Stitch structure of double-chain-ring seam

A double link and stitch technology, which is applied to the thread cutting mechanism in the sewing machine, the thread hook for sewing machines, the ferrule mechanism for sewing machines, etc., can solve the problem of stitch opening, side wave and movement, stitch M opening and other problems to achieve the effect of preventing the stitches from opening and strengthening the pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Hereinafter, an embodiment of the present invention will be described based on the drawings.

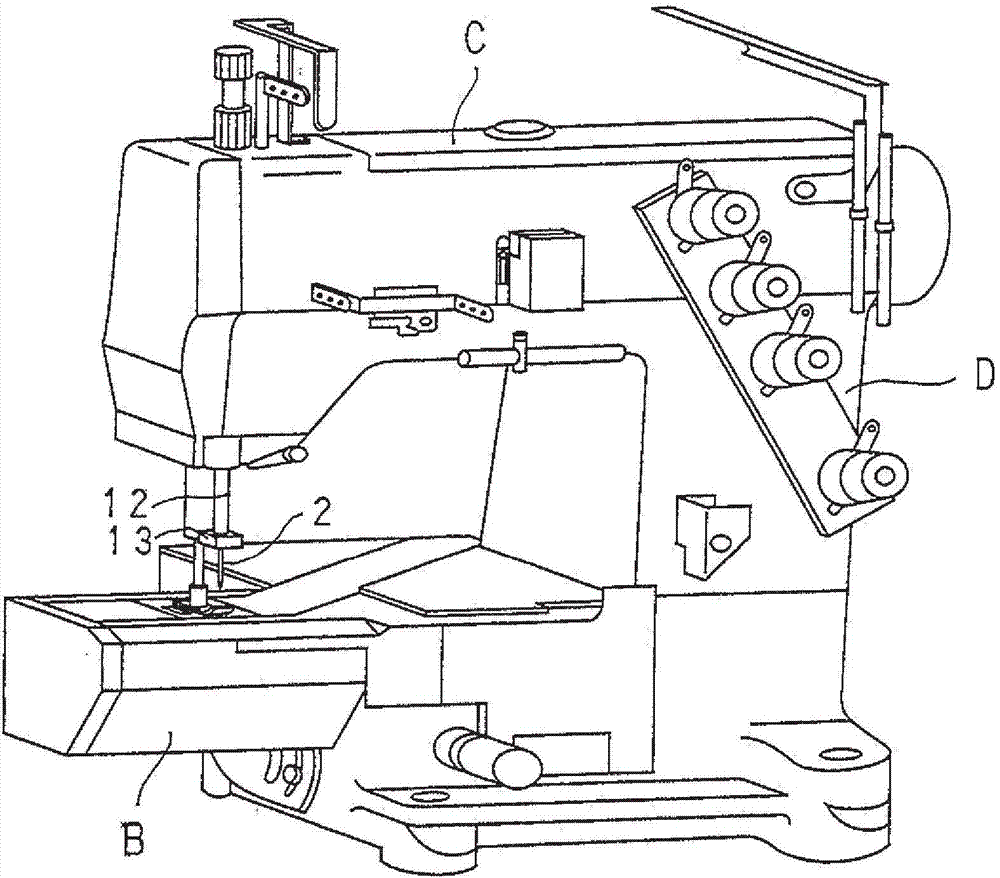

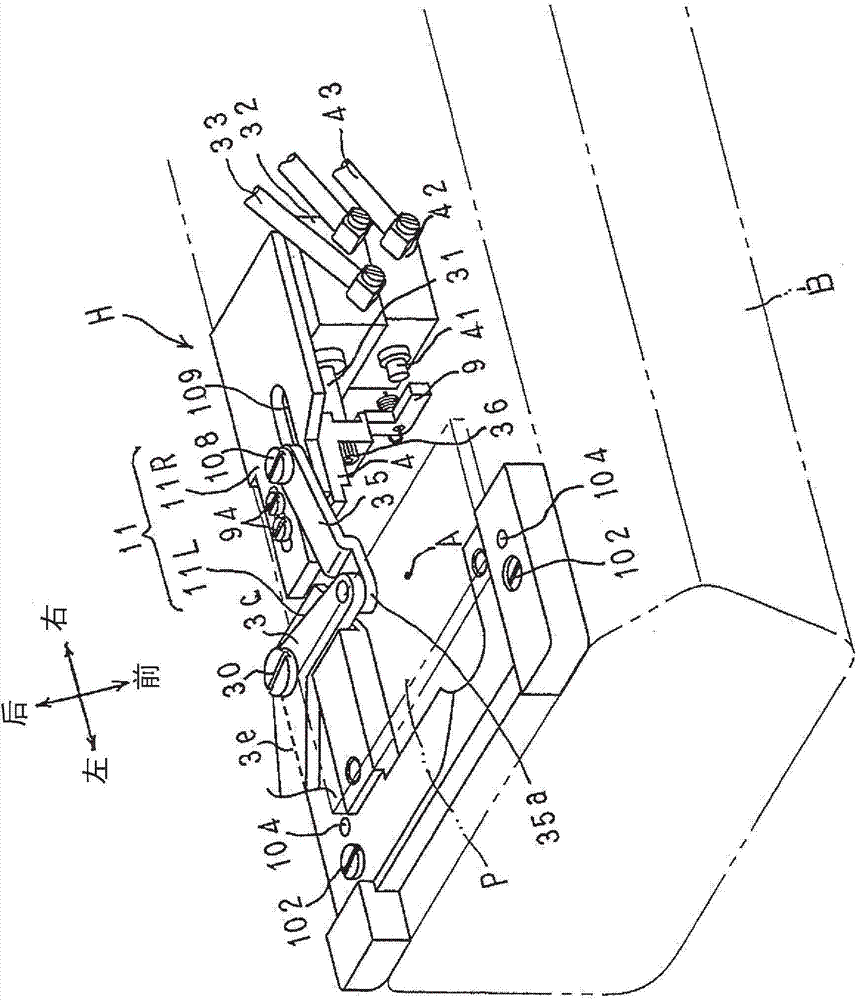

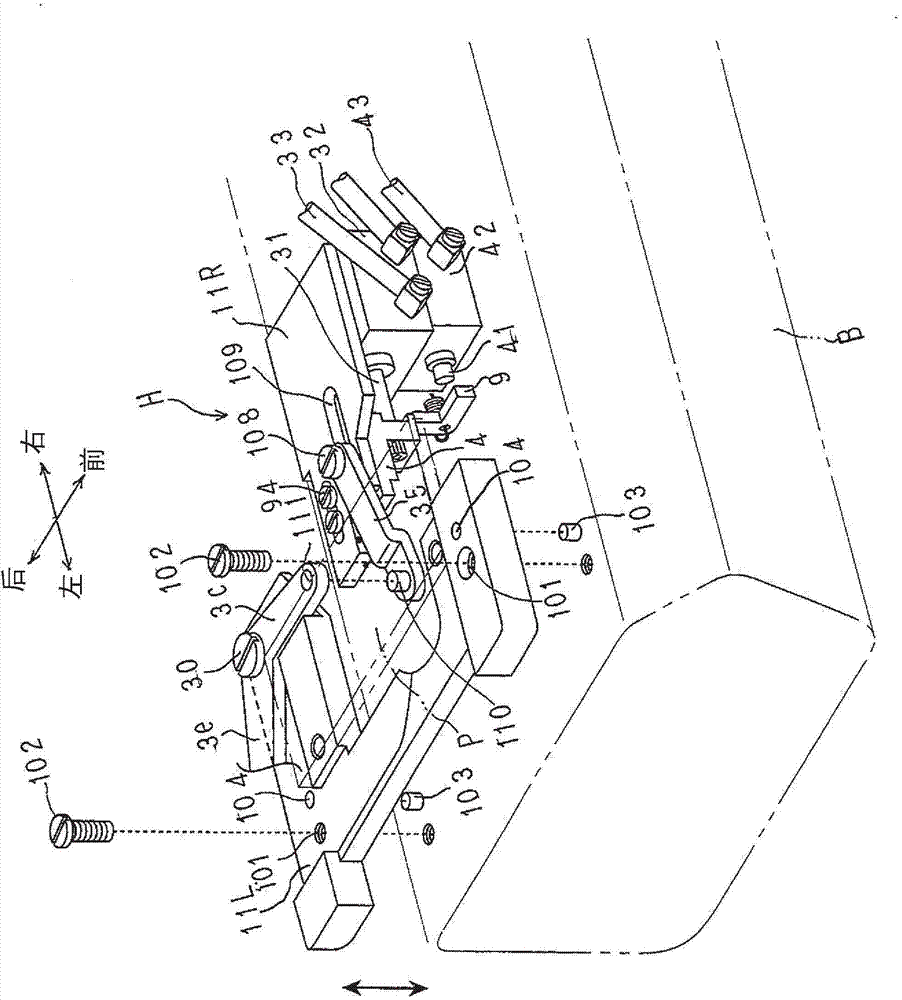

[0069] figure 1 It is a perspective view of the overall appearance of the horizontal cylinder type double-link sewing machine of the first embodiment used to obtain the stitch structure of the present invention, figure 2 and image 3 It is a perspective view showing the structure of the main part of the stitch opening prevention device installed on the horizontal cylinder type double-link sewing machine of the first embodiment, Figure 4 It is a plan view showing the structure of the main part of the above-mentioned stitch opening prevention device. In the following instructions, use Figure 2 ~ Figure 4 The "left, right" and "front, back" expressions shown by the arrows in the middle will explain. Here, "front" is the side close to the sewing manufacturer, "back" is the side away from the sewing manufacturer, and "left and right" are "left and right" when viewed from the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com