Diaphragm assembly

A diaphragm and component technology, applied in the direction of instruments, measuring devices, volume measurement, etc., can solve the problems of poor movement stability of the driving diaphragm, and achieve the effects of ensuring smooth movement, prolonging service life and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

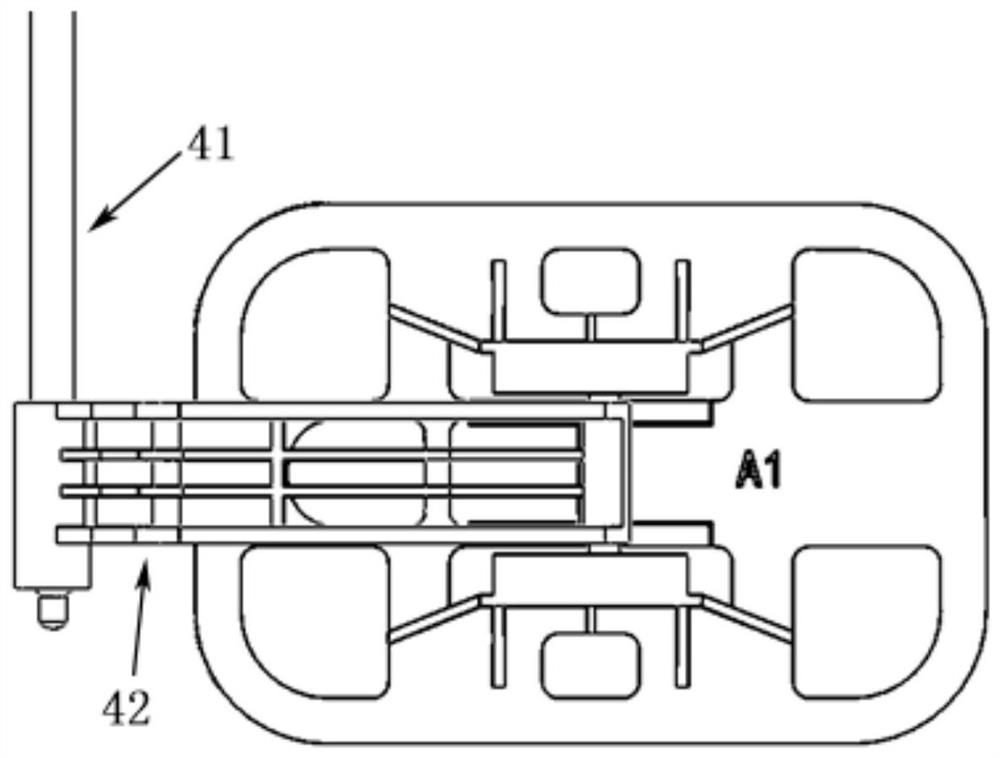

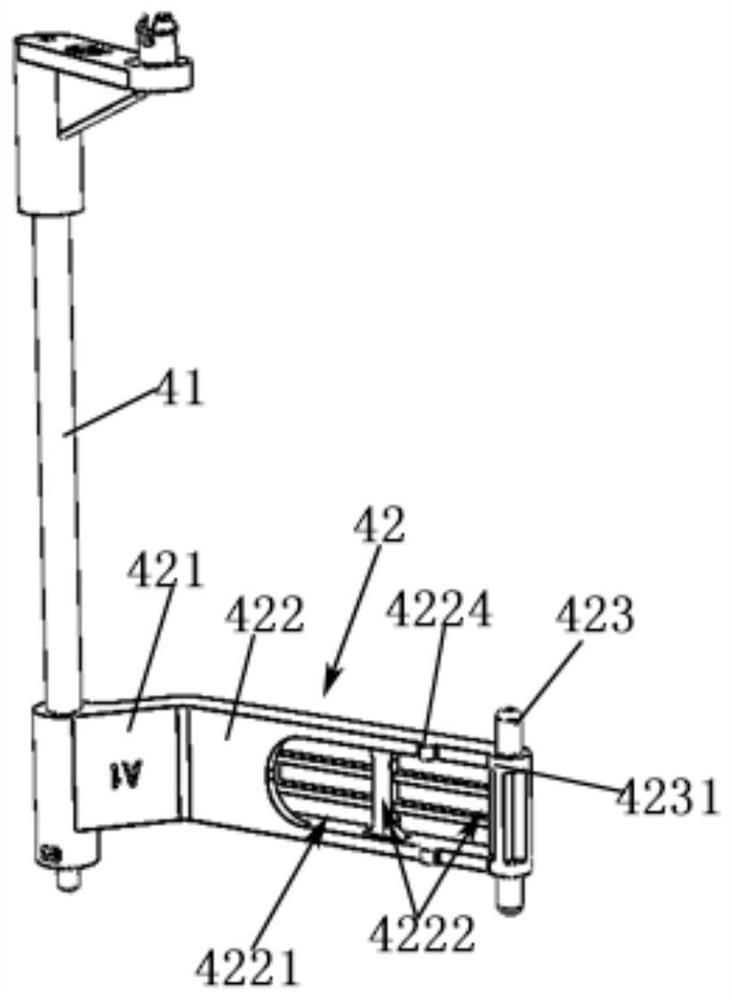

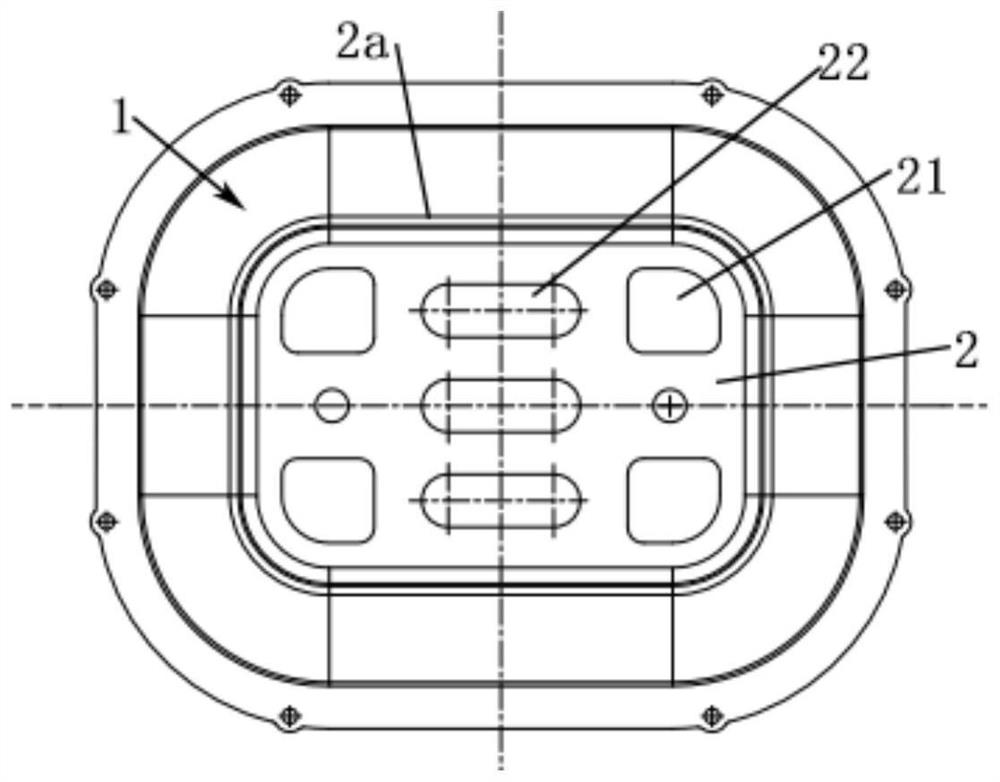

[0039] combinefigure 1 , image 3 and Figure 4 Therefore, the membrane structure of the present invention includes a membrane 1 , parallel plates 2 and clamping plates 3 respectively arranged on both sides of the membrane 1 and fixedly connected with the membrane 1 . According to an embodiment of the present invention, the parallel plate 2 is a double-sided galvanized plate, the sandwich plate 3 is a plastic material plate, and the diaphragm 1 is made of polyester fiber + NBR material. The sandwich plate 3, the diaphragm 1 and the parallel plate 2 are welded and connected to ensure that the parallel plate 2, the diaphragm 1 and the sandwich plate 3 are connected and fixed without falling off, and the durability and stable operation of the diaphragm structure of the present invention are improved sex.

[0040] It should be noted that, for the polyester fiber+NBR material of the diaphragm 1 of the present invention, the diaphragm 1 has no rigidity and can be bent in any direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com