Method and apparatus for forming single-thread chain sewing end knot

A chain and single-thread technology, applied in the field of chain-stitch sewing machines, can solve the problems of high technical cost of single-thread chain-stitch sewing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] First, the method will be described below, followed by a chain stitch sewing machine manufactured for carrying out the method.

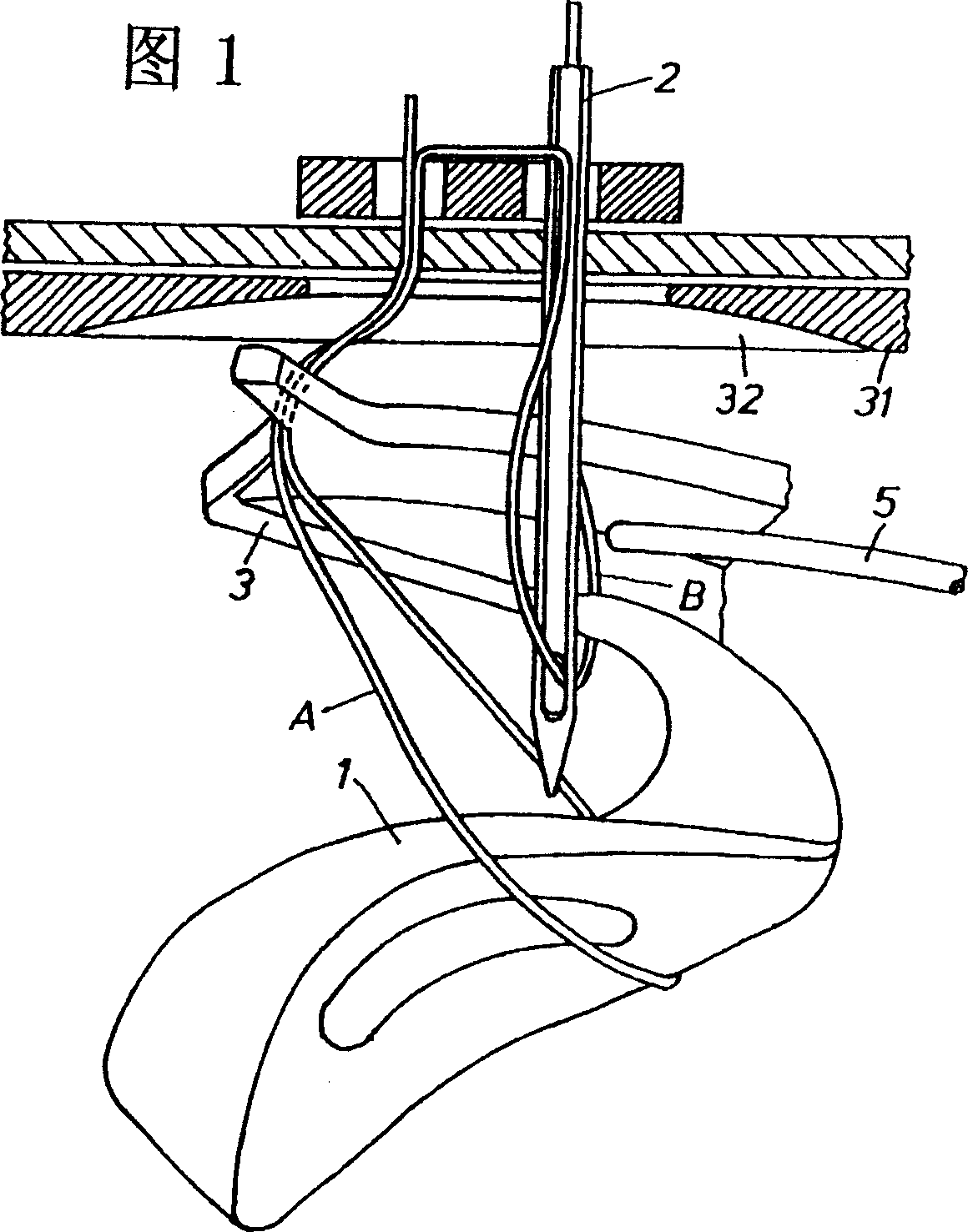

[0042] FIG. 1 shows the state of the coil at the beginning of formation of the end knot. The loop A formed in the previous stitch at this moment is still hanging on the shuttle. It extends from the sewing product to the shuttle via the auxiliary thread catcher in its forward reverse position. The needle is in the needle bar stroke position, then it leaves this position and goes up. The next stitch B is formed, into which the tip of the shuttle is squeezed. The stop pin moves toward the needle from its rear reverse position, when the pin tip is inserted into neither coil A nor coil B. But the tip of the stop pin is located not far in front of the coil B. When the shuttle continues to rotate, the coil A hanging on the shuttle moves toward the tip of the shuttle on the back of the shuttle, and is about to fall off the back of the shuttle. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com