Stitch structure of double chain loop seam

一种双链环、线迹的技术,应用在缝纫机用套圈机构、缝纫器械、缝纫机元件等方向,能够解决侧波及移动、线迹开线、系紧不足等问题,达到强化压紧、防止线迹开线的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Embodiments of the present invention will be described below based on the drawings.

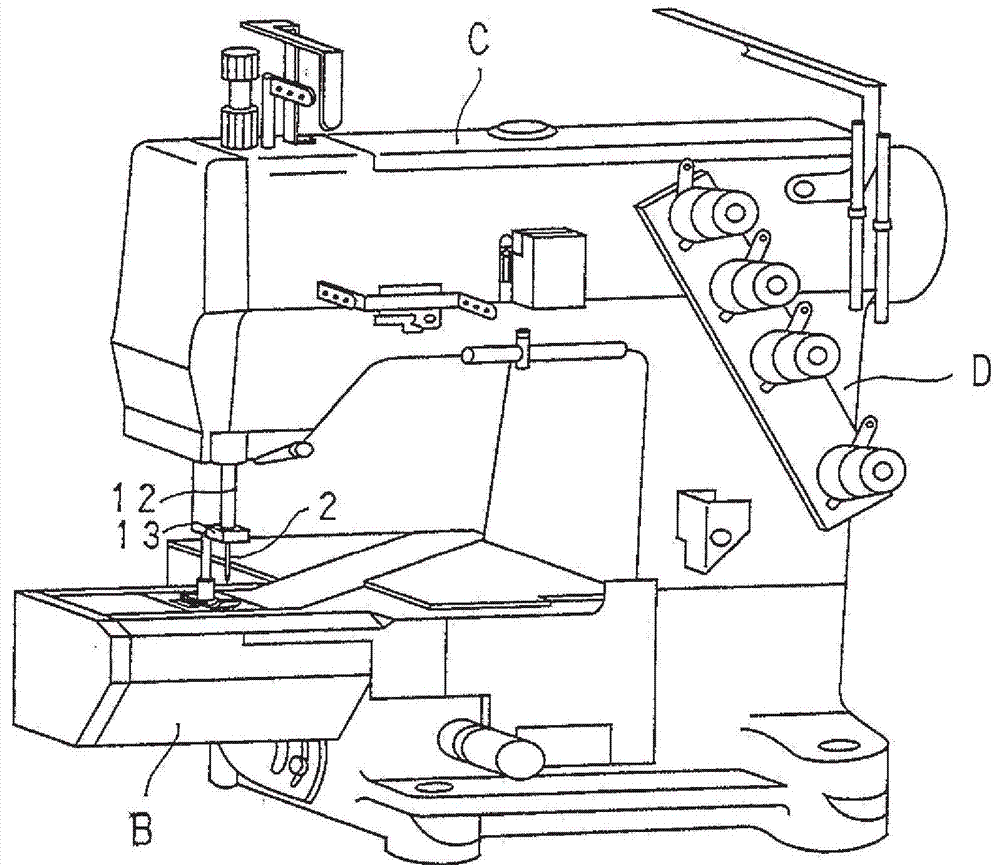

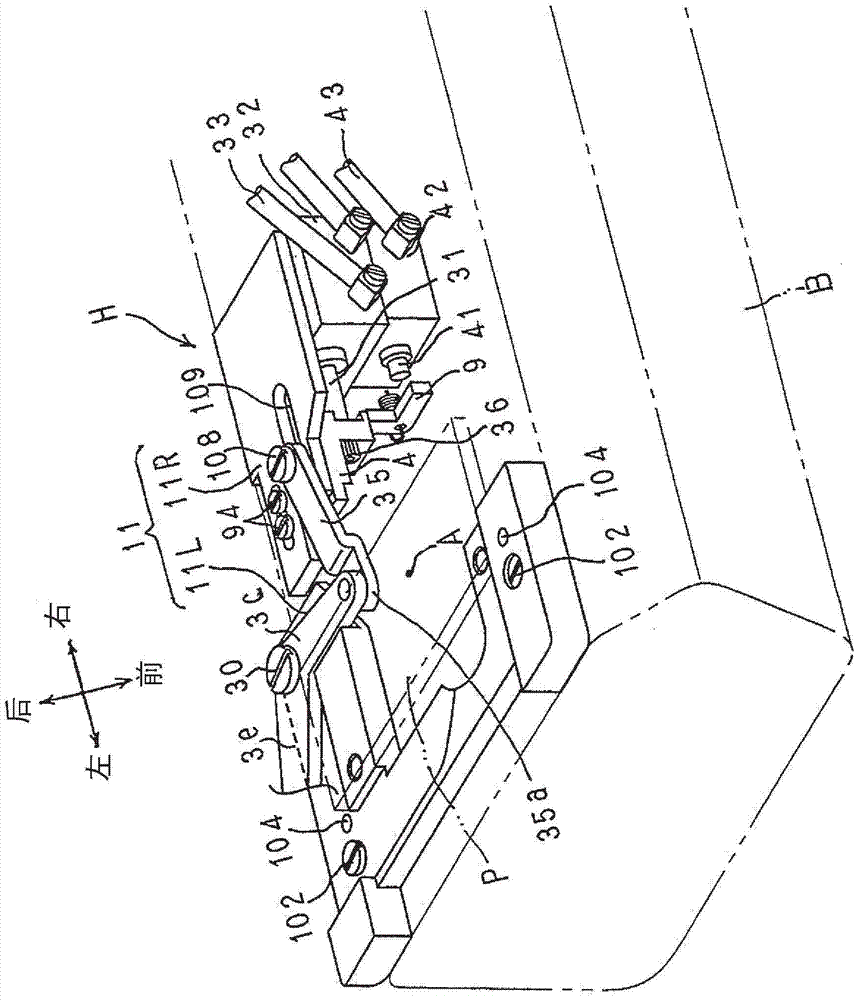

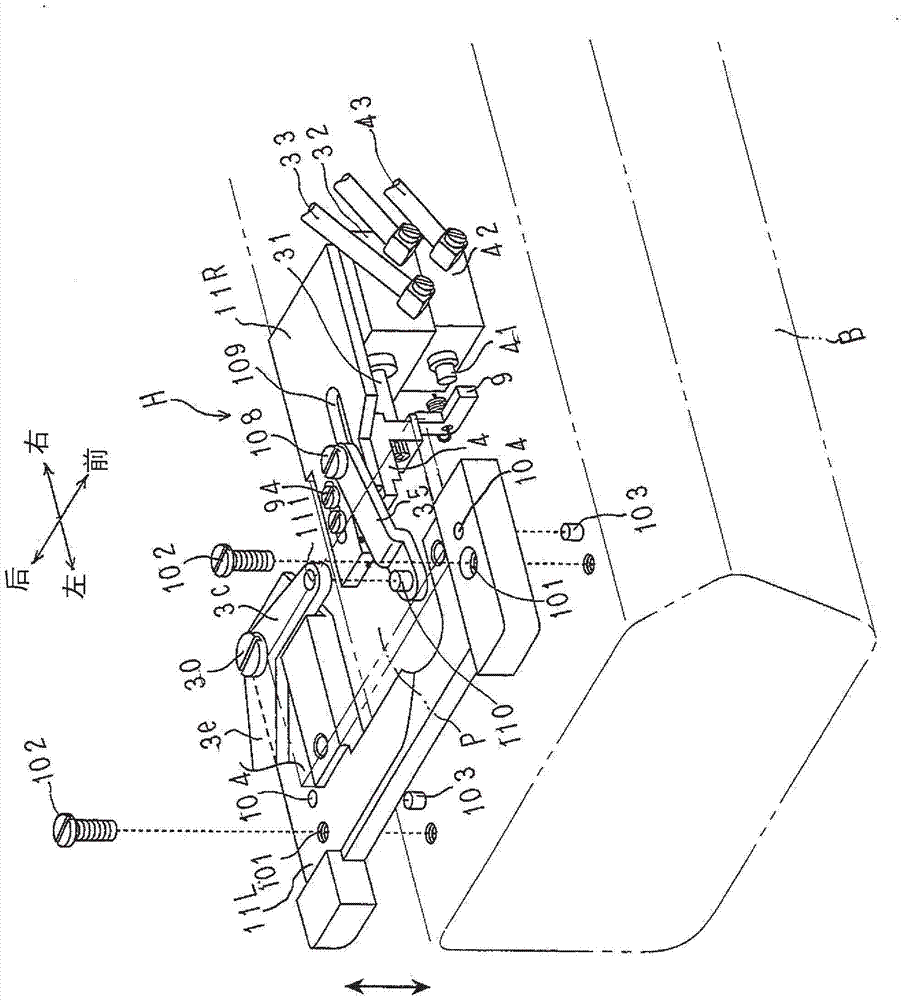

[0069] figure 1 It is a perspective view of the overall appearance of the horizontal cylinder type double chain link sewing machine of the first embodiment used to obtain the stitch structure of the present invention, figure 2 and image 3 It is a perspective view showing the structure of the main part of the stitch preventing device mounted on the horizontal cylinder type double chain link sewing machine according to the first embodiment, Figure 4 It is a plan view showing the structure of the main part of the above-mentioned stitch preventing device. In the instructions below, use Figure 2 ~ Figure 4 The expressions "left, right" and "front, back" indicated by the middle arrows are used for explanation. Here, "front" is the side close to the sewing operator, "rear" is the side away from the sewing operator, and "left and right" are "left and right" when viewed from the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com