elevator

A technology for elevators and elevator cars, applied in the field of elevators, can solve problems such as damage to threaded parts, and achieve the effect of stabilizing and maintaining the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

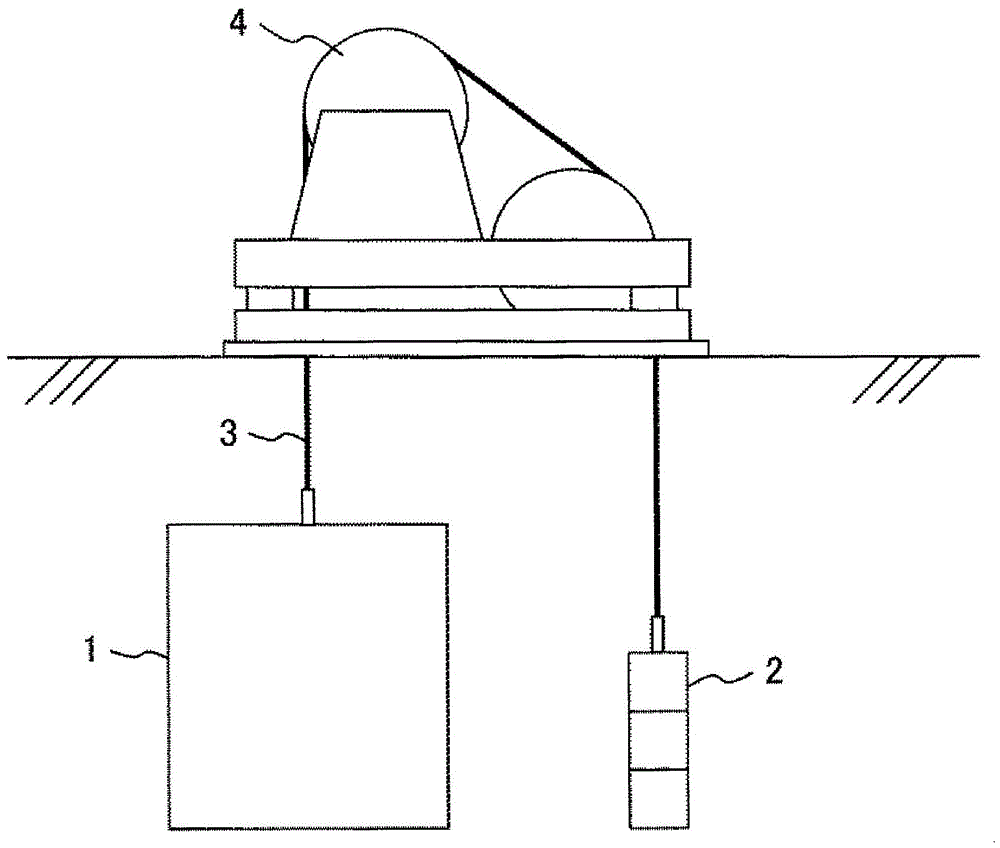

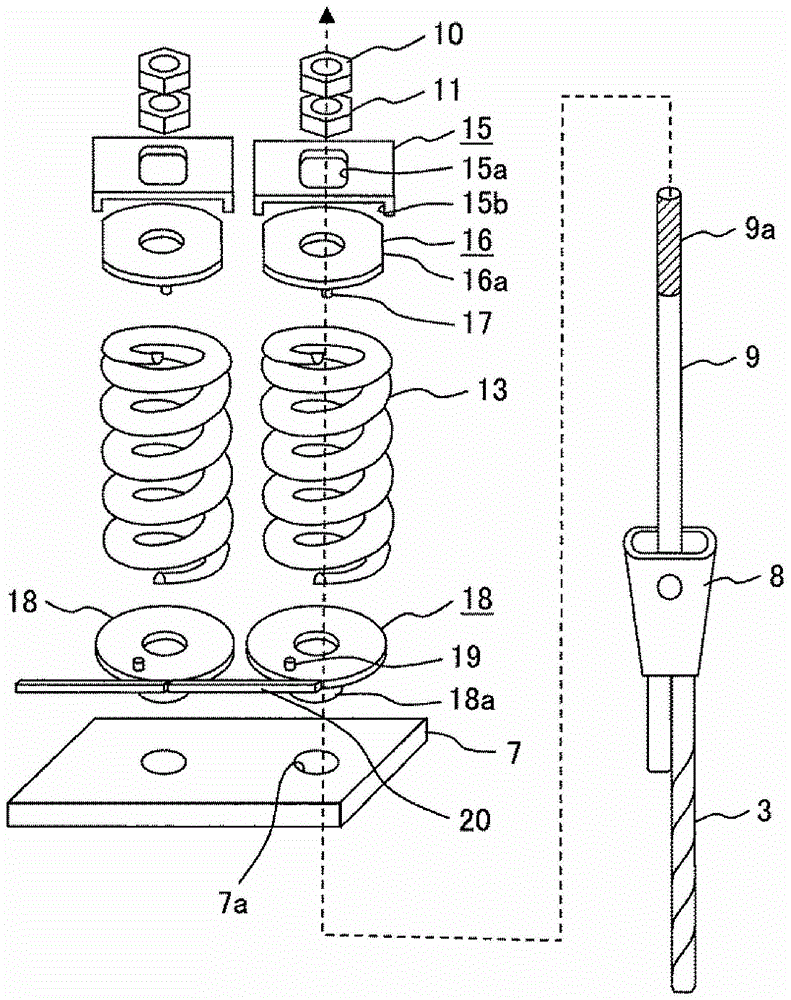

[0050] exist figure 1 In the elevator shown, the wire rope is wound in a 1:1 winding method, and the elevator car 1 and the counterweight 2 are connected by a wire rope 3 . The wire rope 3 is wound around a hoist 4 , and the hoist 4 drives the wire rope 3 to raise and lower the elevator car 1 and the counterweight 2 .

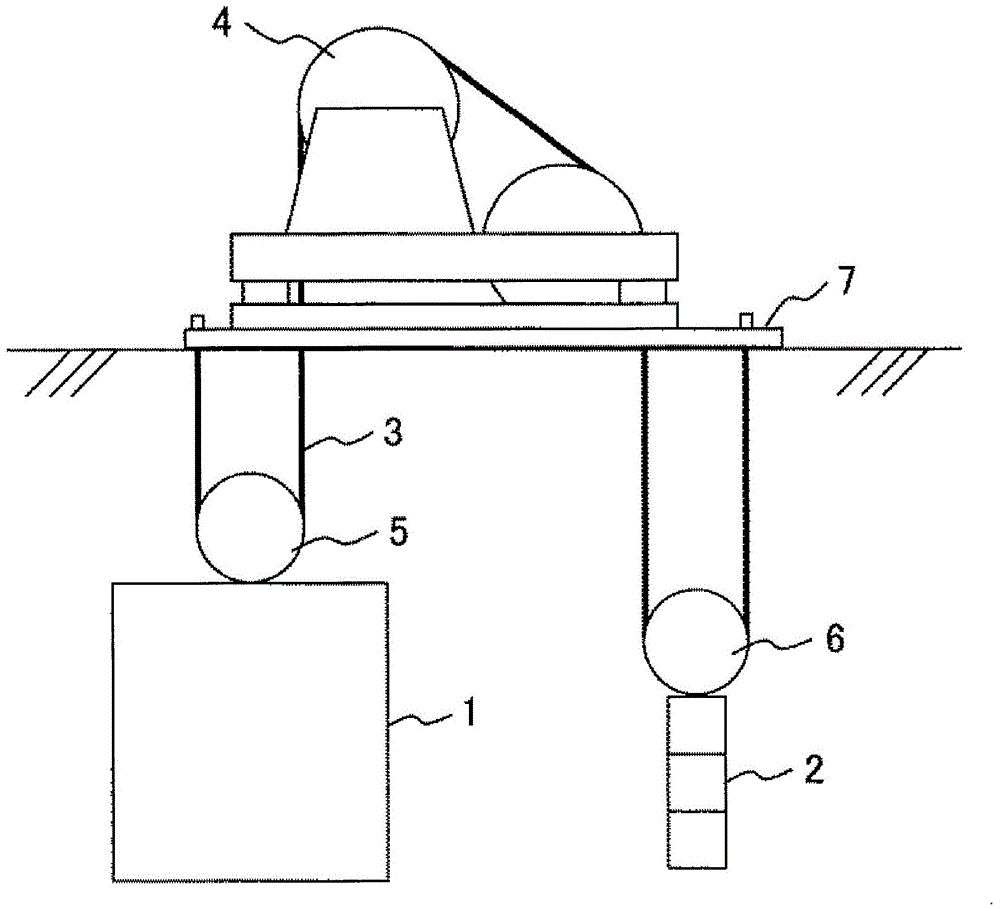

[0051] exist figure 2 In the elevator shown, the steel wire rope is wound with a 2:1 winding method, and the steel wire rope 3 is suspended via a movable pulley, namely pulley 5, installed on the elevator car 1, and a movable pulley, namely, pulley 6, installed on the counterweight 2. The elevator car 1 and the counterweight 2, the ends of the wire ropes 3 are installed on the top base 7 as a support member. The ends of the wire ropes 3 can also be installed directly on beam members as supporting members of the building.

[0052] exist figure 1 with figure 2 In the elevator structure shown, the installation parts of the wire rope 3 are different, some ...

no. 2 example

[0061] Figure 4 Shows the second embodiment of the present invention. A convex portion 22a and two screw holes 22b are provided on the lower portion of the upper washer 22, and the screws 23 are fixed after tightening the nut 11 and applying a predetermined tension to the rod 9. The relative rotation of the nut 11 and the washer 22 can be prevented by making the end surface of the nut 11 which is the nut for setting the tension among the double nuts contact the side surface of the screw 23 .

[0062] The protrusion 22 a of the washer 22 engages with the end of the spring 13 , thereby preventing the washer 22 and the spring 13 from rotating relative to each other. In addition, by engaging the convex portion 19 of the washer 18 with the end of the spring 13 , it is possible to prevent the relative rotation of the spring 13 and the washer 18 .

[0063] The torque transmitting member 20 is welded on the washer 18 . The torque generated by the wire rope 3 is transmitted to the ...

no. 3 example

[0065] Figure 5 A third embodiment of the present invention is shown. The nuts used for fastening in the double nuts, that is, the nut 11 and the washer 24 are fixed together by welding in advance, and there is no relative rotation between the two. Six holes 24a for inserting pins 25 are opened in the washer 24, and after tightening the nut 11 and applying a predetermined tension to the rod 9, the pins 25 are inserted into the holes 24a closest to the end of the spring 13. By engaging the spring 13 with the pin 25 , the relative rotation of the spring 13 and the washer 24 can be prevented. Other structures are the same as those of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com