Button keyhole sewing machine

A sewing machine and button technology, which is applied to sewing machine components, thread hooks for sewing machines, and ferrule mechanisms for sewing machines, etc., can solve problems such as complicated threading operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] (Overall structure of the embodiment)

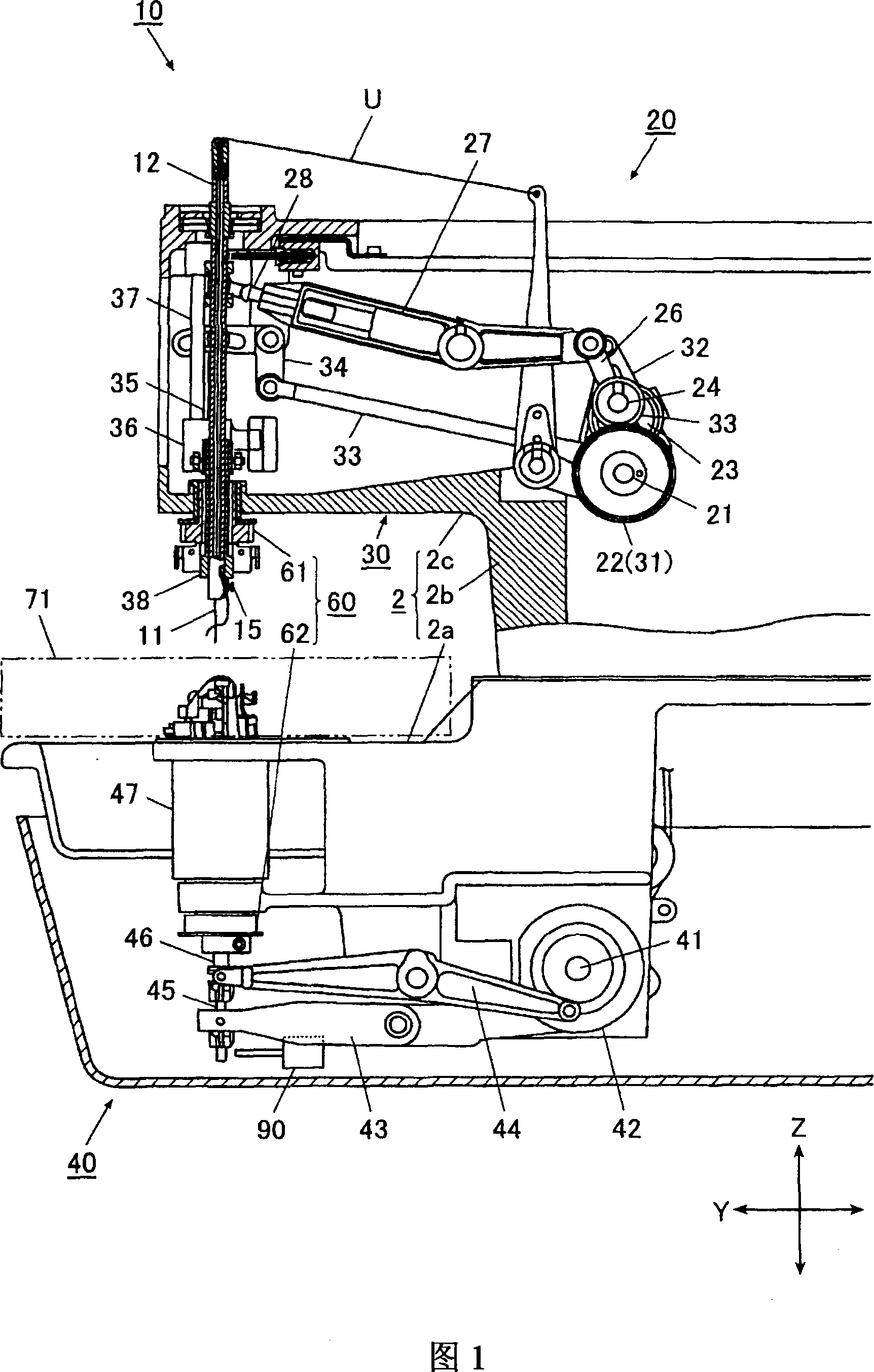

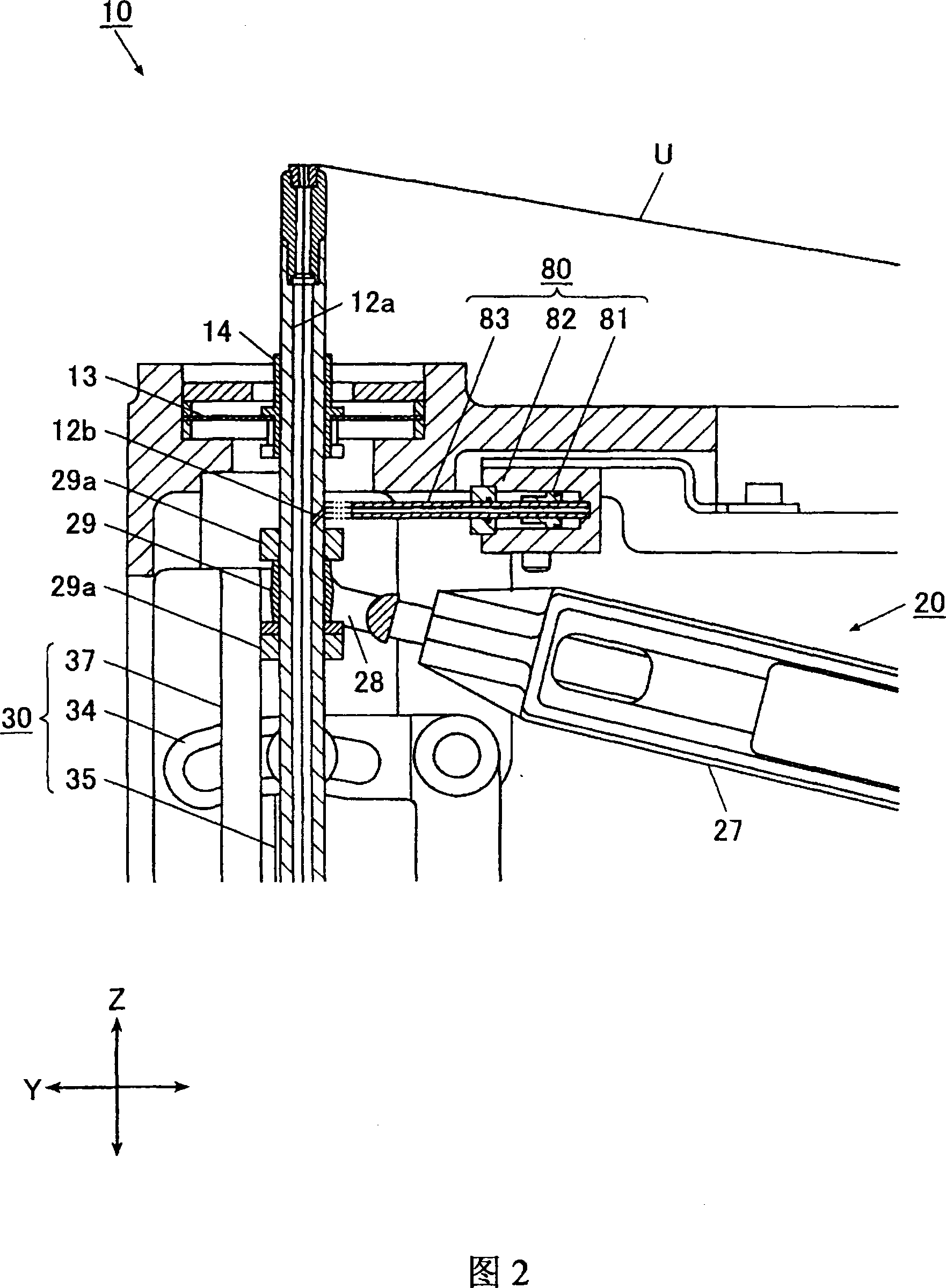

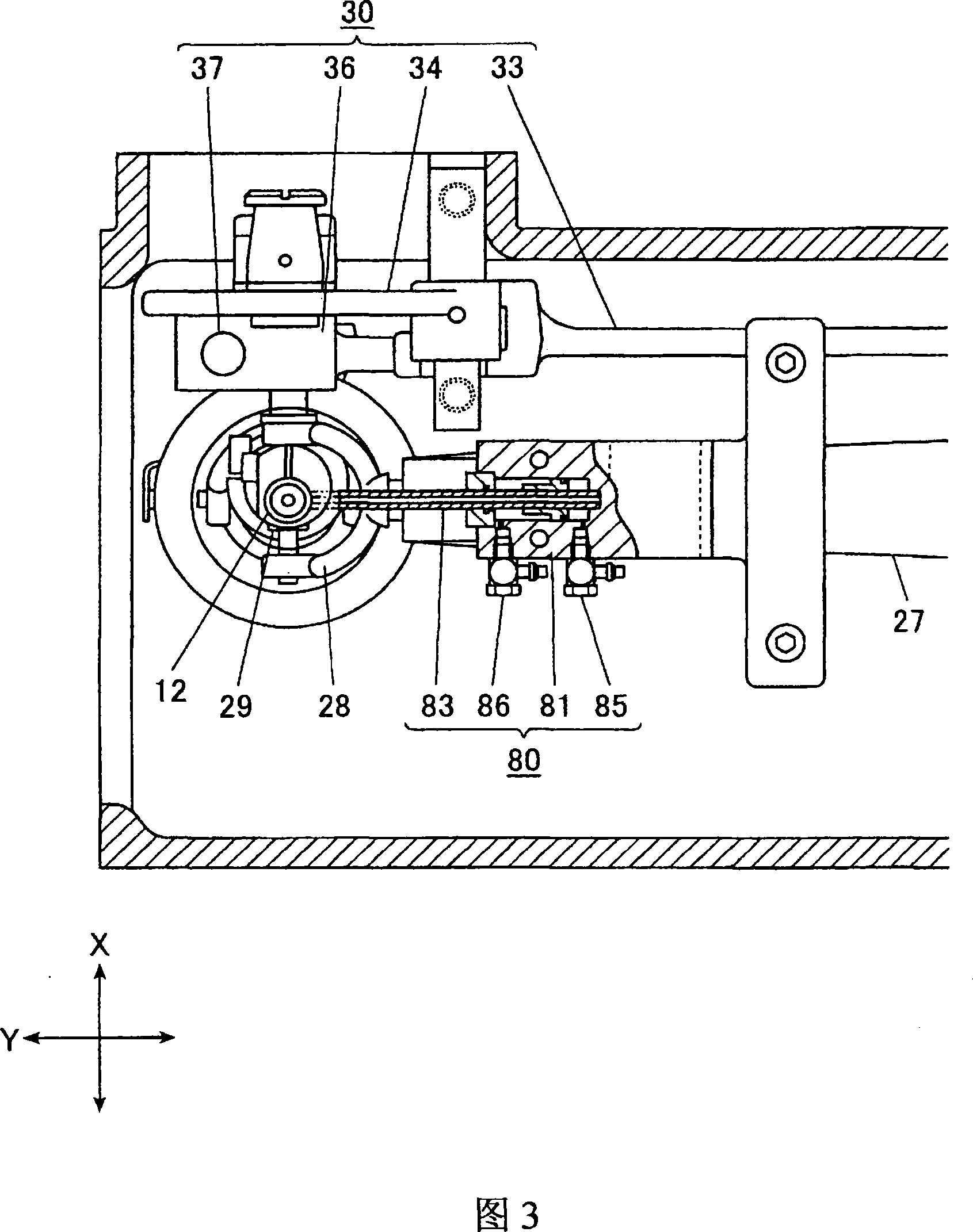

[0046] The buttonhole sewing machine 10 according to the embodiment of the present invention will be described based on FIGS. 1 to 10. 1 is a side sectional view of the buttonhole sewing machine 10, FIG. 2 is an enlarged sectional view showing the upper periphery of the needle bar 12, and FIG. 3 is an enlarged sectional view showing the upper periphery of the needle bar 12 viewed from above.

[0047] As shown in Figure 1, the buttonhole sewing machine 10 has: a base portion 2a, which is located at the lower part of the sewing machine as a whole, and has a substantially rectangular box shape; a longitudinal body portion 2b, which is provided on one end of the base portion 2a; And the arm portion 2c is provided to extend from the longitudinal body portion 2b and the base portion 2a in the same direction. Here, in the following description, the direction in which the longitudinal body portion 2b is erected is set to the Z-axis direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com