Machine tool having extendable cover

A technology of telescopic cover and machine tool, which is applied in the direction of manufacturing tools, mechanical equipment, metal processing machinery parts, etc., and can solve the problems of unexplained telescopic cover assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

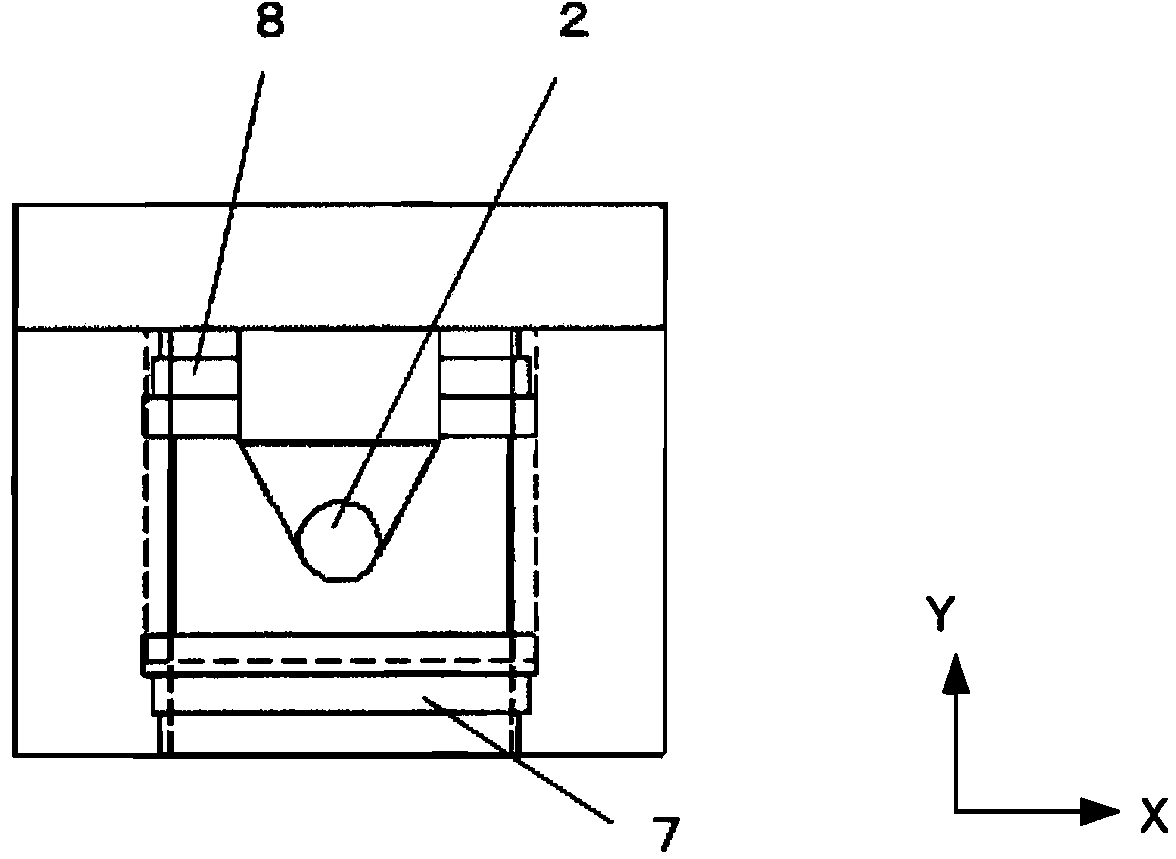

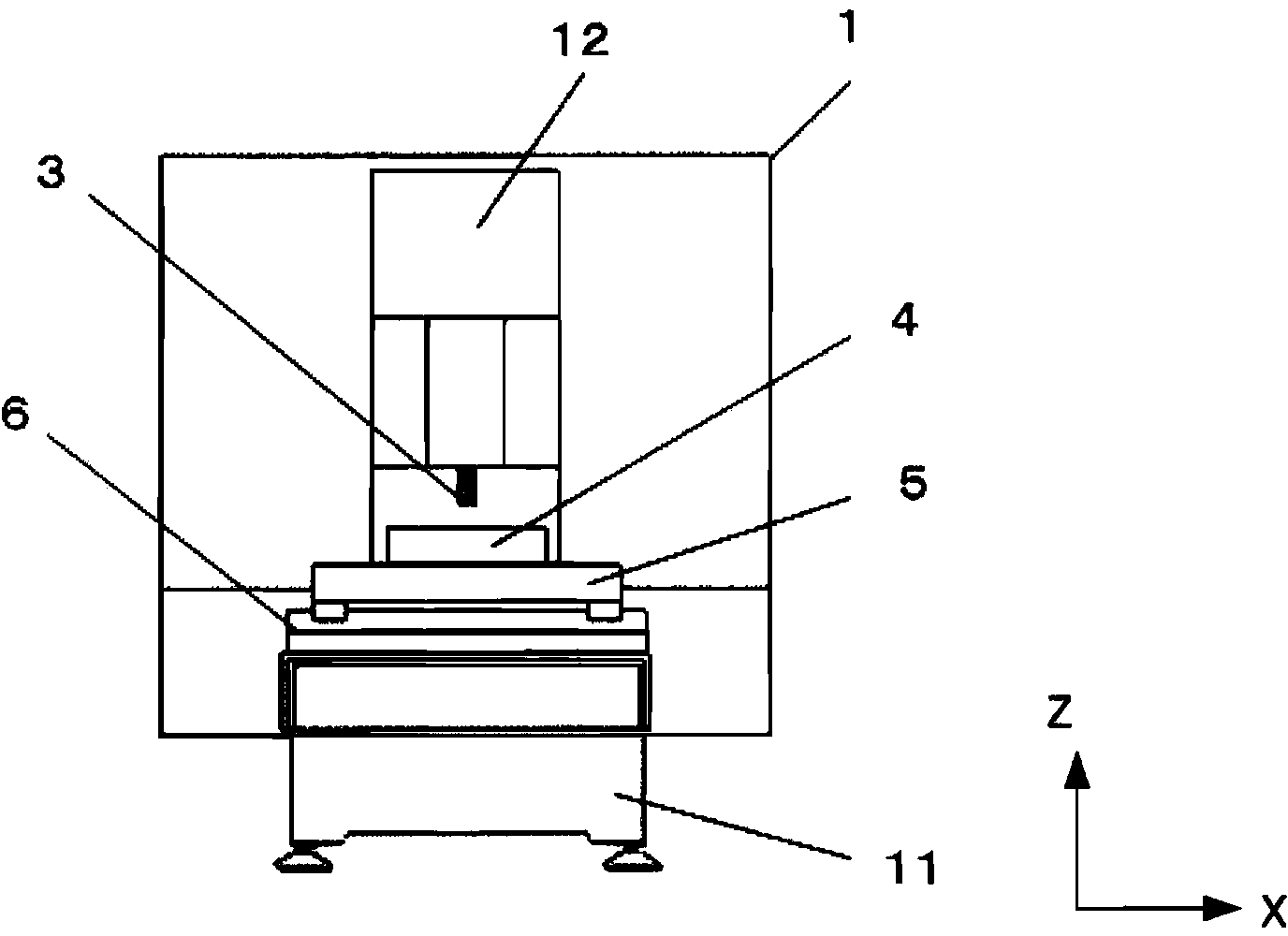

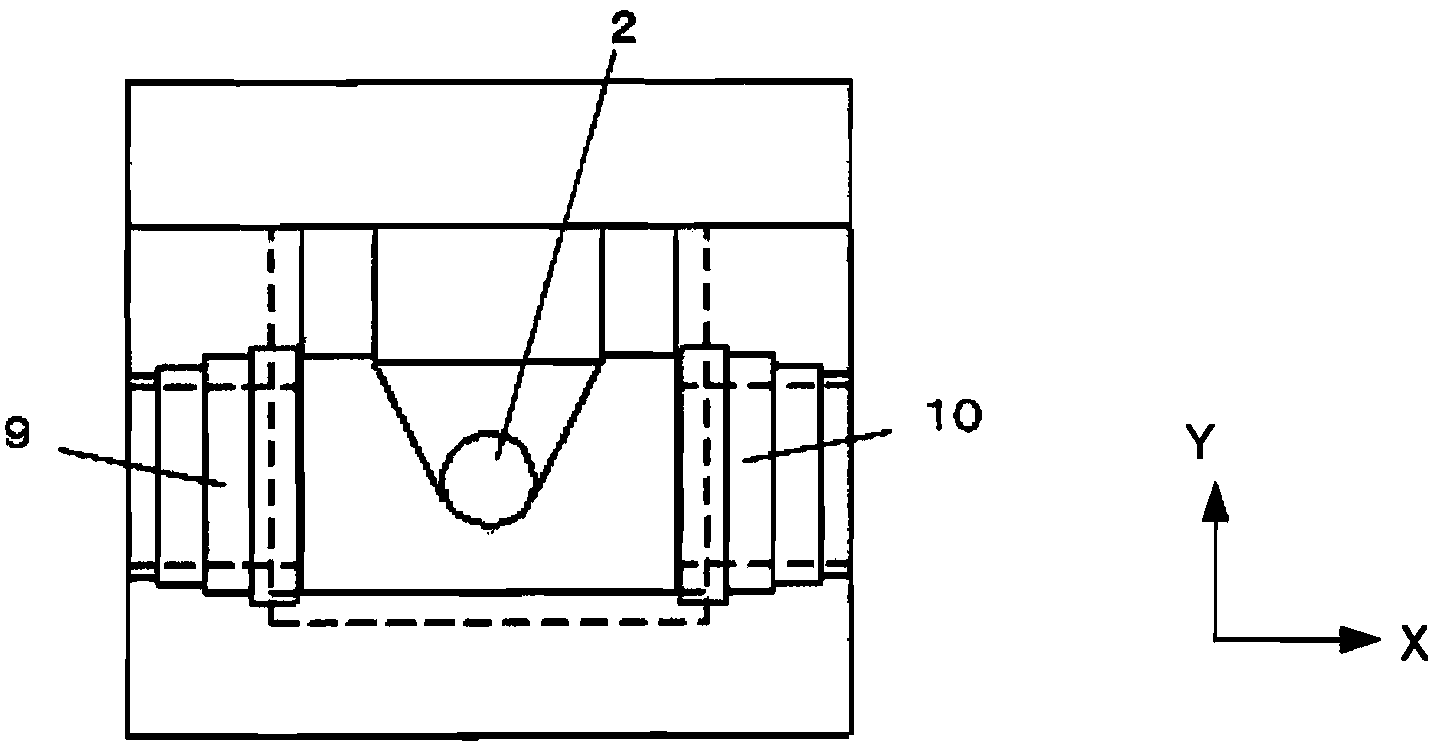

[0030] use Figure 1A and Figure 1B A first example of a machine tool having a telescopic cover (telescopic cover) will be described.

[0031] The processing area formed on the upper part of the bed 11 is covered by the guard plate 1 . A column 12 on which the main shaft 2 is mounted is erected on the bed 11 . A tool 3 is mounted on the spindle 2 . The spindle 2 is controlled so as to be able to move up and down relative to the table 5 (that is, to be able to move in the Z-axis direction). A saddle 6 is supported on the bed 11 , and a workbench 5 is supported on the saddle 6 . The workpiece 4 is placed on the table 5 . The saddle 6 moves in the Y-axis direction on the bed 11 , and the table 5 moves in the X-axis direction perpendicular to the Y-axis on the saddle 6 .

[0032] Symbols 7 and 8 are telescopic covers, which prevent the chips and cutting fluid generated during the processing of the workpiece 4 from scattering in a wide range. The movable end) is attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com