Control device for thread gripper of sewing machine

A technology of a control device and a thread gripper, which is applied to the sewing machine control device, sewing equipment, sewing machine components, etc., can solve the problems that the suture cannot reach the tension force, the use stability is poor, the spring elasticity is weakened, etc., and the working stability is achieved. High, good use effect, high practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

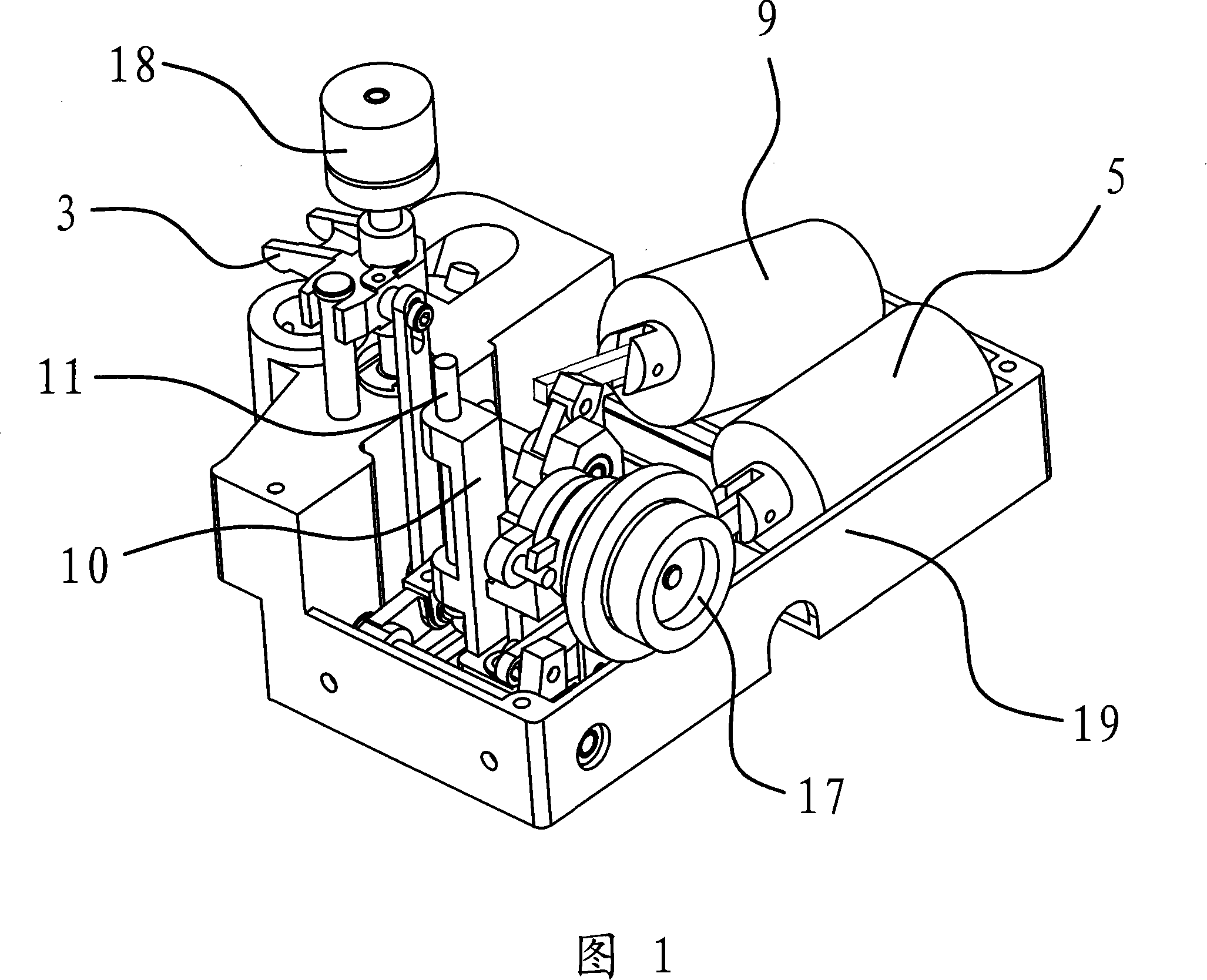

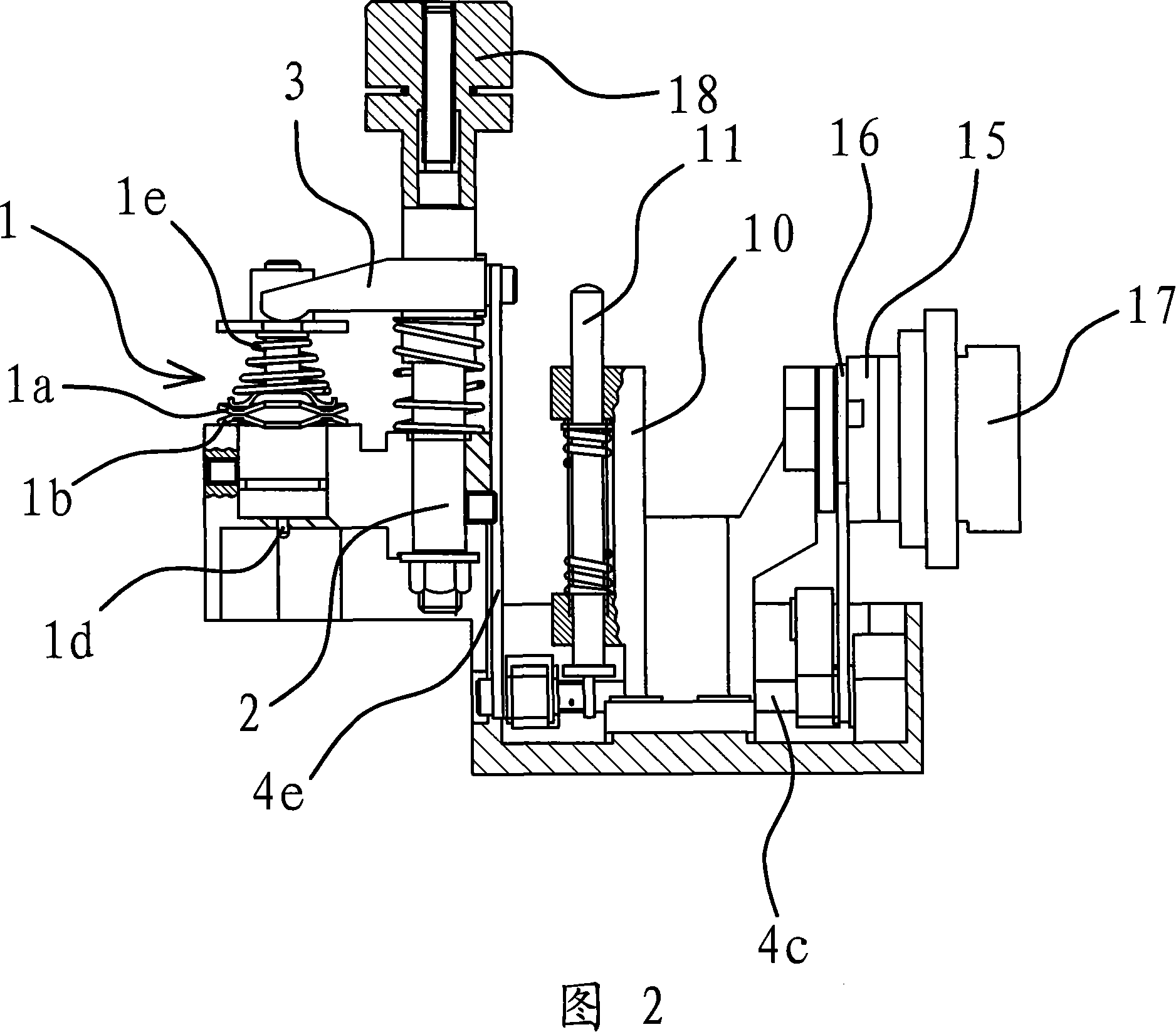

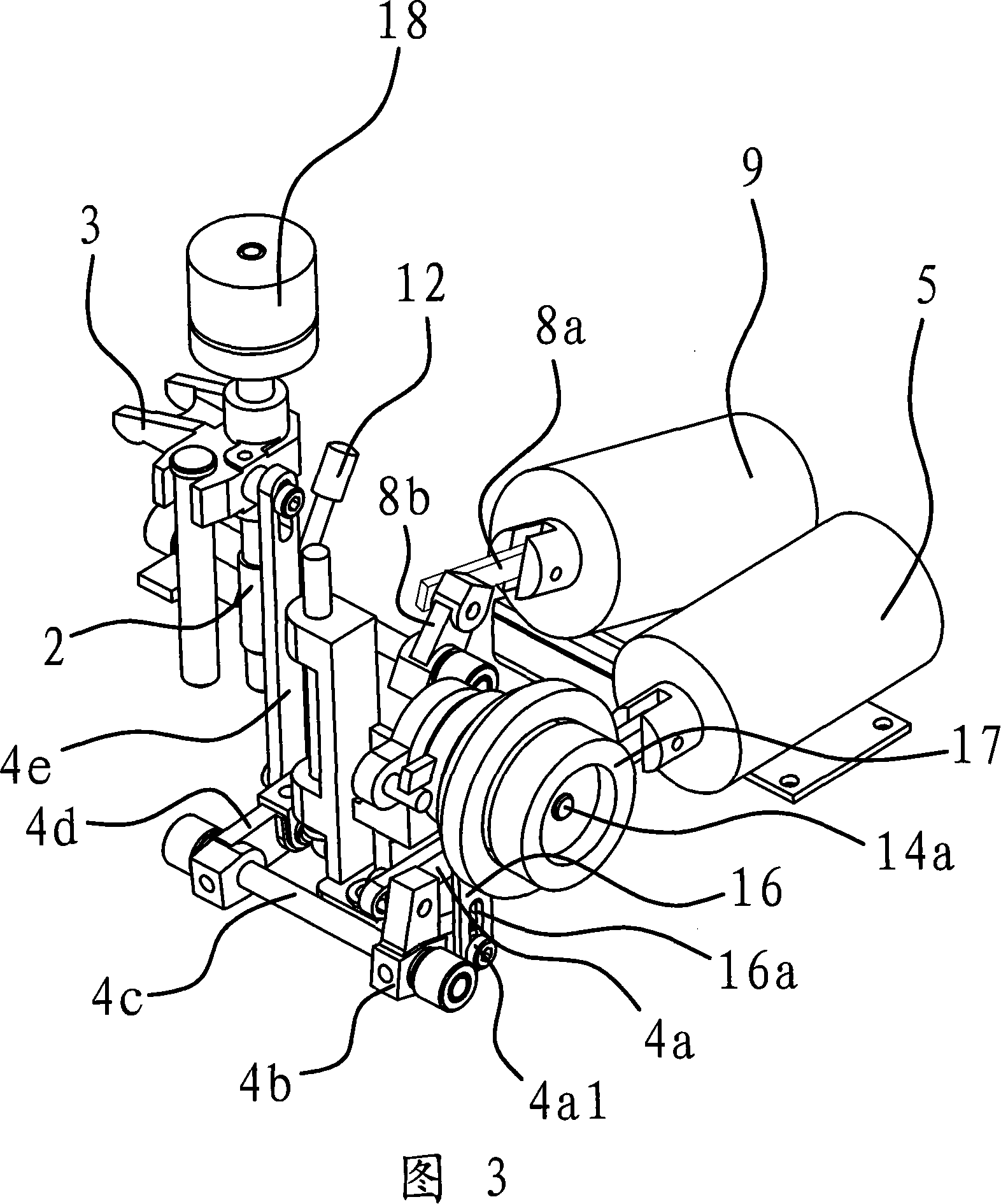

[0036] As shown in Figures 1 and 2, a thread clamp 1 is connected to the housing 19 on the sewing machine, through which the tension of the suture during the sewing process can be controlled.

[0037]As shown in Figure 2, the thread clamp 1 includes a rod body 1c, an upper chuck 1a, a lower chuck 1b, and a spring 1e sleeved on the rod body 1c, the rod body 1c is cylindrical, and a core rod 1d is arranged inside the rod body 1c . Under the elastic force of the spring 1e, the upper chuck 1a and the lower chuck 1b are in close contact with each other. The inner end of the core rod 1d abuts on the above-mentioned upper chuck 1a, and the outer end of the core rod 1d protrudes from the rod body 1c and is located at the bottom of the upper chuck 1a and the lower chuck 1b. The control device of the thread clamp in this sewing machine is just arranged on the side of the thread clamp 1, and the thread clamp 1 can be loosened or tightened by this control device.

[0038] As shown in FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com