2 needle sewing machine for angular seam

A technology for sewing machines and corner seams, which is applied in the field of sewing machines and can solve problems such as damage to the aesthetics of sewing products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

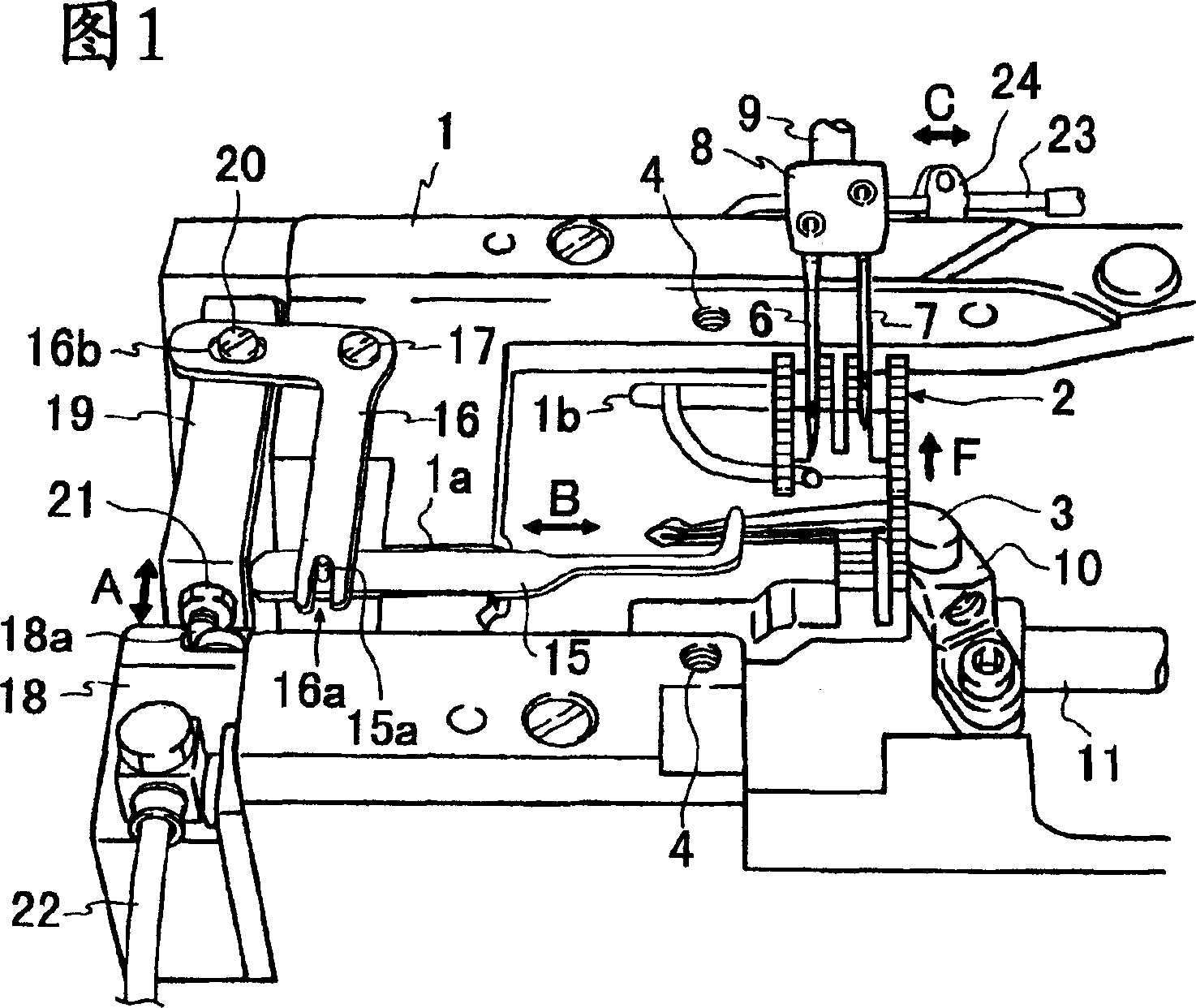

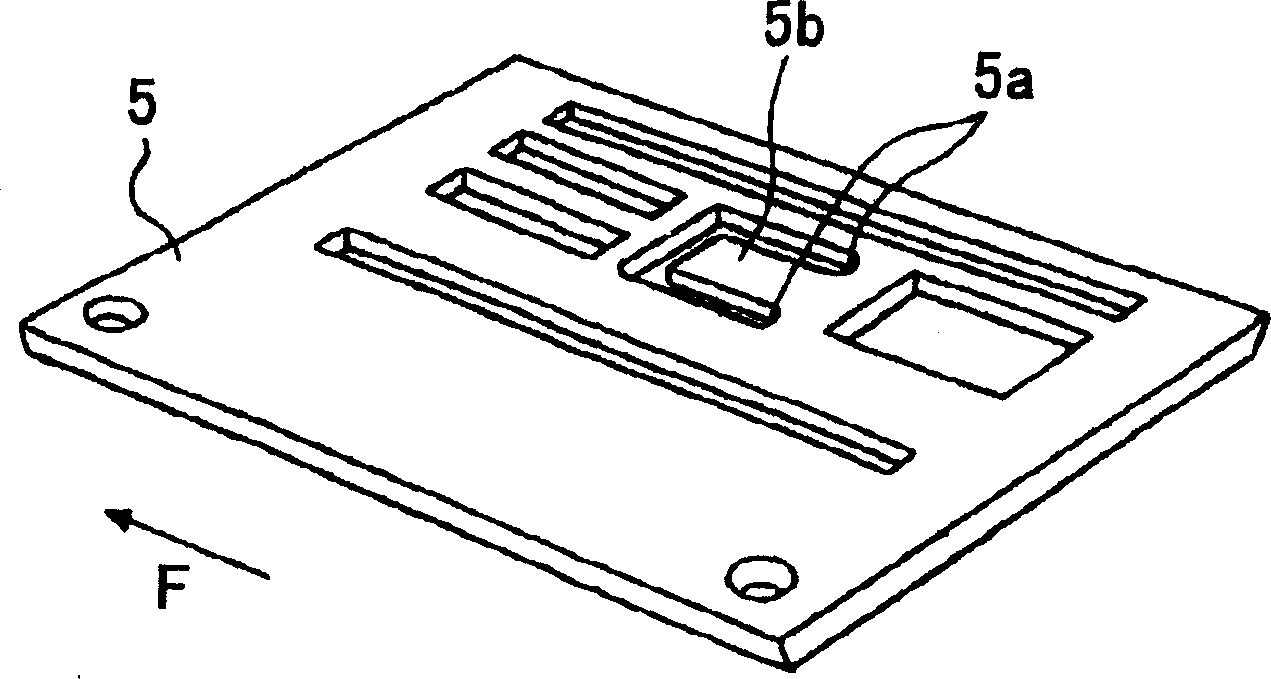

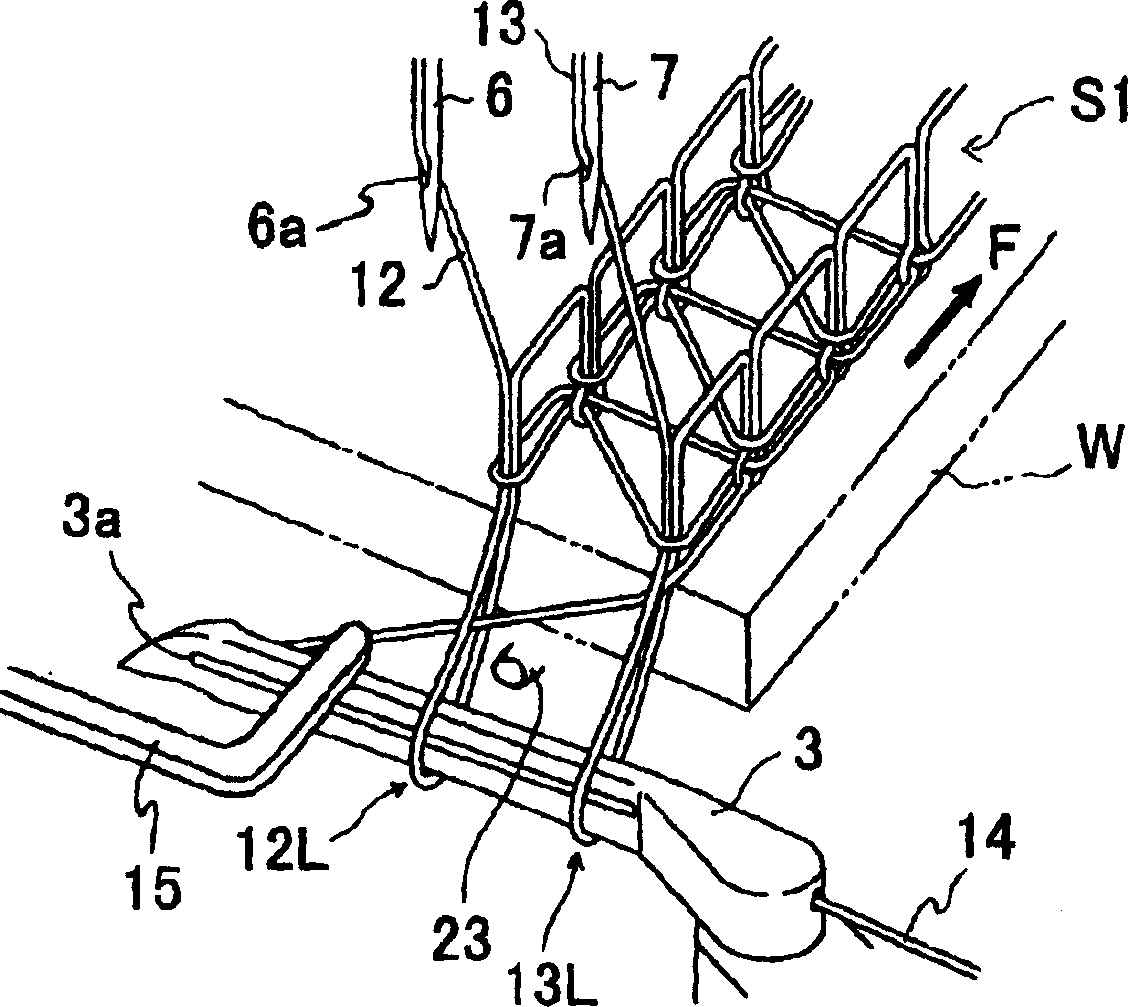

[0028] Embodiments of the present invention will be described below with reference to the drawings. Fig. 1 is a perspective view of main parts of a 2-needle sewing machine for corner stitching using the present invention. On the cylinder head 1 of the sewing machine, there are feed teeth 2 that can move up and down, forward and backward, and feed the gray cloth in the direction of arrow F, and a rapier 3 that swings in a direction intersecting with the gray cloth feeding direction F, and is fixed in the threaded hole. Needle plate 5 of 4 (refer to figure 2 ). Above the cylinder head 1, a needle bar 9 on which a left needle 6 and a right needle 7 are installed through a needle plant 8 is arranged. Each of the needles 6 and 7 extends downward, and the tip thereof penetrates the needle plate 5 as the needle bar 9 moves up and down. The needle penetration points 5a, 5a of the needle plate 5, such as figure 2 As shown, it is on the base side of the needle plate claw 5b extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com