Coil frame and transformer using the coil frame

A coil bobbin and bobbin technology, applied in the field of transformers, can solve problems such as inability to perform height and adjustment, and achieve the effects of simplifying component management, ensuring the adjustment amount, and improving the bonding state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, modes for implementing the present invention (hereinafter referred to as "embodiments") will be described in detail with reference to the drawings.

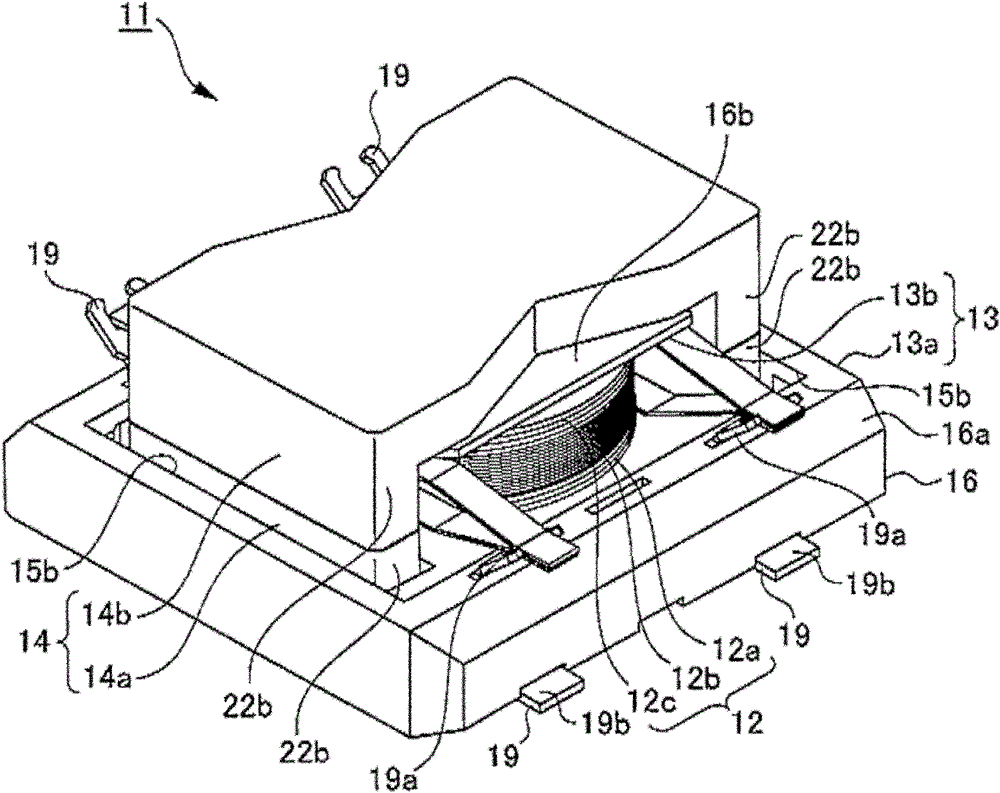

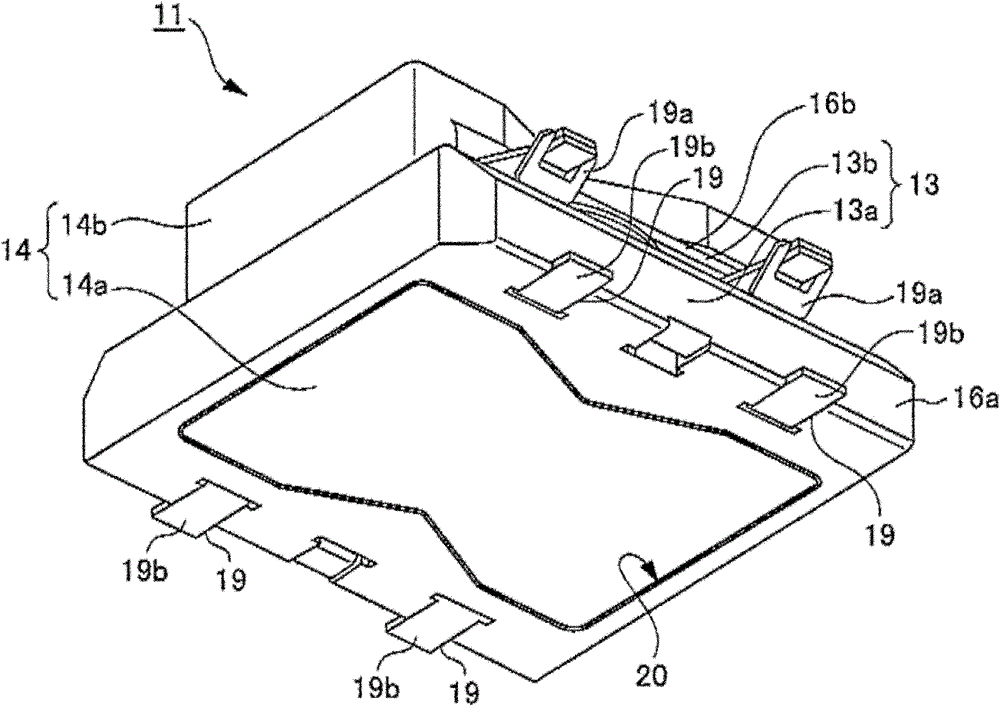

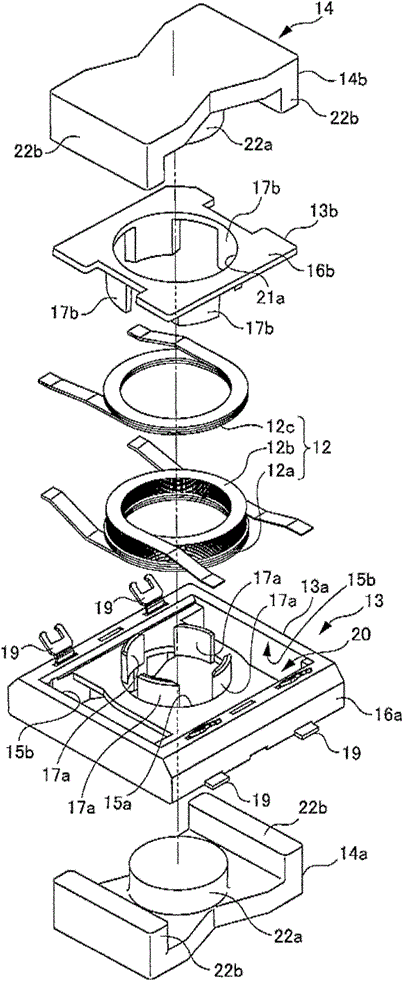

[0033] Figure 1 to Figure 6 shows a transformer as an embodiment of the present invention, figure 1 is a perspective view of the above-mentioned transformer viewed from the upper side, figure 2 is a perspective view of the above-mentioned transformer viewed from the lower side, image 3 is an exploded perspective view of the main parts of the above transformer, Figure 4 is a perspective view showing the coil bobbin of the above-mentioned transformer, Figure 5 Represents the bobbin of the above transformer, where Figure 5 (a) is a side view in the state where the coil is not assembled, Figure 5 (b) is a side view of the state where the coil is assembled, Figure 6 is along Figure 5 A cross-sectional view of line A-A in. In addition, in all descriptions of embodiment, the same code|symbol is attac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com