Thread adjusting device for sewing machine

A thread adjusting device and sewing machine technology, applied in the direction of sewing machine control devices, sewing machine components, program-controlled sewing machines, etc., can solve problems such as tension, operation interruption, etc., to suppress heat generation, eliminate operation interruption, and realize sewing operation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]

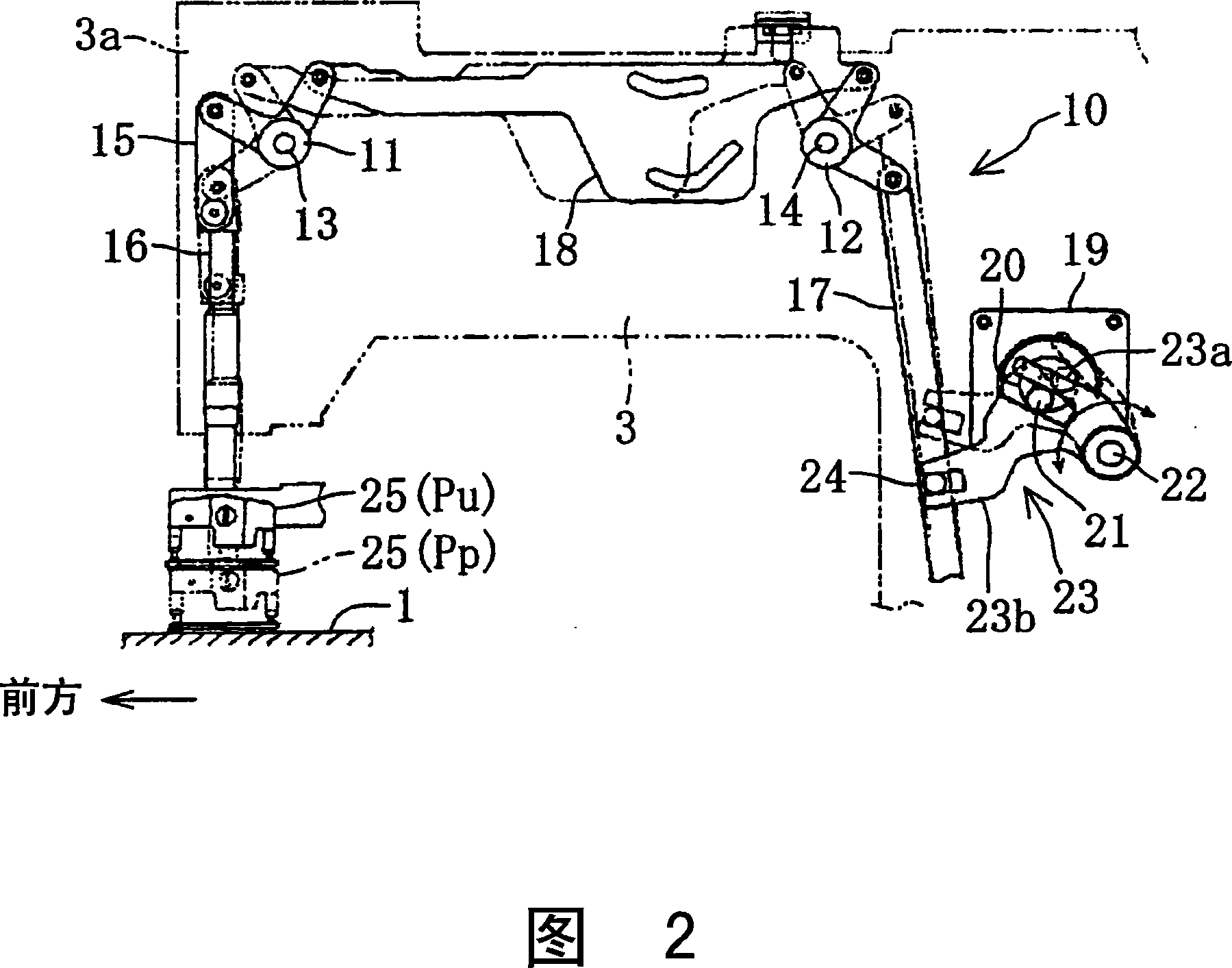

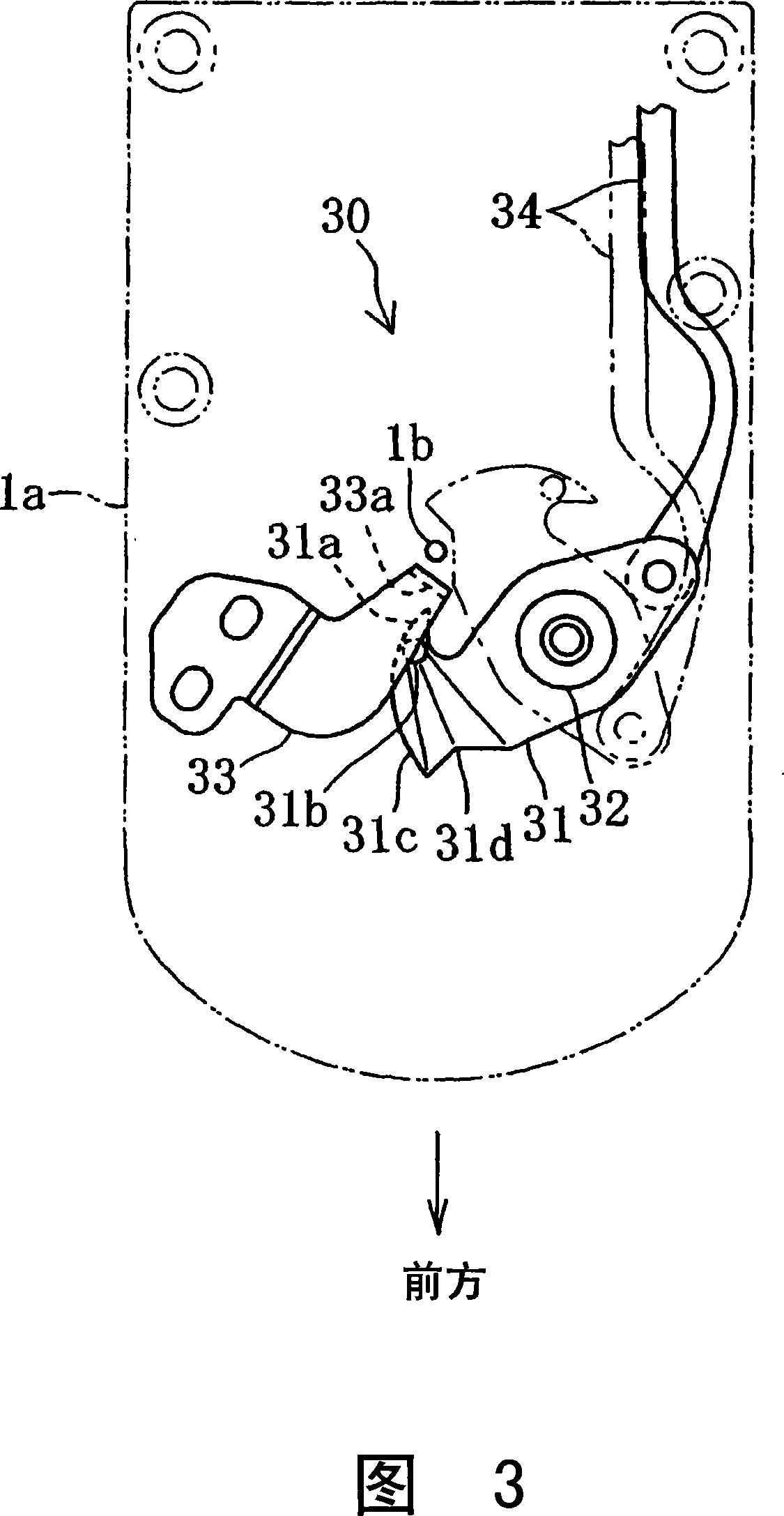

[0031] Next, a first embodiment of the present invention will be described with reference to the drawings. This embodiment is an example in which the present invention is applied to a thread adjusting device of a buttonhole sewing machine for forming buttonhole stitches.

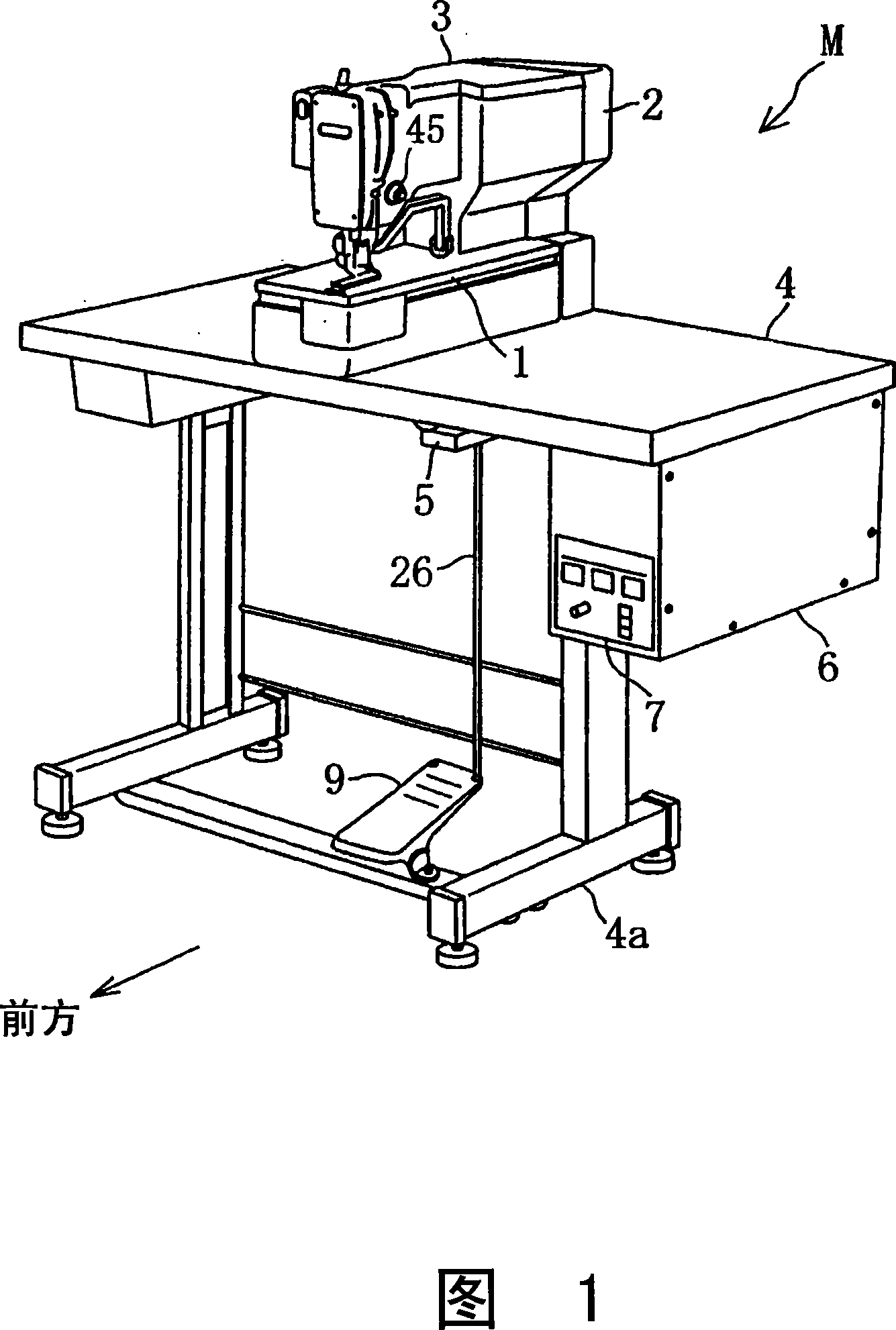

[0032] As shown in FIG. 1 , the buttonhole sewing machine M is installed on the sewing machine bed 4 . A control box 6 is provided at the right end portion (the direction of the arrow in FIG. 1 is the front) on the lower side of the sewing machine table 4 . An operation panel 7 for inputting various pattern data for forming keyhole stitches (not shown) and buttonholes is provided on the front portion of the control box 6 . The control box 6 has a control device 8 (see FIG. 7 ) for performing various sewing controls. A sewing machine motor 5 is provided at the central portion of the lower side of the sewing machine table 4 . The sewing machine motor 5 is driven to rotate a sewing machine main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com