Sewing control system and sewing equipment

A control system and sewing technology, applied in sewing machine control devices, sewing equipment, sewing machine components, etc., can solve the problems of inability to control the length of excess stitches, inability to achieve electrical control, shortening service life, etc., to achieve easy automatic control, easy Automatic control and maintenance, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

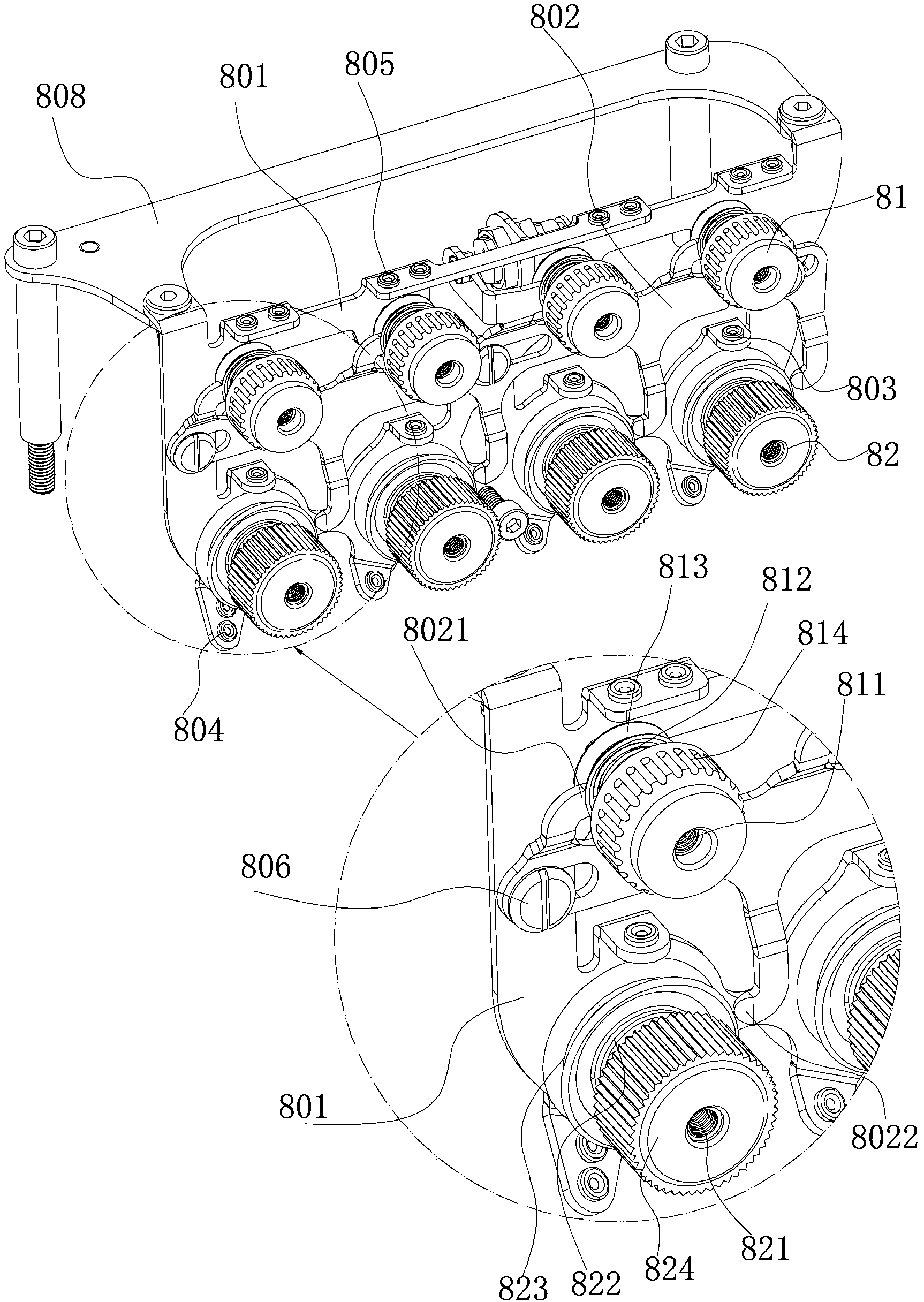

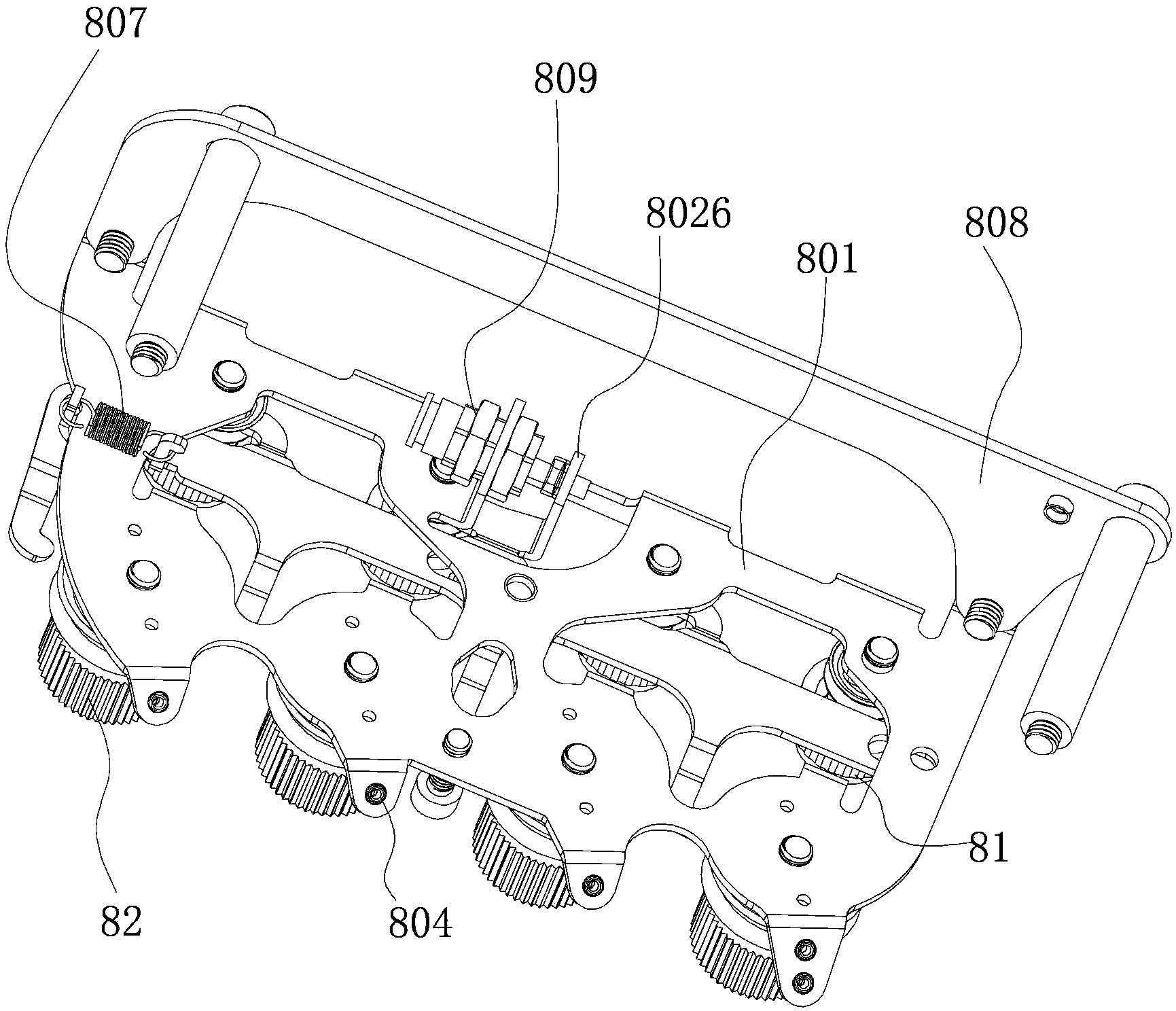

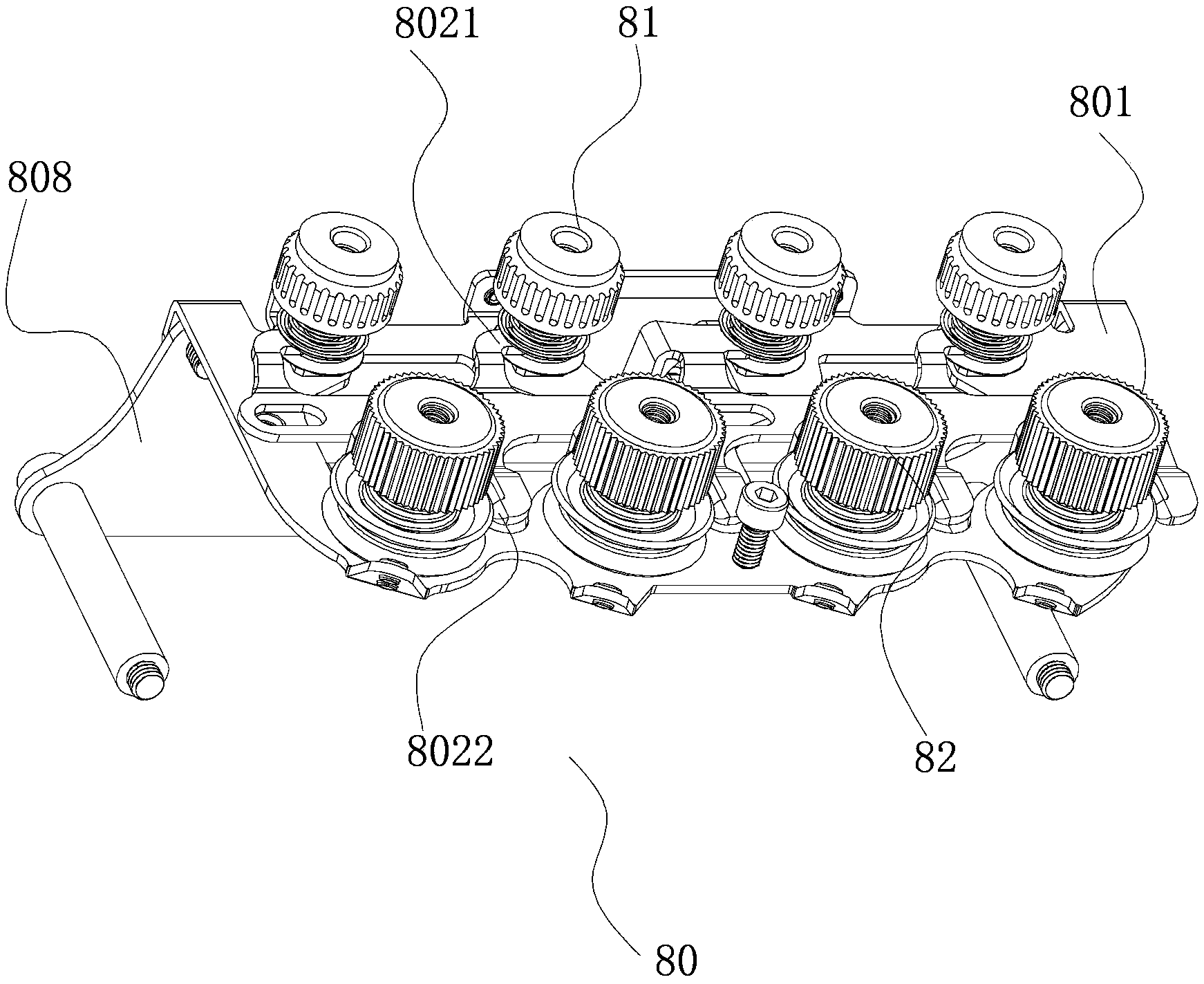

[0044] The sewing equipment of the present invention comprises a main frame (that is, the main structure of the sewing machine) arranged on a base, and a thread loosening device 80 is arranged on the main frame. Such as Figure 1-4As shown, the thread release device 80 includes a bracket 801, a thread release carriage 802 slidingly coupled with the support 801, and a thread release cylinder 809 for driving the thread release carriage 802 to move; The lower thread passing device 82; the upper thread passing device 81 includes an upper thread passing screw 811 fixed to the bracket 801 (the outer end of the upper thread passing screw is threadedly connected with an upper adjusting nut 814), and is sleeved on the upper thread passing scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com