Method for controlling chassis of full-hydraulic drive high-speed rice transplanter

A control method and technology for a rice transplanter, which are applied in planting methods, transplanting machinery, applications, etc., can solve the problems of difficult remote manipulation, insensitive adjustment of the lifting mechanism of the seedling box, unfavorable automation, and intelligent control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

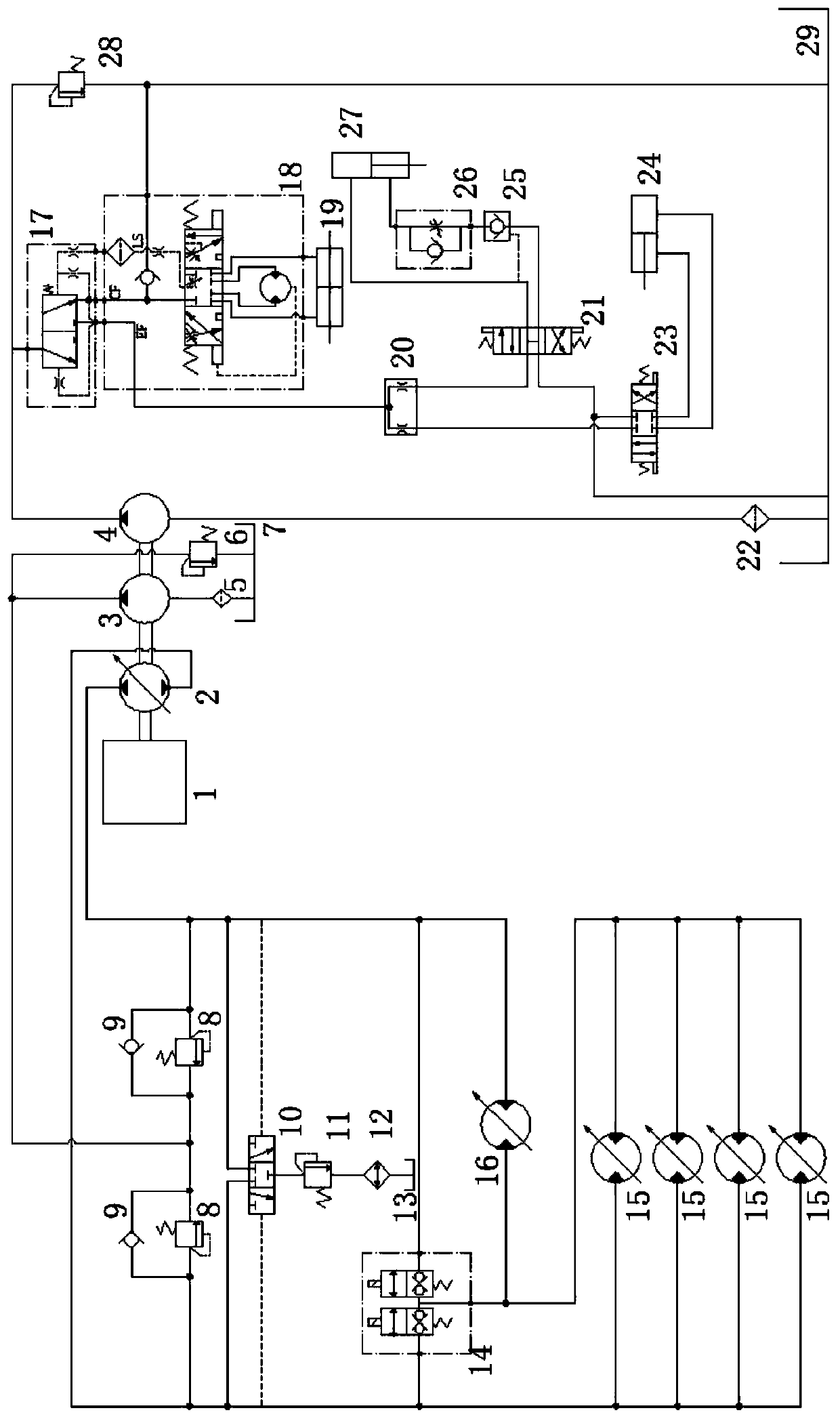

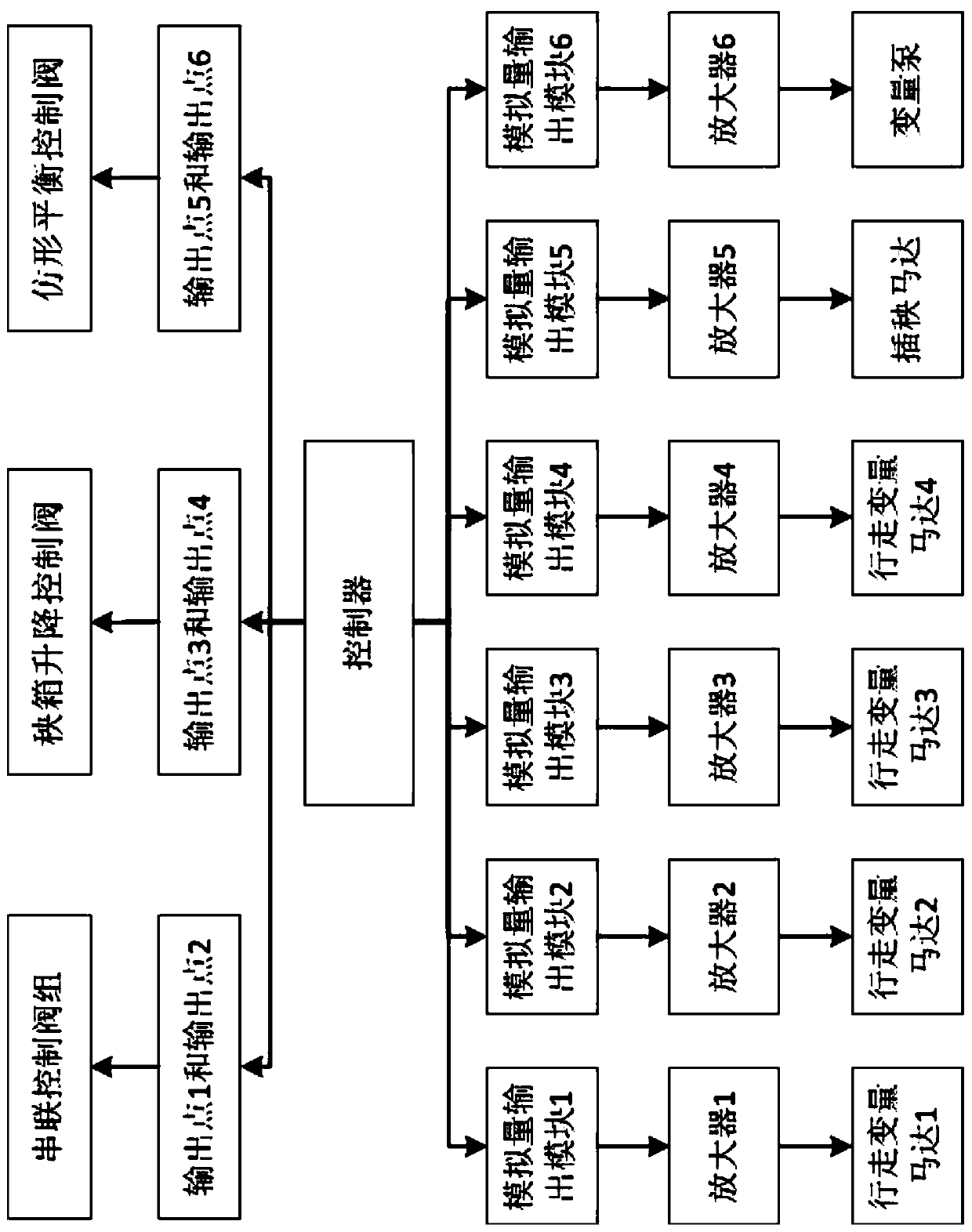

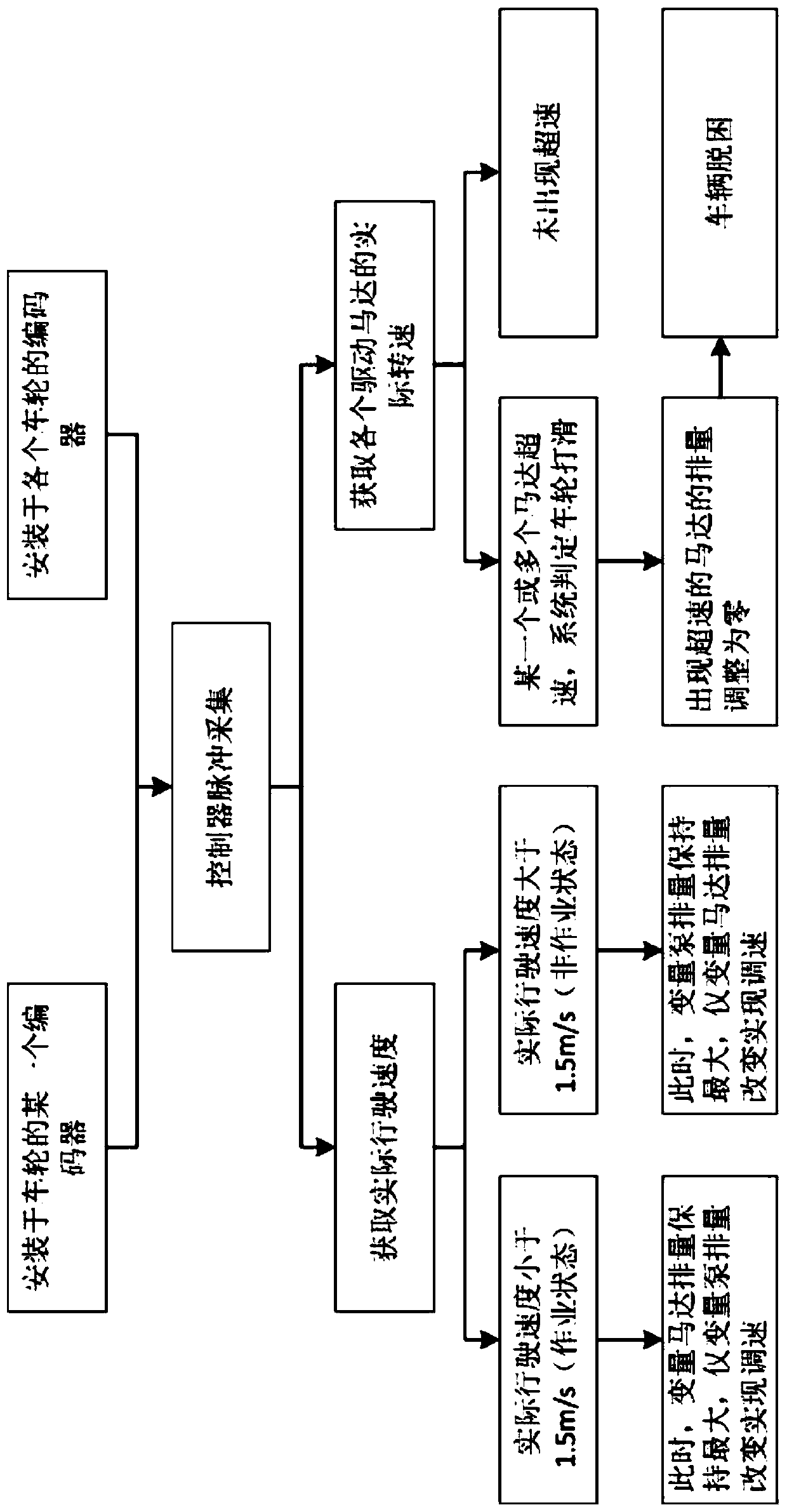

[0044] Such as Figure 1 to Figure 4 As shown, the present invention provides a control method for a fully hydraulically driven high-speed rice transplanter chassis. The fully hydraulically driven high-speed rice transplanter chassis includes a walking drive mechanism, a steering mechanism, a profiling balance mechanism, a seedling box lifting mechanism, and a gear pump. 4. Priority valve 17, diverter valve 20, horizontal inclination sensor installed on the seedling box, pressure sensor installed inside the middle floating plate, encoder A installed on the steering wheel, encoder B installed on the driving wheel, control device;

[0045] The traveling drive mechanism includes an engine 1, a plunger pump 2, an oil charge pump 3, four traveling variable motors 15, a rice transplanting motor 16 and a series control valve group 14;

[0046] The engine 1 is connected to the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com