Linear bearing used in high-precision zoom lens

A zoom lens and linear bearing technology, which is applied in the direction of linear motion bearings, bearings, shafts, bearings, etc., can solve the problems of difficulty in ensuring the accuracy of the optical axis movement amount, changes in the optical axis movement amount, etc., to reduce the optical axis movement amount, The effect of compact structure and exquisite design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

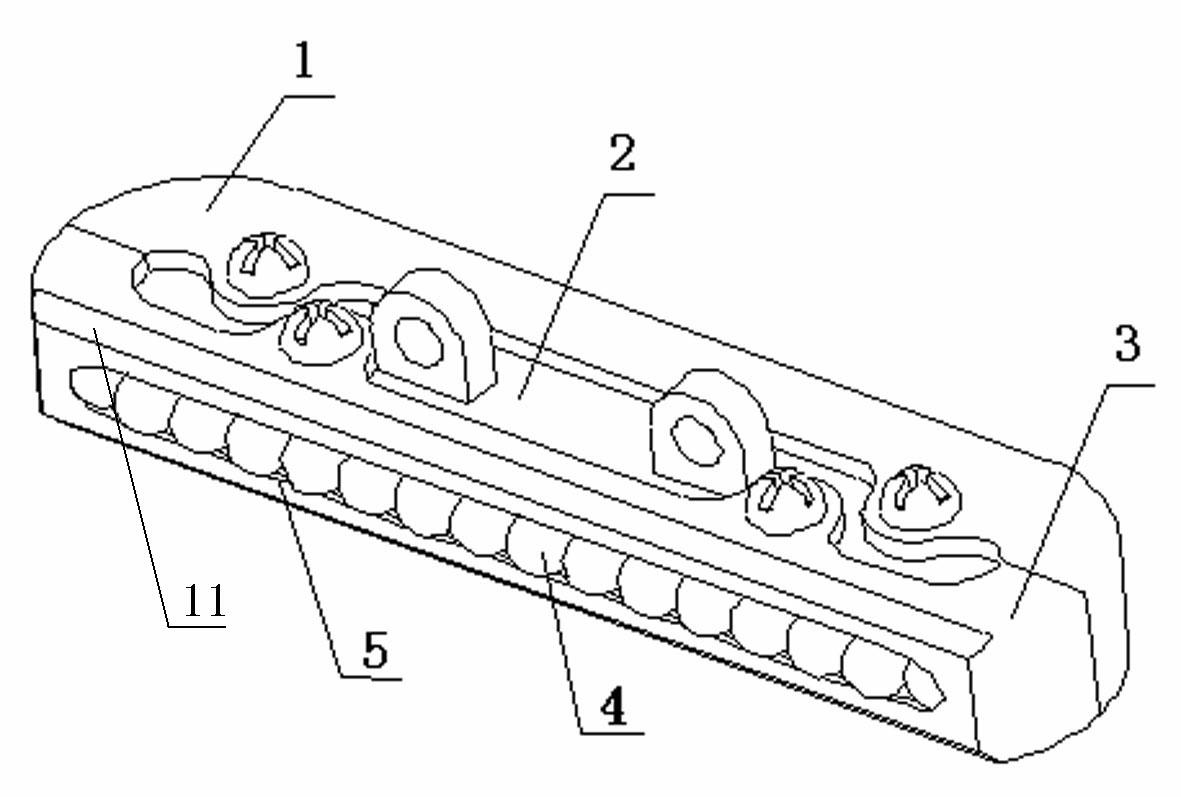

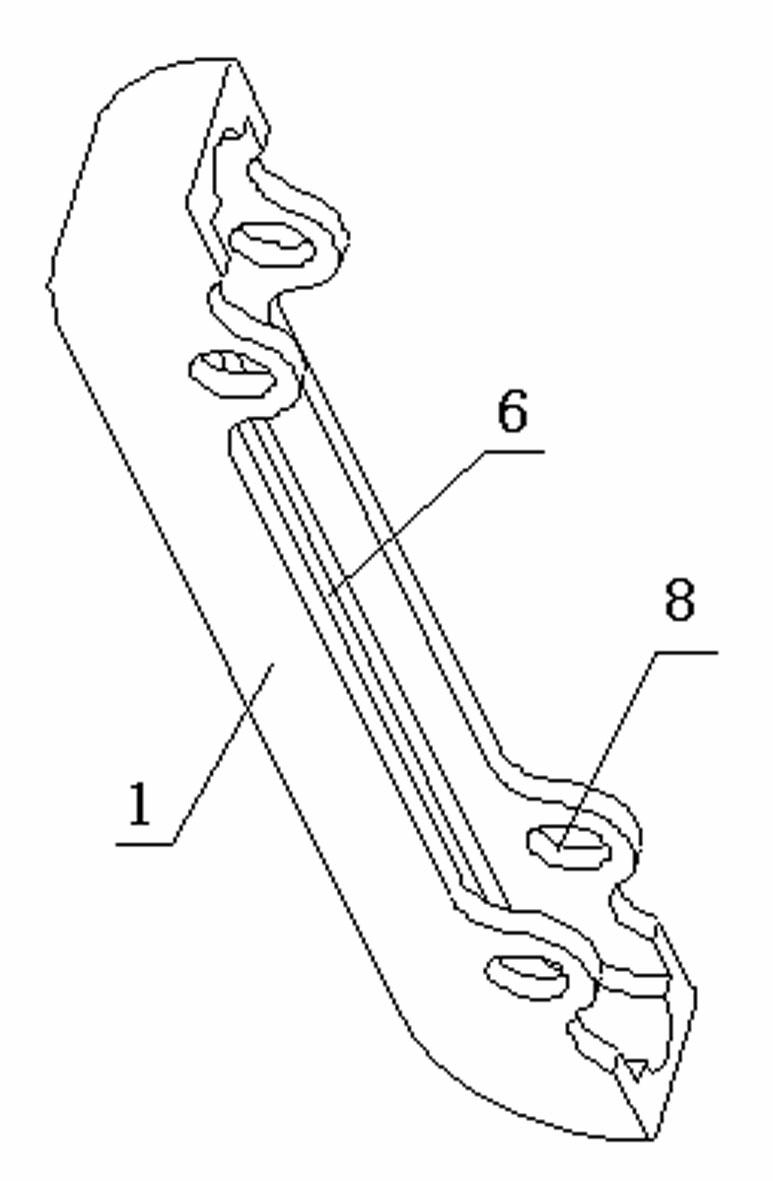

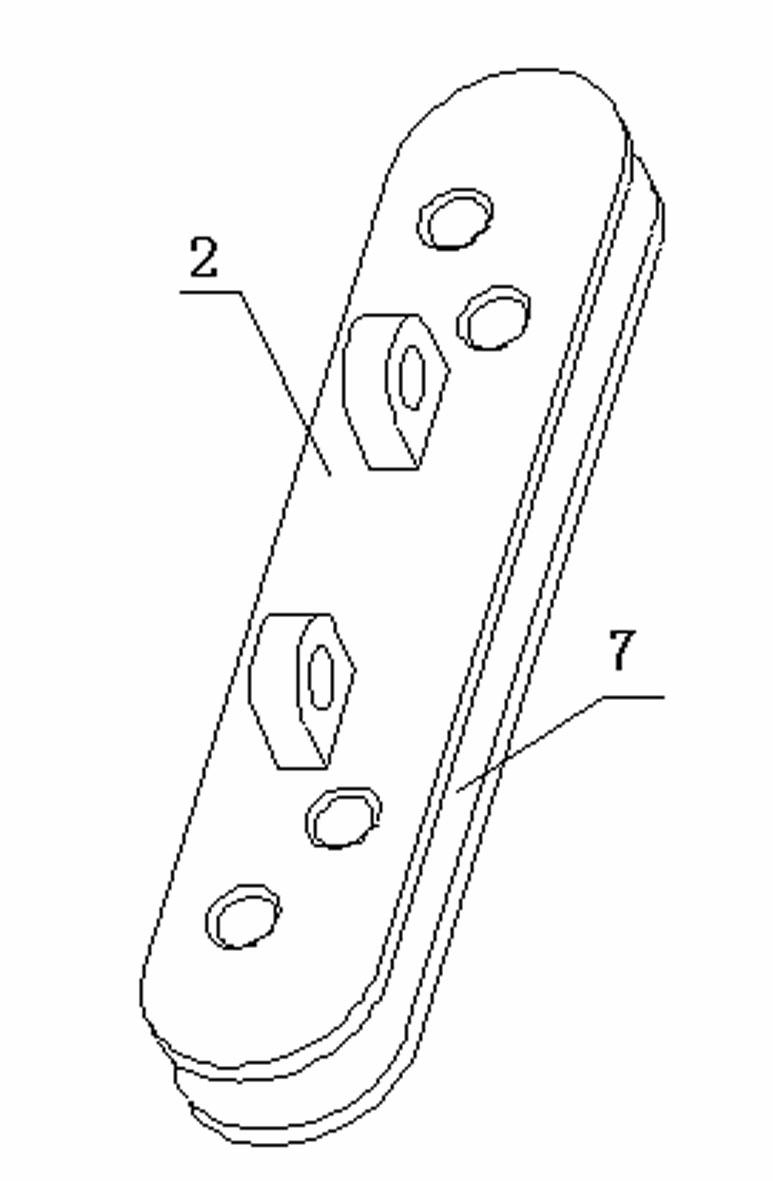

[0013] Such as figure 1 , 2 , The linear bearing for the high-precision zoom lens shown in 3 and 4 is composed of a cover body 1, a fixed frame 2, a sliding frame 3 and a steel ball 4. The connection between the fixed frame 2 and the zoom lens, the fixed frame 2 is a rectangular structure, its outer periphery is provided with an annular fixed frame chute 7, the cover body 1 is covered on one side of the fixed frame 2, and the inside of the cover body 1 A cover body chute 6 is provided, and the connection between the cover body 1 and the fixed frame 2 is a screw fastening connection, and the connection hole on the described cover body 1 is a waist-shaped hole 8, and its connection with the fixed frame can be adjusted. For the adjustment of the rolling clearance with the steel ball. The sliding frame 3 is covered on the other side of the fixed frame 2, and the connection between the sliding frame 3 and the fixed frame 2 is a screw fastening connection. The connection of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com