Uper and lower conveying sewing machine and thread adjuster

A thread adjusting device and sewing machine technology, applied in the direction of sewing machine control devices, sewing machine components, program-controlled sewing machines, etc., can solve problems such as unstable thread tension, uneven pressure on platen parts, and unstable thread tension, etc., to achieve Effect of reducing thread tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

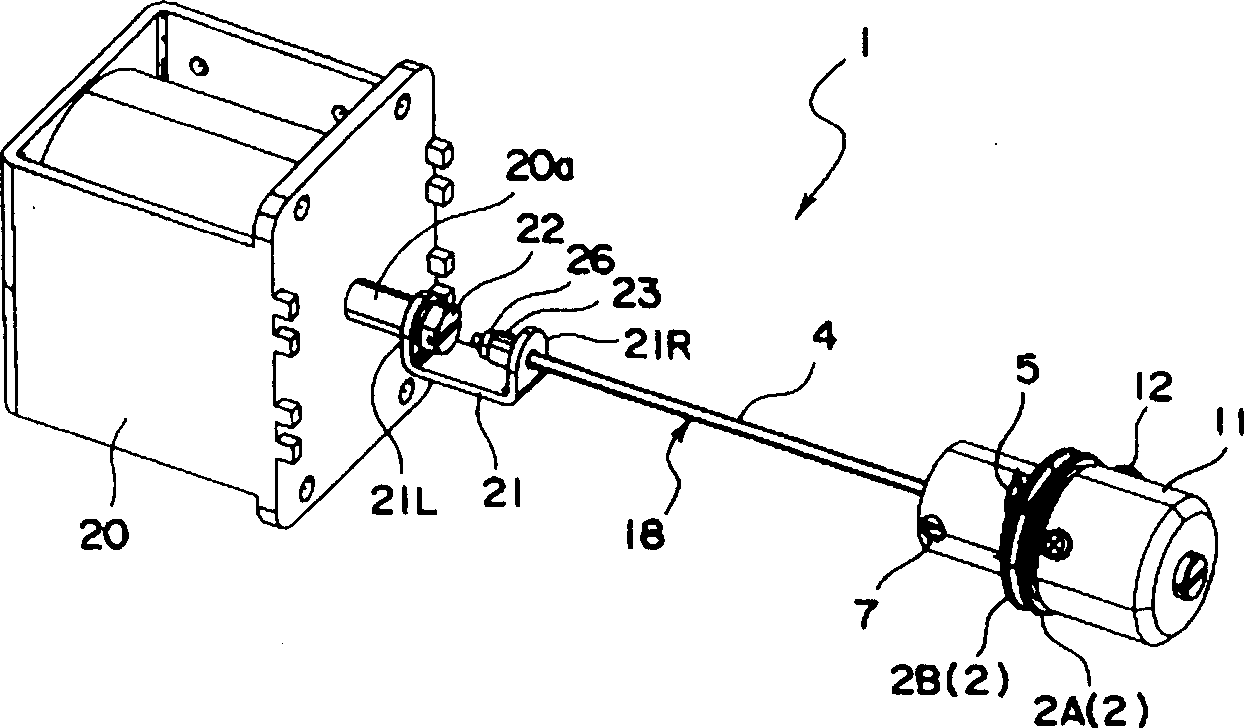

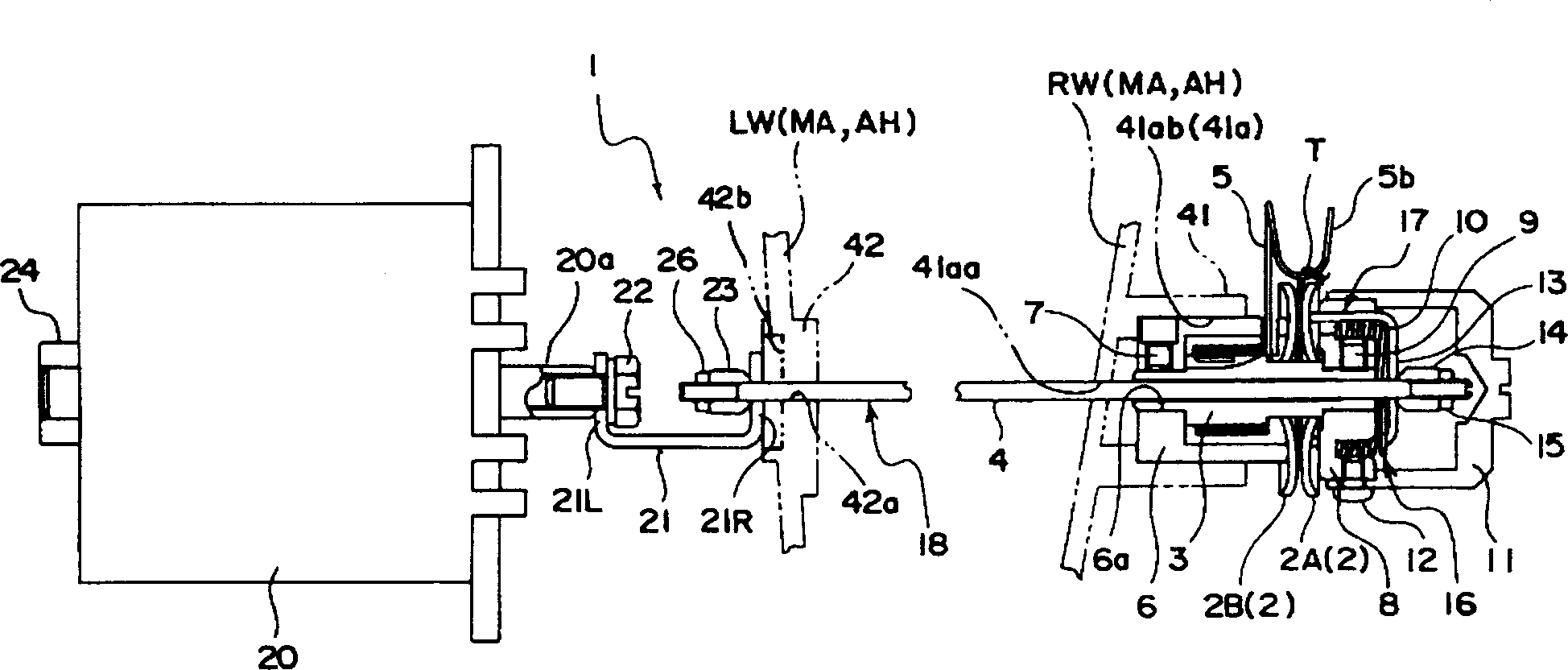

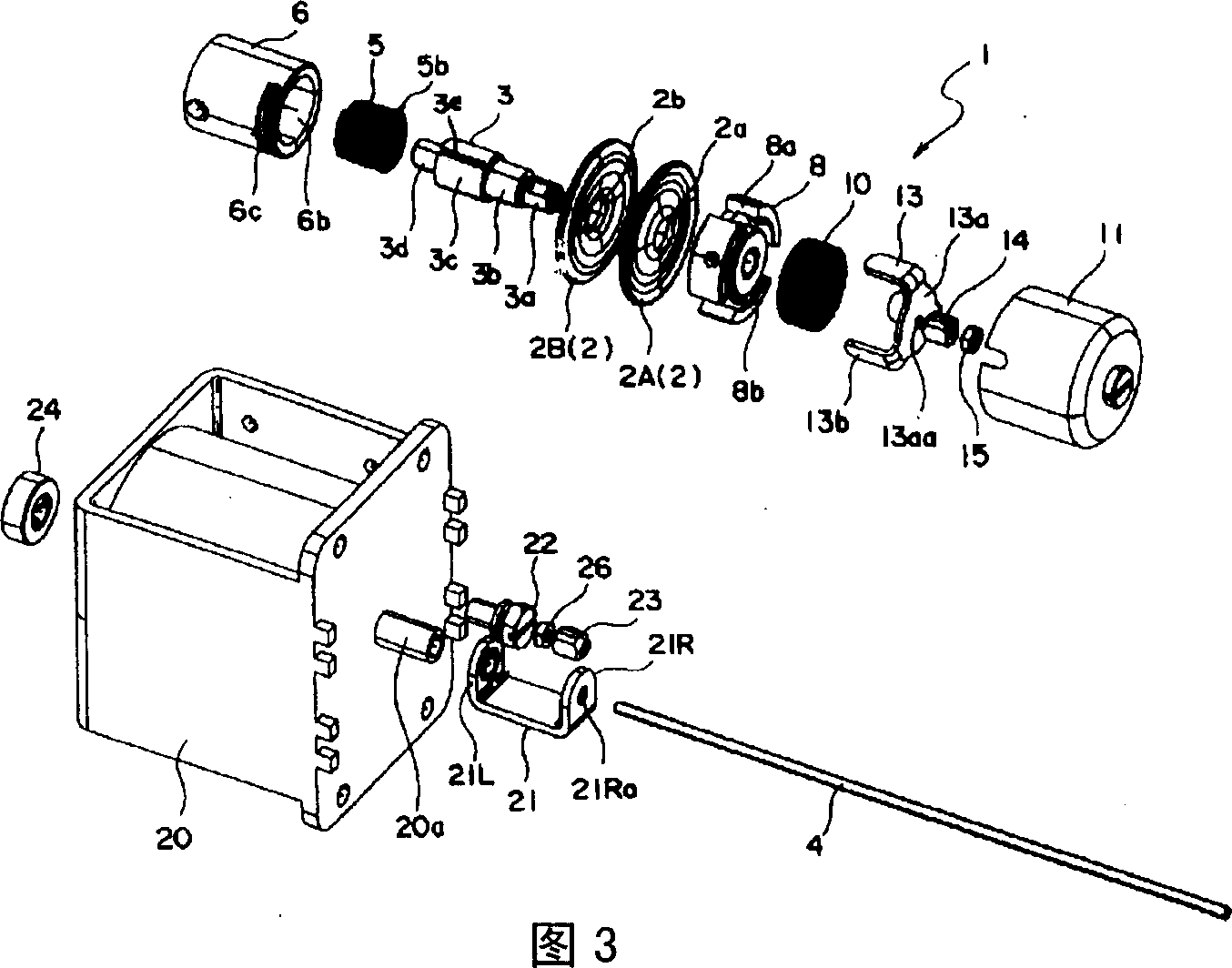

[0046] First, refer to Figure 1 to Figure 5 Embodiments of the sewing machine thread adjusting device of the present invention will be described.

[0047] Such as figure 1 As shown, the thread adjustment device 1 of this embodiment has the ability to hold the upper thread ( figure 2 ) A pair of ring-shaped wire-adjusting discs 2 (2A, 2B). Such as figure 2 And as shown in FIG. 3 , these wire adjusting discs 2 are supported on the wire adjusting rods 3 . Such as figure 2 As shown in FIG. 4, the wire adjusting rod 3 forms four cylindrical outer peripheral surfaces, and each outer peripheral surface in FIG. , the spring mounting portion 3c, and the table mounting portion 3d. Moreover, the diameter of the outer peripheral surface of the wire adjusting rod 3 is the largest at the spring mounting portion 3c, the diameters of the wire adjusting disc mounting portion 3b and the anti-rotation member mounting portion 3a are sequentially reduced, and the diameter of the table mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com