Light pressing machine for fermented grains

A technology of light pressing and fermented grains, which is applied in the preparation of alcoholic beverages, etc. It can solve the problems of tilting the pressing panel, affecting the fermentation quality of fermented fermented grains, and uneven pressing of fermented fermented grains, so as to ensure stability, good technical effect, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

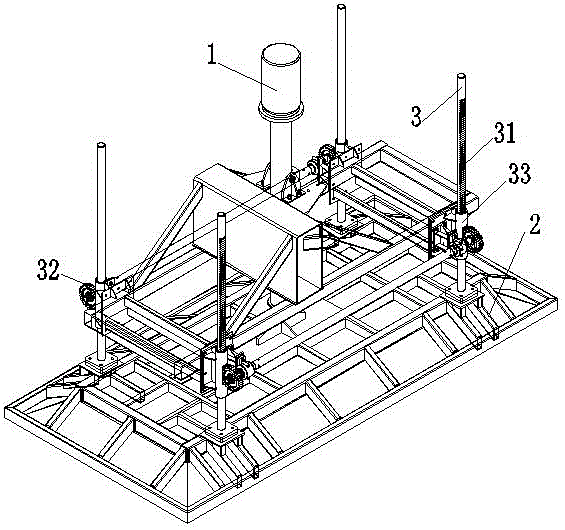

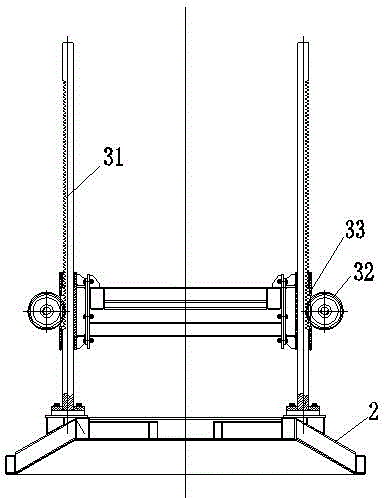

[0020] The present invention includes a driving device 1 and a pressing panel 2 driven up and down by the driving device 1, and a guide device 3 for guiding the pressing panel 2 to move up and down smoothly;

[0021] The guide device 3 includes a rack shaft 31 fixedly connected to the pressing panel 2, and a gear 32 corresponding to the rack shaft 31. The rack shaft 31 is covered with a fixed guide sleeve 33, so The guide sleeve 33 is provided with a slotted hole, and the gear 32 is inserted into the slotted hole to cooperate with the rack shaft 31 .

[0022] A rack is provided on the side of the rack shaft 31 facing the gear 32 , and the side of the rack shaft 31 facing away from the gear 32 is an optical axis.

[0023] Four sets of guide devices 3 are provided, and the four sets of guide devices 3 are arranged at the four corners of the rectangular frame.

[0024] The driving device is in the form of an electro-hydraulic push rod.

[0025] The pressing panel 2 is in the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com