Building board cutting device

A technology for cutting devices and building boards, applied to clamping devices, sawing equipment, wood processing appliances, etc., can solve the problems that the adjustment method cannot meet the actual adjustment needs, and achieve the effect of strong flexibility and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

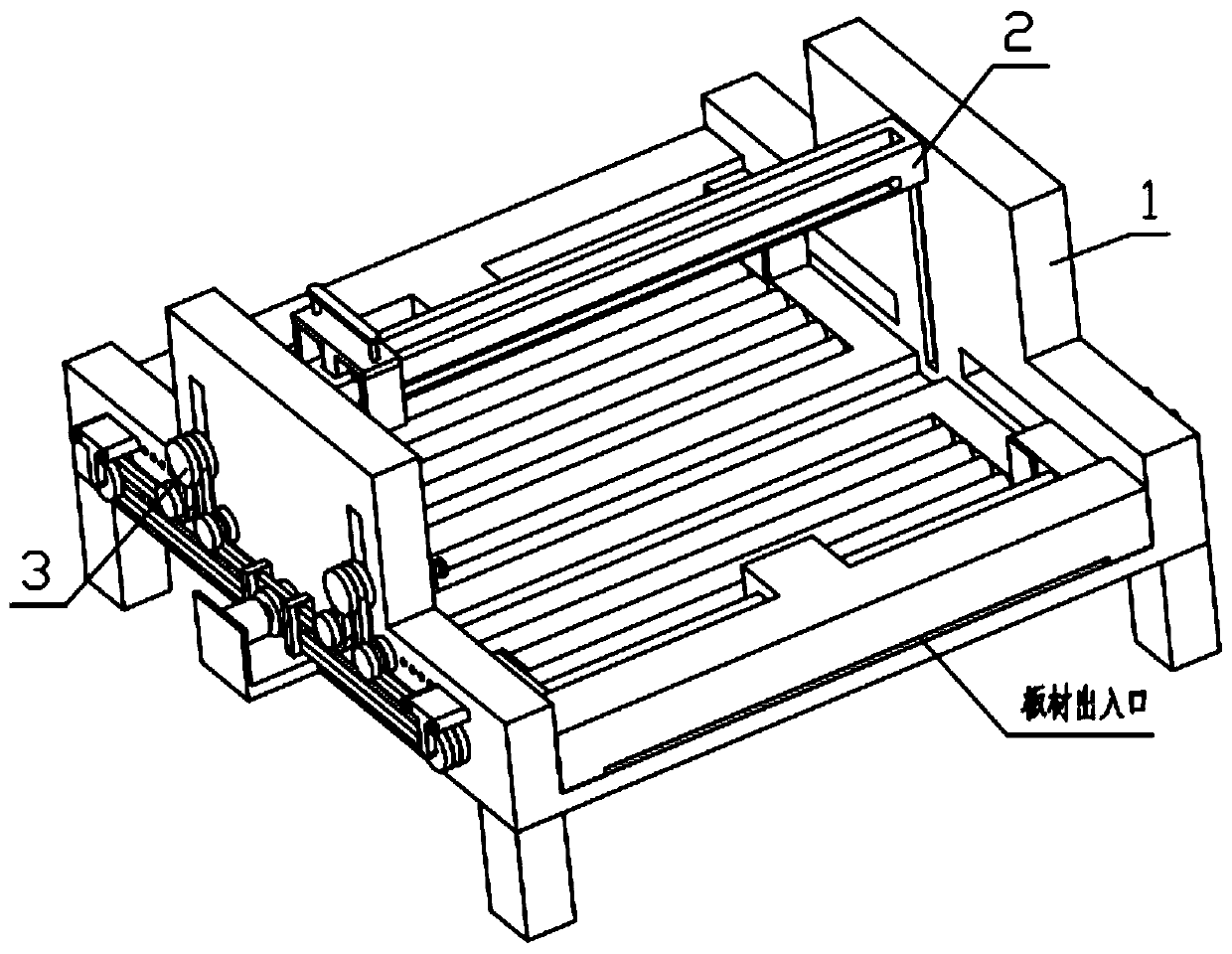

[0030] Combine below Figure 1-13 Describe this embodiment, a building board cutting device, including a device base 1, a cutting mechanism 2 and a centralized adjustment mechanism 3, the cutting mechanism 2 is movably installed on the device base 1, and the centralized adjustment mechanism 3 is installed on the device base 1 .

specific Embodiment approach 2

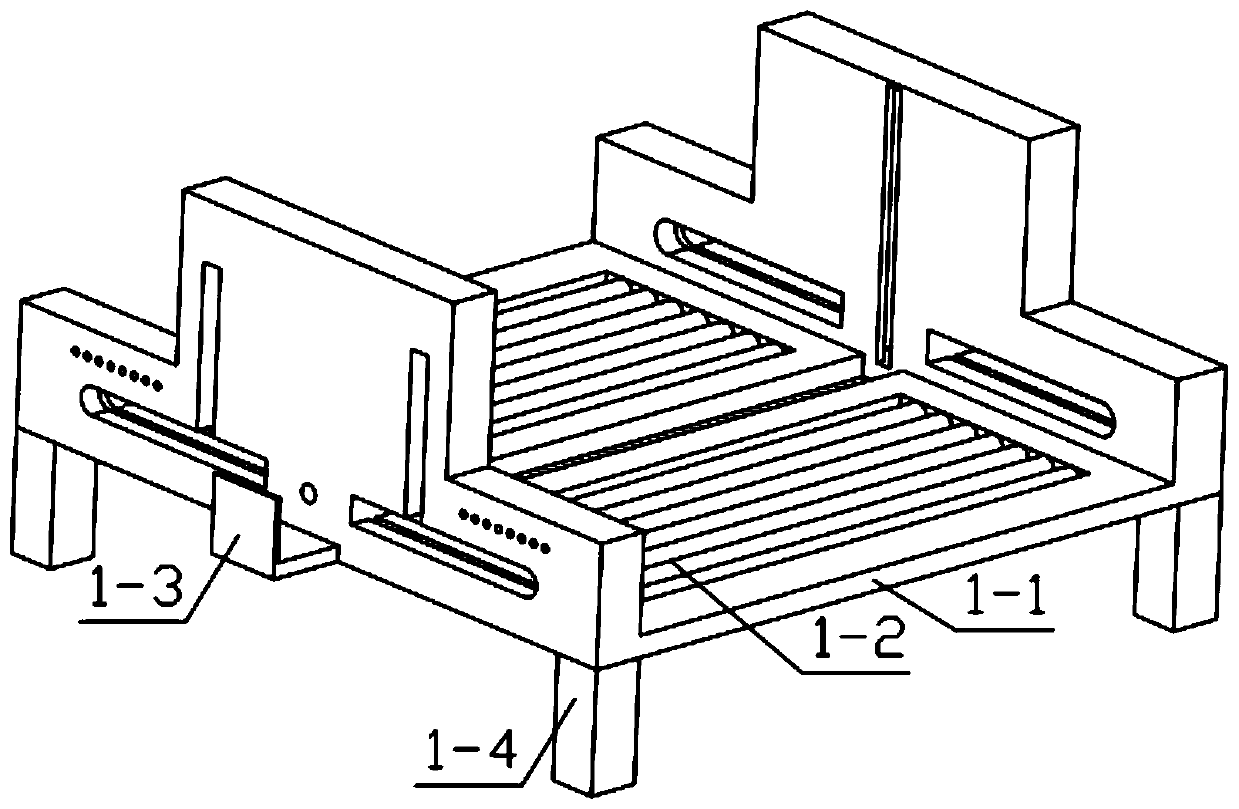

[0032] Combine below Figure 1-13 This embodiment will be described. This embodiment will further describe Embodiment 1. The device base 1 includes a mounting frame main body 1-1, a transmission roller 1-2, an L-shaped mounting plate 1-3, and an anchor 1-4. The feet 1-4 are fixedly installed on the main body 1-1 of the installation frame, the transmission roller 1-2 is rotatably installed on the main body 1-1 of the installation frame, and the L-shaped installation plate 1-3 is fixedly installed on the main body 1-1 of the installation frame .

specific Embodiment approach 3

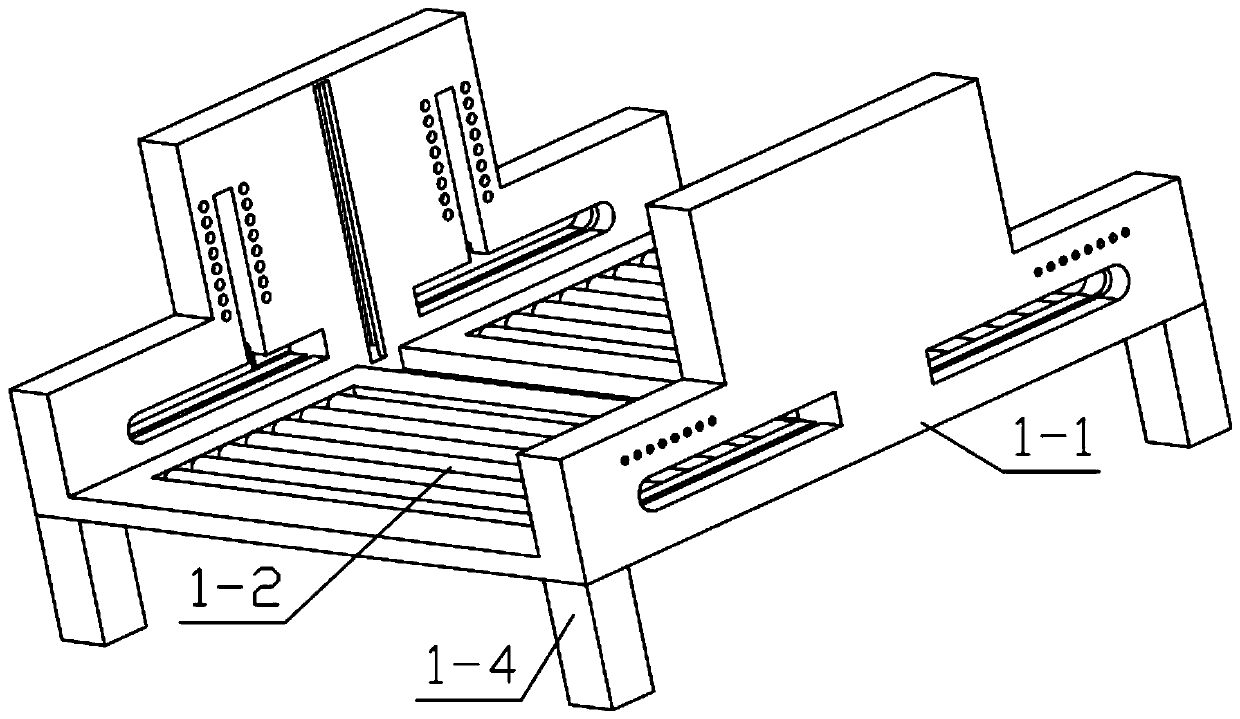

[0034] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain Embodiment 2, the cutting mechanism 2 includes a sliding slat 2-1, a support spring 2-2, a handle 2-3, a U-shaped frame 2-4, a roller Shaft wheel 2-5, motor 2-6, circular saw 2-7, balance column 2-8, auxiliary bearing 2-9, the number of support spring 2-2 has two, is fixedly installed on sliding slat 2 respectively On both sides of -1, the grip 2-3 is fixedly installed on the U-shaped frame 2-4, the auxiliary bearing 2-9 is fixedly installed on the through hole provided on the U-shaped frame 2-4, and the auxiliary bearing 2-9 is fixedly installed On the roller wheel 2-5, the roller wheel 2-5 is movably installed on the U-shaped frame 2-4, the motor 2-6 is fixedly installed on the U-shaped frame 2-4, and the output end of the U-shaped frame 2-4 A circular saw 2-7 is fixedly installed, and the other end of the circular saw 2-7 is rotatably installed on a balance column 2-8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com