Industrial sewing machine

An industrial sewing machine and needle technology, applied in the field of sewing machines, can solve the problem that the sewing machine cannot sew pattern curve stitches, reduce the appearance quality and locking quality of the sewing stitches, and affect the timing and strength of the hook and loop of the hook. problem, to achieve the effect of strong and beautiful product stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

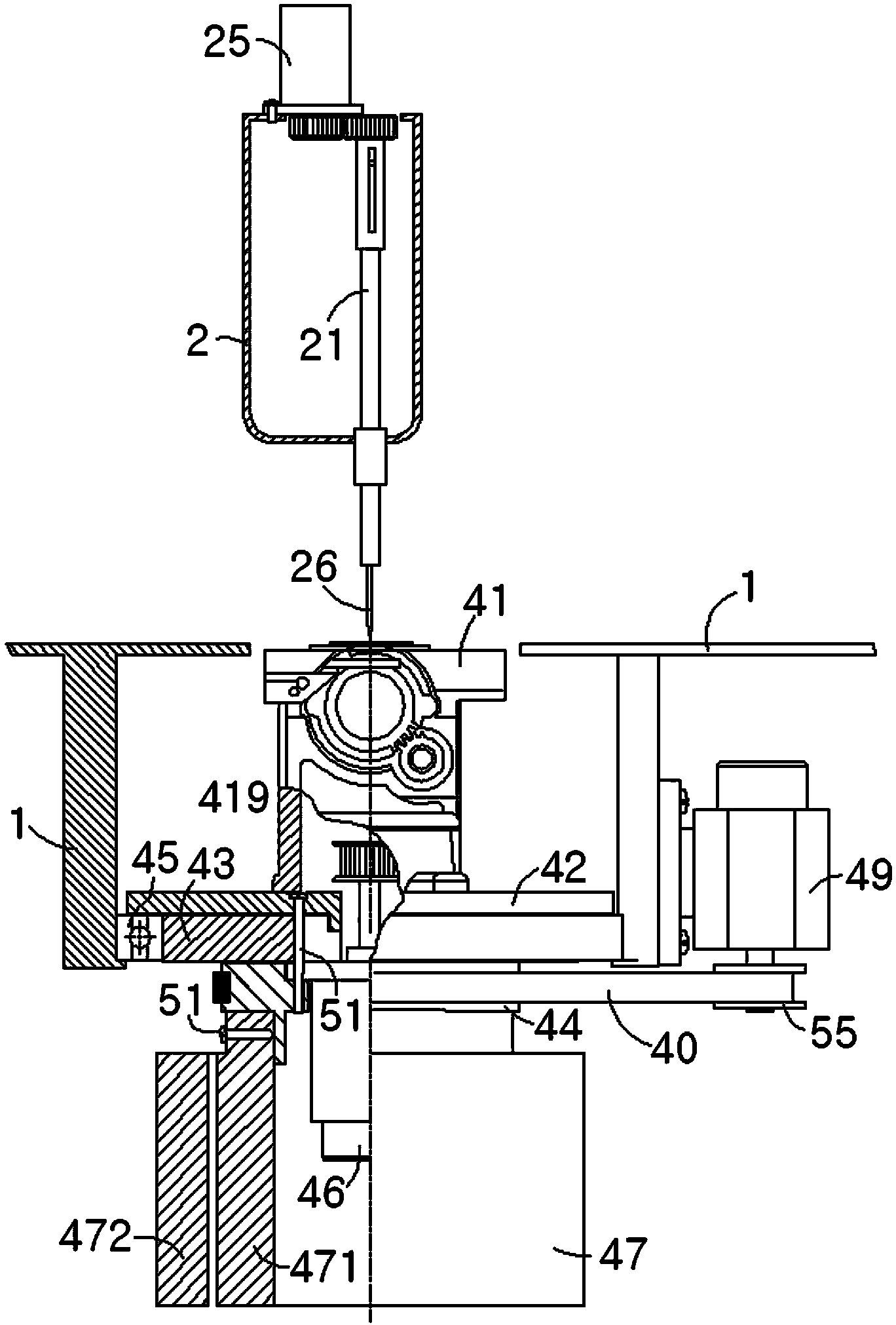

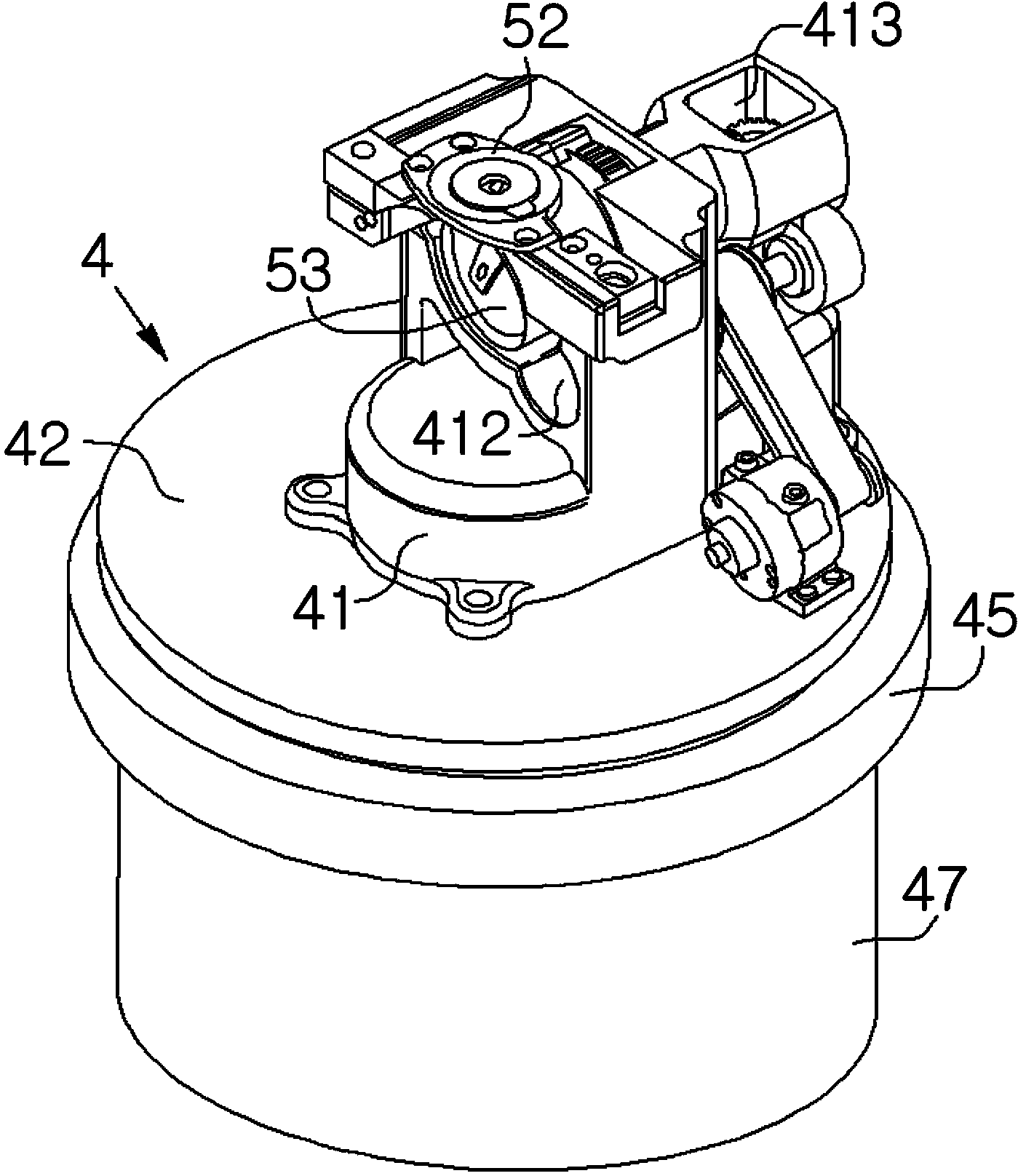

[0017] see figure 1 , The present invention is made up of machine base 1, machine head 2, table top 5, shuttle bed seat assembly 4 and cloth feeding mechanism (not shown).

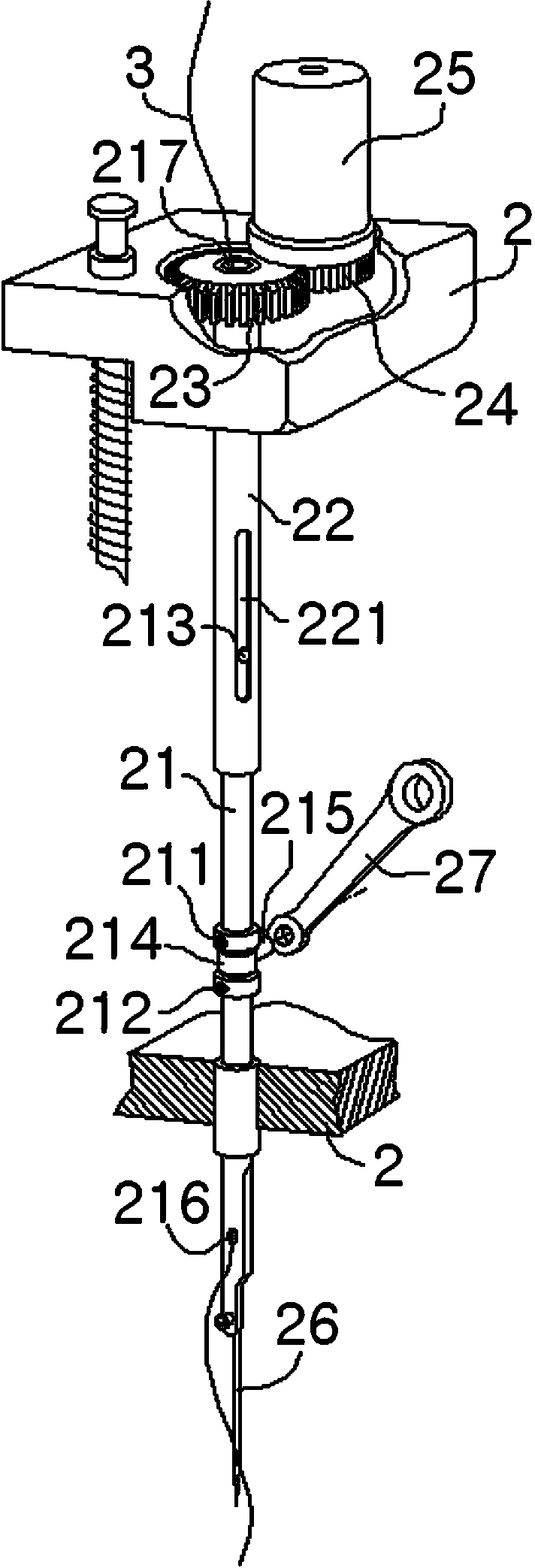

[0018] see figure 2 and figure 1 , there is a needle bar 21 in the machine head 2; the needle bar 21 is a hollow needle bar, and the suture thread 3 passes through the needle bar center 217 and is connected to the machine needle 26 from the thread outlet hole 216; the upper part of the needle bar 21 is slidably covered with a belt There is the sleeve 22 of straight seam 221, and a first gear 23 is fixed on the top of the sleeve 22; a needle bar rotating motor 25 is fixed on the sewing machine head 2, and the needle bar rotating motor 25 has a second gear 24, the second The gear 24 meshes with the first gear 23; the shaft of the needle bar 21 is inlaid with a convex pin 213, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com