Method for sewing machine to prevent miss-sewing

A sewing machine and thread leakage technology, which is applied to the thread cutting mechanism, sewing machine components, sewing equipment and other directions in the sewing machine, can solve the problem of losing the force clamp when it cannot be clamped by the thread hooking and clamping group, and is separated from the thread hooking and clamping group. The system can no longer be pressed, the suture cannot be clamped by the thread hook clamping group, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

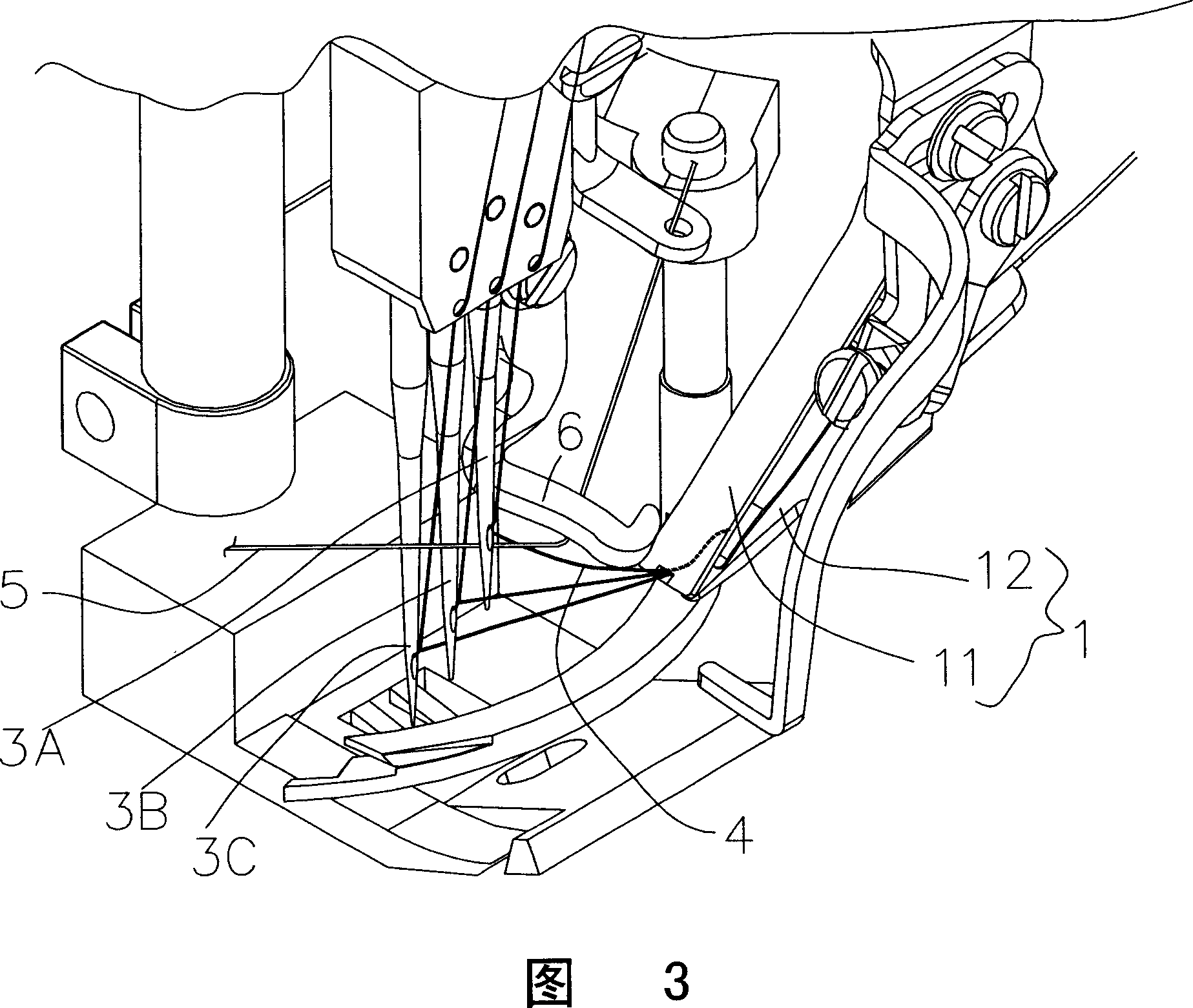

[0024] First, please refer to Fig. 6-8 and Fig. 3, there is a thread hooking group 2 behind the clamping group 1, and the thread hooking piece 21 of the thread hooking group 2 can be controlled by the upper and lower clips of the clamping group 1 Pass through between 11 and 12, and protrude to the corresponding first bur 3A, to hook the suture 4 passing through the first bur 3A, and another upper thread 5 traverses the first, Two, three burs 3A, 3B, 3C are cut off and clamped by the upper thread cutting device (not shown in the figure).

[0025] Accordingly, when the sewing machine finishes sewing for the first time, the upper thread 5 can be cut and clamped by the upper thread cutting device, so as to maintain its moderately tensioned state, while the thread hook piece 21 of the thread hook group 2 is not The upper and lower clips 11 and 12 of the clamping group 1 protrude out and hook the suture 4 that passes through the first bur 3A, and after the hooking piece 21 is retrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com