Control system of normal sewing machine

A control system and technology for a lockstitch sewing machine, which are applied to sewing machine control devices, sewing machine components, and sewing machine casings, etc., can solve the problems that the heat dissipation aluminum plate cannot be normally installed on the shell, and the connection of the heat dissipation aluminum plate is troublesome, etc., so as to improve the convenience High performance, good heat dissipation effect and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

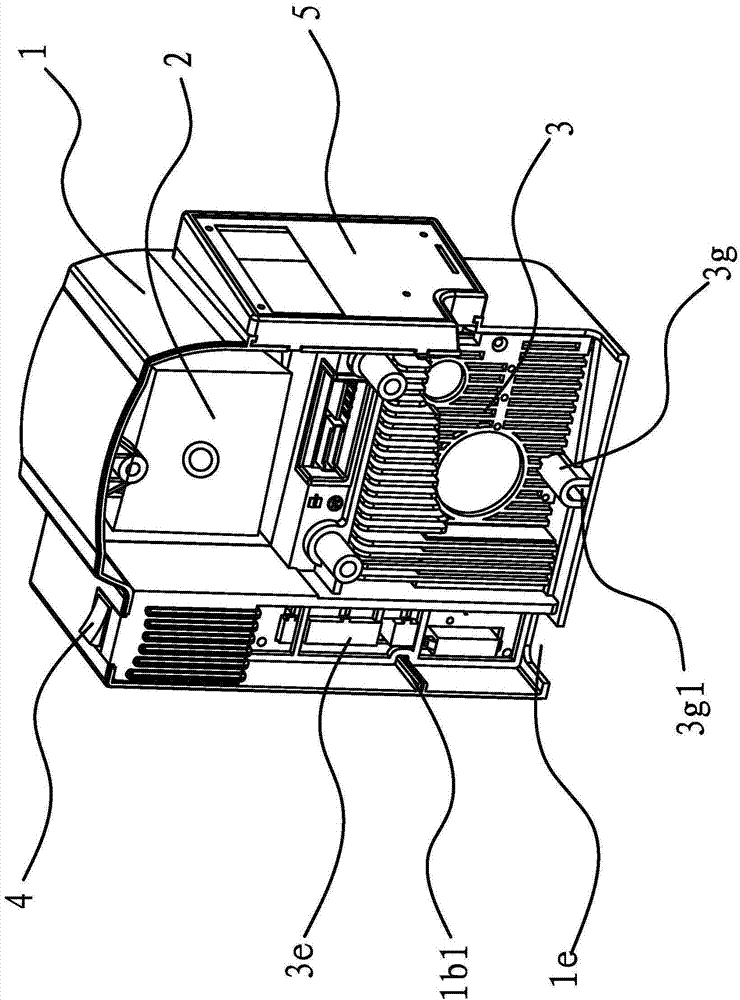

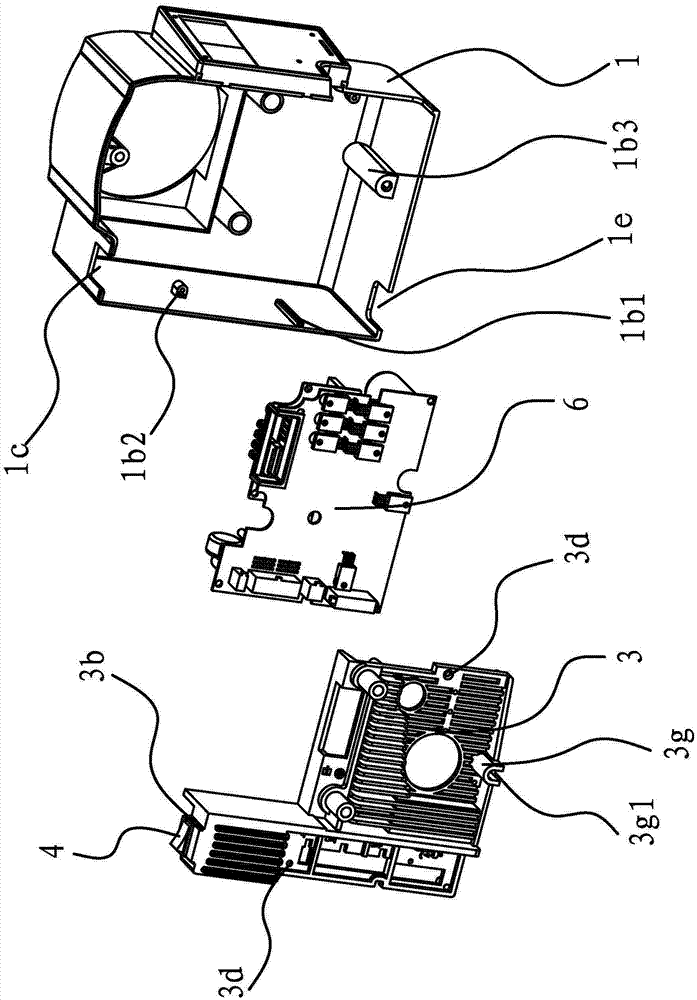

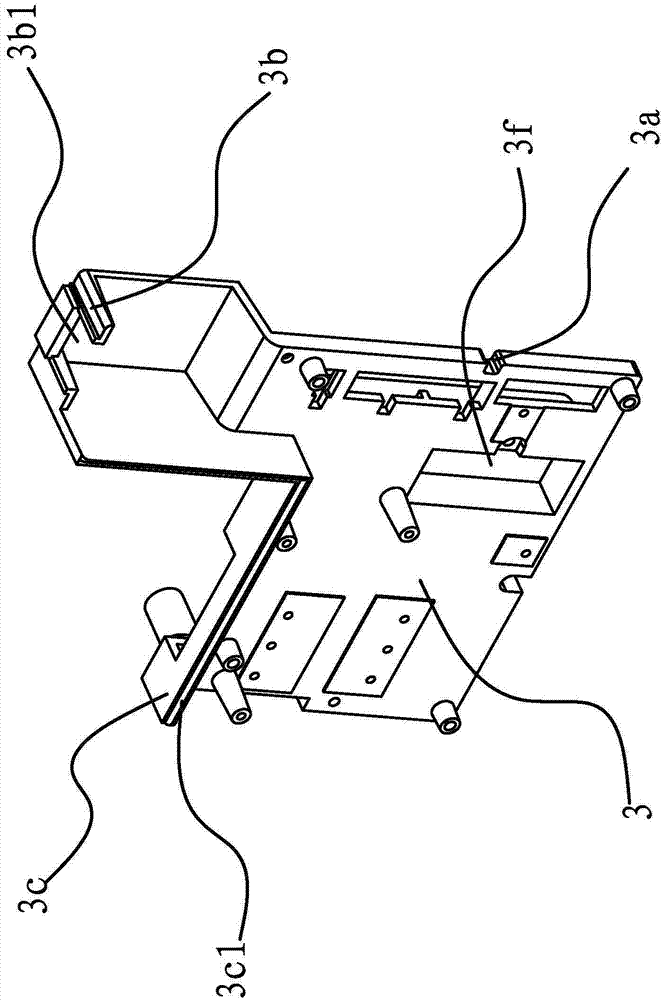

[0035] like figure 1 , figure 2 and Figure 4 As shown, the control system of the lockstitch sewing machine includes a housing 1 connected to the head of the locket sewing machine at one end, and one end of the housing 1 connected to the head of the locket sewing machine is open, and the inside of the housing 1 is a cavity. There is an L-shaped partition 1d inside the casing 1, an upper cavity 1a is formed between the upper end surface of the partition 1d and the inner side wall of the casing 1, and a servo motor 2 is arranged in the upper cavity 1a, and the lower end surface of the partition 1d is in contact with the inner wall of the casing 1. A lower cavity 1b is formed between the inner side walls of the housing 1, and a control circuit board 6 is arranged in the lower cavity 1b, and the side surface of the housing 1 facing the operator is provided with a card slot 1f along the axial direction, and a card slot 1f is inserted in the card slot 1f. The control panel 5 is c...

Embodiment 2

[0042] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is: in this embodiment, if Figure 5 and Image 6 As shown, a buckle 1d1 is fixedly connected to the upper end surface of the partition 1d, and the end of the buckle 1d1 is barb-shaped. When the heat dissipation aluminum plate 3 is connected to the housing 1 along the guide strip 1b1, the heat dissipation aluminum plate 3 During the movement, the heat dissipation aluminum plate 3 pushes the buckle 1d1 upward. When the heat dissipation aluminum plate 3 is connected in place, the buckle 1d1 is automatically buckled on the edge of the outer side of the heat dissipation aluminum plate 3, so that the heat dissipation aluminum plate 3 and the shell 1 are fixed together. The use of the buckle 1d1 further simplifies the connection process between the heat dissipation aluminum plate 3 and the housing 1, and the connection is very convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com