Sewing machine

A sewing machine and sewing department technology, applied in the direction of sewing machine components, sewing equipment, tension devices, etc., can solve the problems of shortening the transmission interval of driving signals, discreteness, and the inability of the sewing machine to smoothly control the rotation position of the pulse motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

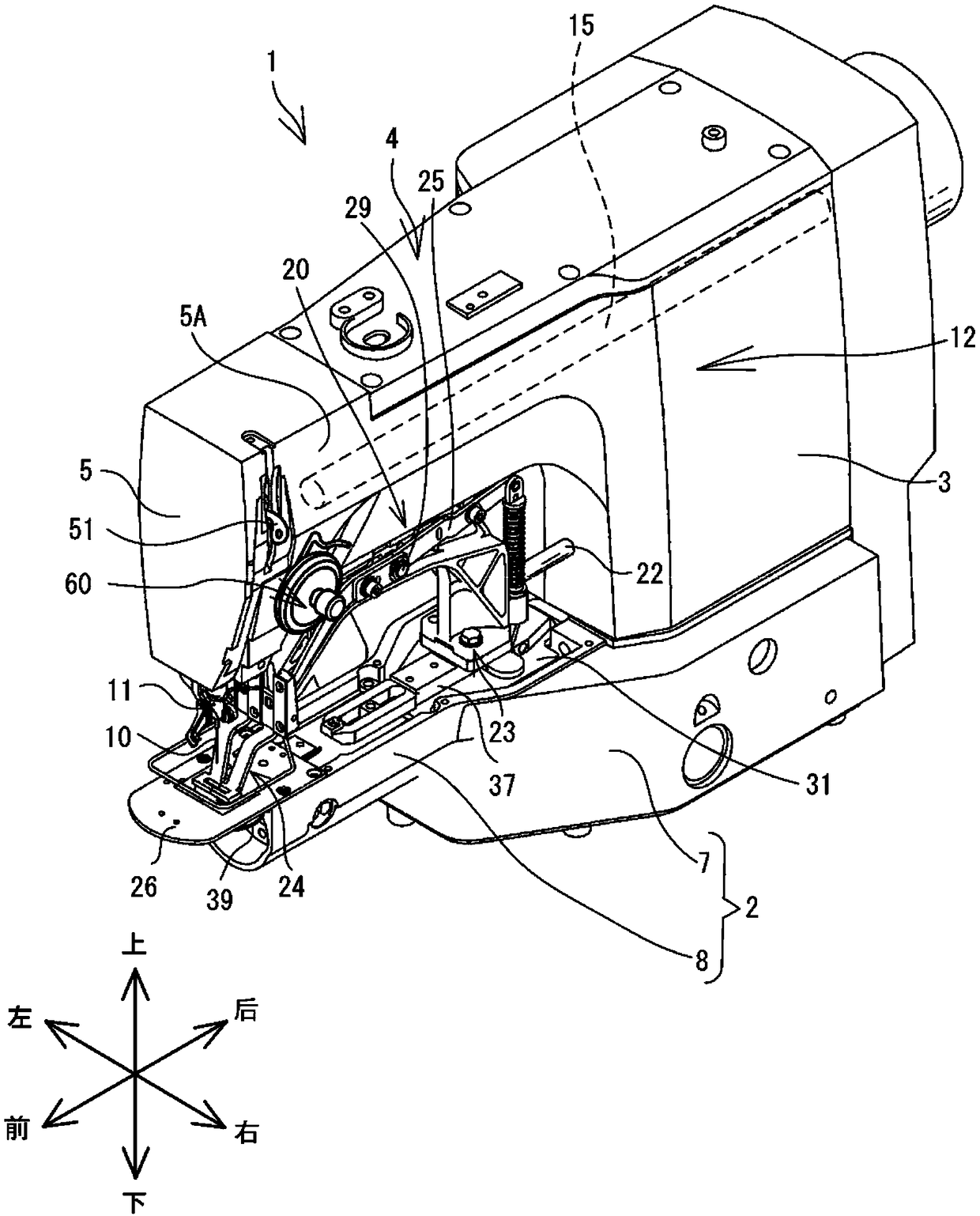

[0030] The embodiments of the present invention will be described below. The following description uses the left and right, front and back, and up and down indicated by arrows in the figure. figure 1 The sewing machine 1 shown is used for fabric 105 (refer to Figure 6A ) To form a knotting machine with reinforcement stitches.

[0031] Reference Figure 1 ~ Figure 3 , The schematic structure of the sewing machine 1 will be described. The sewing machine 1 has a base 2, a support 3, and an arm 4. The machine base 2 is the base of the sewing machine 1 and is arranged on a horizontally extending workbench. The base portion 2 has a base body portion 7 and a cylindrical base portion 8. The main body portion 7 of the machine base is substantially box-shaped. The cylindrical seat portion 8 extends forward from the base body portion 7. The inside of the stand main body 7 and the inside of the cylindrical seat 8 communicate with each other. The cylindrical seat portion 8 has a needle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com