Cutting edge position adjustment mechanism and indexable insert type cutting tool

A technology for adjusting mechanisms and cutting tools, which is applied in the manufacture of tools, milling cutters, metal processing, etc., can solve the problems of reducing the number of regrinding, difficulty in ensuring processing accuracy, and shortening tool life, so as to improve processing accuracy and realize adjustment Operation, the effect of increasing the number of regrinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

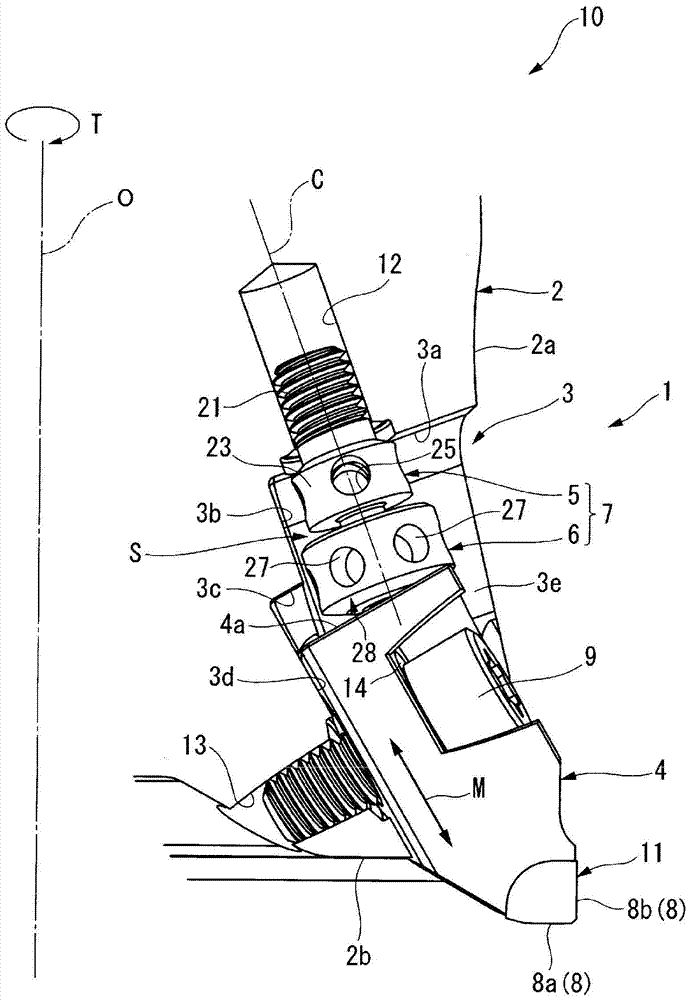

[0032] Hereinafter, a cutting edge position adjustment mechanism 1 according to an embodiment of the present invention and an indexable insert type cutting tool 10 using the same will be described with reference to the drawings.

[0033] The indexable insert type cutting tool 10 of the present embodiment is, for example, an indexable insert type face mill (indexable insert type milling tool) for finishing.

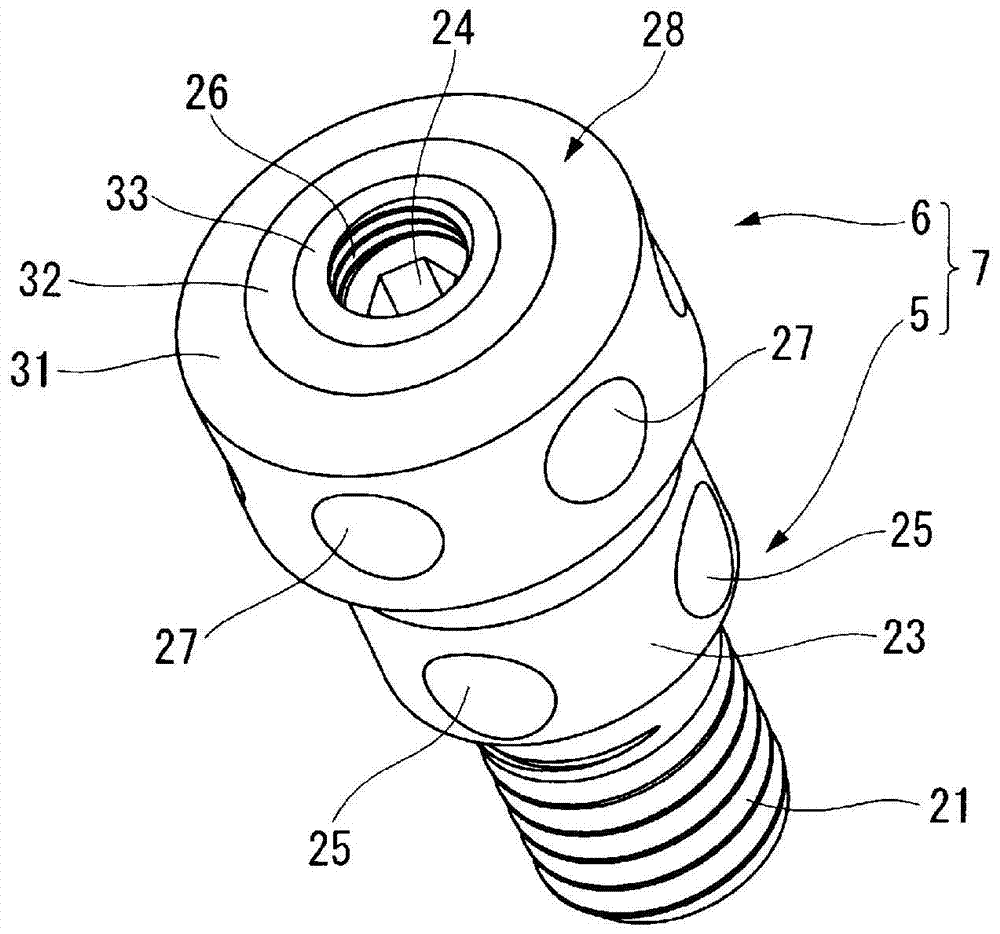

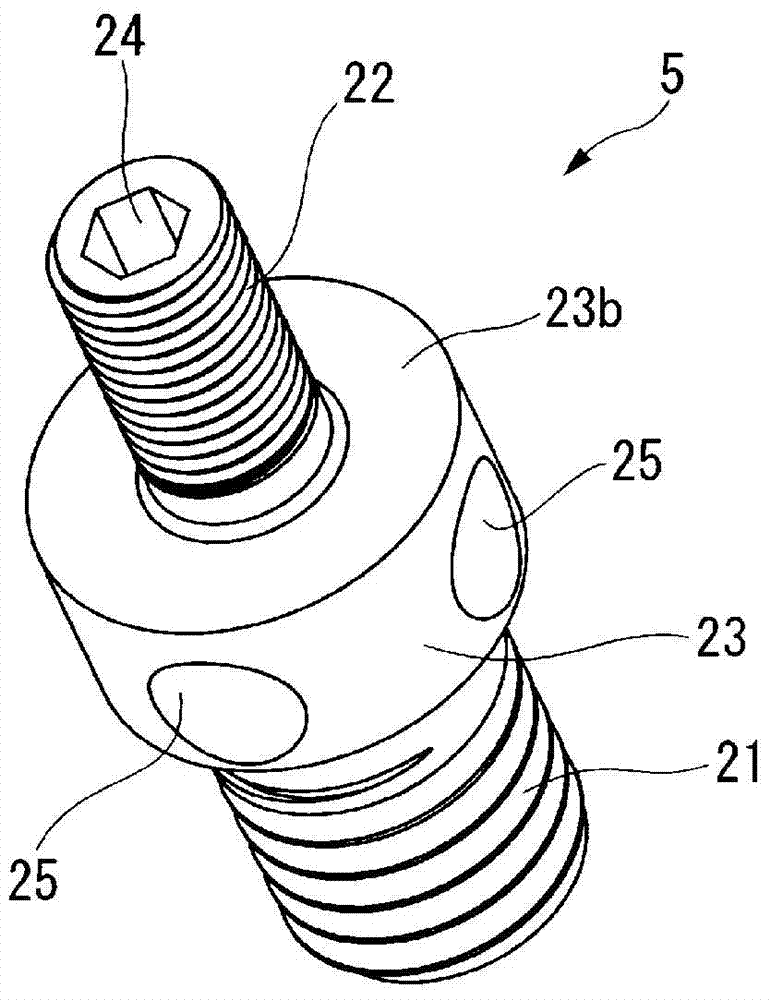

[0034] Such as figure 1 As shown, the indexable insert type cutting tool 10 has: a tool body 2, which is cylindrical or cylindrical (disc-shaped) and rotates around the tool axis O; a cutting edge member 4 is detachably installed on the The outer peripheral portion of the front end of the tool body 2, and the cutting edge 8 protrudes toward at least one of the tool front end side and the radially outer side of the tool; and the cutting edge position adjustment mechanism 1 moves the cutting edge member 4 relative to the tool body 2 to adjust the position of the cutting edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com