Sewing machine with sewing frame exchanging structure and sequence control method thereof

A sewing machine and sewing technology, applied in the direction of program-controlled sewing machines, sewing machine control devices, sewing machine components, etc., can solve the problem of inability to sew large-scale air curtains, and achieve the effects of convenient work, improved productivity, and increased operating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The detection device based on the movement detection sensor of the present invention will be further described below with reference to the accompanying drawings.

[0083] Sewing machine with sewing frame replacement mechanism

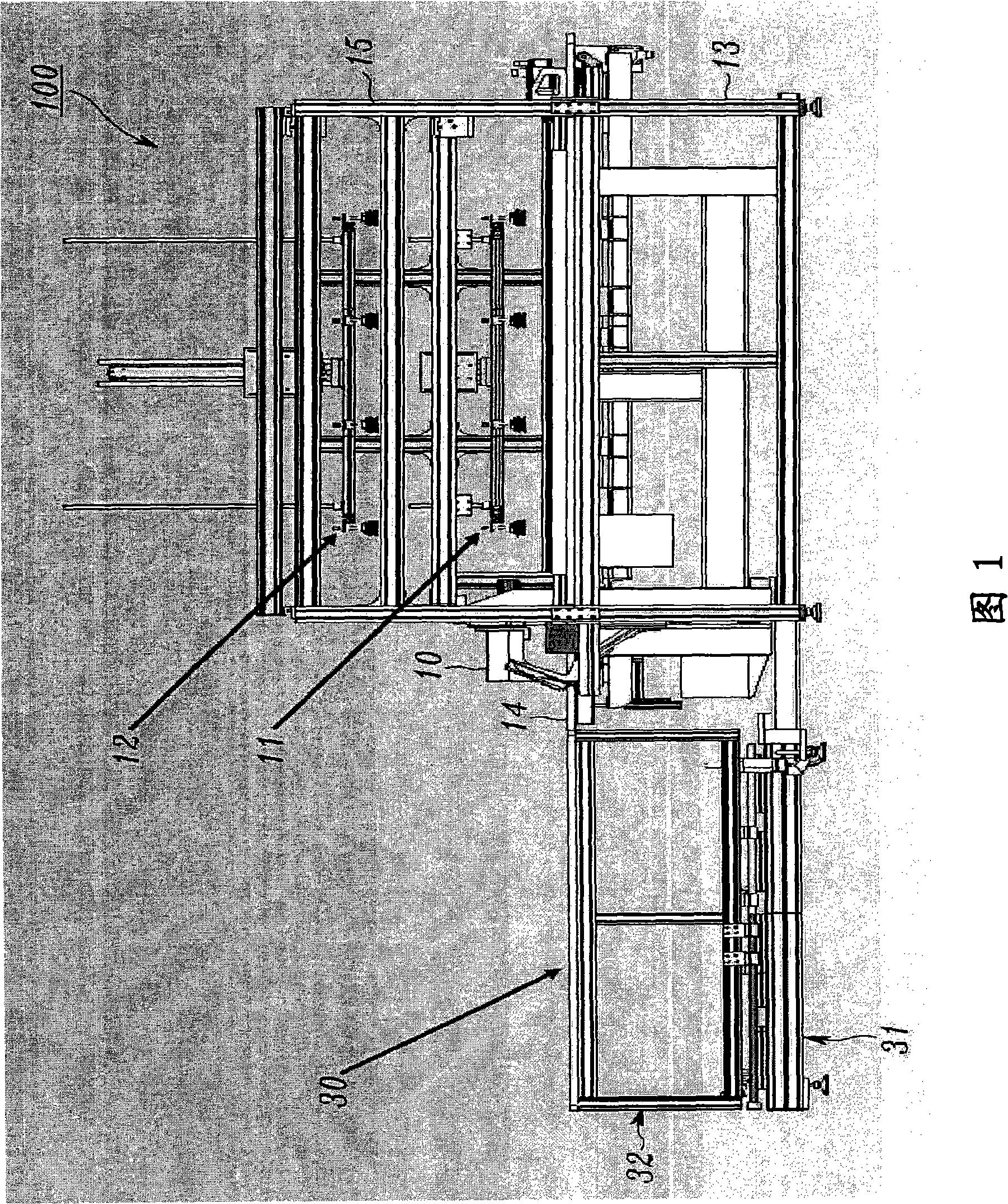

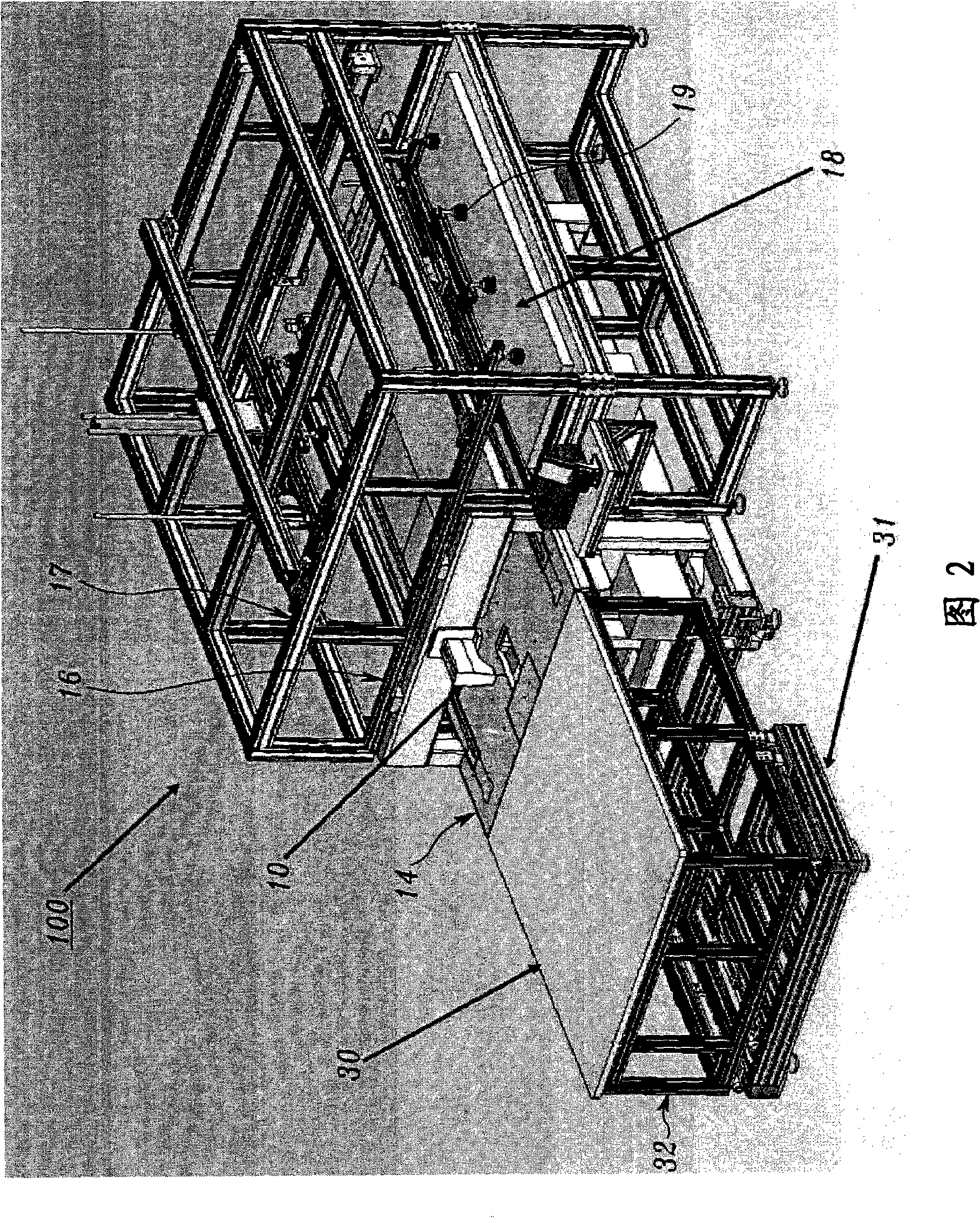

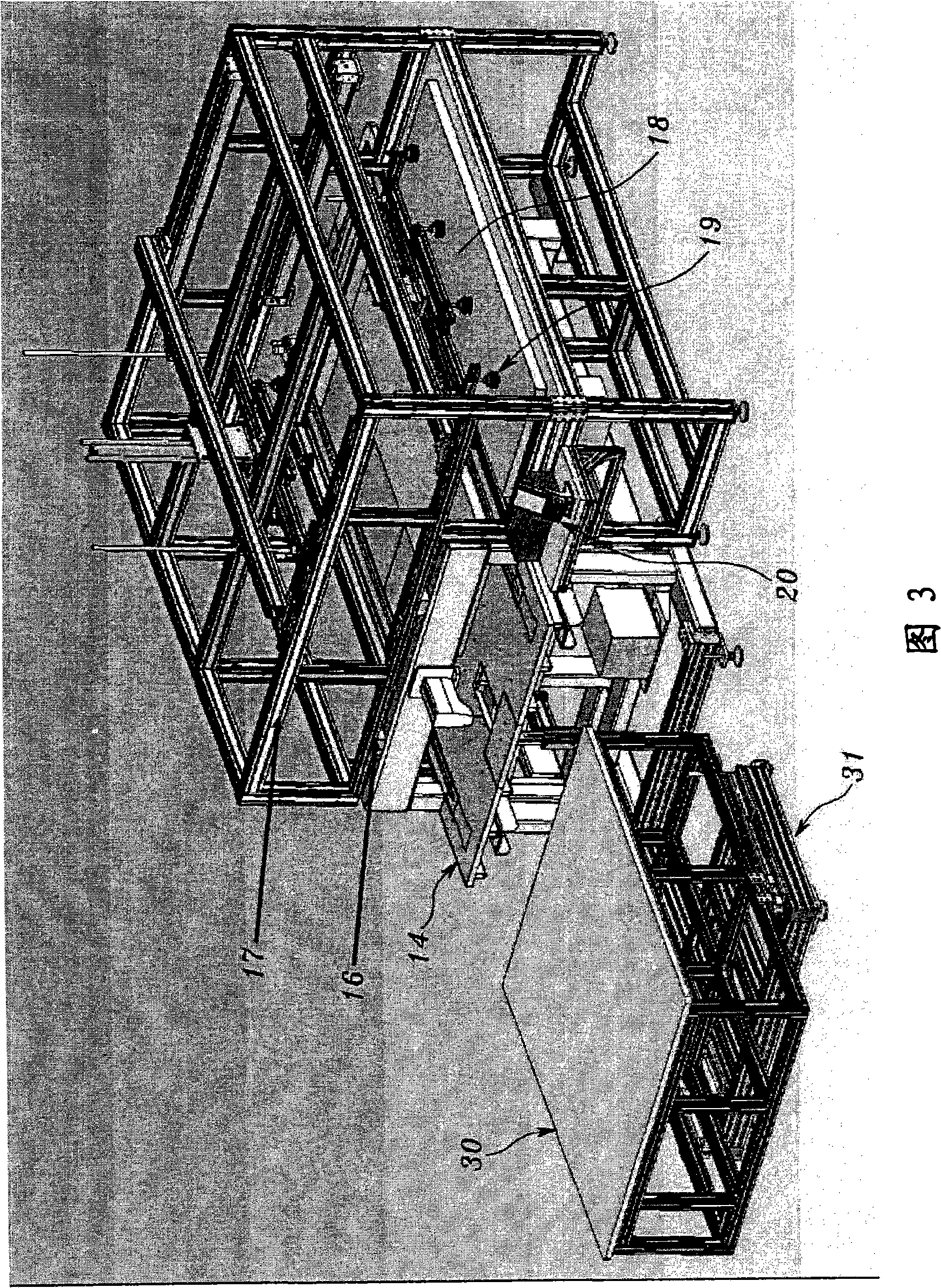

[0084] 1 to 9 are diagrams of a sewing machine equipped with a sewing frame replacement structure according to a preferred embodiment of the present invention. Fig. 1 is a right side view of the sewing machine; Fig. 2 is a perspective view when the auxiliary table is in a closed state; Fig. 3 is a perspective view when the auxiliary table is in an open state; Table sliding device diagram; Figure 6 is a supporting plate fixing structure diagram; Figure 7 is the first and second upper plate actuator structure diagram; Figure 8a and Figure 8b are the actuator structure and action diagram of the shuttle table; Figure 9 is a diagram of an X-axis drive motor and a Y-axis drive motor.

[0085] As shown in FIGS. 1 to 4 , the above-mentioned sewing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com