Face yarn holder for sewing machine

A technology for holding devices and sewing machines, which is applied to the sewing machine's mechanism for cutting threads, sewing machine components, sewing machine housings, etc., and can solve the problems of fabric wrinkle processing, upper thread holding device size (large size, complex actuator, etc.) , to achieve the effect of preventing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

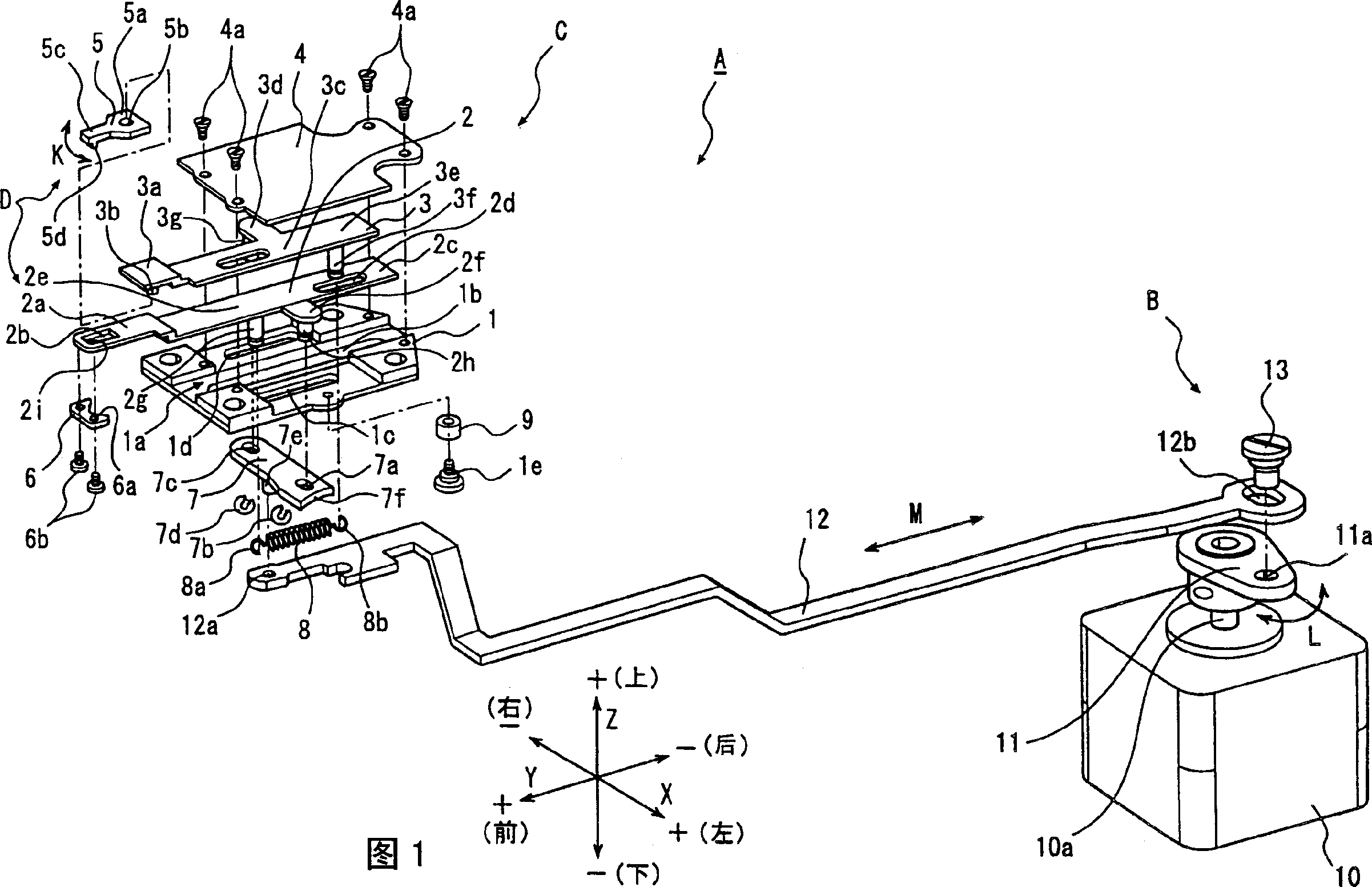

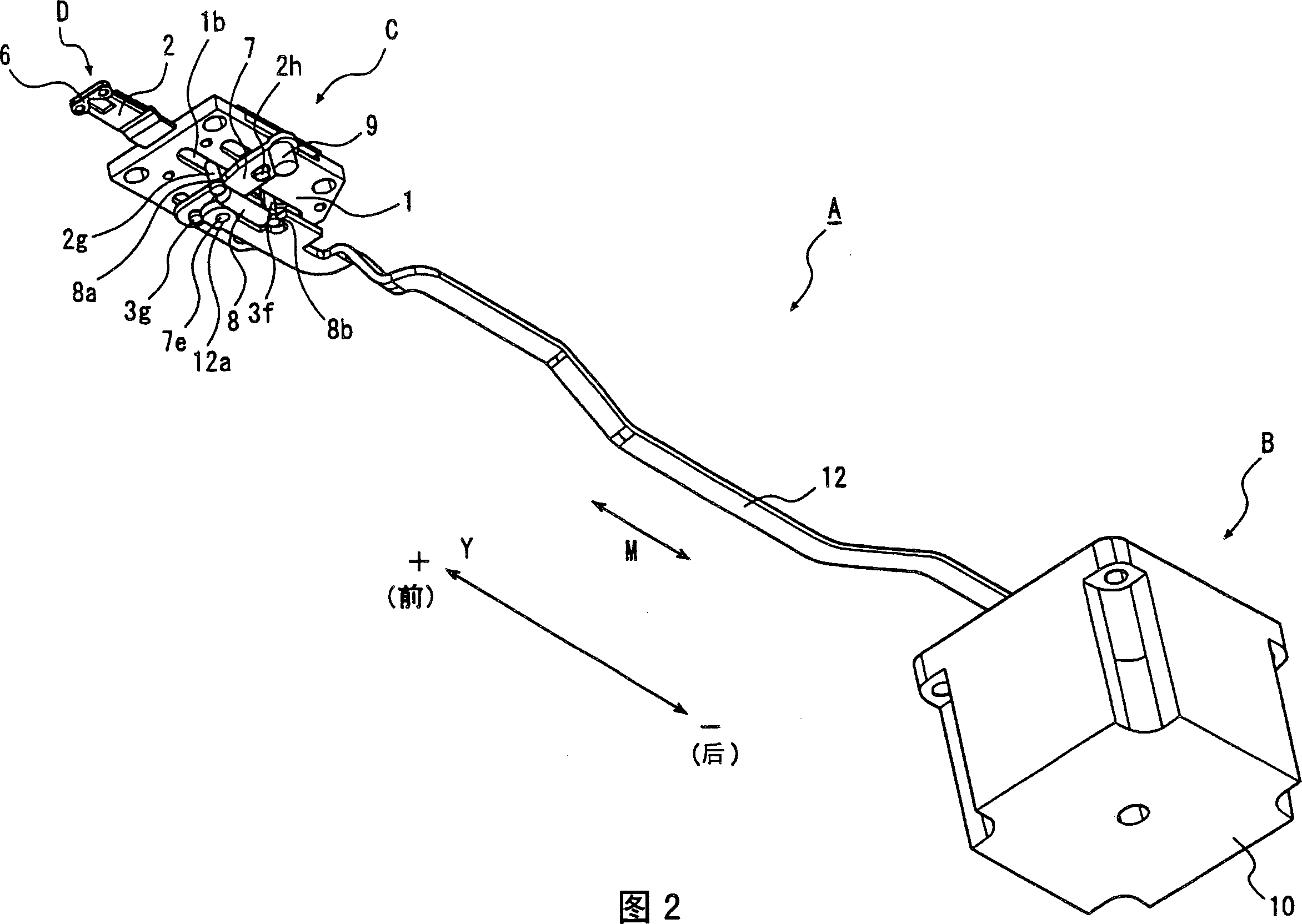

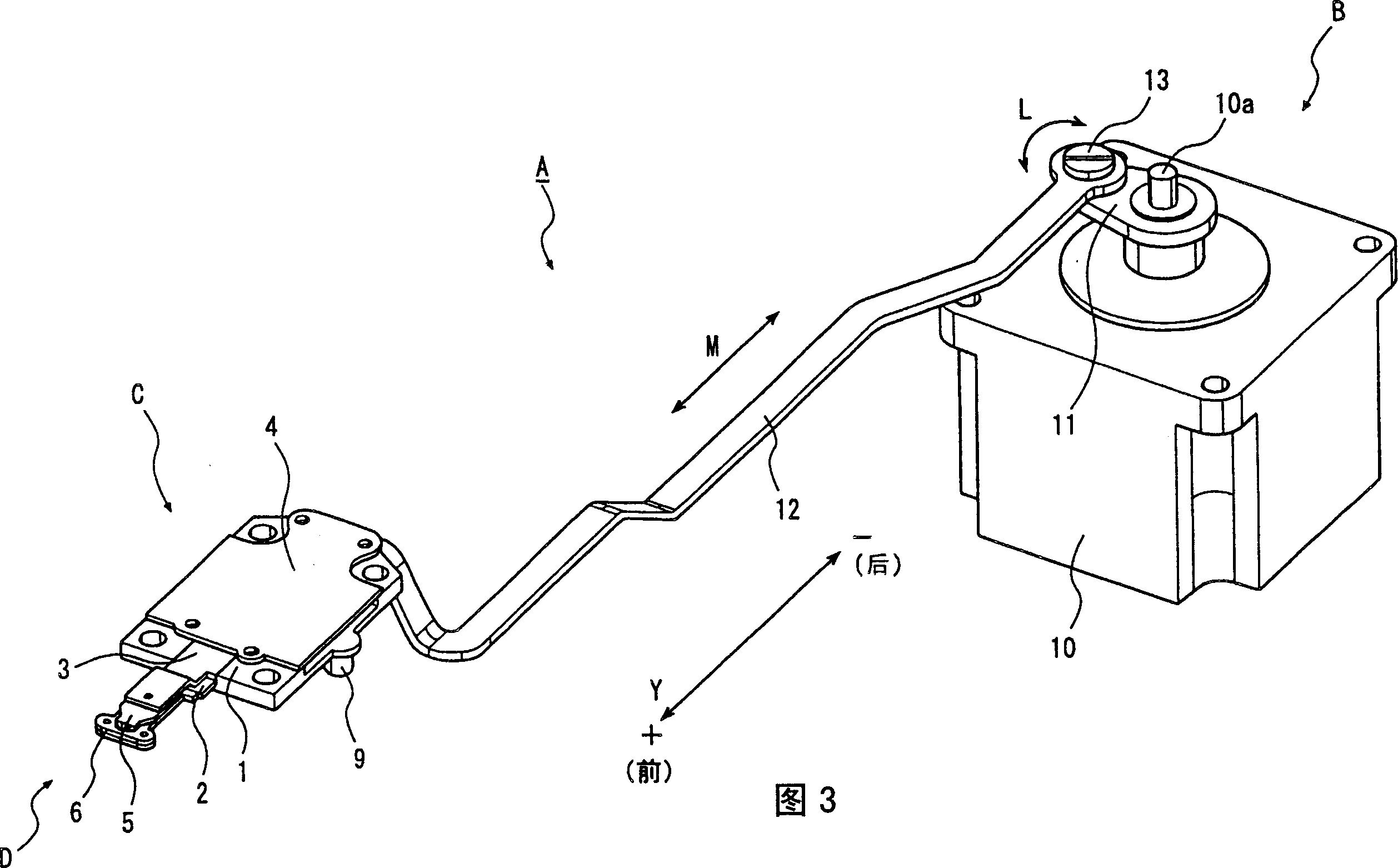

[0072] Hereinafter, embodiments of the needle thread holding device according to the present invention will be described with reference to the drawings. And, the upper thread holding device of the present invention is a device assembled on various sewing machines, and clamps the end of the upper thread passing through the needle when sewing starts under the needle plate, and holds the clamped surface. The end of the thread moves to the holding position away from the up and down movement path of the machine needle, and after the specified number of needles drop, the device related to the sewing machine upper thread holding device that releases the end of the clamped upper thread.

[0073] Next, the specific structure of the needle thread holding device will be described.

[0074] Figure 1~ Figure 5 As shown, the upper thread holding device A is mainly composed of: a moving mechanism B capable of moving in the forward and backward direction; The clamping mechanism D that rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com