Curved needle drive device for sewing machine

A technology of a driving device and a sewing machine, which is applied to sewing machine components, sewing machine collar mechanisms, sewing equipment, etc., can solve the problems of troublesome processing of square sliders, troublesome adjustment of square sliders 51, proficiency, etc., and achieves simple and fast adjustment operations. Adjust the effect of the job

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

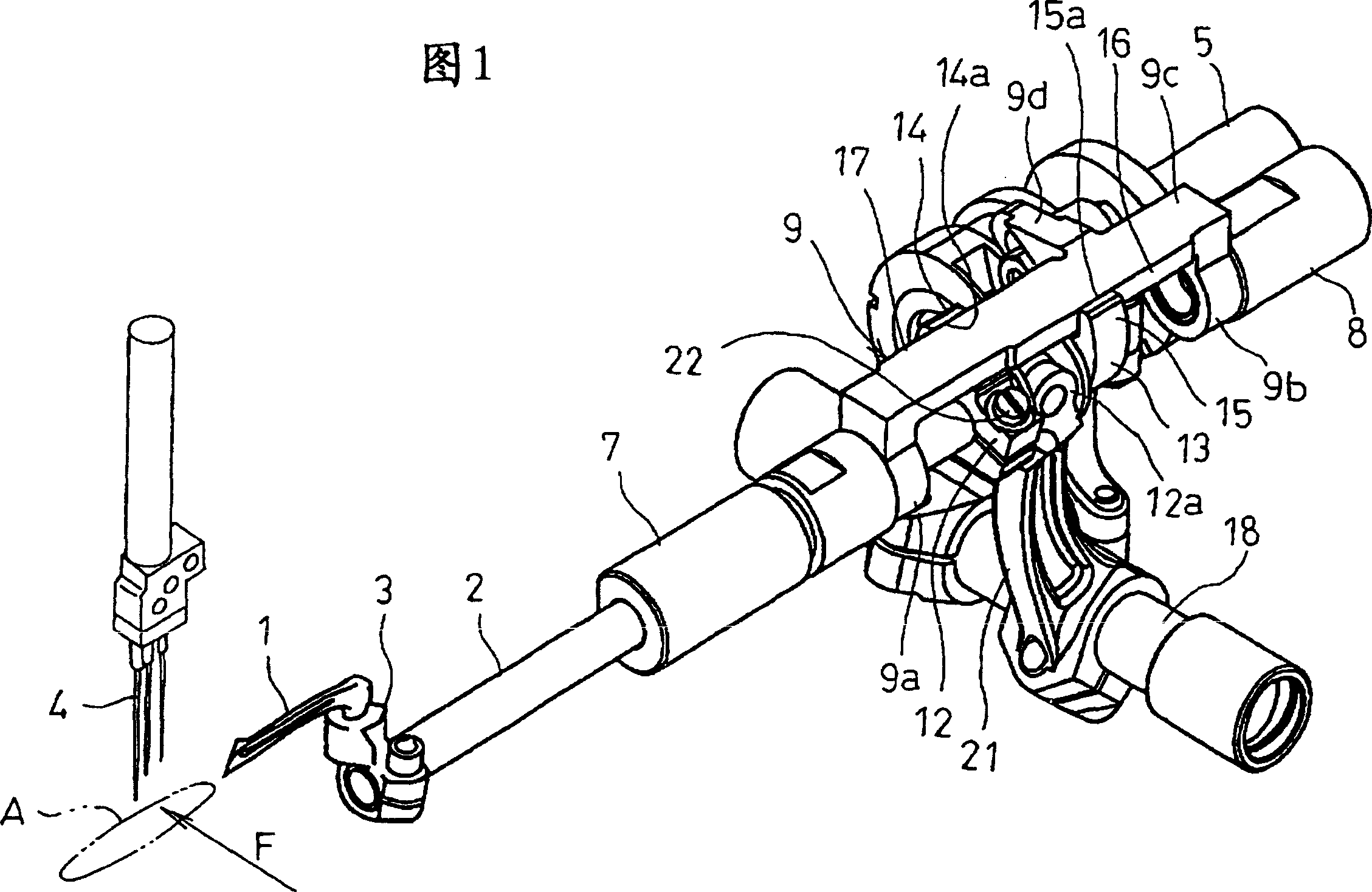

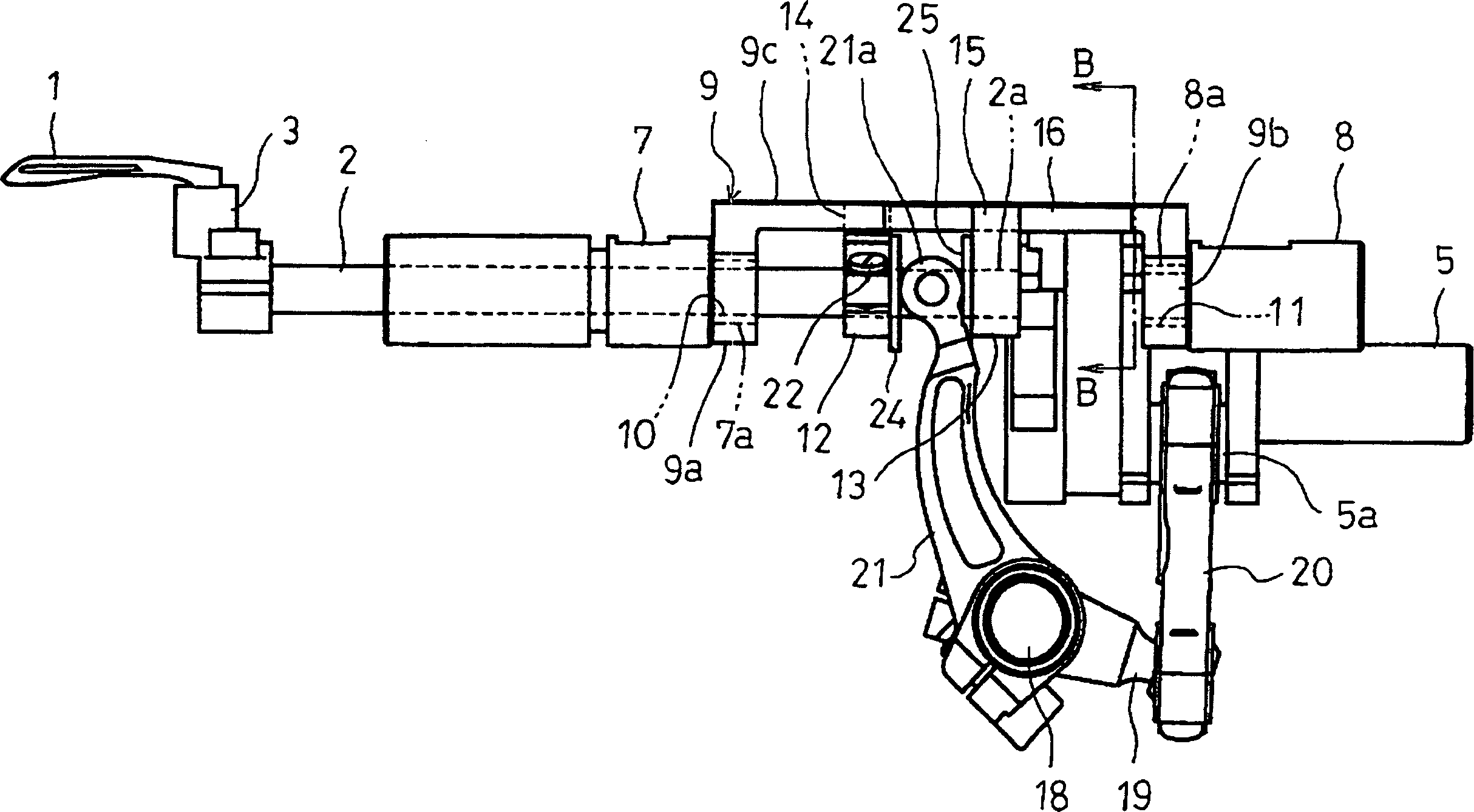

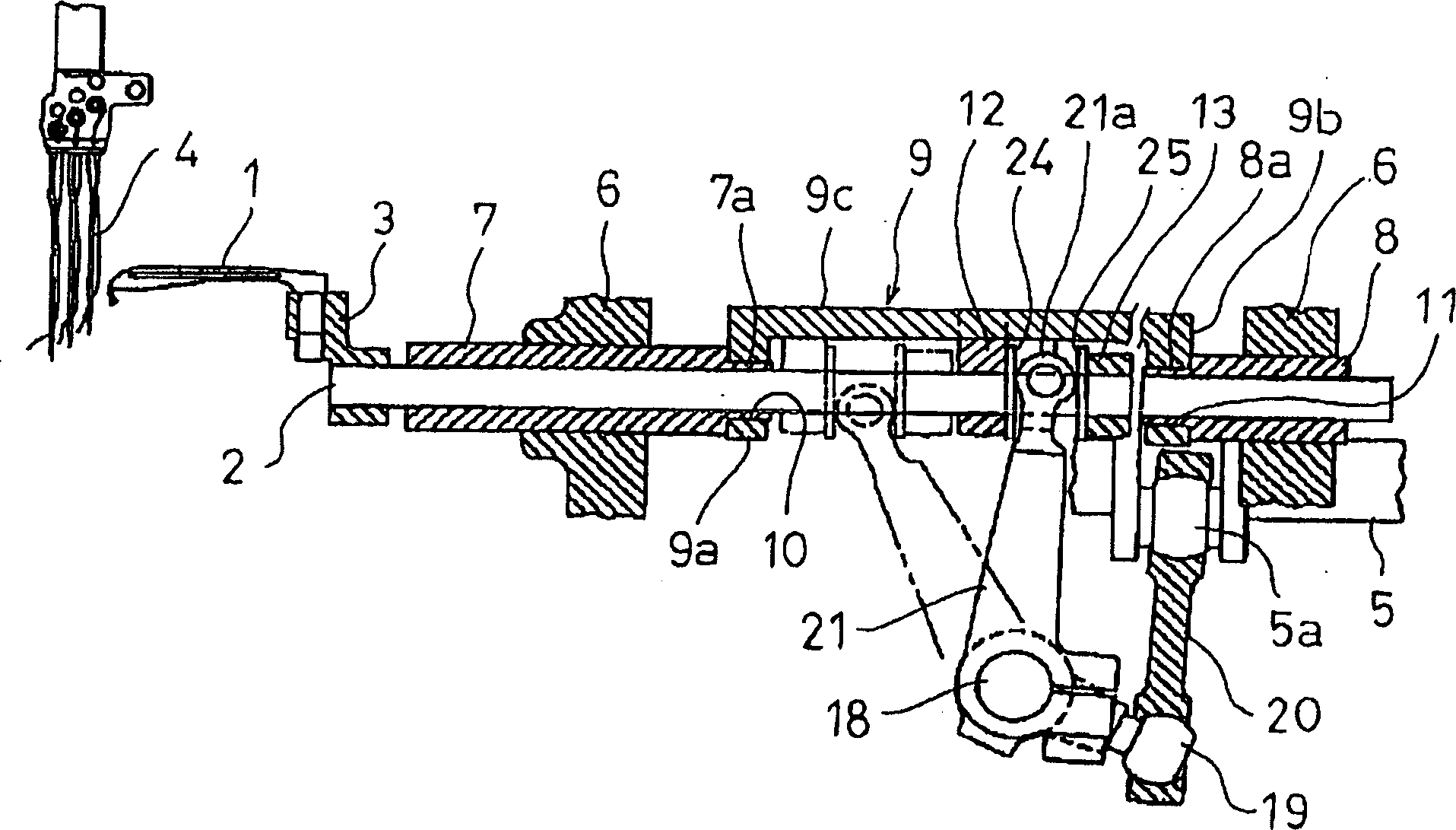

[0032] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Fig. 1 is a perspective view showing a looper driving device of a sewing machine according to an embodiment of the present invention, figure 2 It is the front view of the looper driving device of Fig. 1, image 3 It is a longitudinal sectional front view of the looper driving device of Fig. 1, Figure 4 It is a longitudinal sectional side view of the looper driving device of Fig. 1, Figure 5 for figure 2 Figure 6 is a perspective view of the main parts of the looper driving device of Figure 1 including the looper rod guide and the first and second cages, Figure 7 It is a perspective view of the first and second holders of the looper driving device in FIG. 1 .

[0033] Figure 1~ image 3 As shown, the looper 1 to be driven is attached to one end of the looper bar 2 via the looper stand 3 away from the axis of the looper bar 2 . The looper bar 2 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com