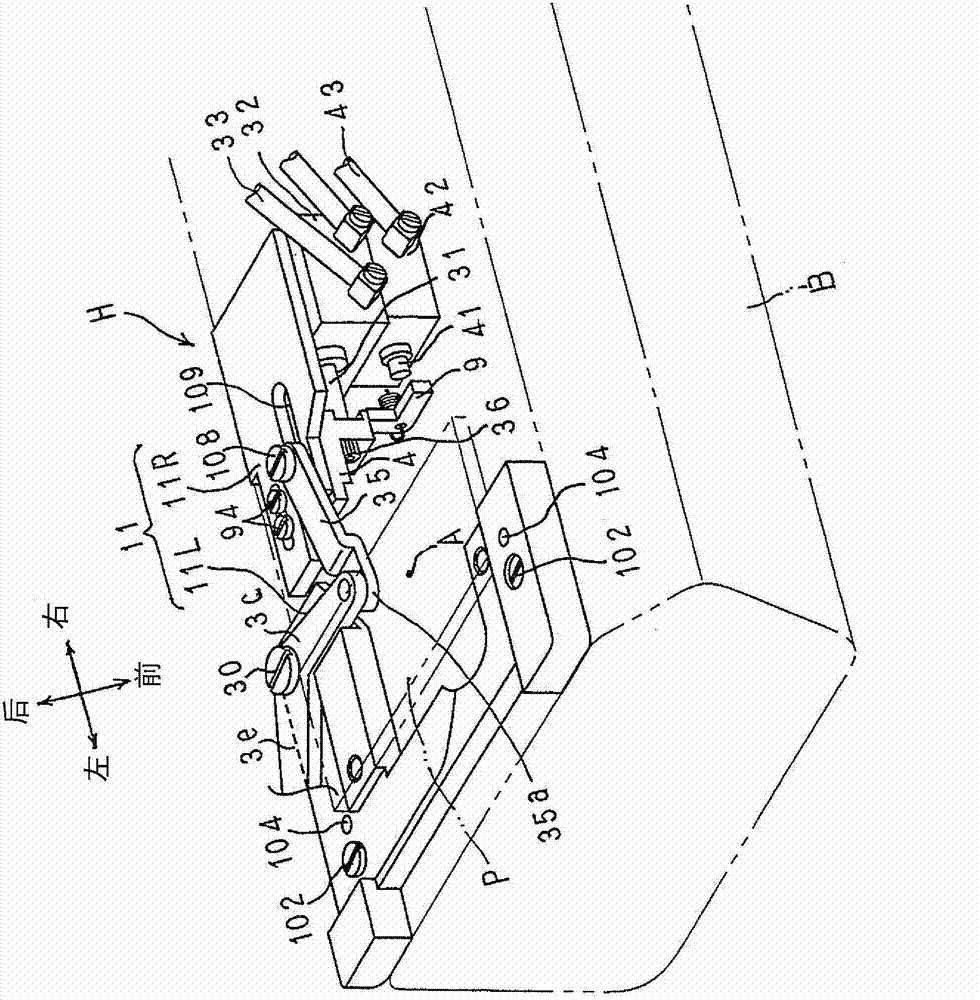

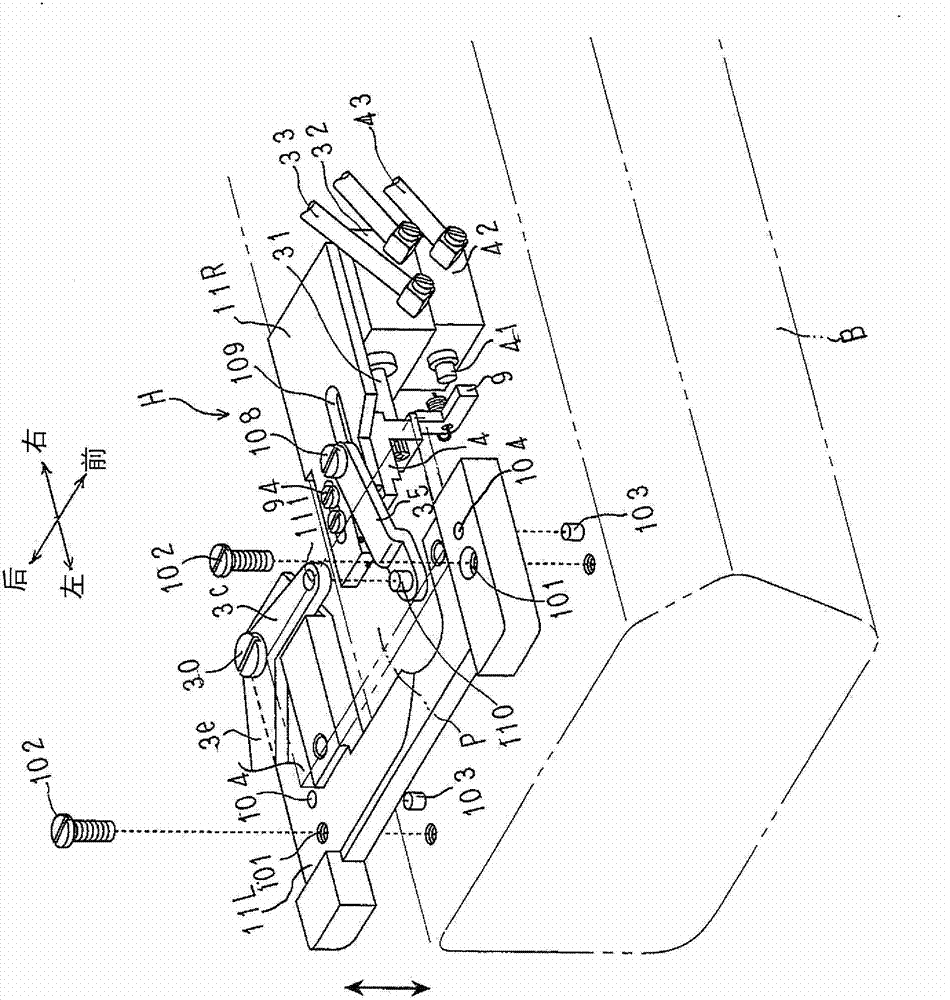

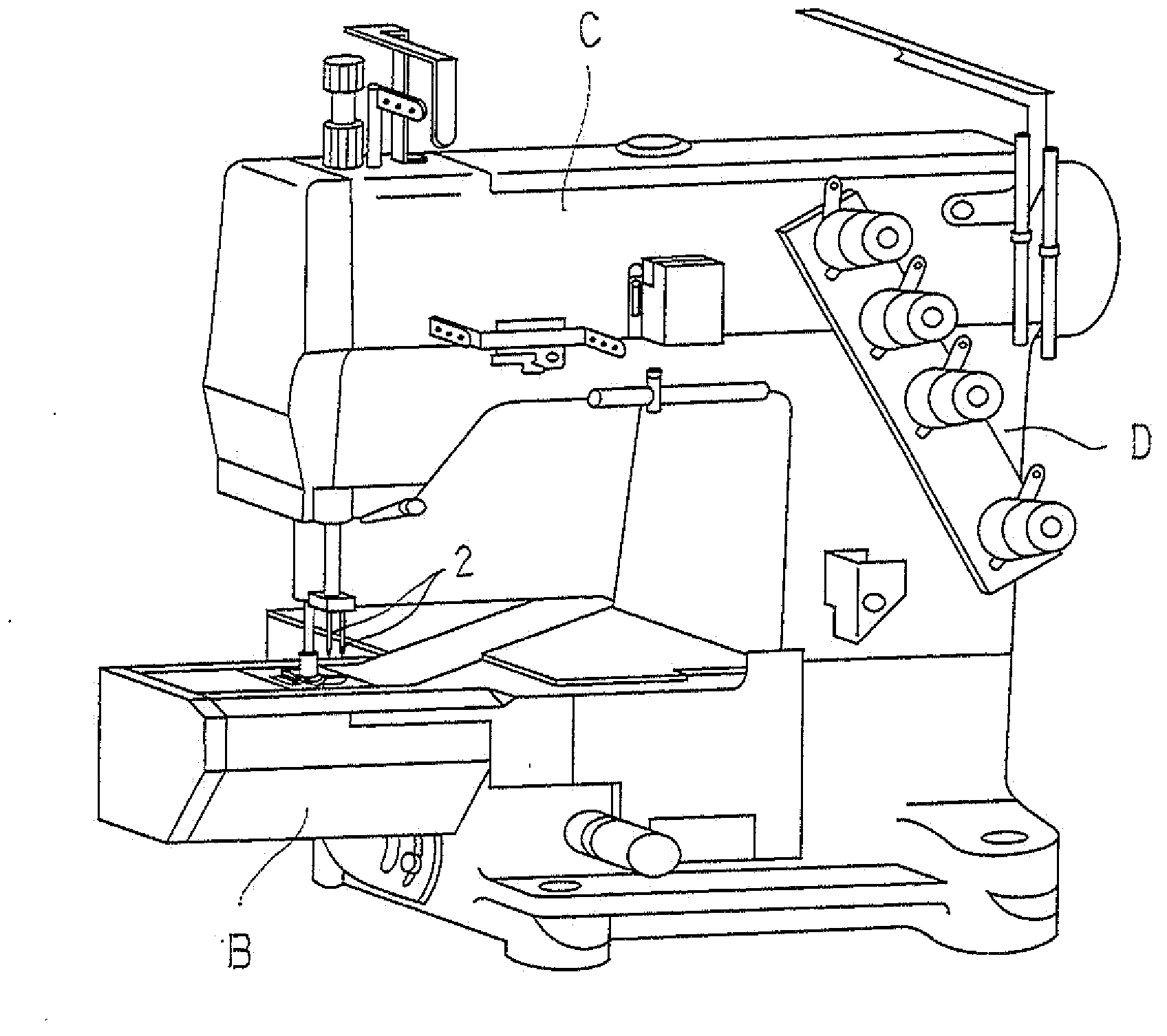

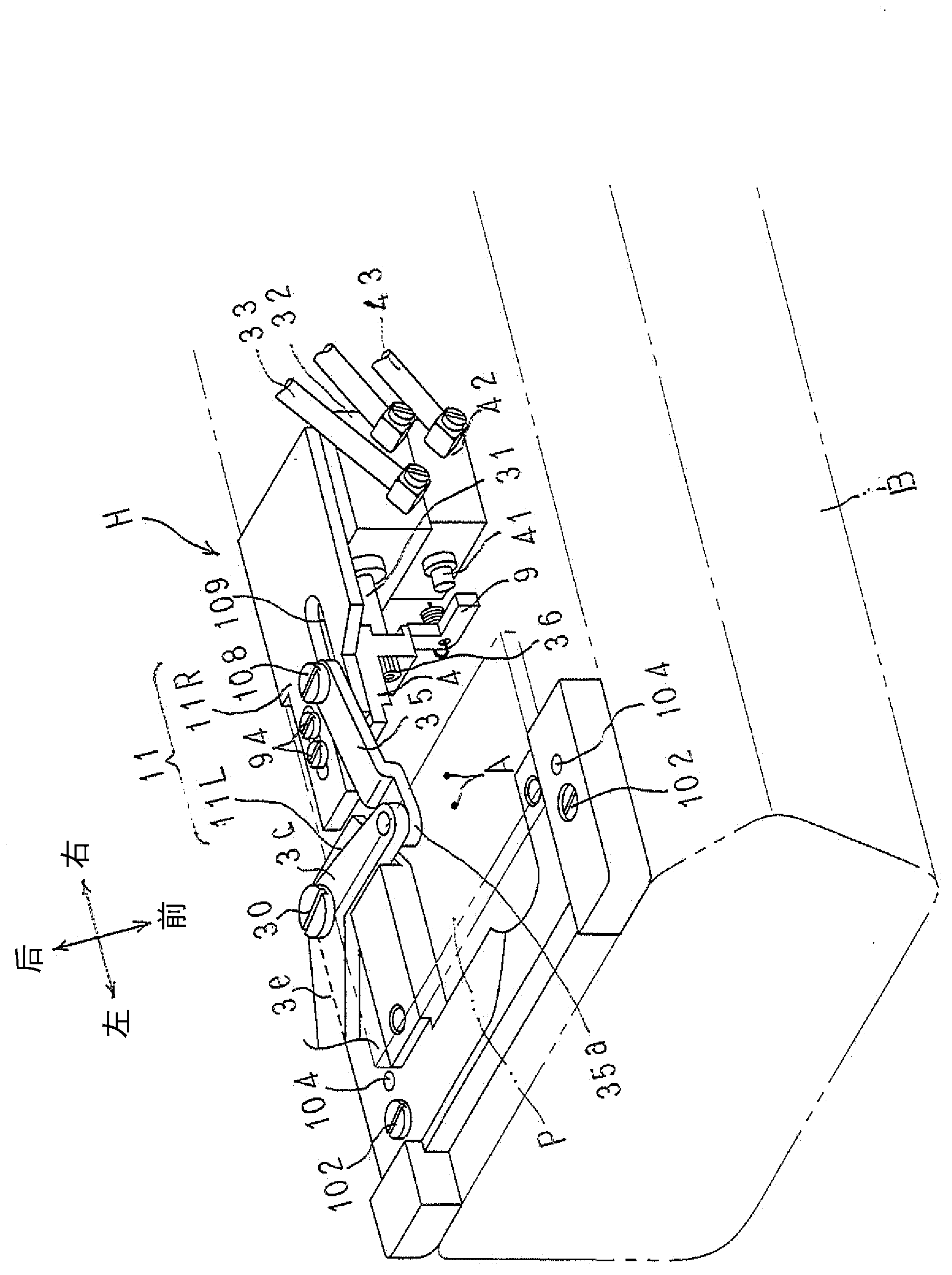

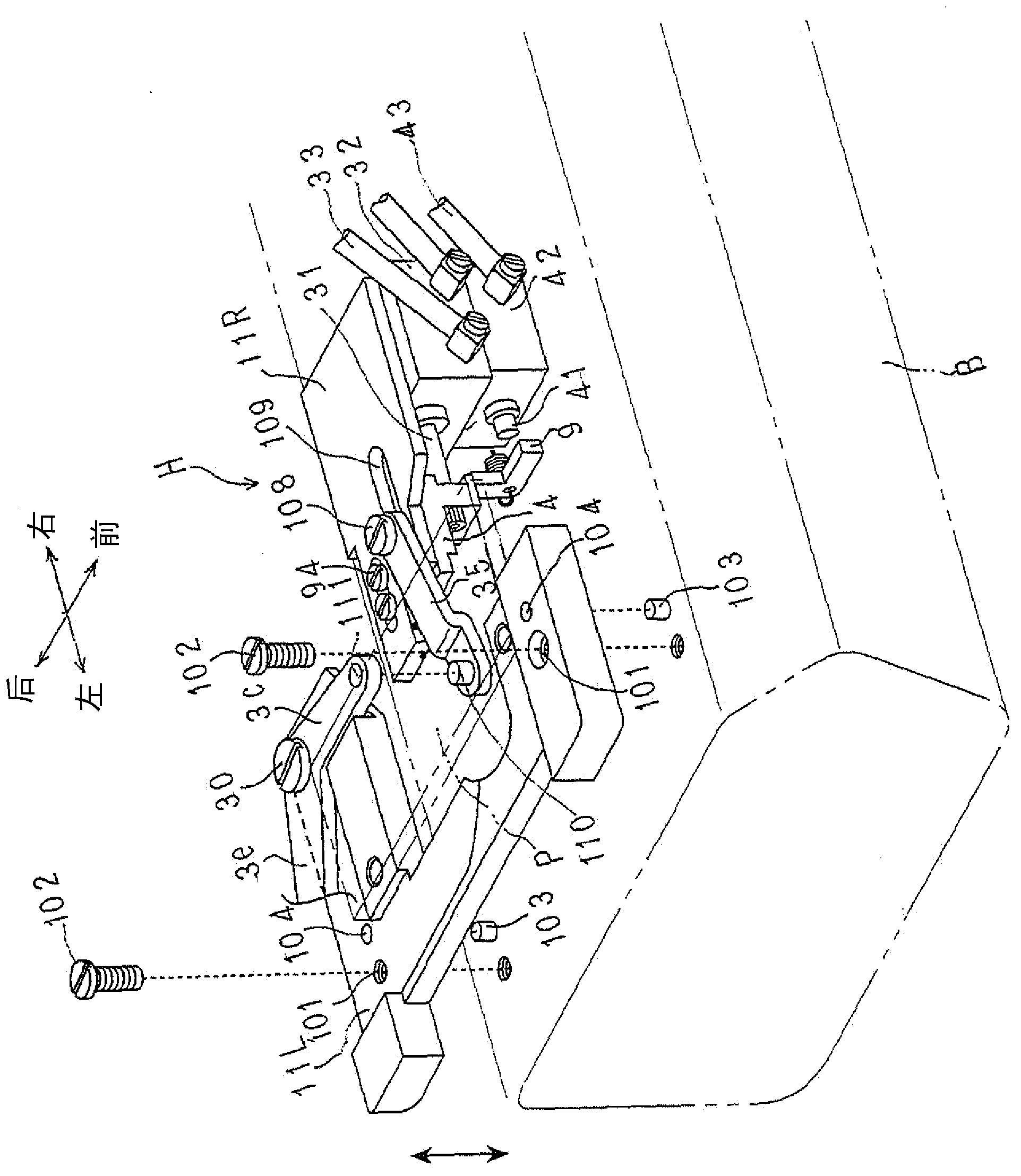

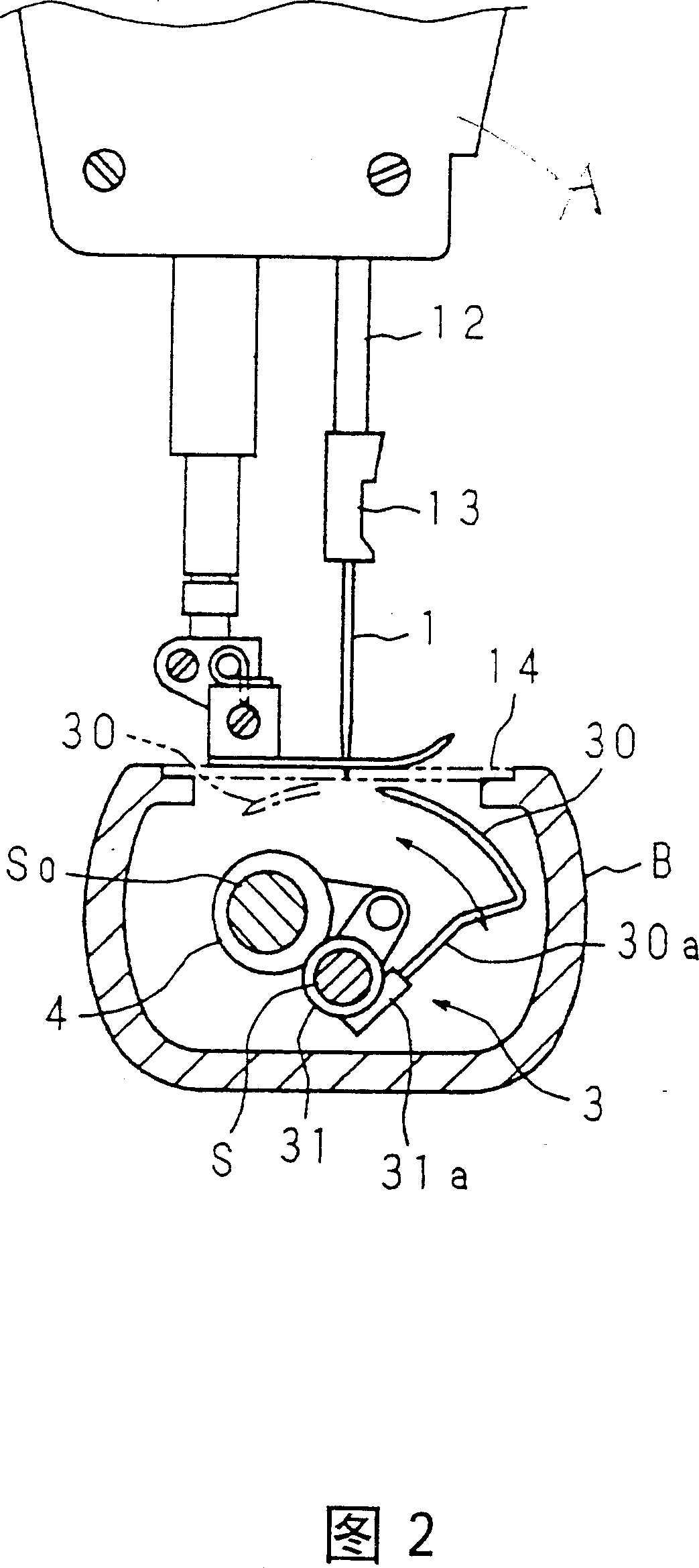

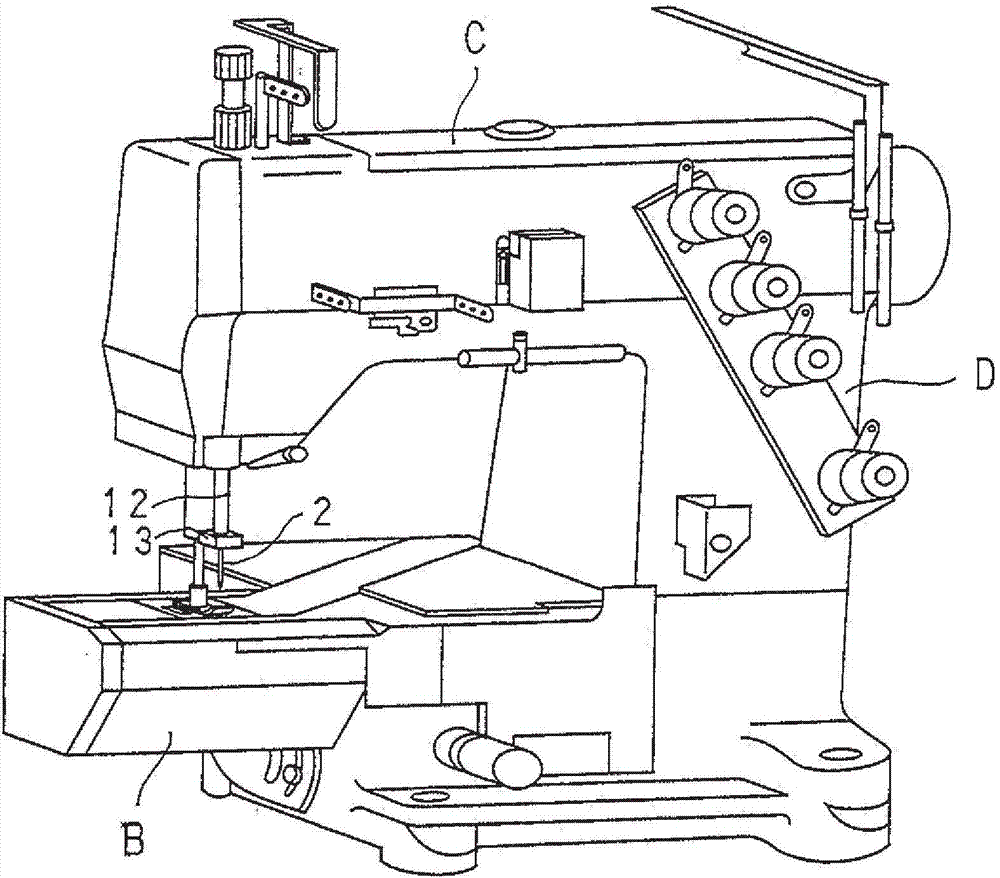

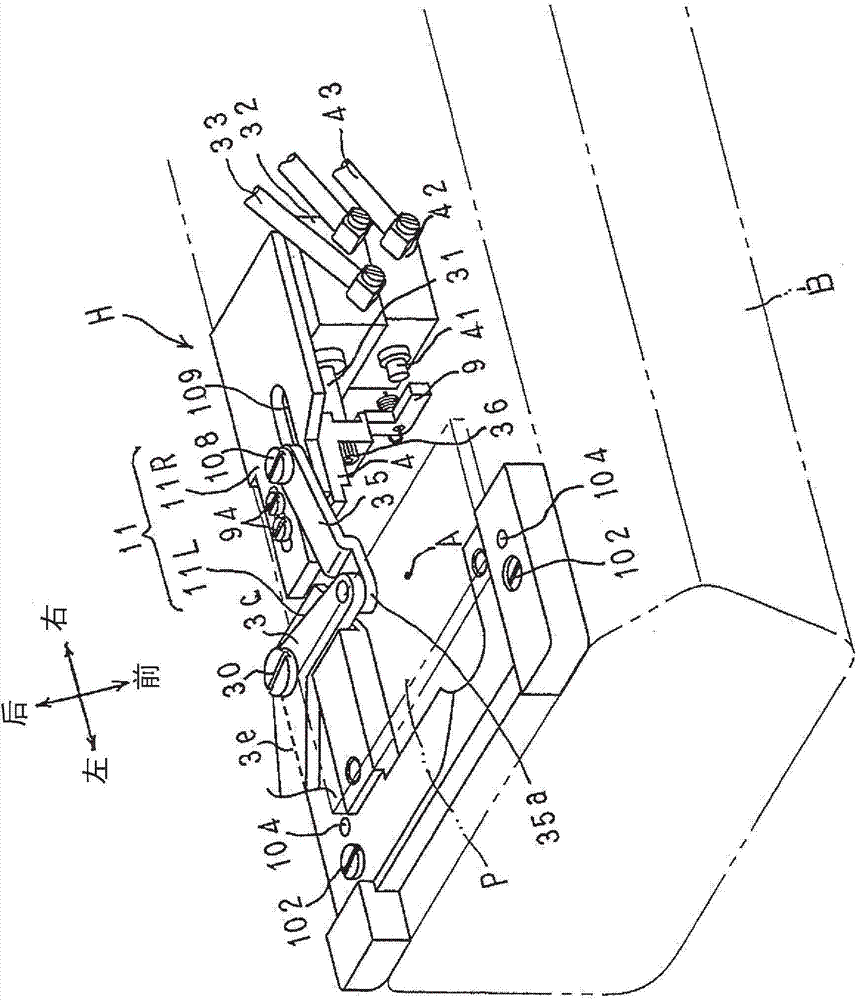

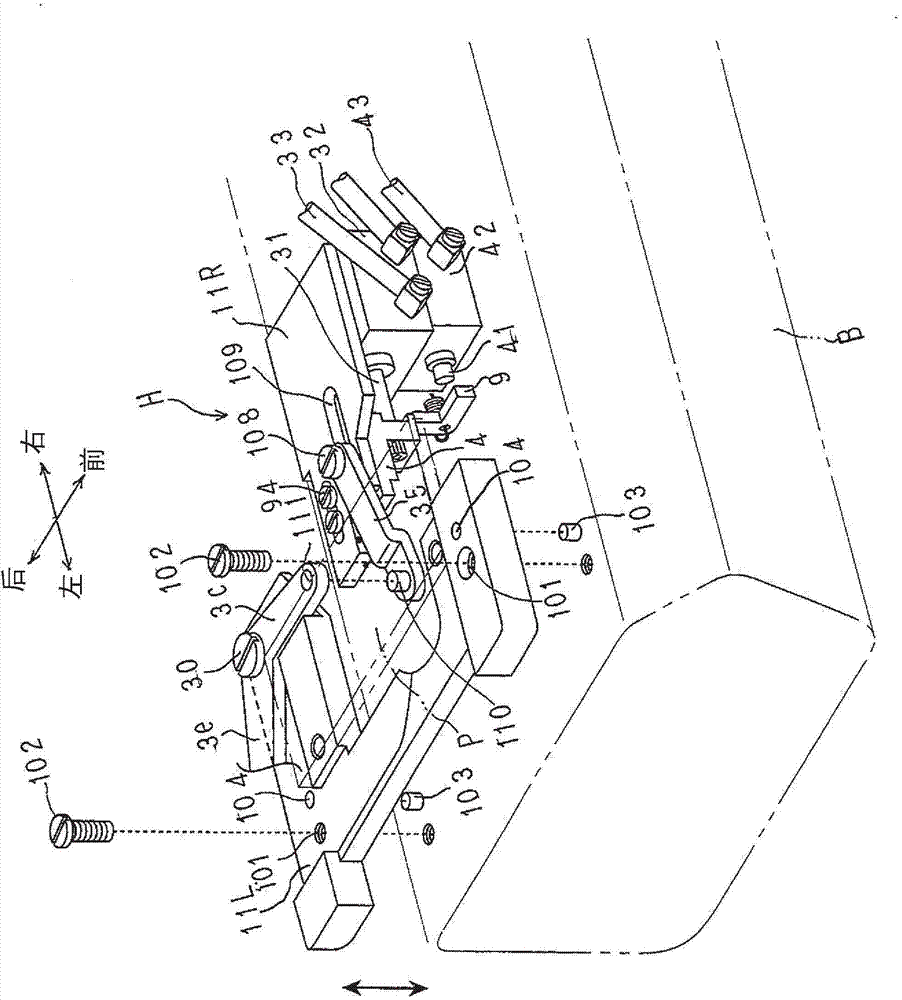

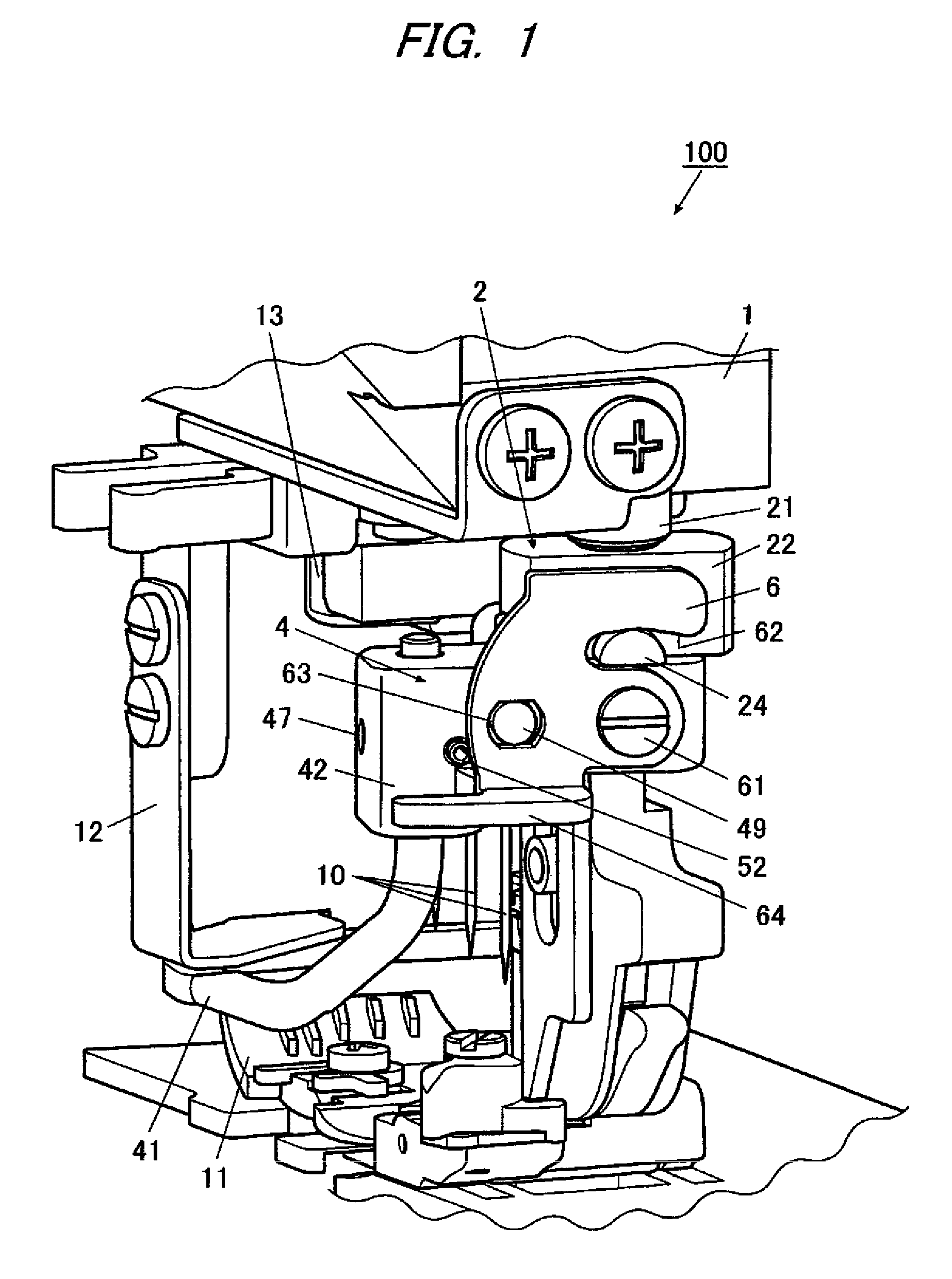

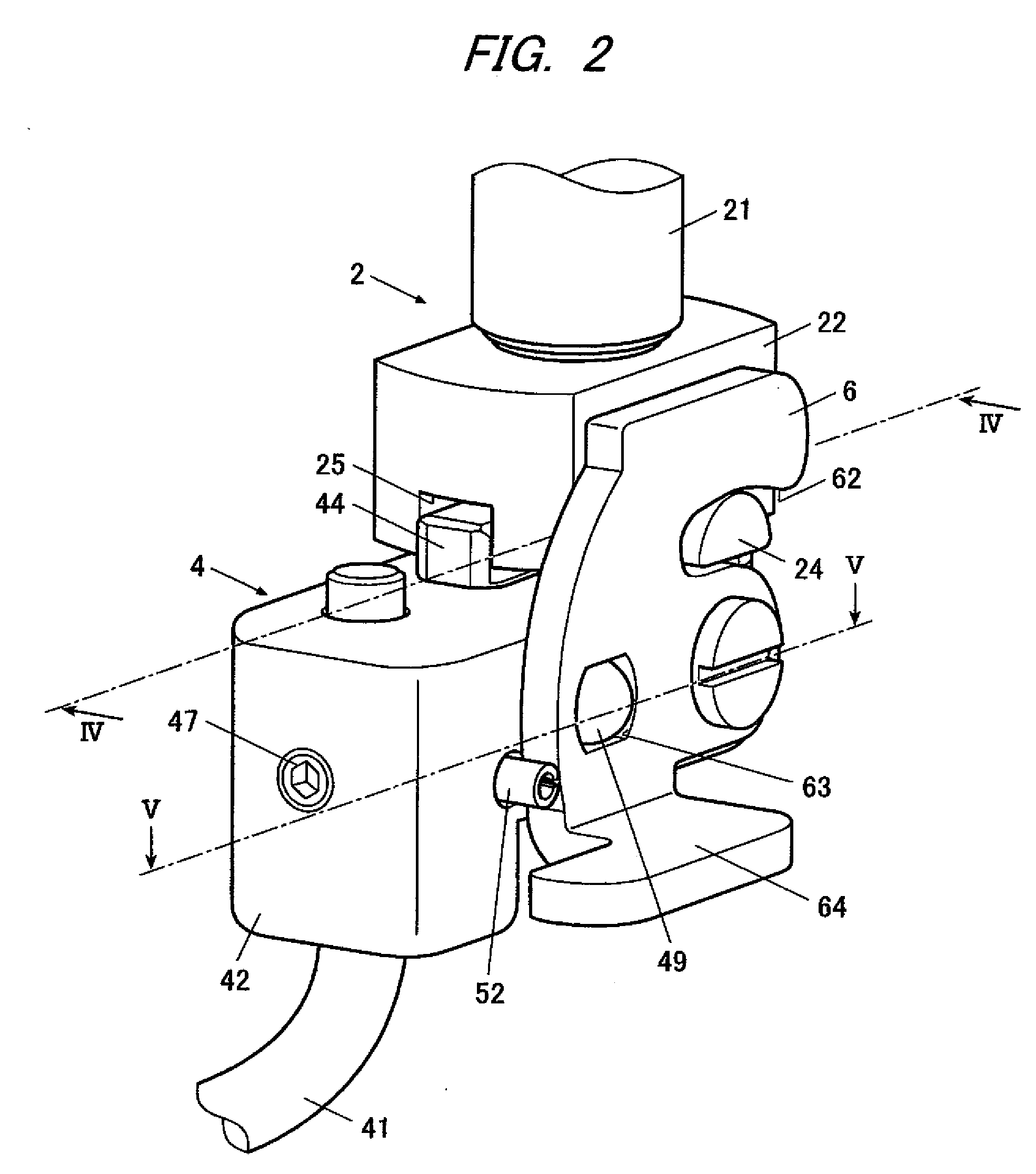

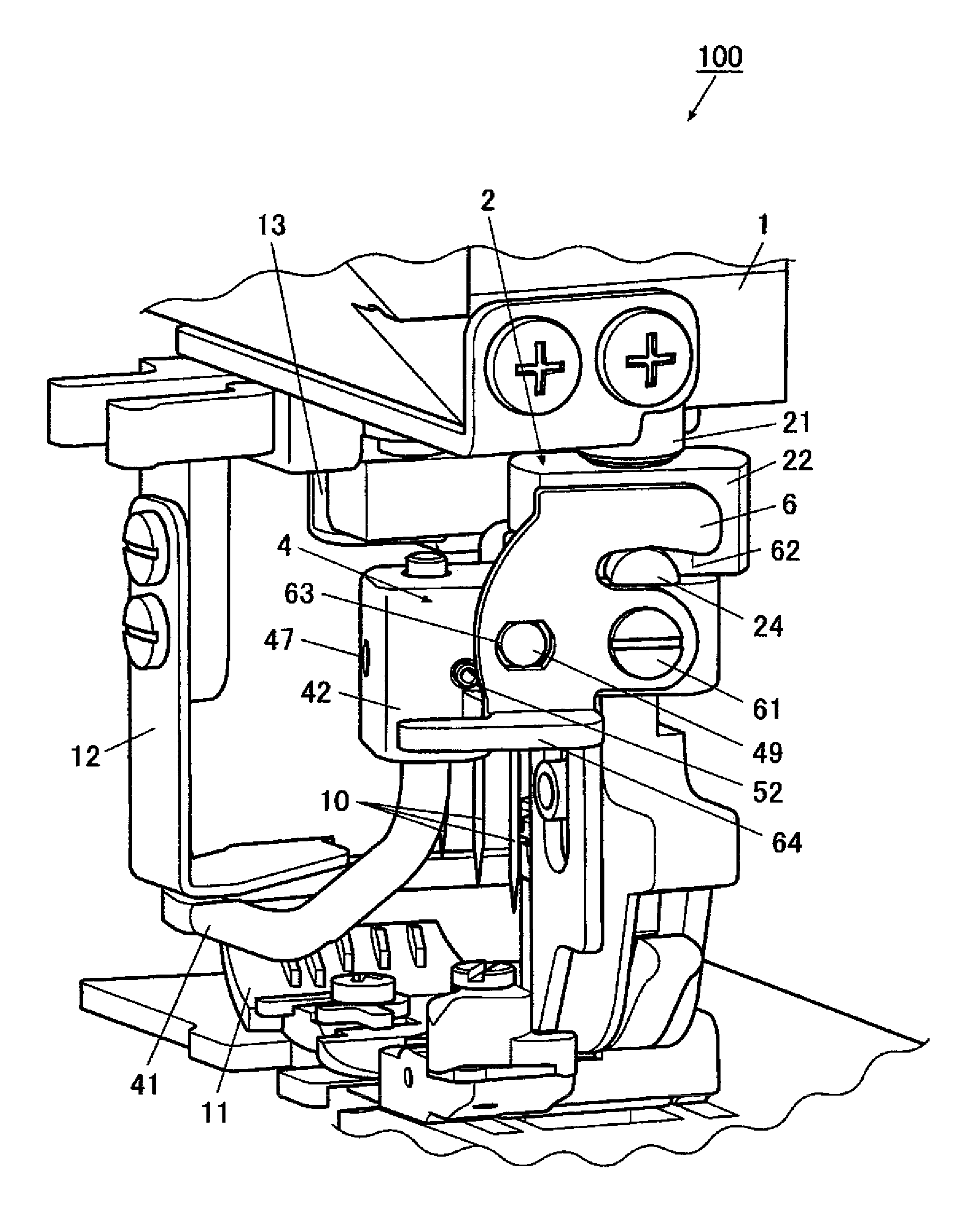

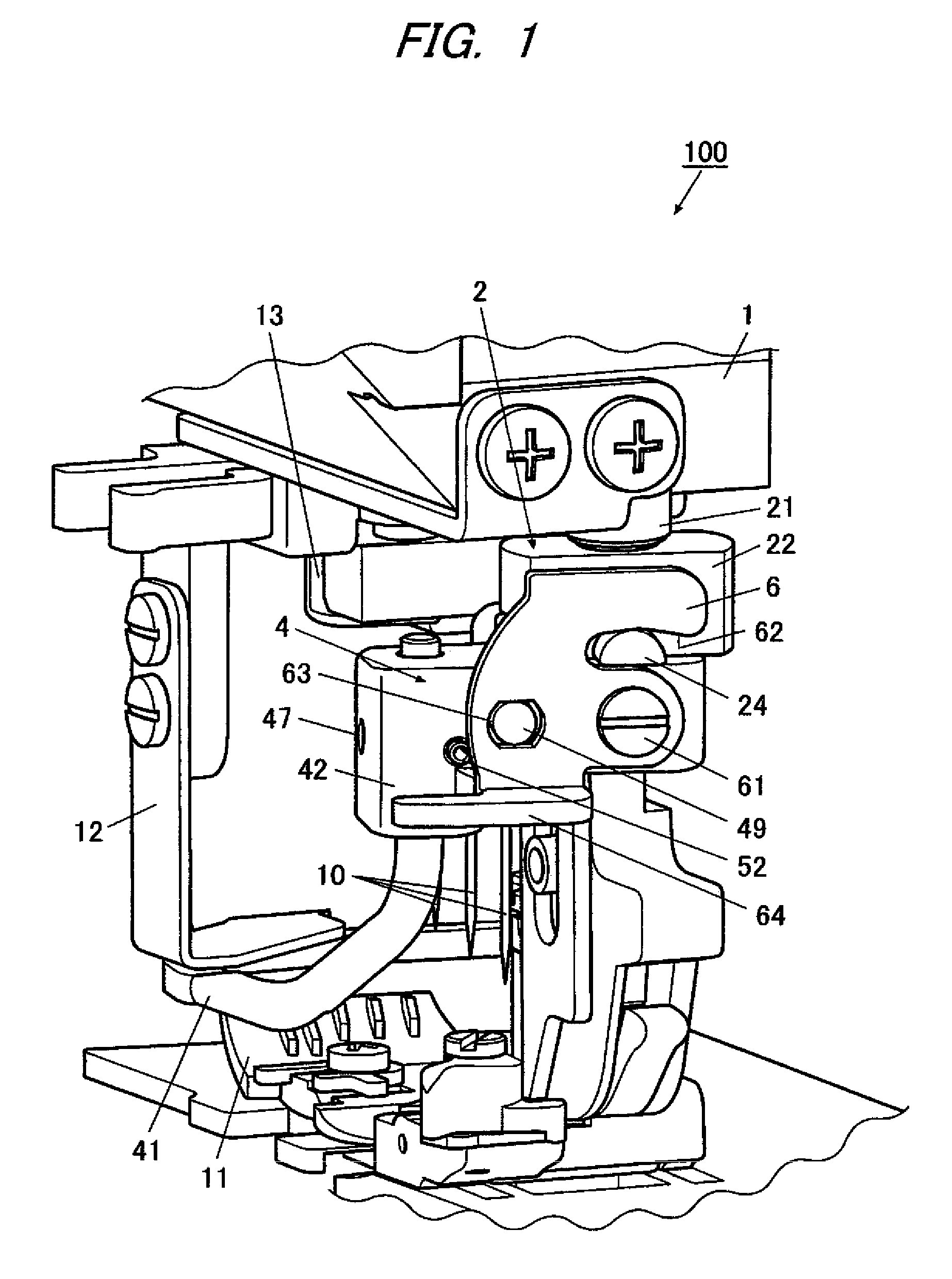

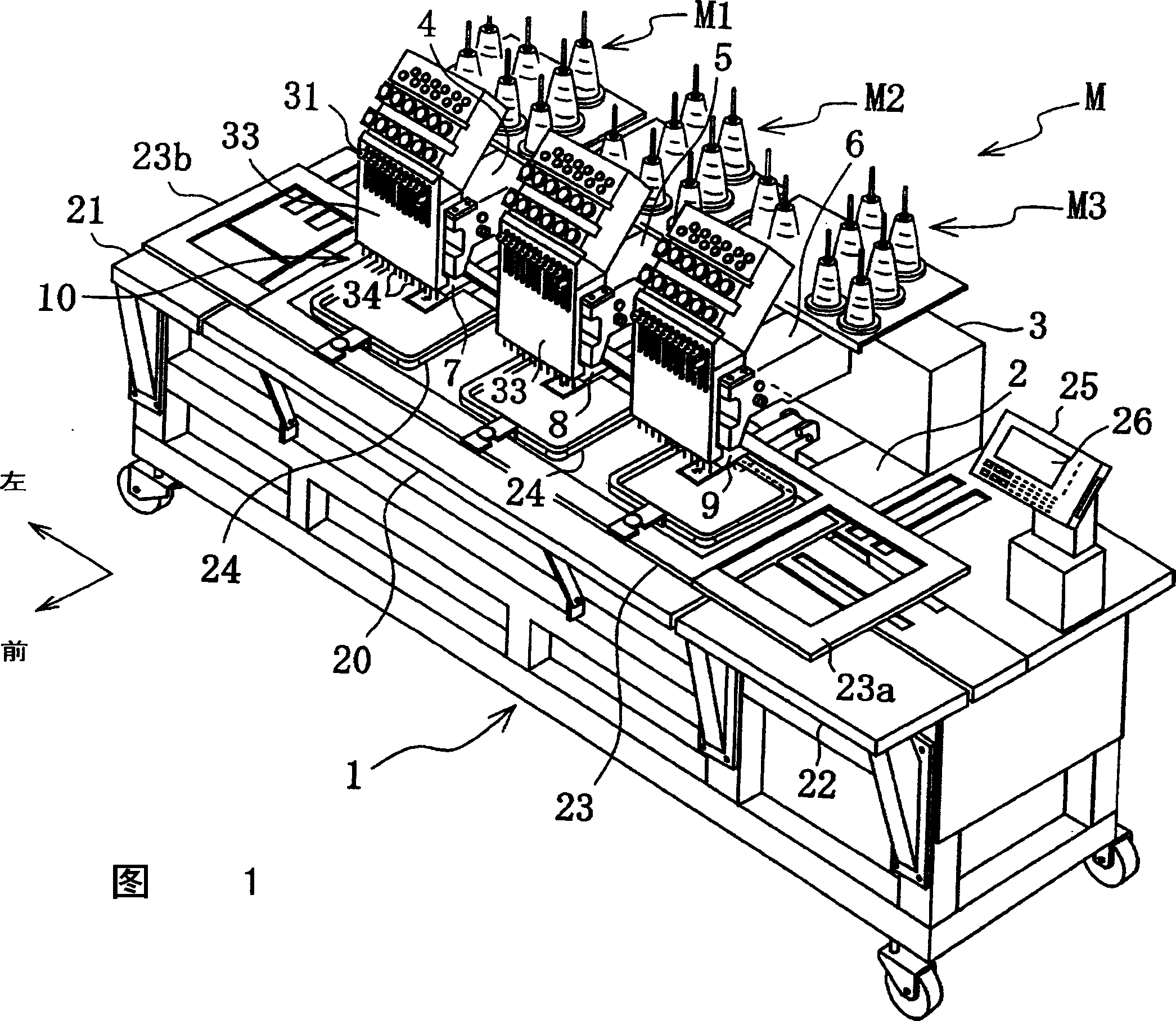

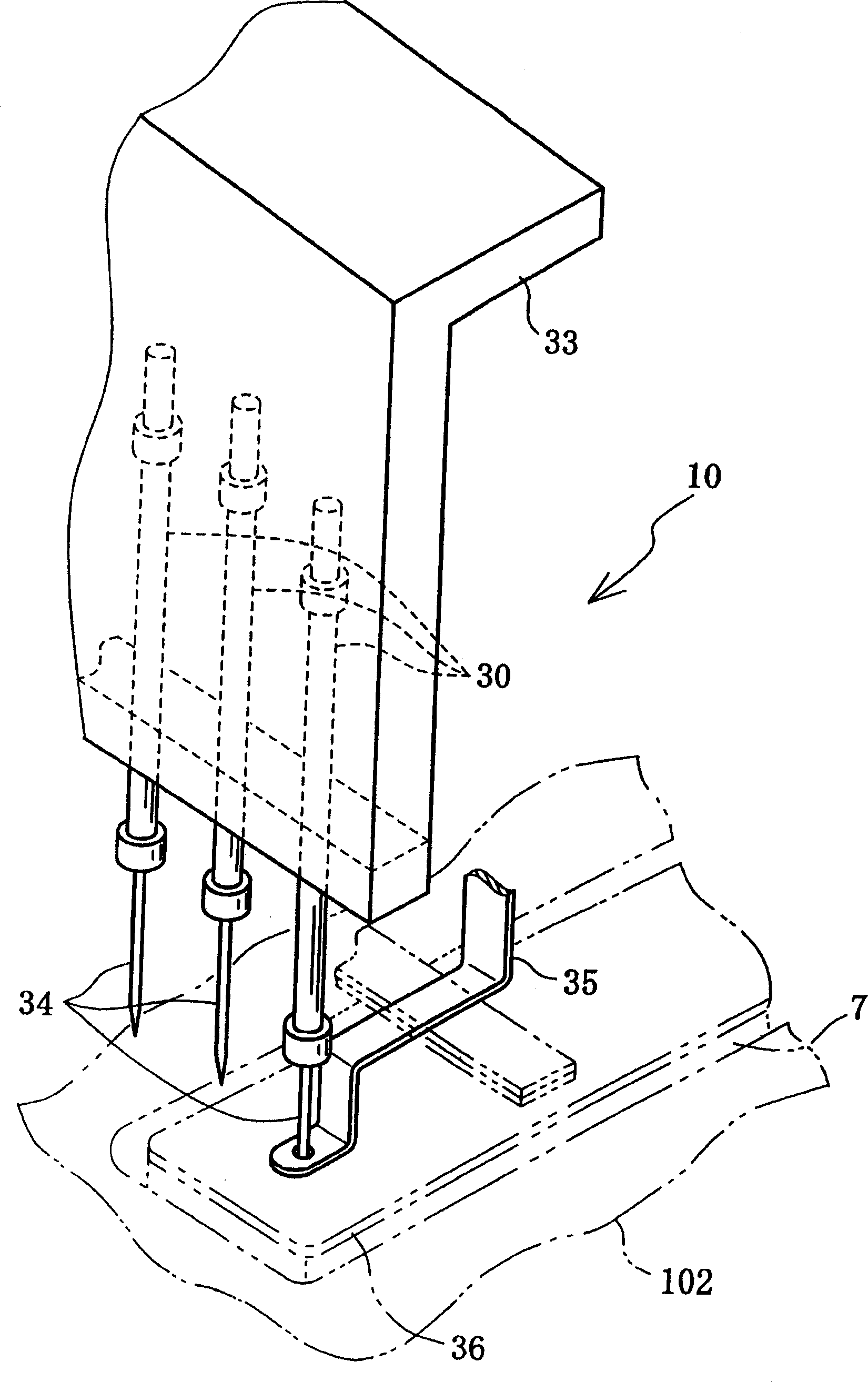

Multi-thread chain stitch sewing machine with seam ravel preventing apparatus

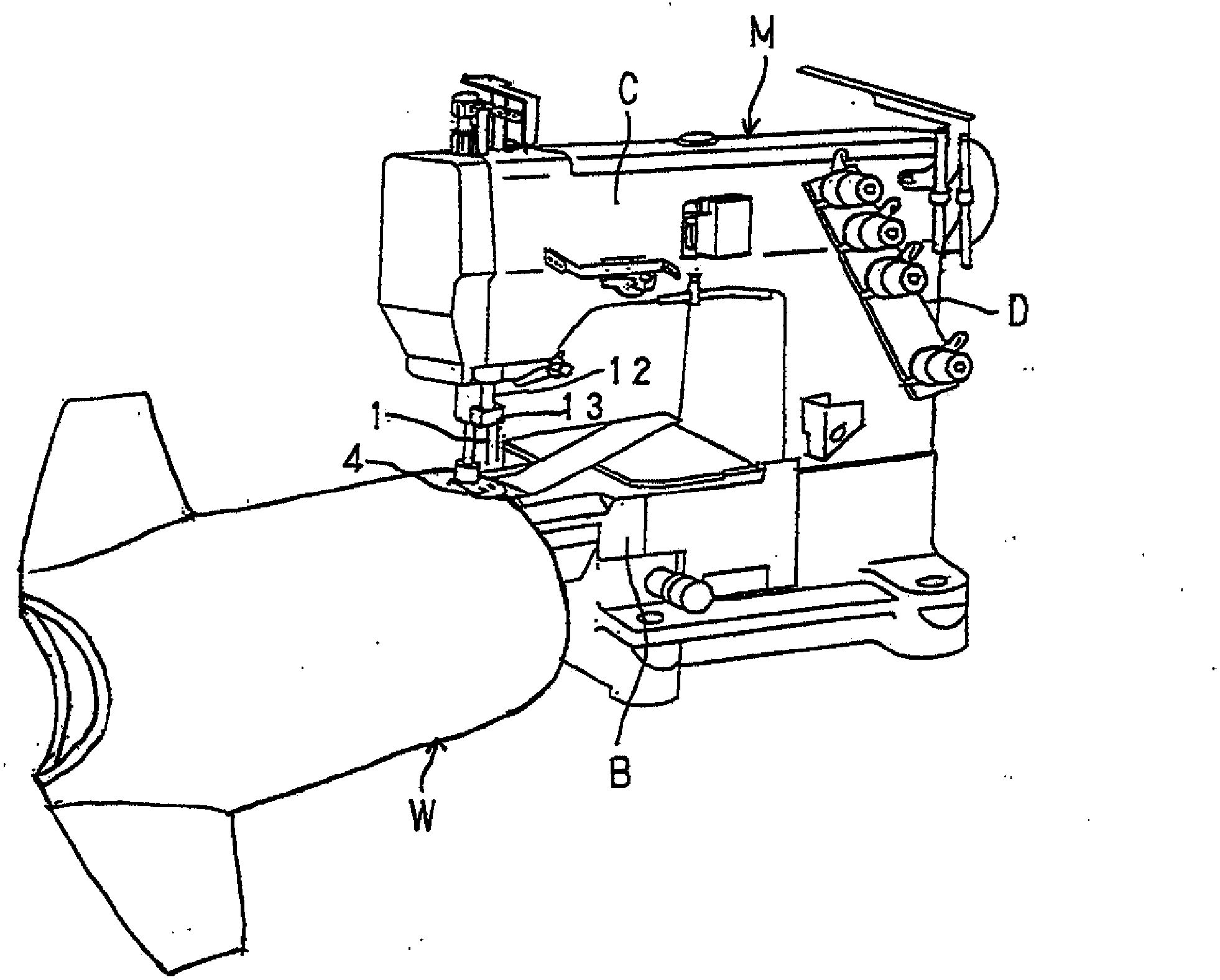

ActiveCN102926142ALarge working spaceEasy to operateSewing-machine casingsNeedle severing devicesEngineeringSewing machine

A needle plate base (11) in a multi-thread chain stitch sewing machine with a seam ravel preventing apparatus is divided into a left needle plate base ( 11L) for attaching a needle plate ( P) thereto and supporting a swinging support shaft (30) of a thread hanging hook (3); and a right needle plate base (11R) for fixedly supporting a stopper member (4) and a thread handling air cylinder (32) and a stopper air cylinder (42). The right needle plate base(llR) is fastened to a sewing machine bed (B). The left needle plate base (11L) is fastenably and unfastenably fastened to an upper surface of the bed(B) via screw members (102). Adj ustment of stitch performation, and maintenance, e.g., replacement of various kinds of components stored inside the bed, can extremely easily and simply be carried out without having much trouble and requiring labor and time, and therefore, the stitch performation and predetermined ravel preventing function can be constantly surely reproduced.

Owner:YAMATO SEWING MASCH MFG CO LTD

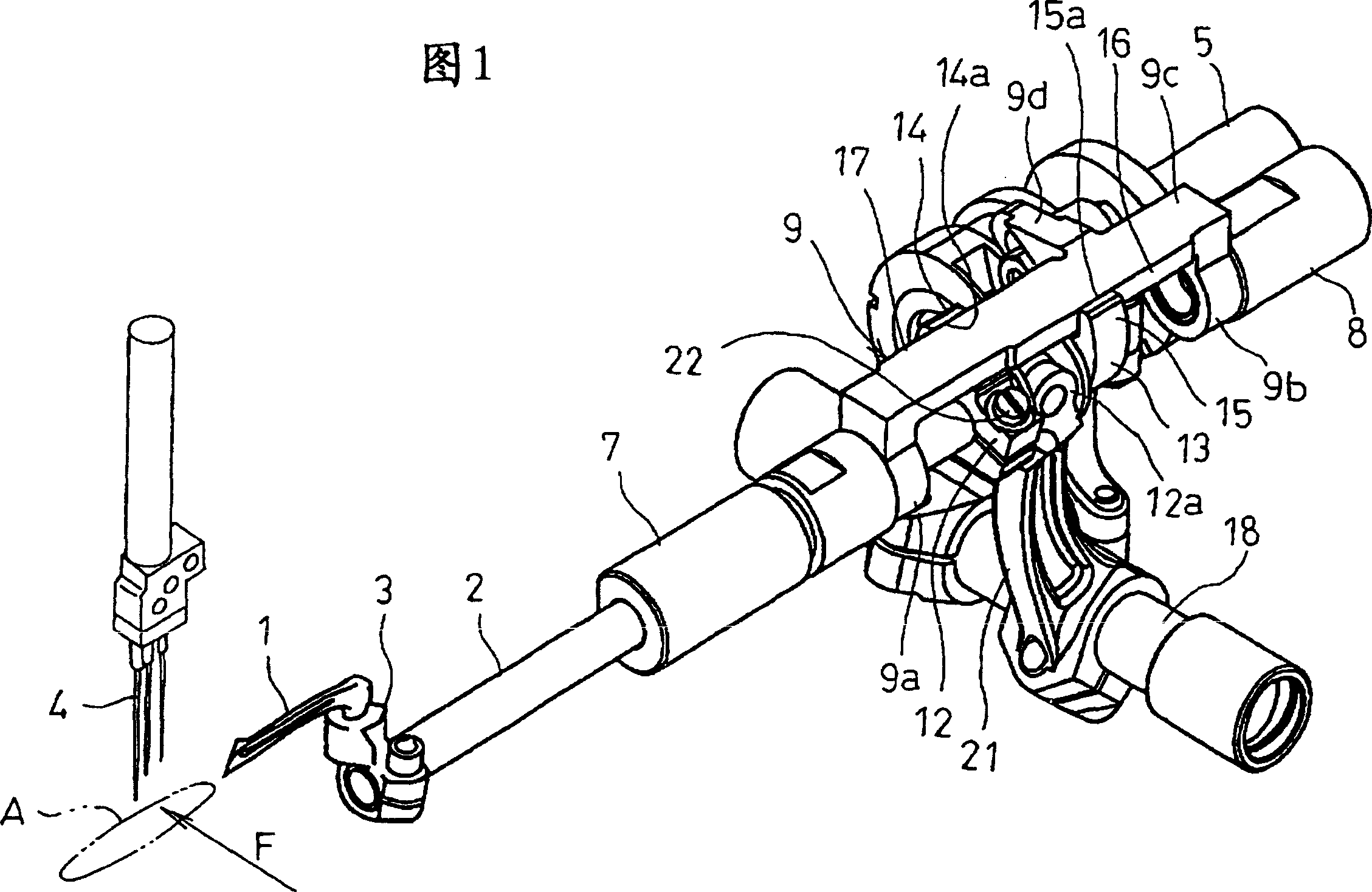

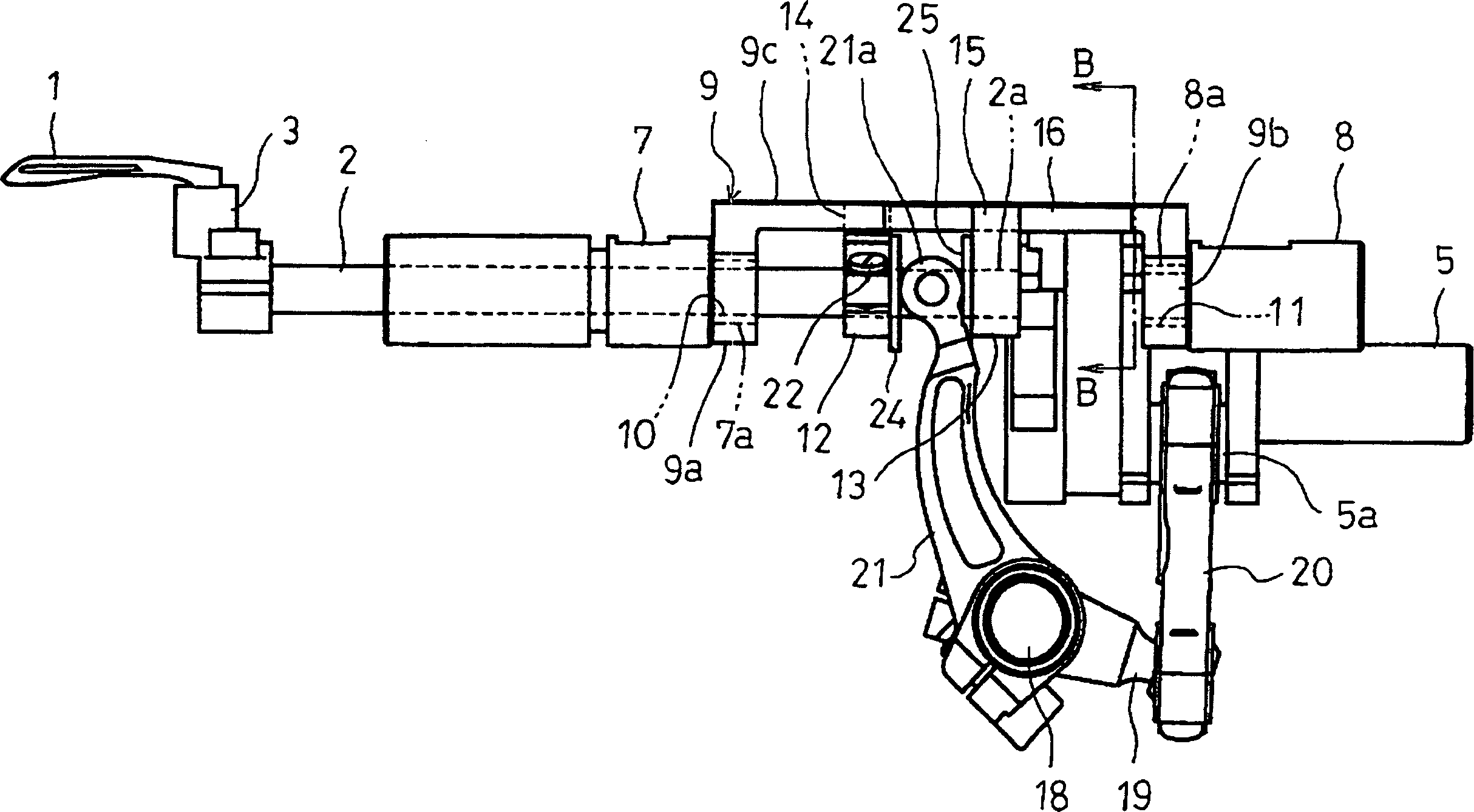

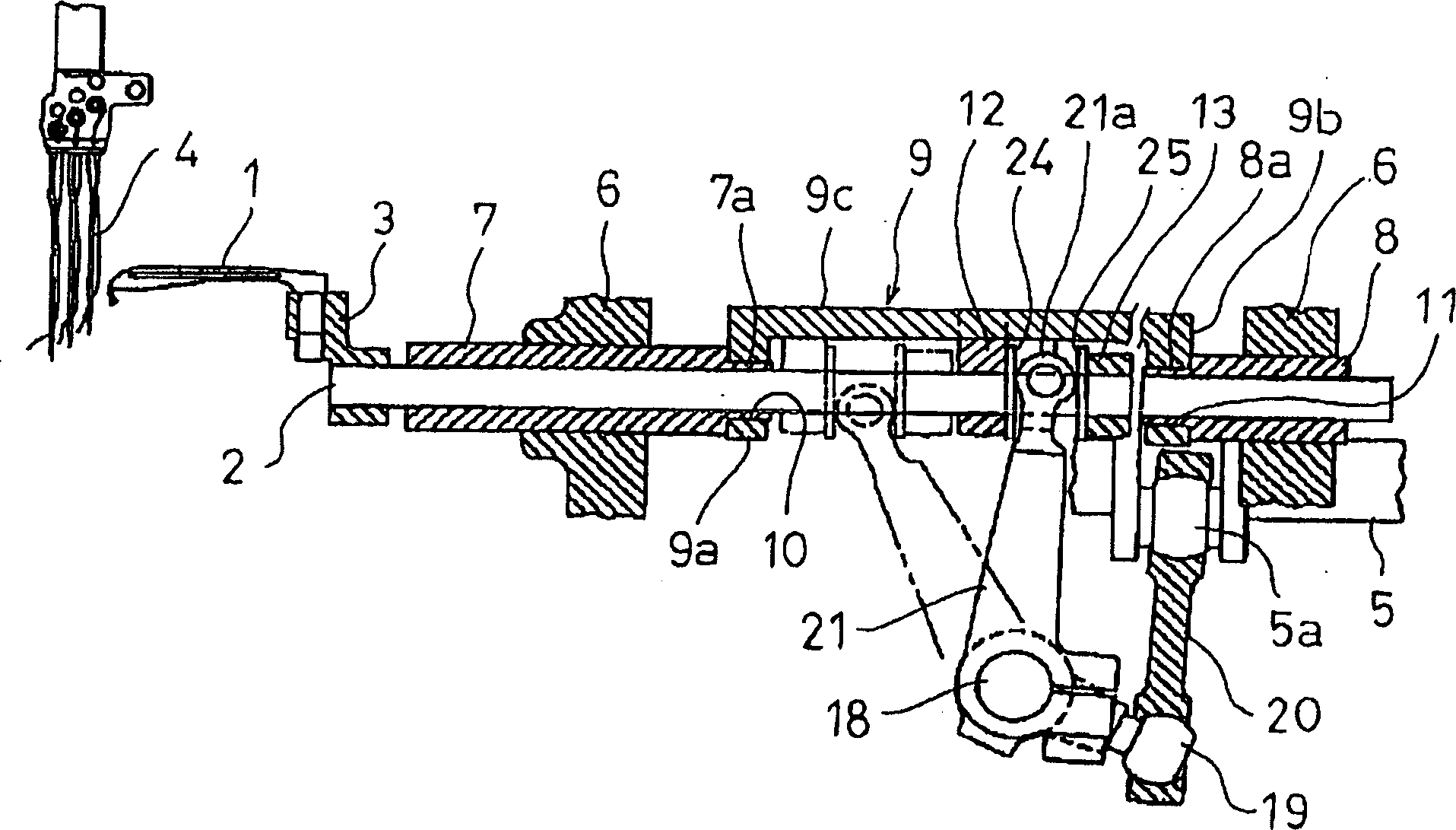

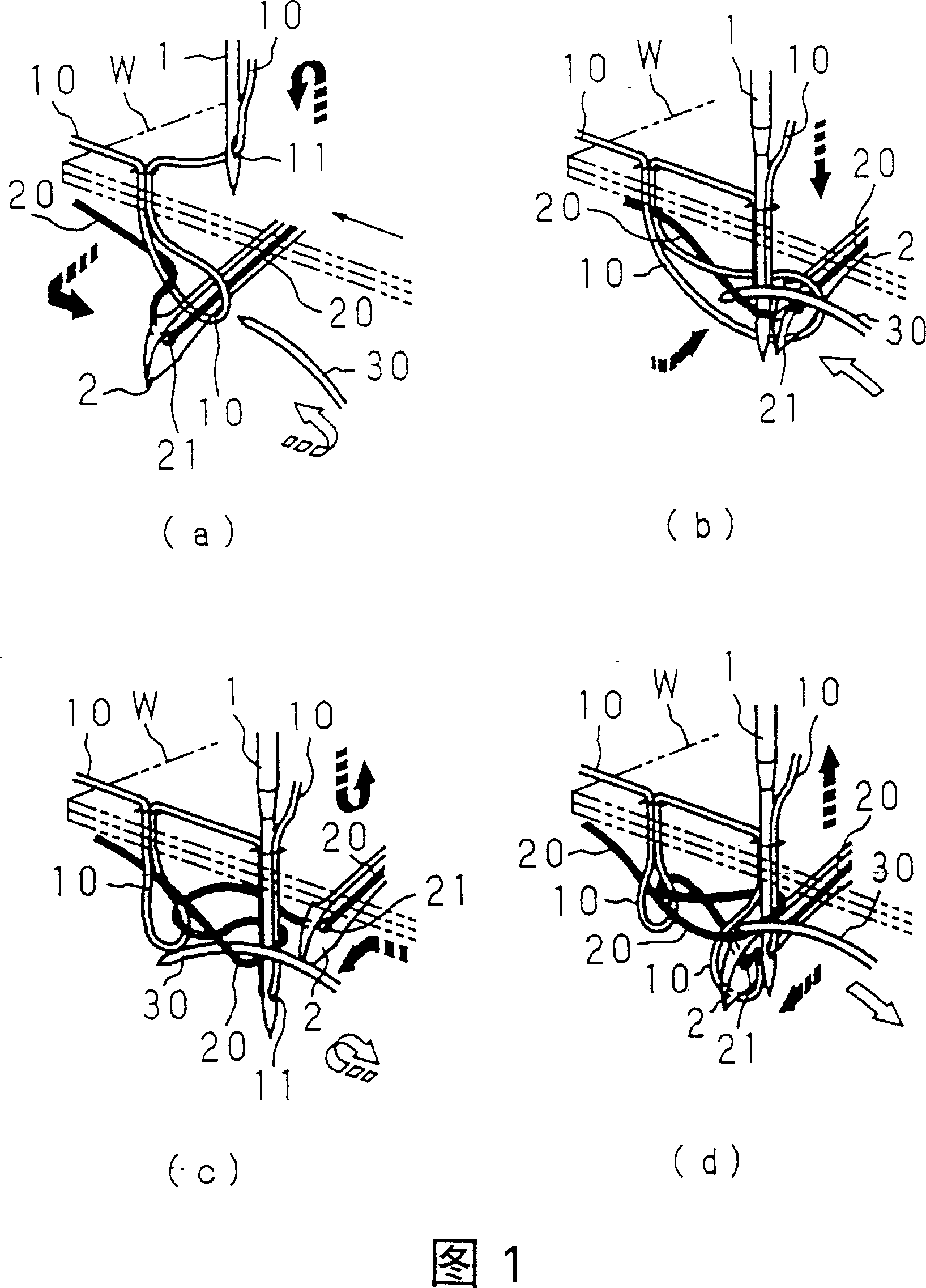

Curved needle drive device for sewing machine

ActiveCN1721608AEasy and quick adjustment workReduce in quantityLoop holdersLoop takersReciprocating motionMan-hour

To provide a looper drive for a sewing machine, by which adjusting work shifting to a suitable sliding state can be simplified even when a looper rod guide is worn attended with high speed operation, working of the looper rod guide can be simplified, and square pieces are omitted and man-hour of assembling work and the number of components can be reduced.In this looper drive for the sewing machine, a looper attached to one end of a looper rod 2 moves in a prescribed oblong orbit by synthetic motion of reciprocal movement in the axial direction by rocking of a rocking arm 21 and back and forth movement around the axis by a looper rod guide 9, a pair of first and second slide faces 16, 17 in parallel with the axial line direction of the looper rod 2 are set on the looper rod guide 9, and a first slide part 14 with a slide face 14a freely slidably abutting on the first slide face 16 is provided to one of first and second holders 12, 13 and a second slide part 15 with a slide face 15a slidably abutting on the second slide face 17 is provided to the other holder.

Owner:PEGASUS SEWING MACHINE MFG

Sewing machine

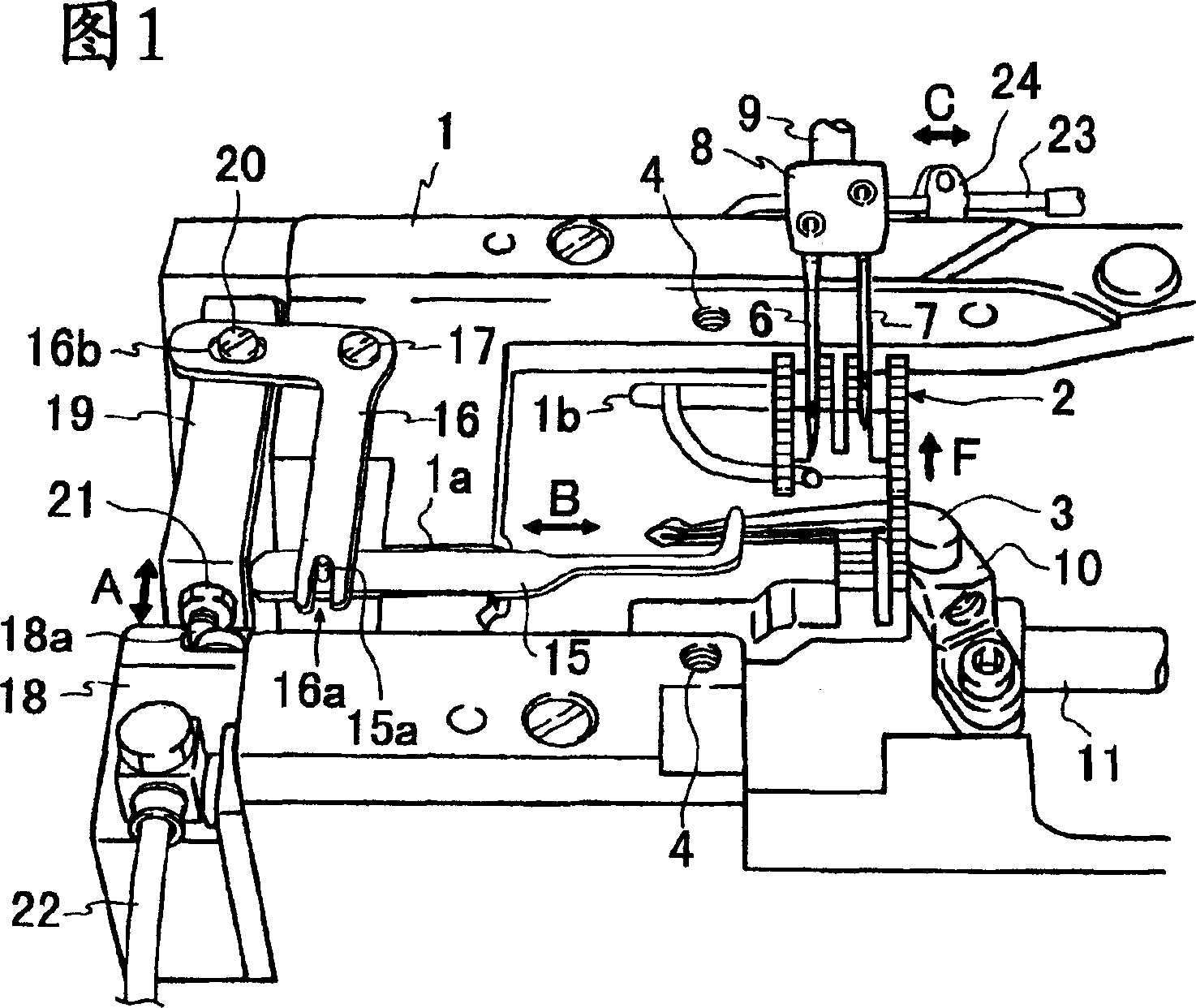

The invention provides a sewing machine, which can obtain the seam of desirable double multi-thread chain stitch where looper string gets caught by the loop of needle thread on the reverse side of cloth while the looper string is loosened without leaving any traces on the cloth, and also can stably obtain the sewing-goods with good quality. The sewing machine is composed of a retainer rod 30 is provided which projects and withdraws backward and forward within a plane roughly in parallel with the feed surface of the cloth W while interlocked with the rise and fall of the needle 1, and this retainer rod 30 catches the looper thread 20 at the projection side of the looper 2 ahead of the needle 1 when projecting rearward, and holds the caught looper thread 20 between the rod and needle 1 under tension.

Owner:YAMATO SEWING MASCH MFG CO LTD

Thread control device for a sewing machine

InactiveCN101012602AAvoid slackPrevent Stitch DisorderThread-laying mechanismsTake-up devicesReciprocating motionEmbedded system

A sewing machine having a reciprocatory needle and a reciprocatory thread-take-up device to deliver thread to the needle employs a thread control device located between the thread take-up device and the needle to engage and apply light tension to the thread. The thread control device can have two opposed plates between which the thread runs and which cooperate to apply spring pressure to the thread, for example, a guide plate and a spring plate. The guide plate or other device can include catcher structure to catch thread escaping the take-up device. The thread control device can help control premature descent of the thread and improperly tensioned stitches.

Owner:THE SINGER CO

Stitch structure of double-chain-ring seam

InactiveCN104278435APrevent open wirePrevent pulling outNeedle severing devicesThread-laying mechanismsEngineeringDouble chain

Owner:YAMATO SEWING MASCH MFG CO LTD

Sewing machine

InactiveUS20090056608A1Good adhesionEasy detachmentSewing-machine control devicesFilament handlingThreaded insertSewing machine

A sewing machine is provided. The sewing machine includes a top covering shaft mechanism, a spreader mechanism detachably attached to the top covering shaft mechanism from below and operable to catch a covering thread and to interlace the covering thread with a needle thread inserted into a needle to form covering stitches, and an operating member having a hook portion and rotatably attached to either one of the top covering shaft mechanism and the spreader mechanism. The other of the top covering shaft mechanism and the spreader mechanism has a protrusion with which the hook portion is engageable. The operating member is rotatable between a position at which the hook portion engages with the protrusion to lock the spreader mechanism with respect to the top covering shaft mechanism and another position at which the spreader mechanism is detachable from the top covering shaft mechanism.

Owner:JUKI CORP

Sewing machine

InactiveUS7913634B2Good adhesionEasy detachmentSewing-machine control devicesFilament handlingThreaded insertSewing machine

A sewing machine is provided. The sewing machine includes a top covering shaft mechanism, a spreader mechanism detachably attached to the top covering shaft mechanism from below and operable to catch a covering thread and to interlace the covering thread with a needle thread inserted into a needle to form covering stitches, and an operating member having a hook portion and rotatably attached to either one of the top covering shaft mechanism and the spreader mechanism. The other of the top covering shaft mechanism and the spreader mechanism has a protrusion with which the hook portion is engageable. The operating member is rotatable between a position at which the hook portion engages with the protrusion to lock the spreader mechanism with respect to the top covering shaft mechanism and another position at which the spreader mechanism is detachable from the top covering shaft mechanism.

Owner:JUKI CORP

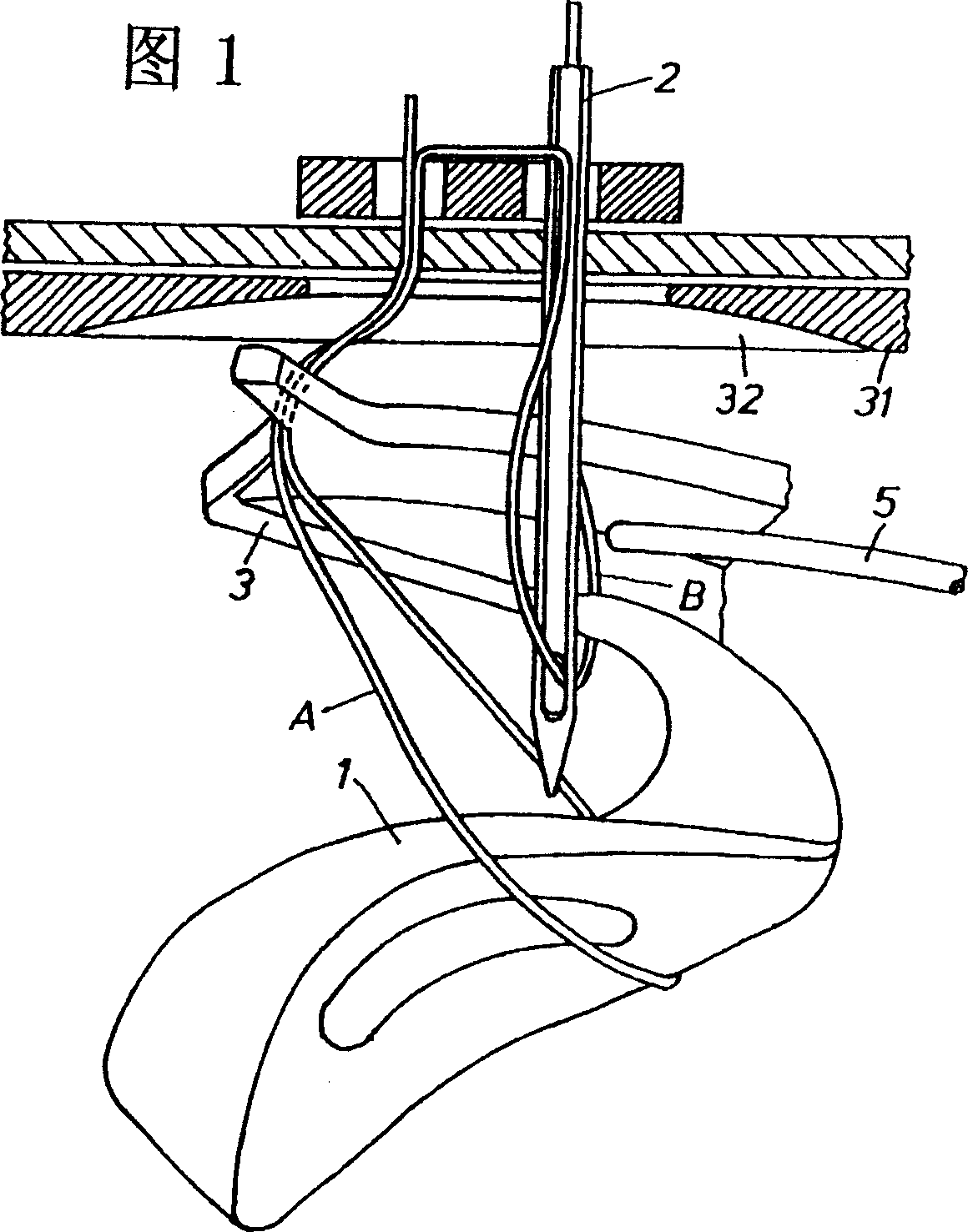

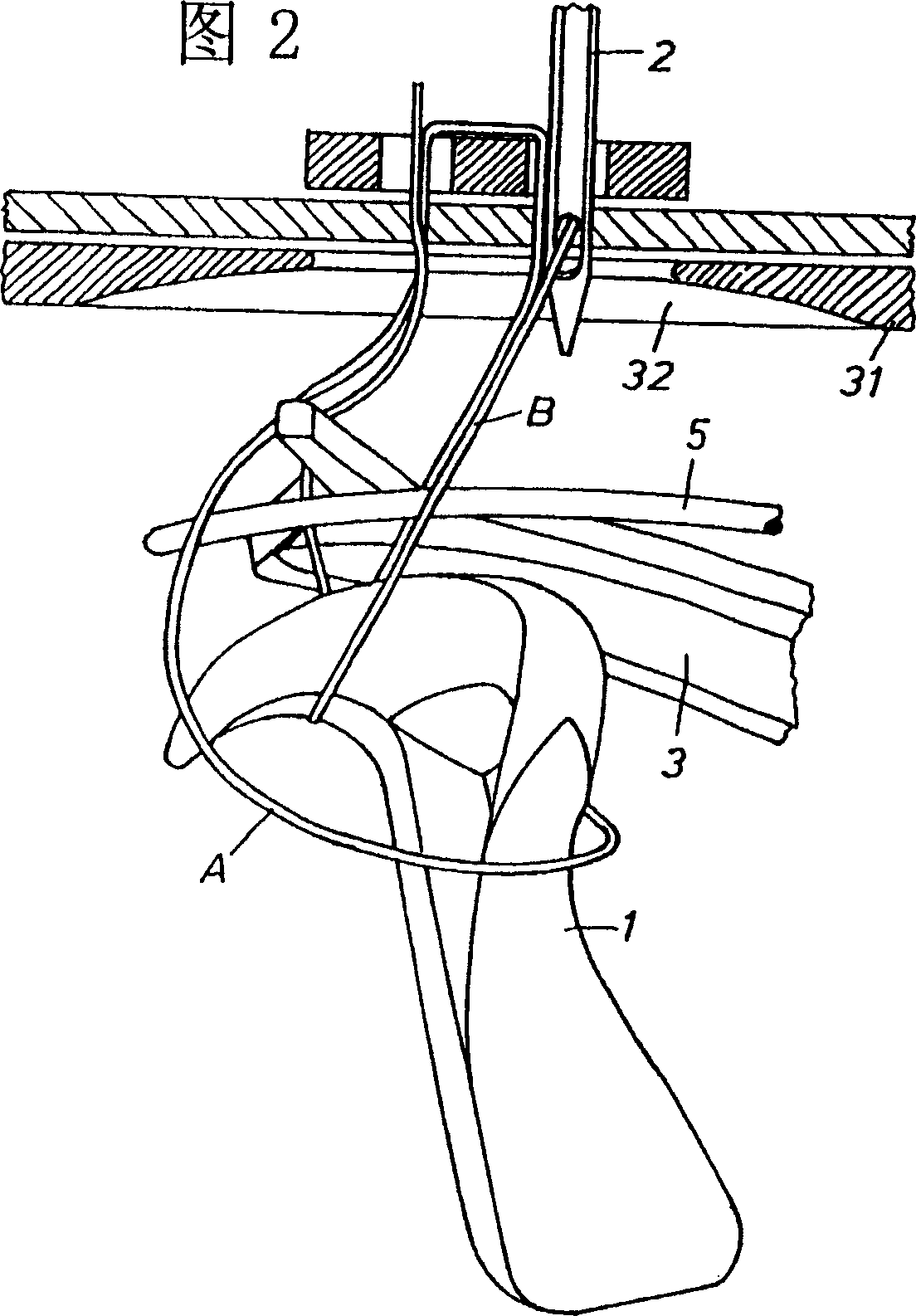

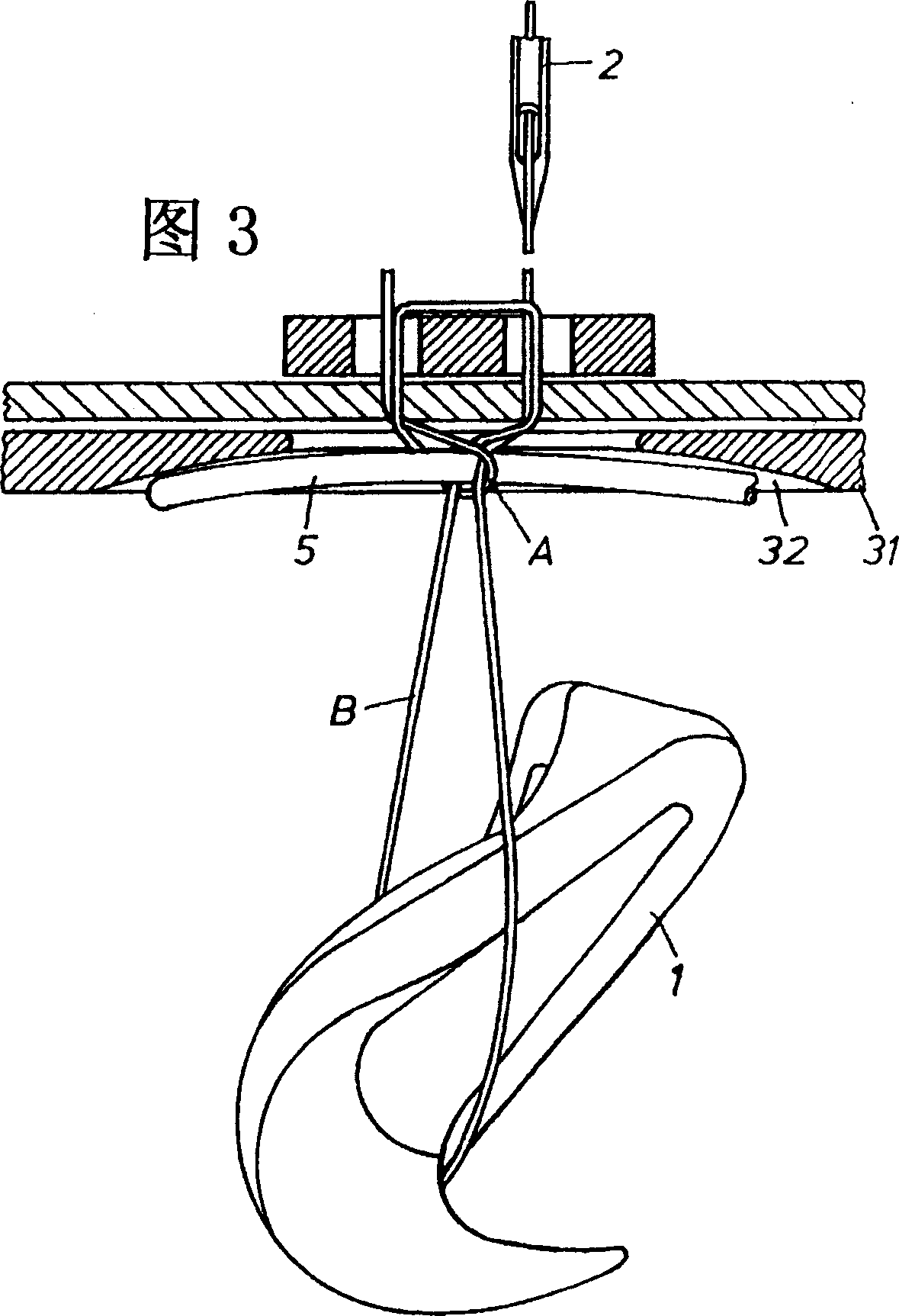

Method and apparatus for forming single-thread chain sewing end knot

The present invention relates to a method and a device for forming an end knot when using a single yarn stitching sartorius to seam. A yarn loop B of a stitch which is formed before the last needle and caught by a looper after over a yarn stitching passes through a yarn loop A of the former stitch formed and caught by a looper, the two yarn loops are circling with a block pin. A yarn loop C formed at the last needle passes through the yarn loop B by the looper at a time, and the torsion formed by the guide of the yarn loop B through encircling the looper is finished at this time, but the yarn loop B is not fell off from the looper.

Owner:G M PFAFF AG

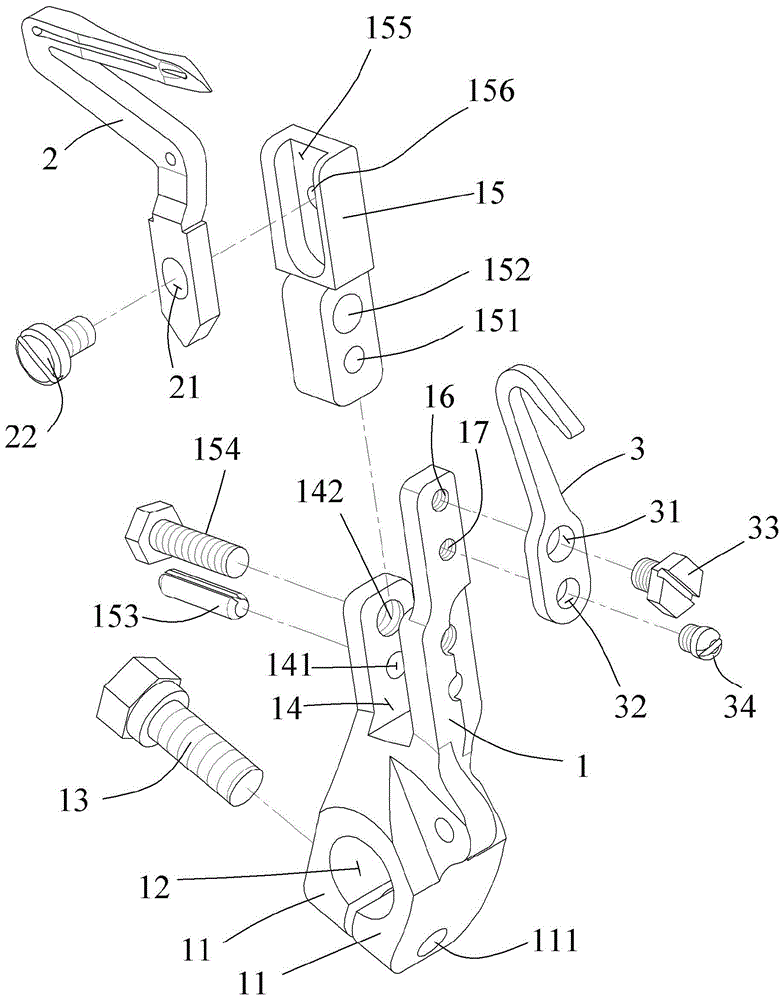

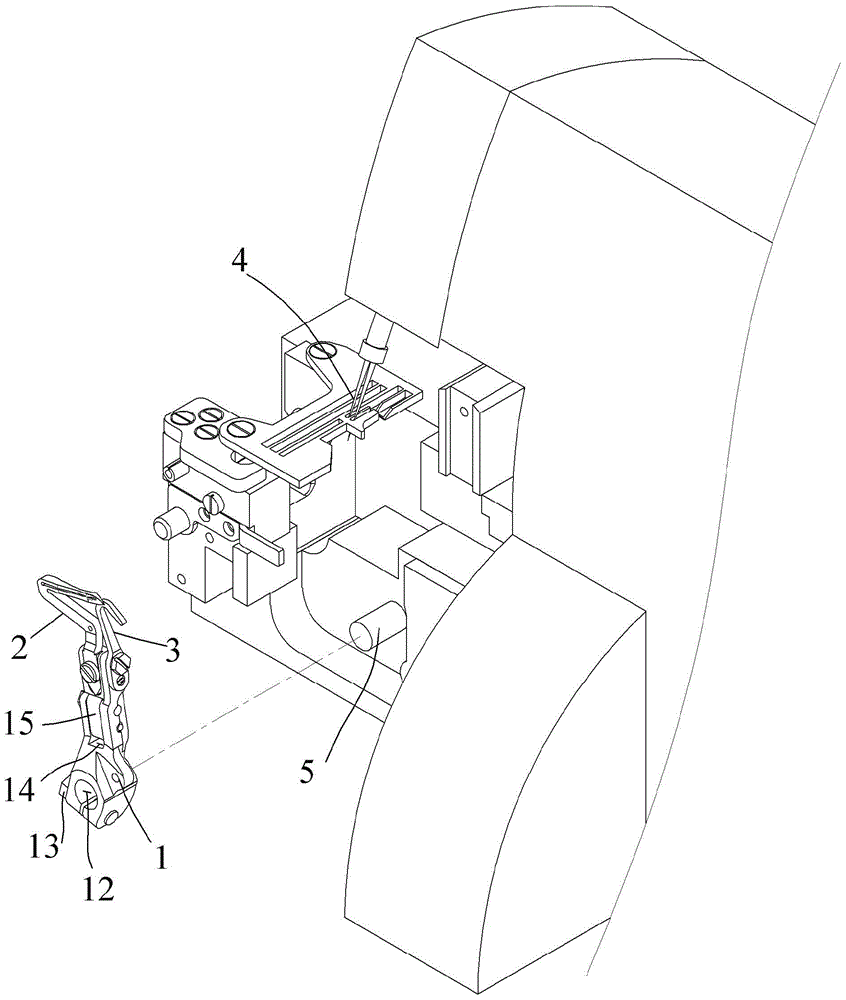

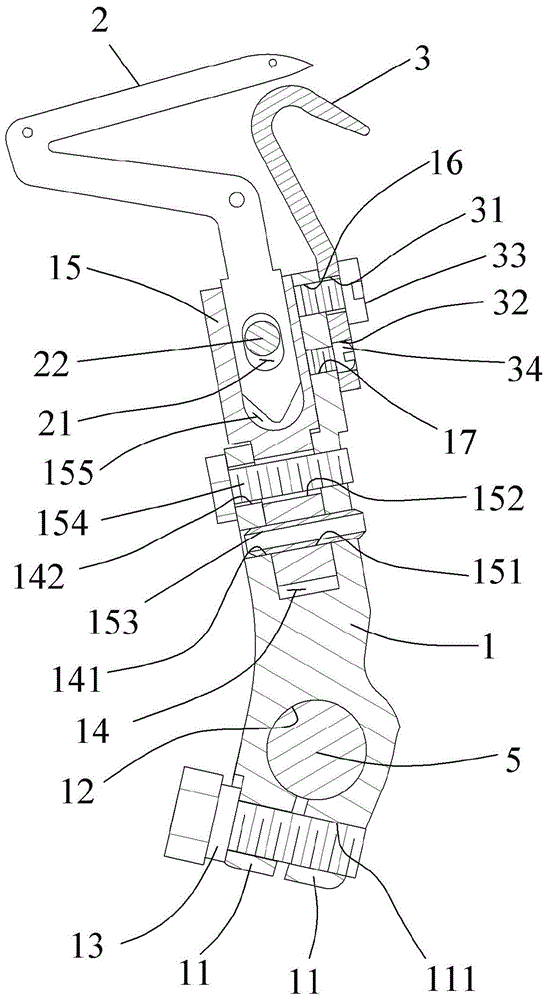

Hook ring swing seat device for sewing machine and adjusting method thereof

InactiveCN105386255AImprove the convenience of adjustmentSewing-machine control devicesLoop holdersNeedle guideEngineering

The invention relates to a hook ring swing seat device for a sewing machine and an adjusting method thereof. A hook ring swing seat is arranged and a rotary shaft installed on the sewing machine. A transverse adjusting part, a shuttle needle adjusting part and a needle-guiding device adjusting part are arranged on the hook ring swing seat. When benchmarks of the shuttle needle, the needle-guiding device and a machine needle are set and adjusted on the hook ring swing seat, the transverse adjusting part is utilized for adjusting and correcting the transverse distance between the shuttle need and the machine needle located at a lower starting point and the needle-guiding device is utilized for adjusting and correcting interference amount of the needle-guiding device to the machine needle. Ultimately, the shuttle needle adjusting part is used for adjusting and correcting the pointed end of the shuttle needle, and a concave part of the machine needle. Therefore, the hook ring swing seat device for the sewing machine and the adjusting method thereof have following beneficial effects: by utilization of separate design of adjusting structures, benchmarks of the shuttle needle, the needle-guiding device and the machine needle are finished setting, adjusting and correcting; no adjusted and corrected benchmarks do not vary; and real benefits such as improvement in convenience for adjustment and correction are achieved.

Owner:顾飞龙

Sewing machine with yarn taking-up device and controlling program of yarn taking-up device

A sewing machine includes a sewing mechanism including a needle bar, a thread take-up lever and a shuttle, a picker capable of holding a needle thread extending from an eye of a sewing needle near the shuttle located below a needle plate, and a picker driver driving the picker between a first stop position where the picker is capable of holding the needle thread and a second stop position spaced farther away from the shuttle than the first position. The picker is movable to a third position spaced farther away from the shuttle than the second position.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com