Thread control device for a sewing machine

A control device and sewing machine technology, which is applied in the direction of sewing machine thread take-up device, sewing machine thread hook, sewing machine components, etc. It can solve the problem of sewing machine that does not want missing thread or too tight sewing thread control, etc., to achieve small resistance and prevent thread Stitch disorder, prevent loose suture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following more detailed description of the present invention is based on the brief content and background technology described above and in context, but is not limited to the foregoing description.

[0031] Throughout the description, the description structure has, includes, or contains specific components, or the description process has, includes, or contains specific steps. It is expected that the composition of the present invention may also consist essentially of the referenced components, or consist of composition. .

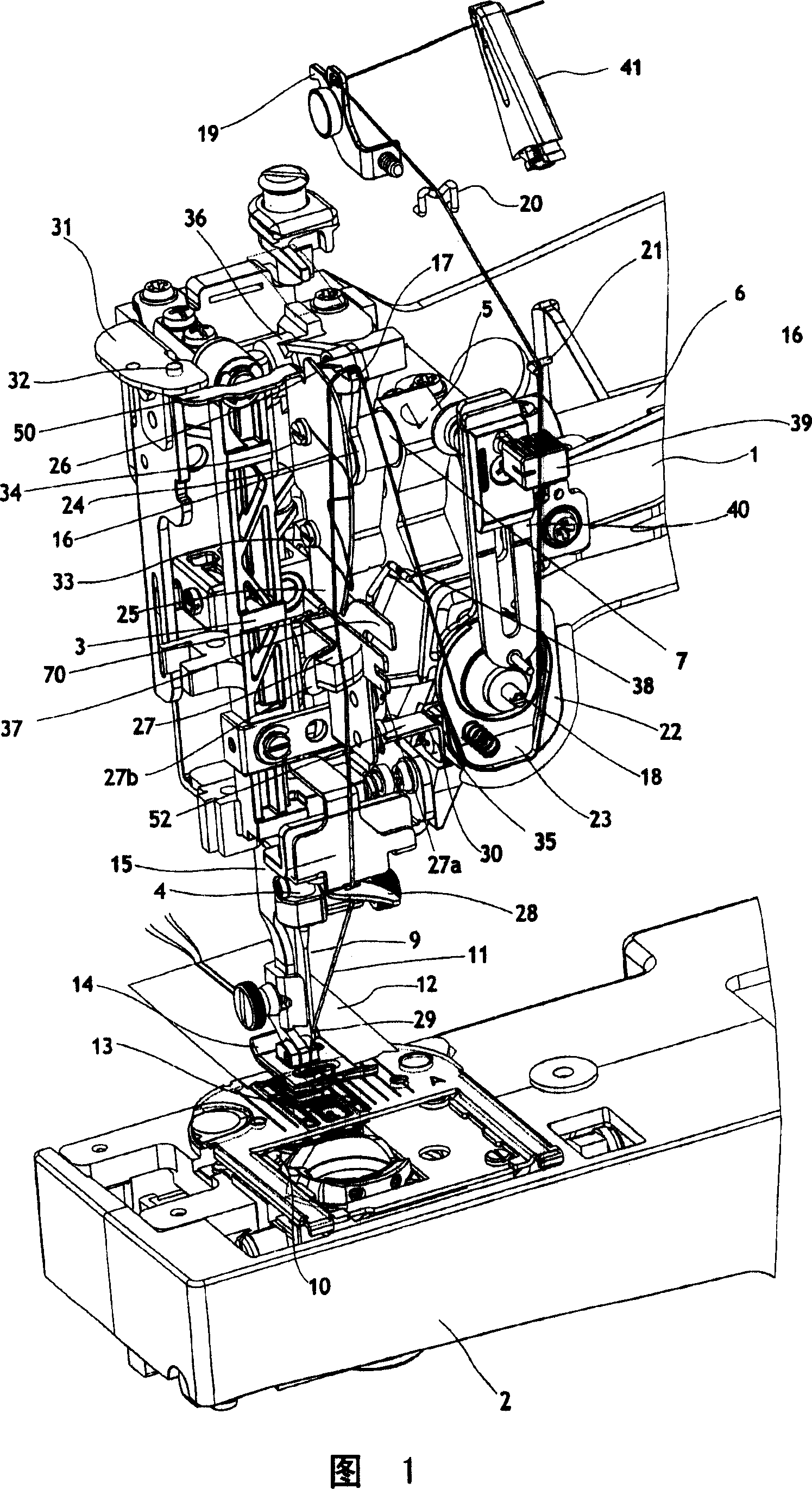

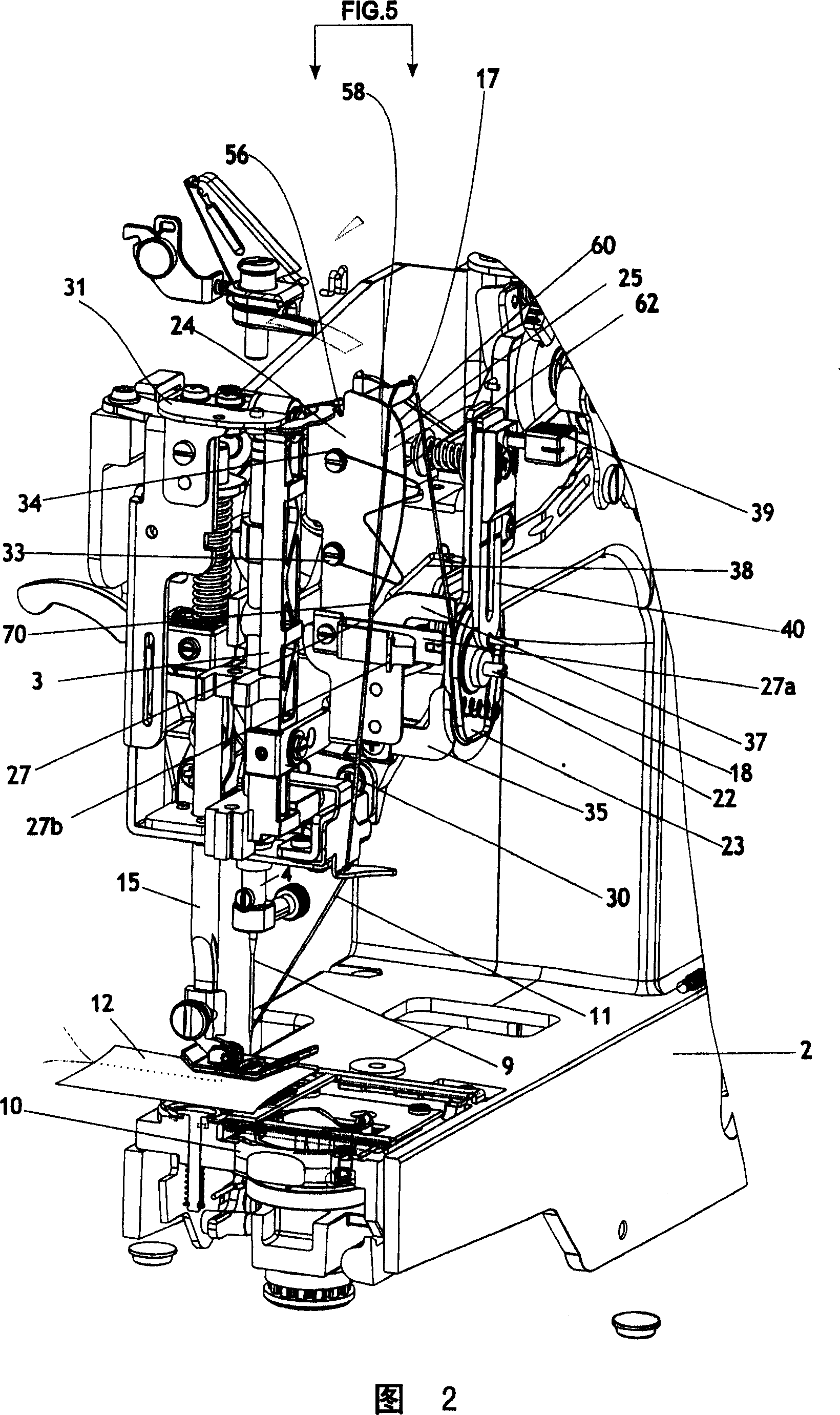

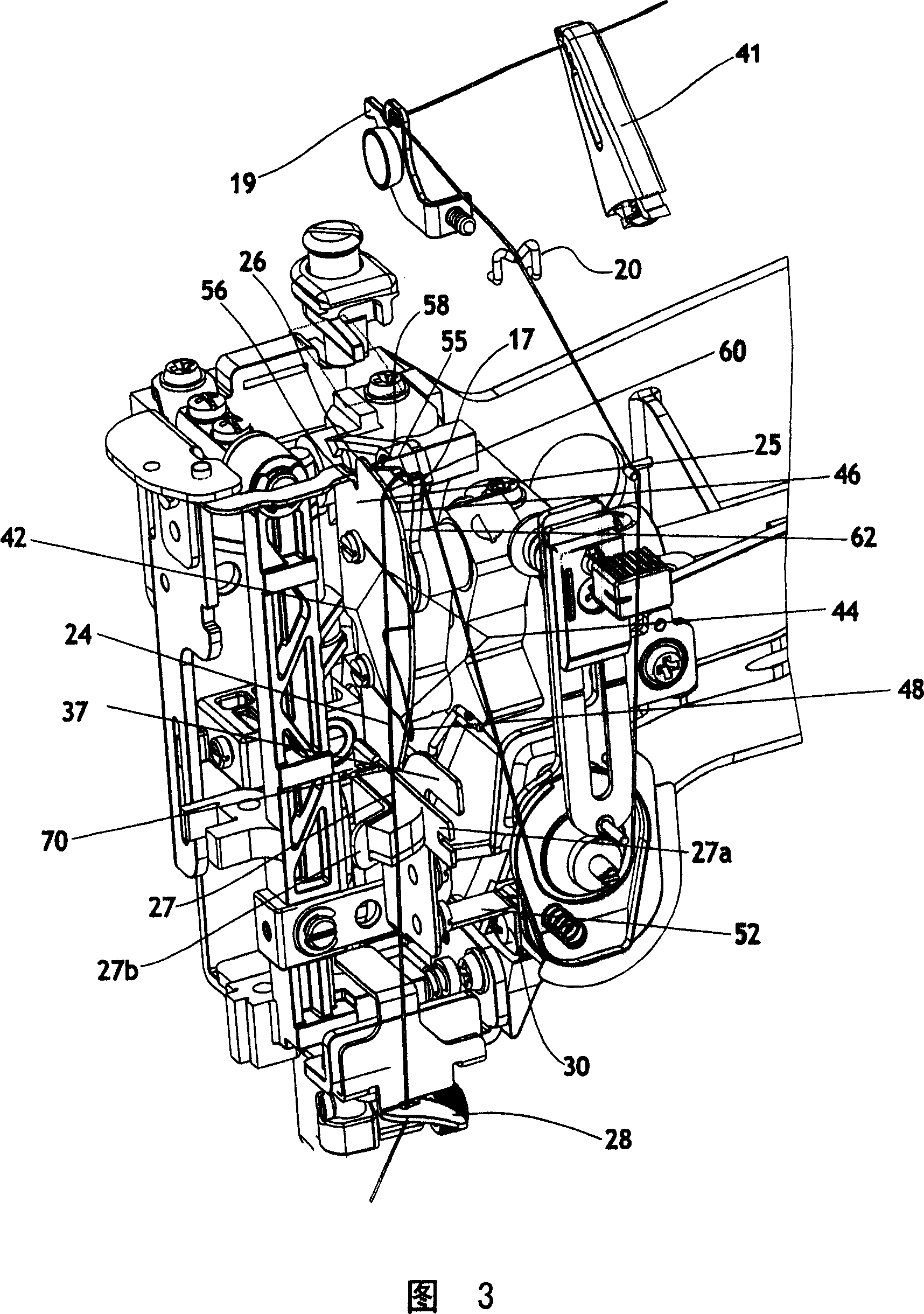

[0032] In an advantageous embodiment of a lockstitch sewing machine according to the present invention, the thread extends from the horizontally mounted spool to the thread guide and pretensioner, and then to the disc gap tensioner. Through these thread control devices, the suture passes through the thread take-up device, such as a thread take-up lever, then passes through the thread control device provided by the present invention, and then ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com