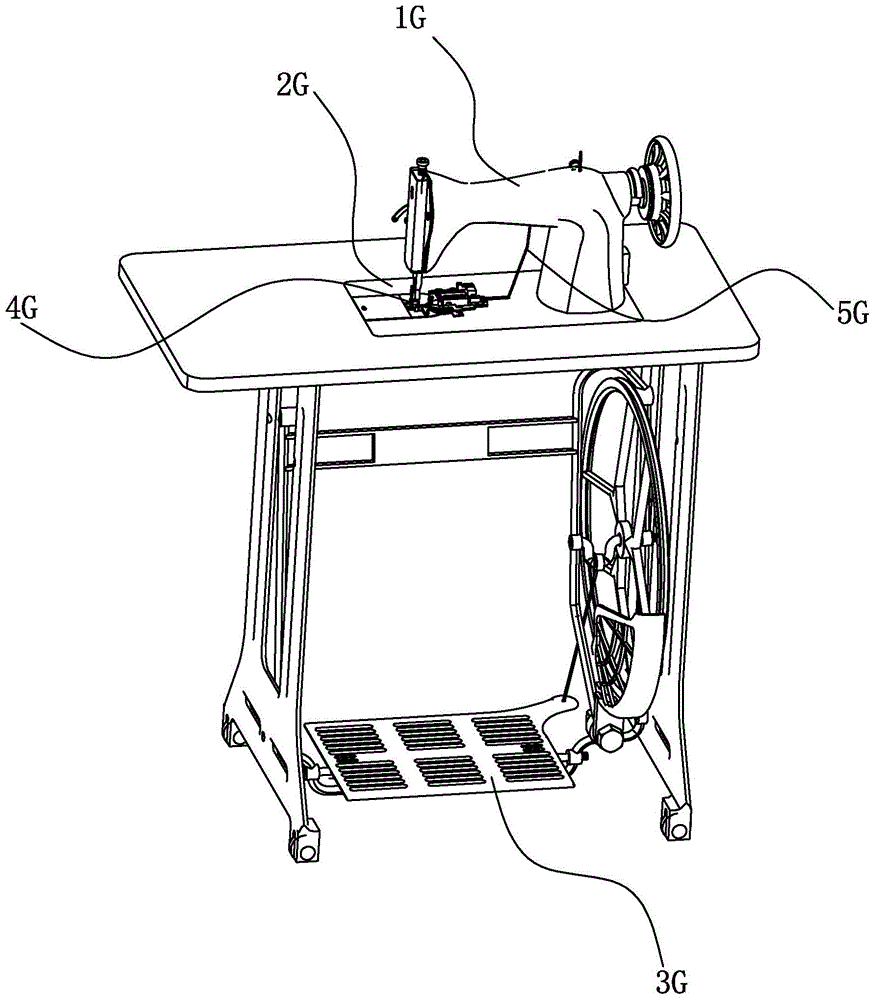

Socketing machine

A technology of looping machine and sewing machine, which is applied to the looping machine, cloth feeding mechanism, and sewing machine components connecting knitted fabrics. It can solve problems such as lack of elasticity, weak stitches, and uneven surface wrinkles, so as to prevent pulling out Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

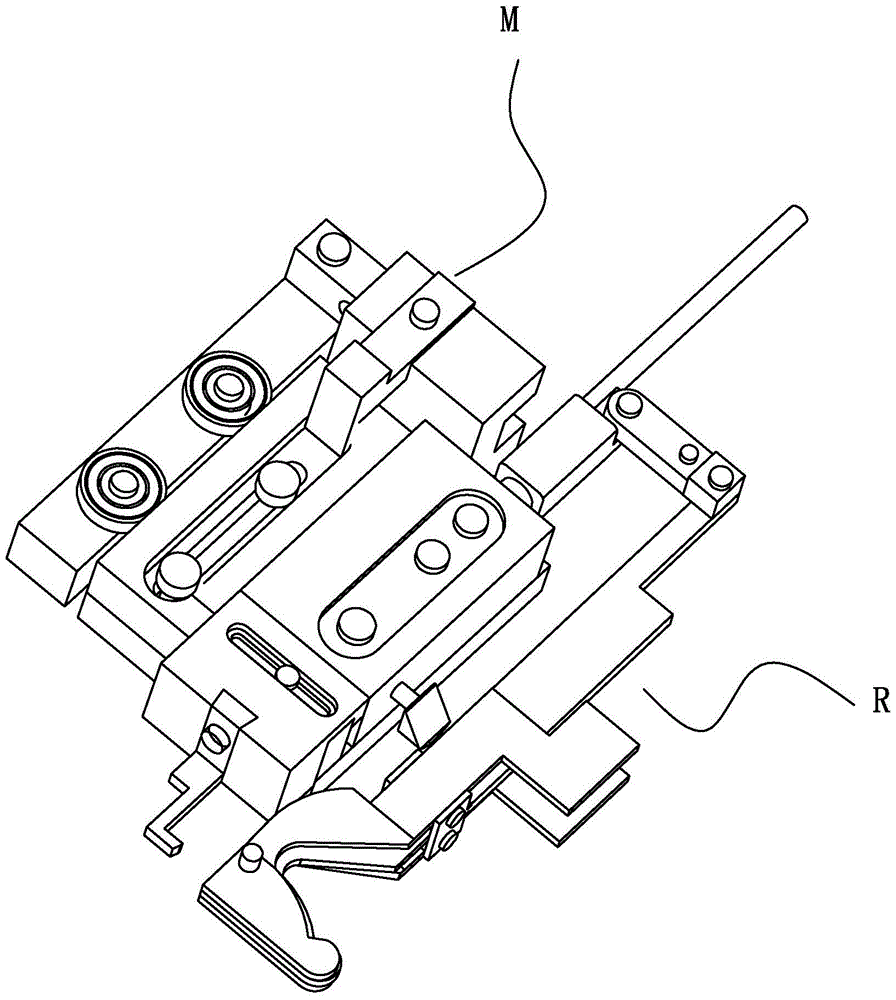

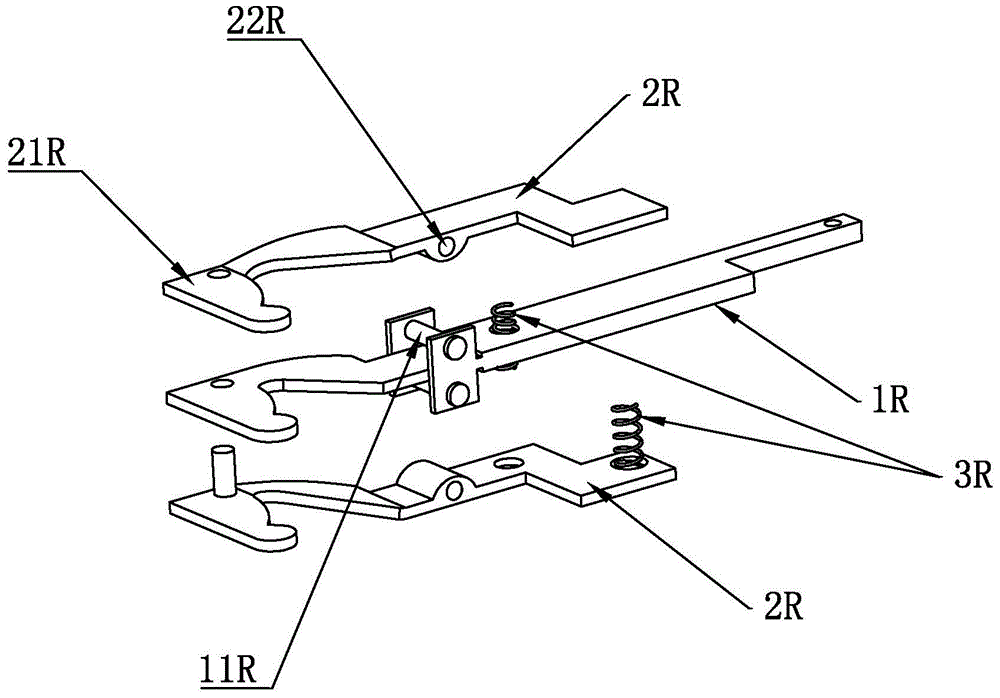

[0022] refer to Figure 1 to Figure 6 The embodiment of the threading machine of the present invention will be further described.

[0023] In this embodiment, at first, according to the model of the cuff to be processed and the model of the sewing machine body 1G, the width of the cuff to be sewn is determined, the adjusting base 1M is installed on the needle plate 2G, and the first adjusting block 2M is slid to be installed on the first Adjust the distance between the second adjustment block 3M and the presser foot 4G on the adjustment block 2M, and then adjust the positioning block 11M so that the hook portion of the positioning block 11M hooks the first adjustment block 2M firmly, thus determining the first adjustment block 2M limit position, and under the action of the tension spring 4M, ensure that the first adjustment block 2M is always in close contact with the positioning block 11M; then adjust the auxiliary adjustment block 31M, and slide the auxiliary adjustment bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com