Intelligent full-automatic hot-melting button wrapping machine

A fully automatic, hot-melt technology, applied to sewing machine components, sewing machine control devices, textiles and papermaking, etc., can solve problems such as waste of thread winding, blockage of outlet pipe and thread suction device, damage to motor drive components, etc., to avoid Waste manpower and material resources, avoid blocking, and ensure the effect of getting out of the line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

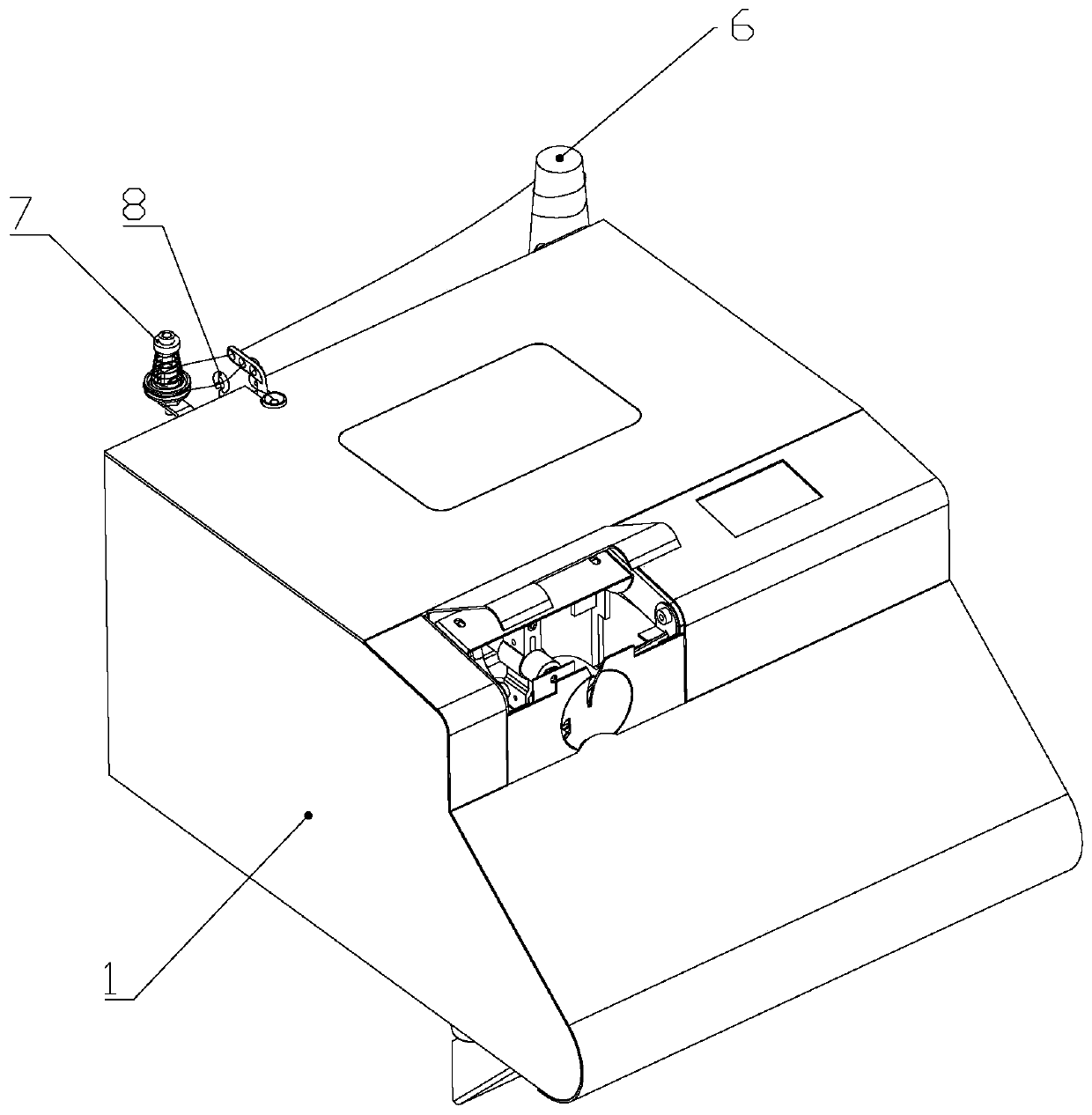

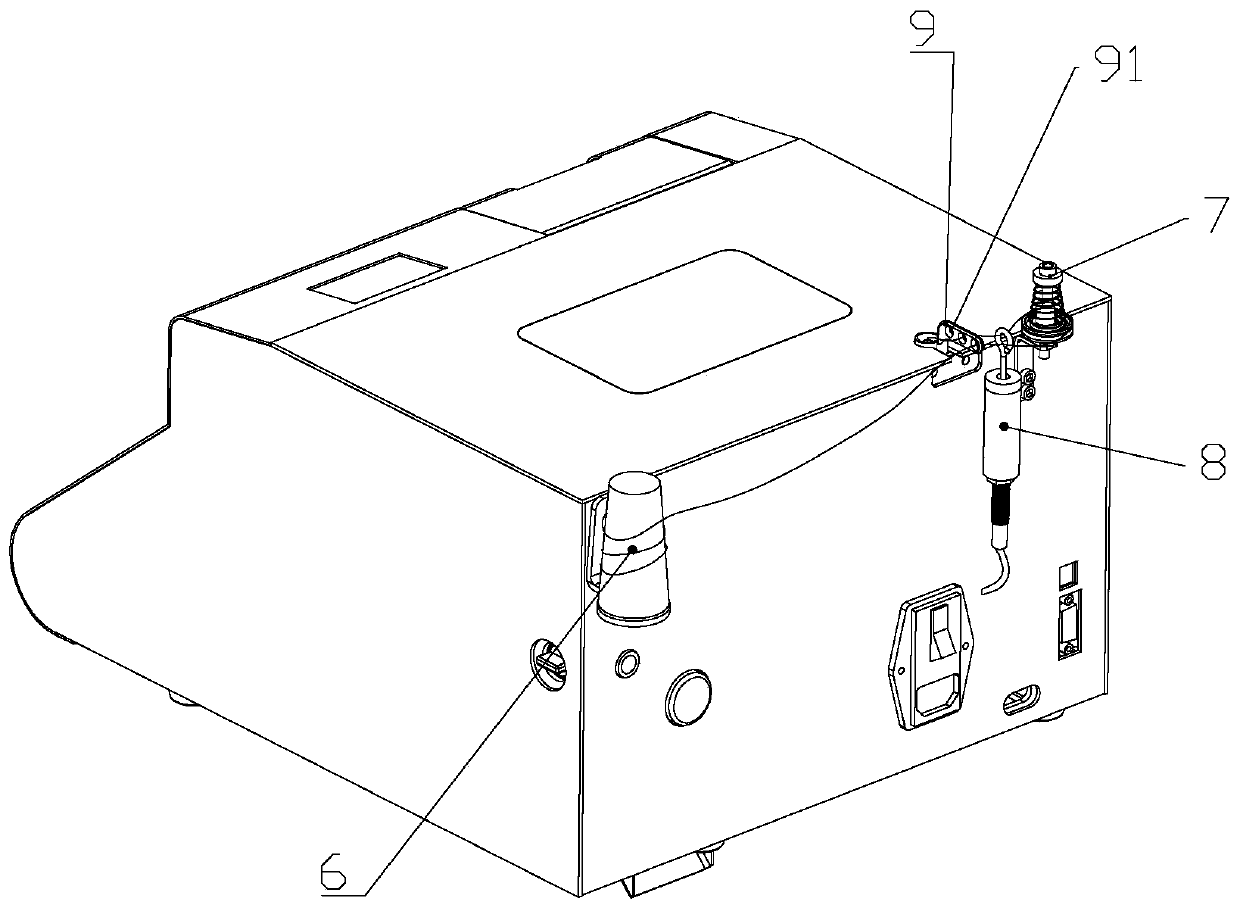

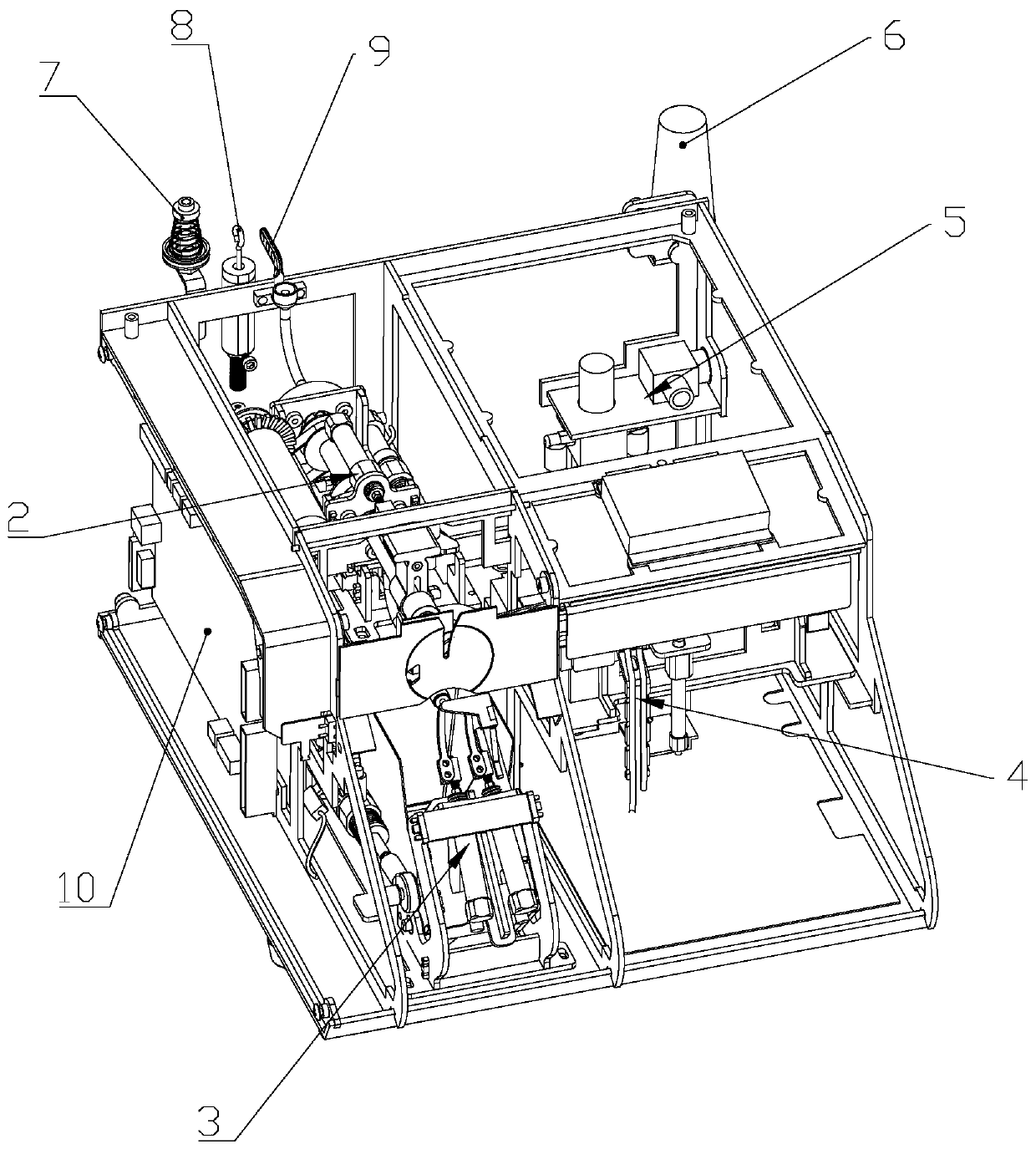

[0039] Such as Figure 1 to Figure 12As shown, in this embodiment, an intelligent automatic hot-melt button winding machine includes a frame 1, and the frame 1 is provided with a winding mechanism 2 that can wind the button wire at the junction of the button and the cloth, Also be provided with in the frame 1 and be able to pull off the backguy breaking mechanism 3 of winding wire, also be provided with in described frame 1 and be used for melting the thermal fuse on winding wire and be fixed on button and winding wire Fusible wire sticking mechanism 4 at the cloth connection, the frame 1 is provided with a drive device 5 capable of controlling the operation of the winding mechanism 2, the wire breaking mechanism 3 and the fuse bonding mechanism 4, the frame 1 is provided with a control system 10 that is connected to the drive device 3, and the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com