Patents

Literature

122results about How to "Detection accuracy meets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

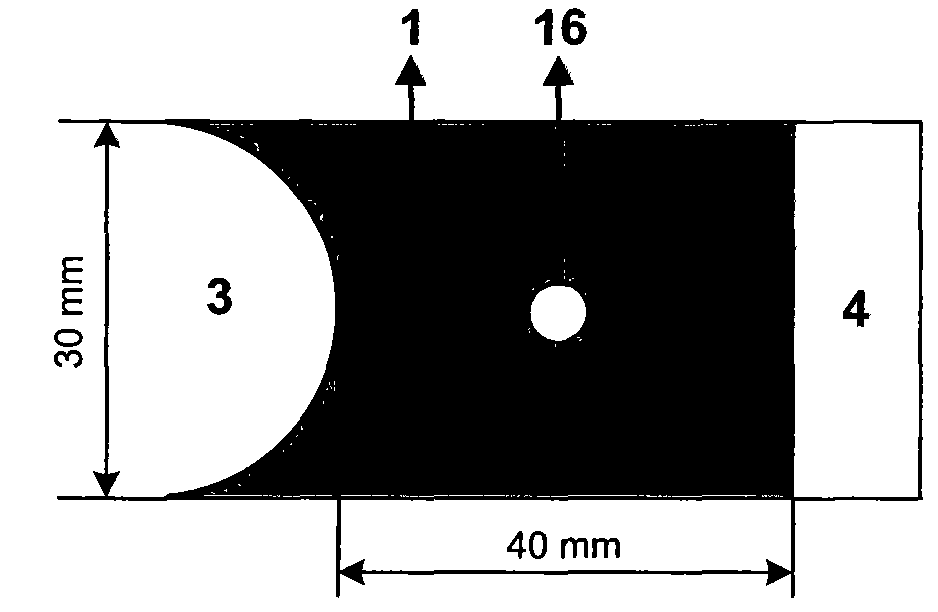

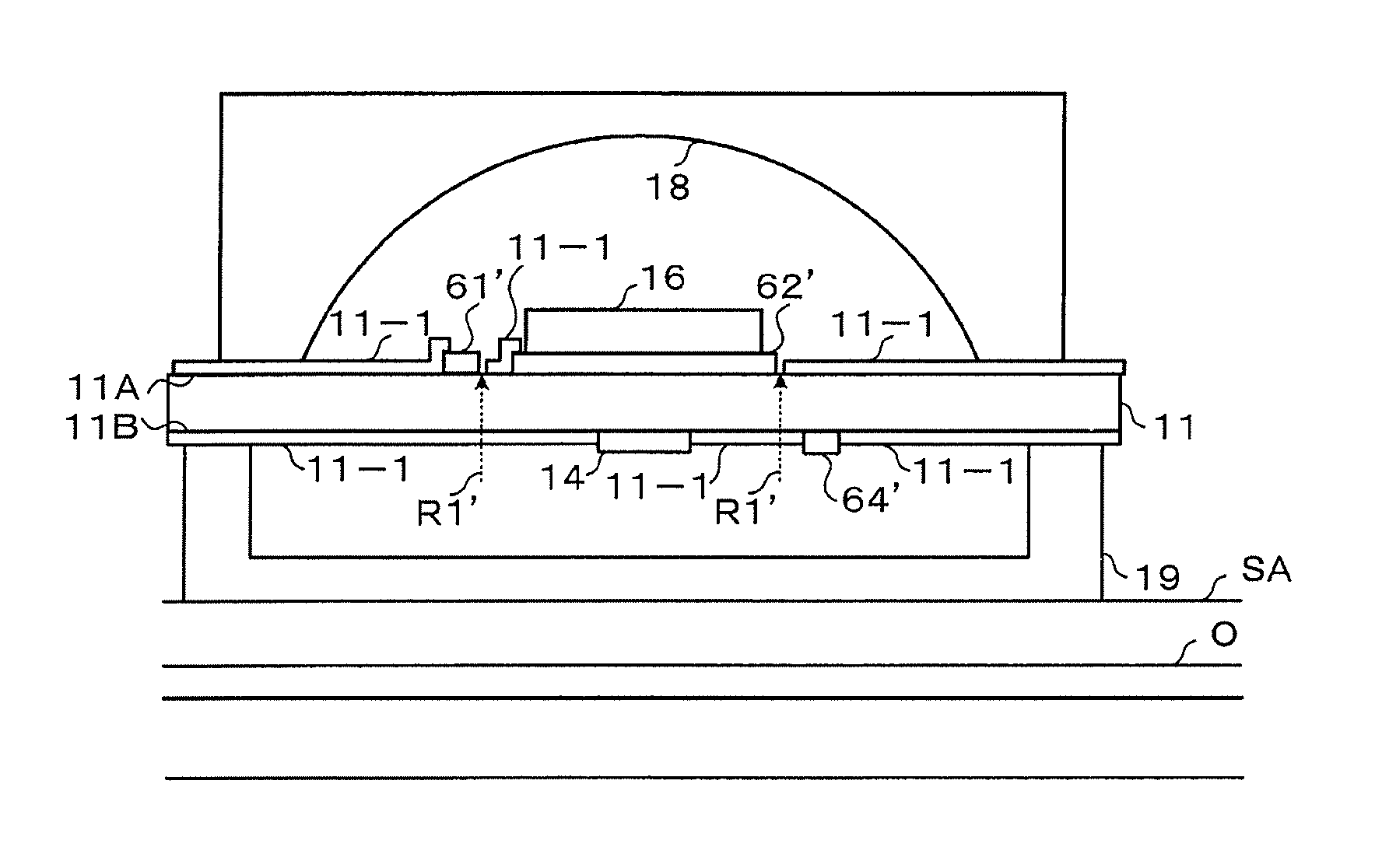

Polishing pad and method for manufacturing semiconductor device

InactiveUS20060037699A1Detection accuracy meetsHigh measurement accuracySemiconductor/solid-state device manufacturingLapping machinesWaferingDevice material

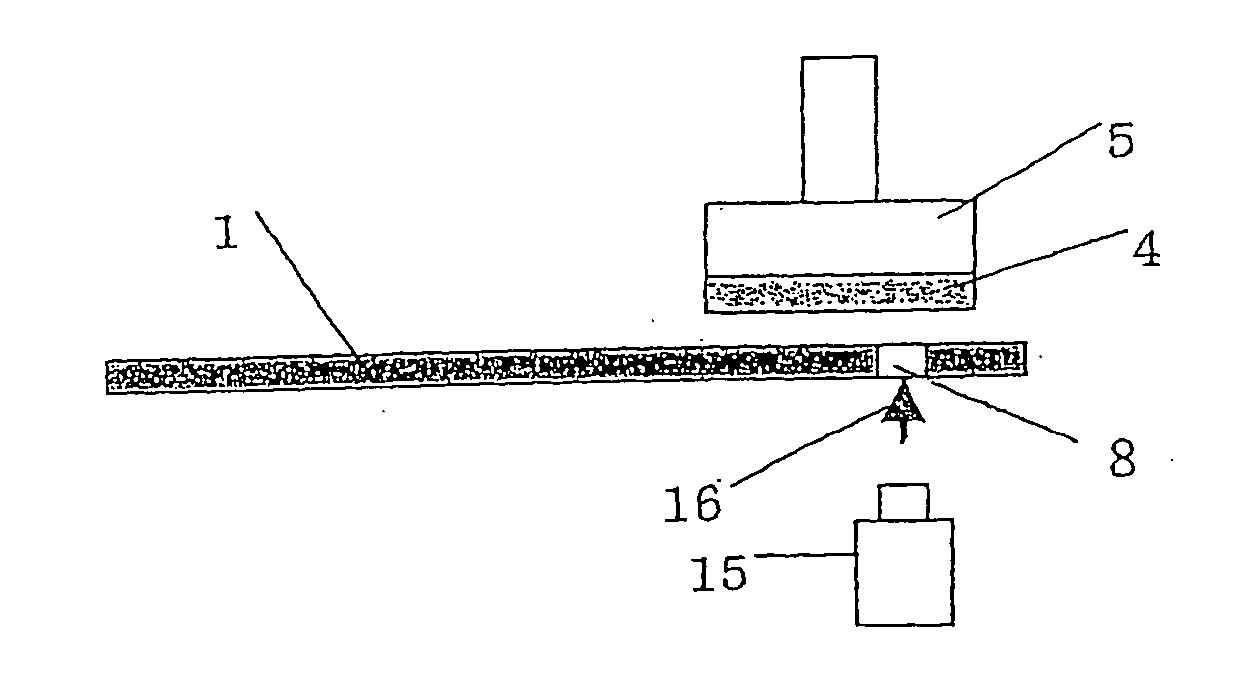

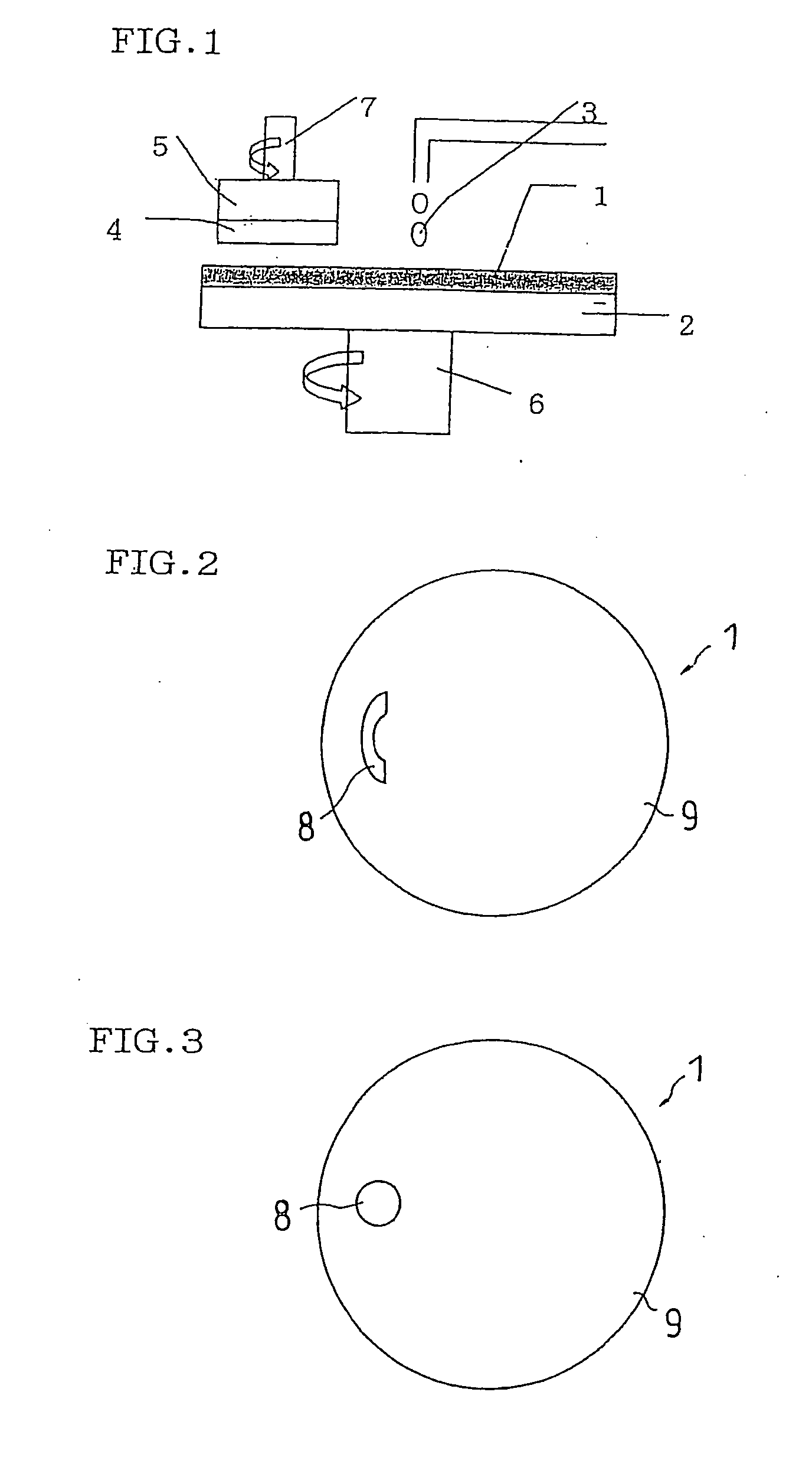

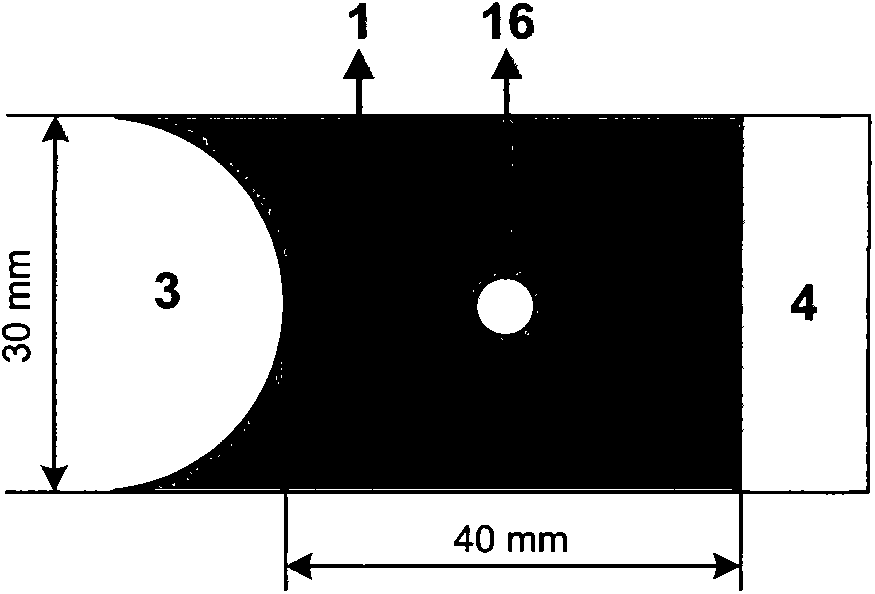

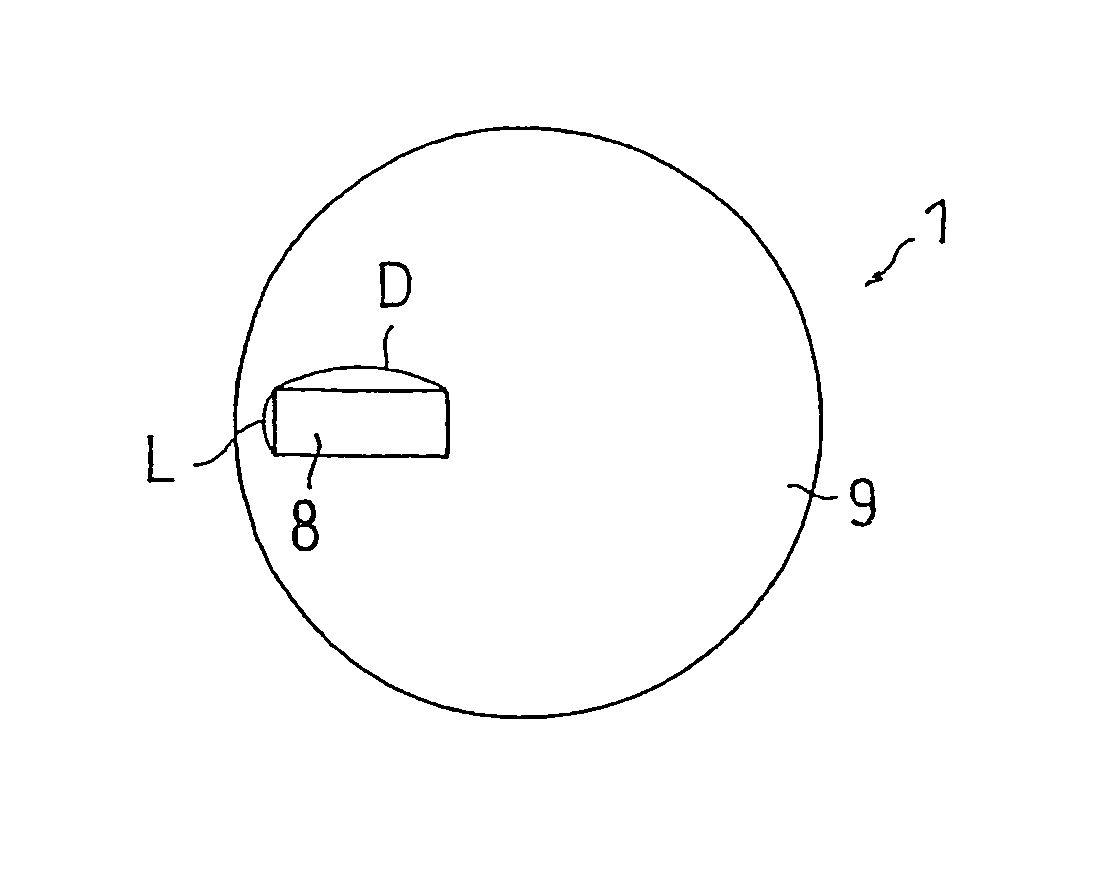

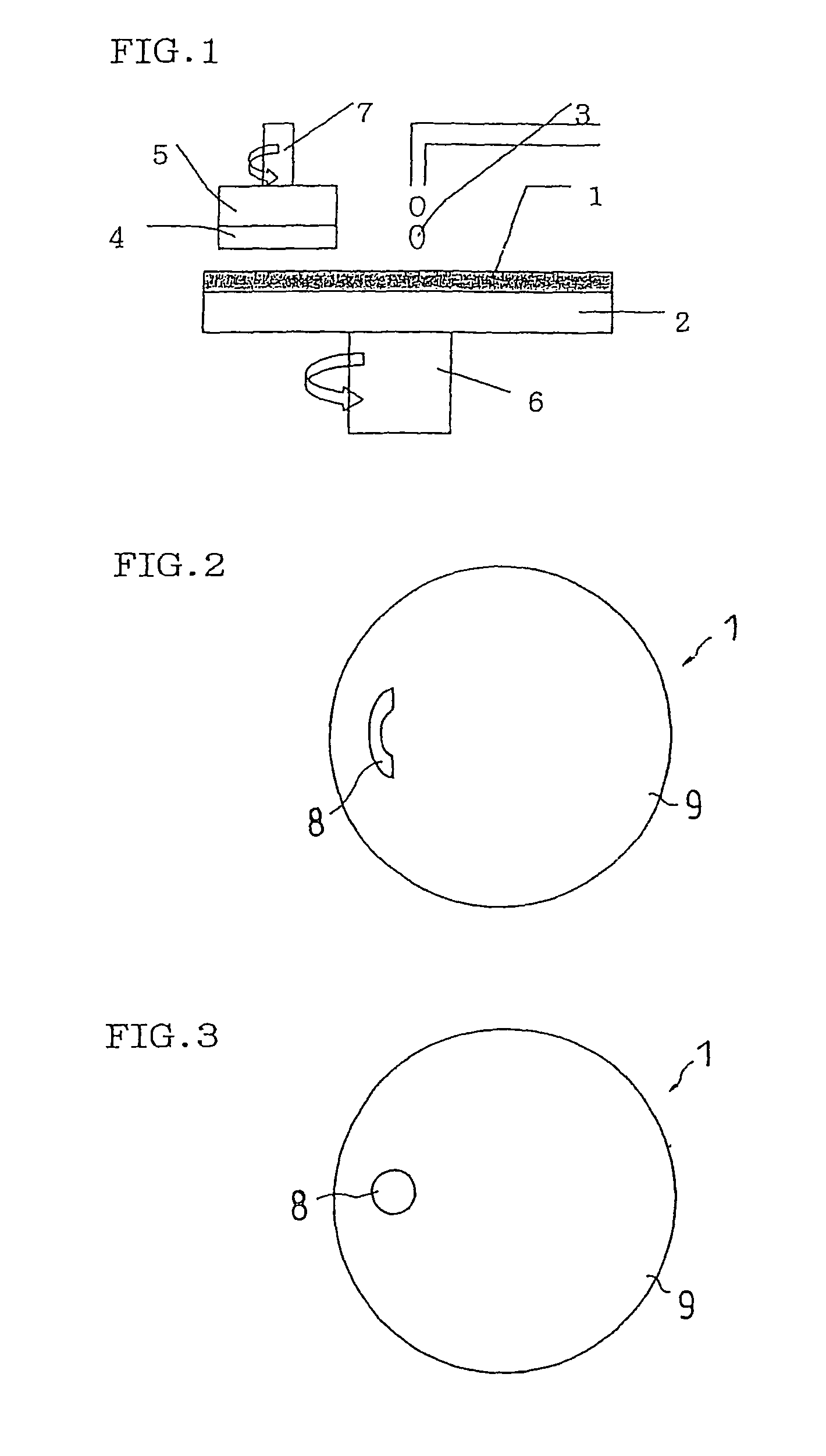

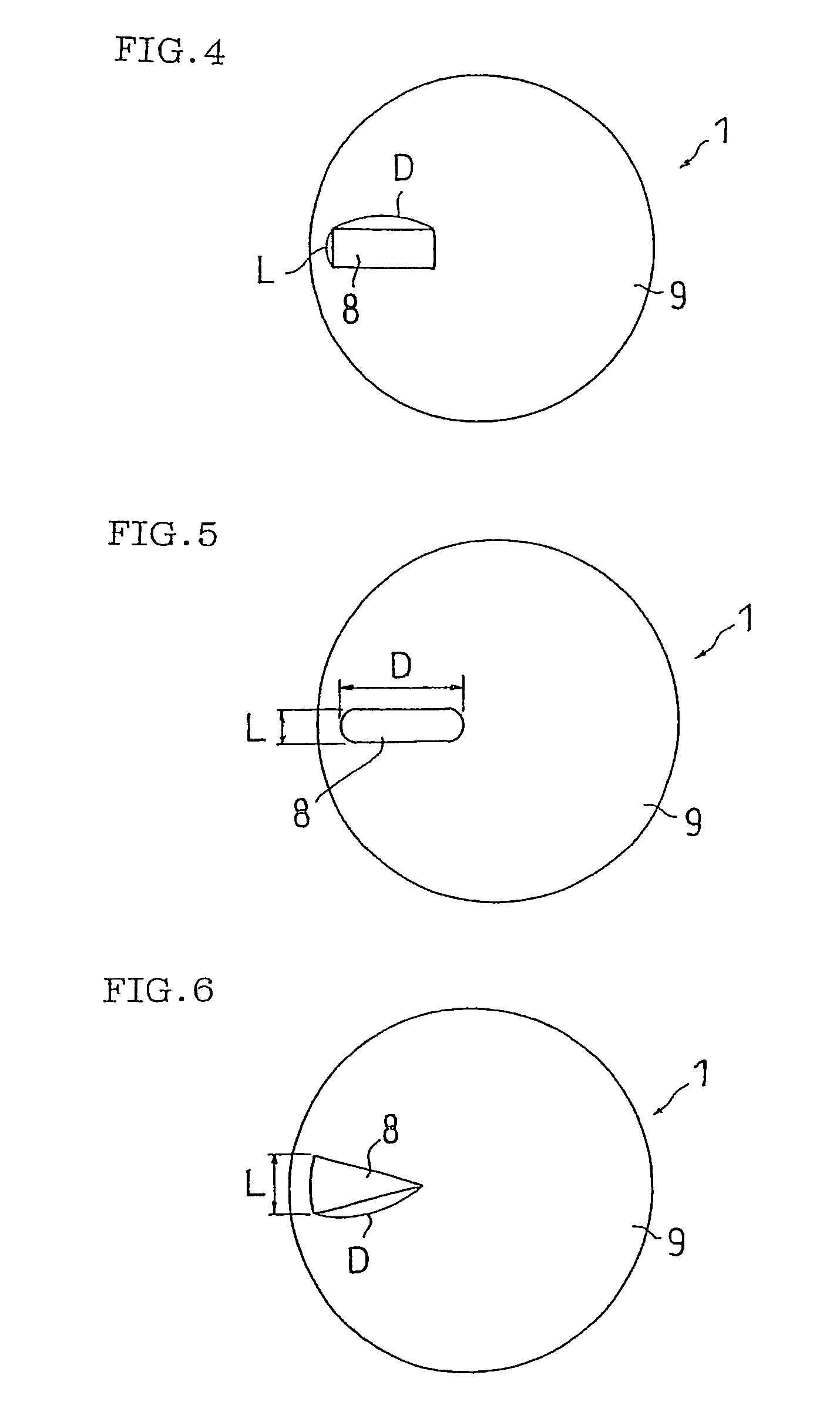

A polishing pad enabling a highly precise optical endpoint sensing during the polishing process and thus having excellent polishing characteristics (such as surface uniformity and in-plane uniformity) is disclosed. A polishing pad enabling to obtain the polishing profile of a large area of a wafer is also disclosed. A polishing pad of a first invention comprises a light-transmitting region having a transmittance of not less than 50% over the wavelength range of 400 to 700 nm. A polishing pad of a second invention comprises a light-transmitting region having a thickness of 0.5 to 4 mm and a transmittance of not less than 80% over the wavelength range of 600 to 700 nm. A polishing pad of a third invention comprises a light-transmitting region arranged between the central portion and the peripheral portion of the polishing pad and having a length (D) in the diametrical direction which is three times or more longer than the length (L) in the circumferential direction.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

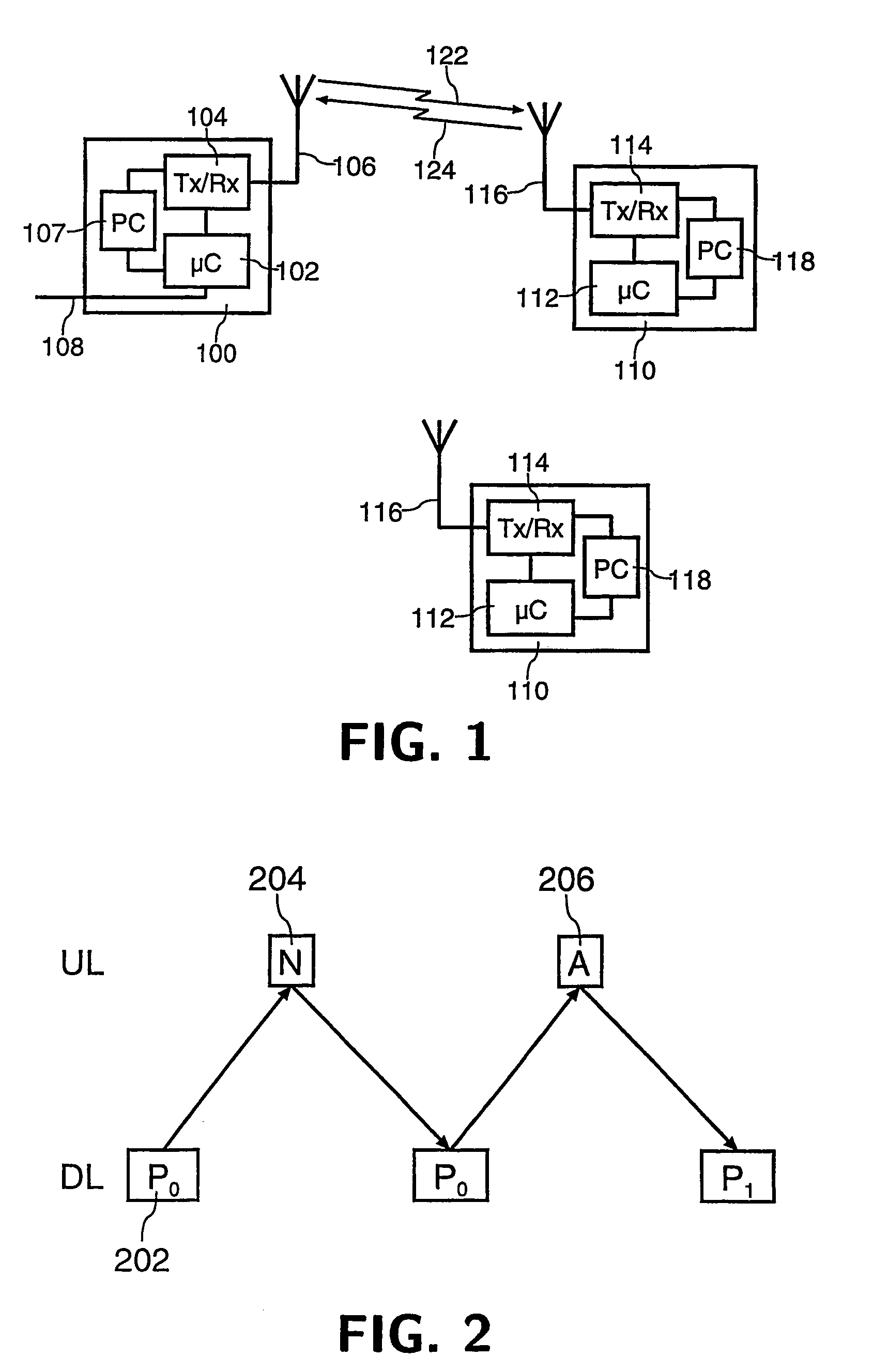

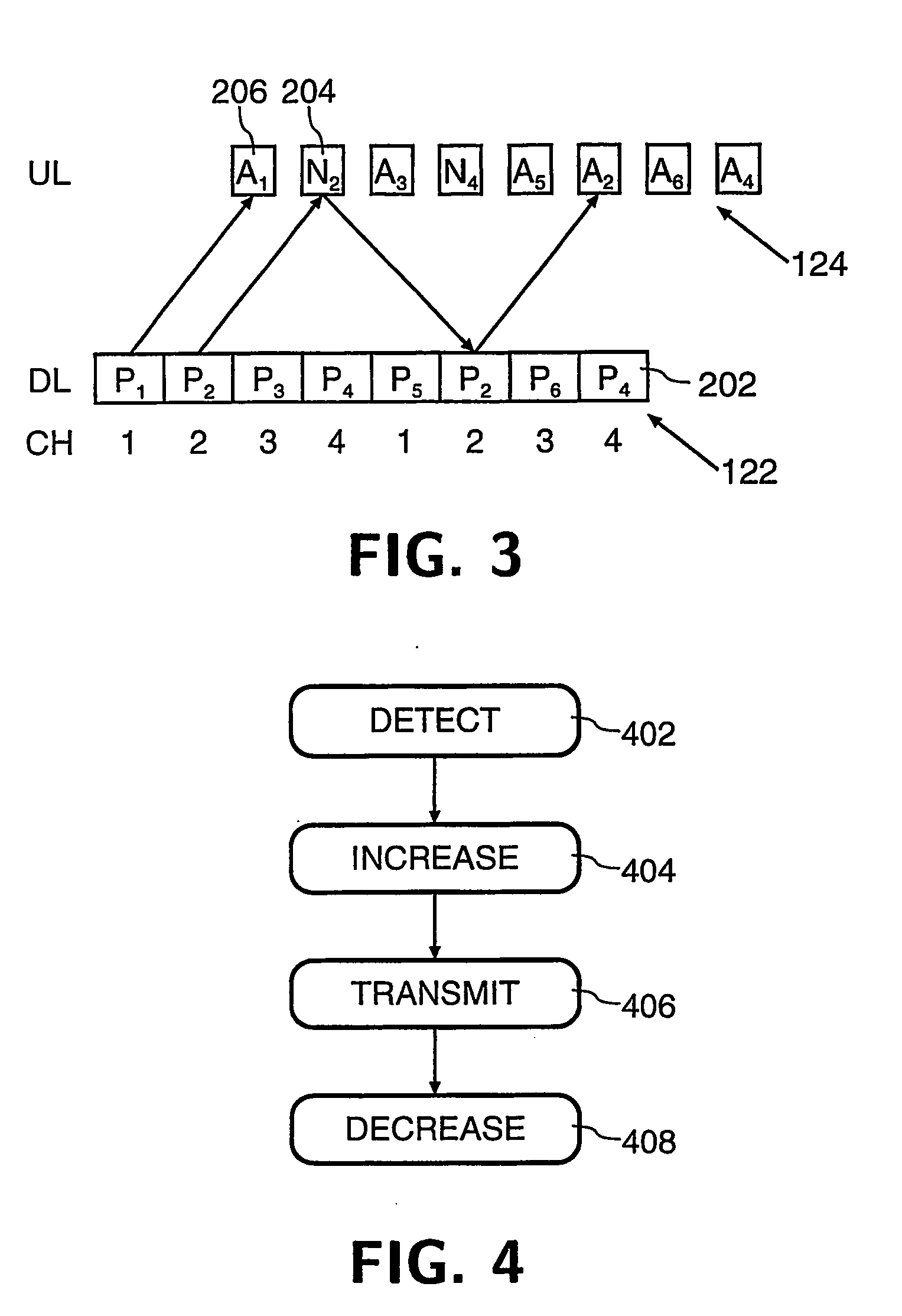

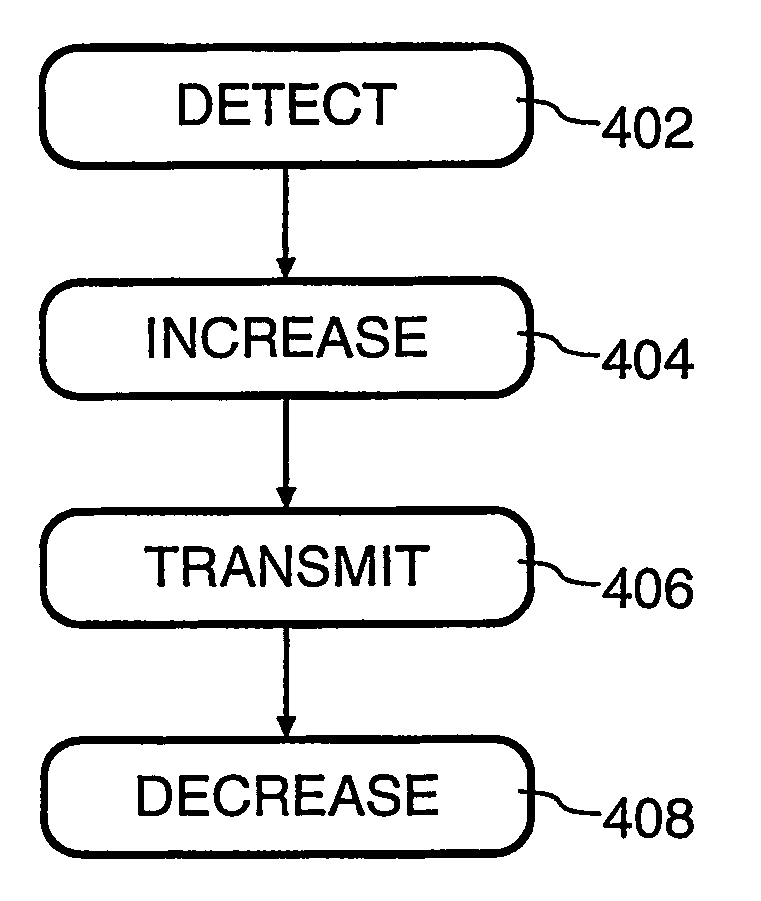

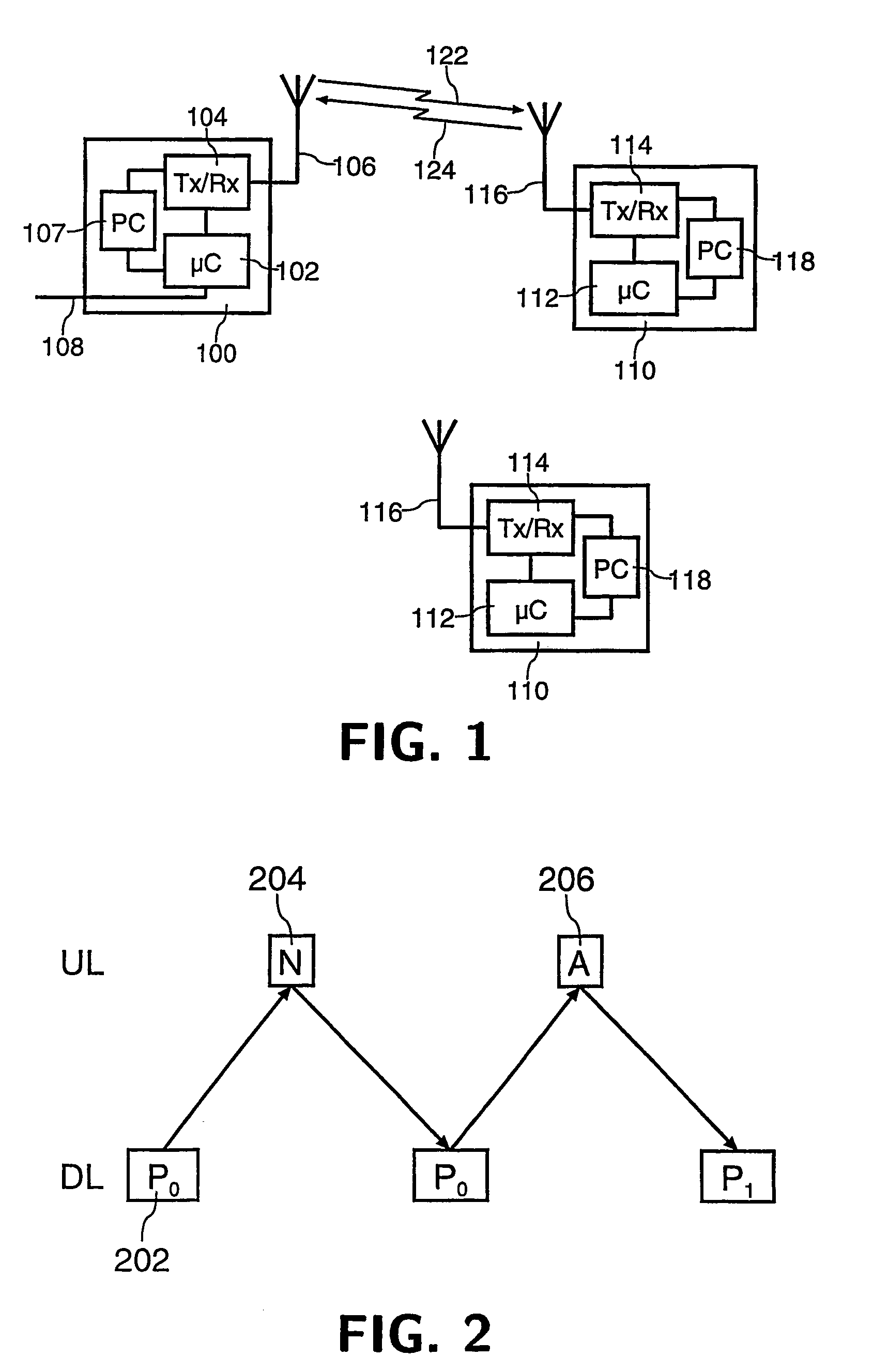

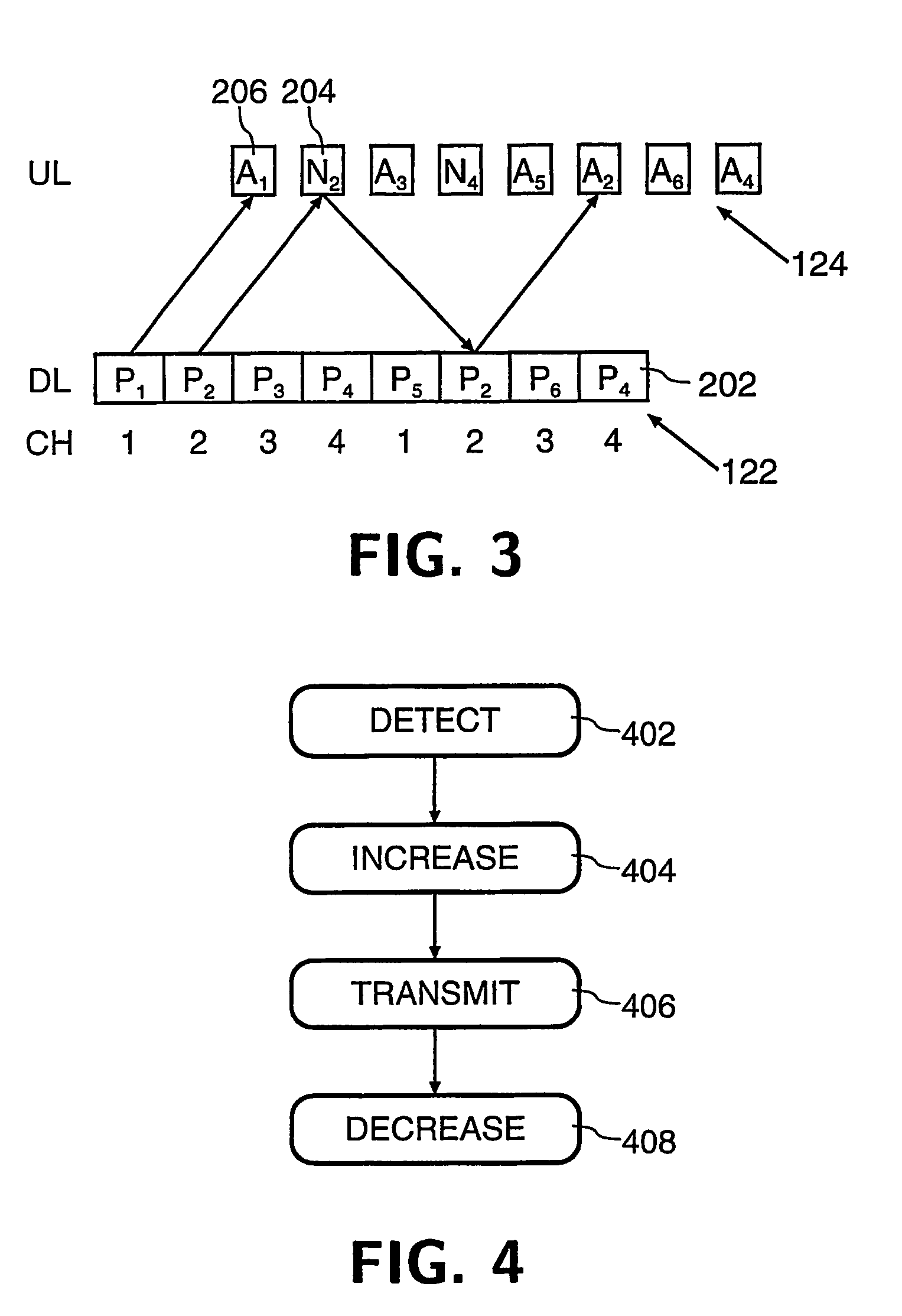

Communication system using arq

ActiveUS20050143114A1Improve accuracyImproved channel estimationPower managementEnergy efficient ICTPrimary stationCommunications system

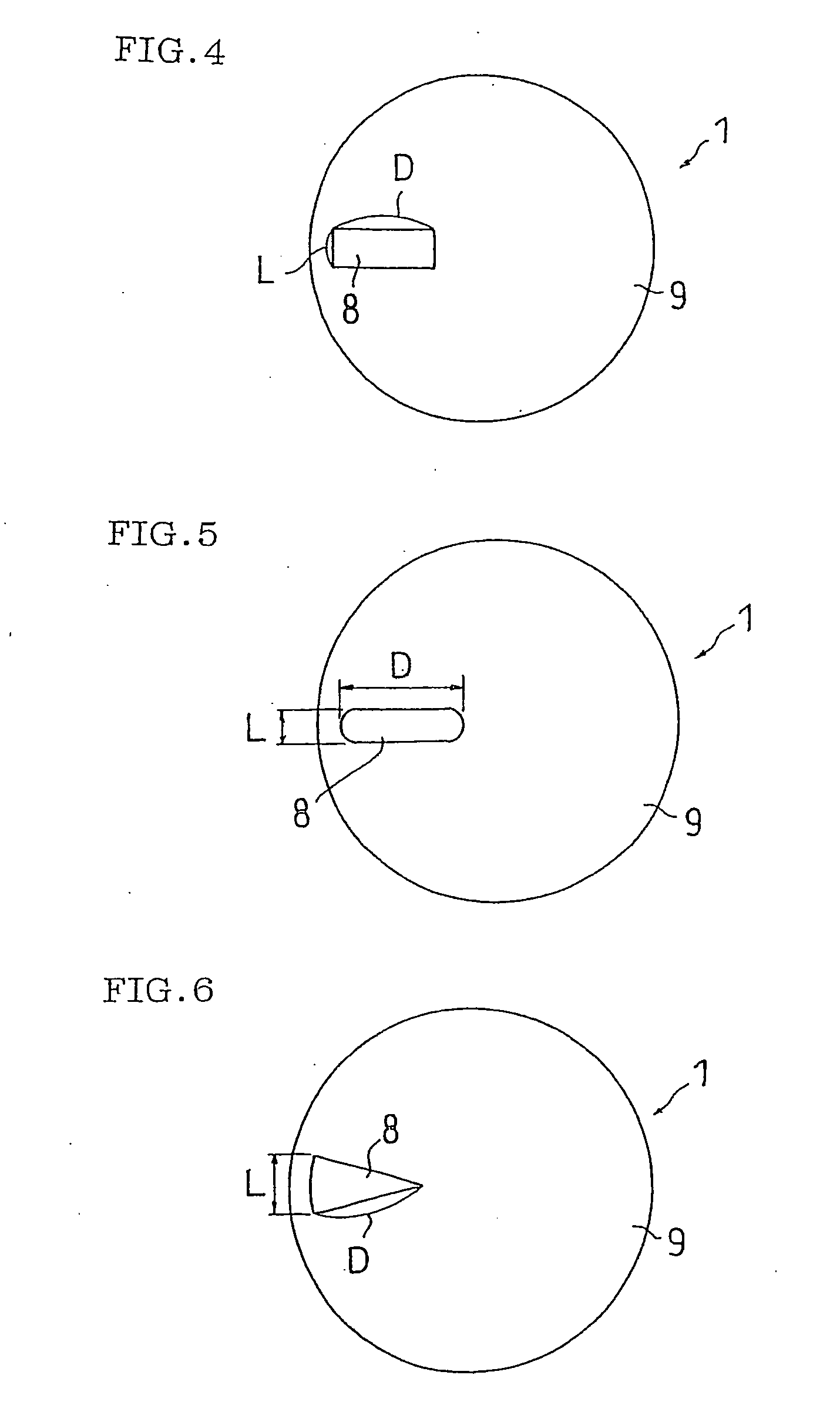

A communication system comprises a downlink data channel for the transmission of data packets from a primary station to a secondary station and two uplink control channels, a first channel for transmission of status signals to indicate the status of received data packets and a second channel for transmission of pilot information. In operation, on detection (402) of a data packet the secondary station increases (404) the transmission power of the second channel, thereby enabling the primary station to obtain a better estimate of uplink channel properties and hence increase the accuracy with which it can decode the status signal. The secondary station transmits (406) the status signal, typically either an acknowledgement (ACK) or negative acknowledgement (NACK), and decreases (408) the transmission power of the second control channel signal. The increase and decrease in power are not necessarily identical, for example as a result of the effects of power control.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

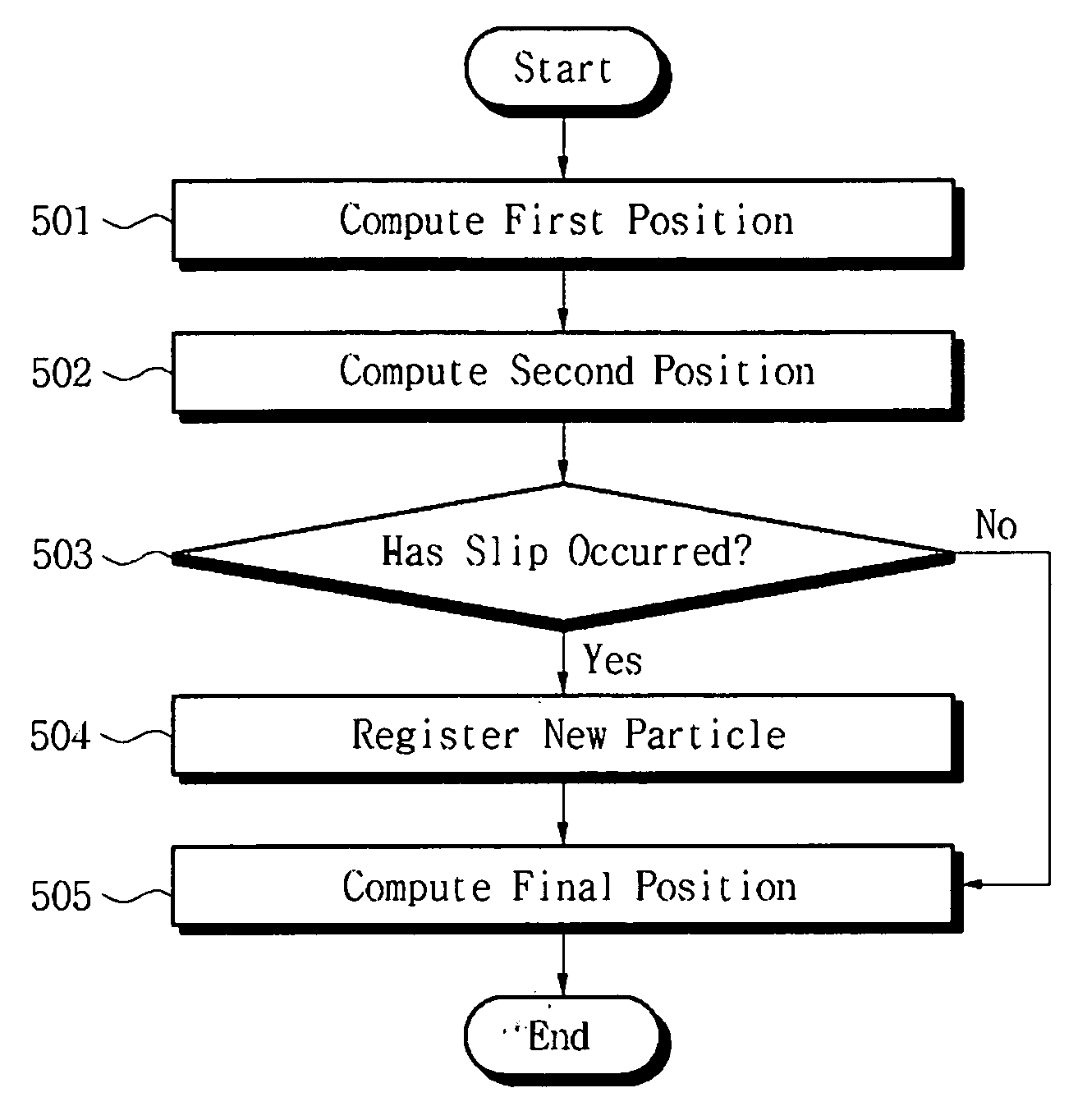

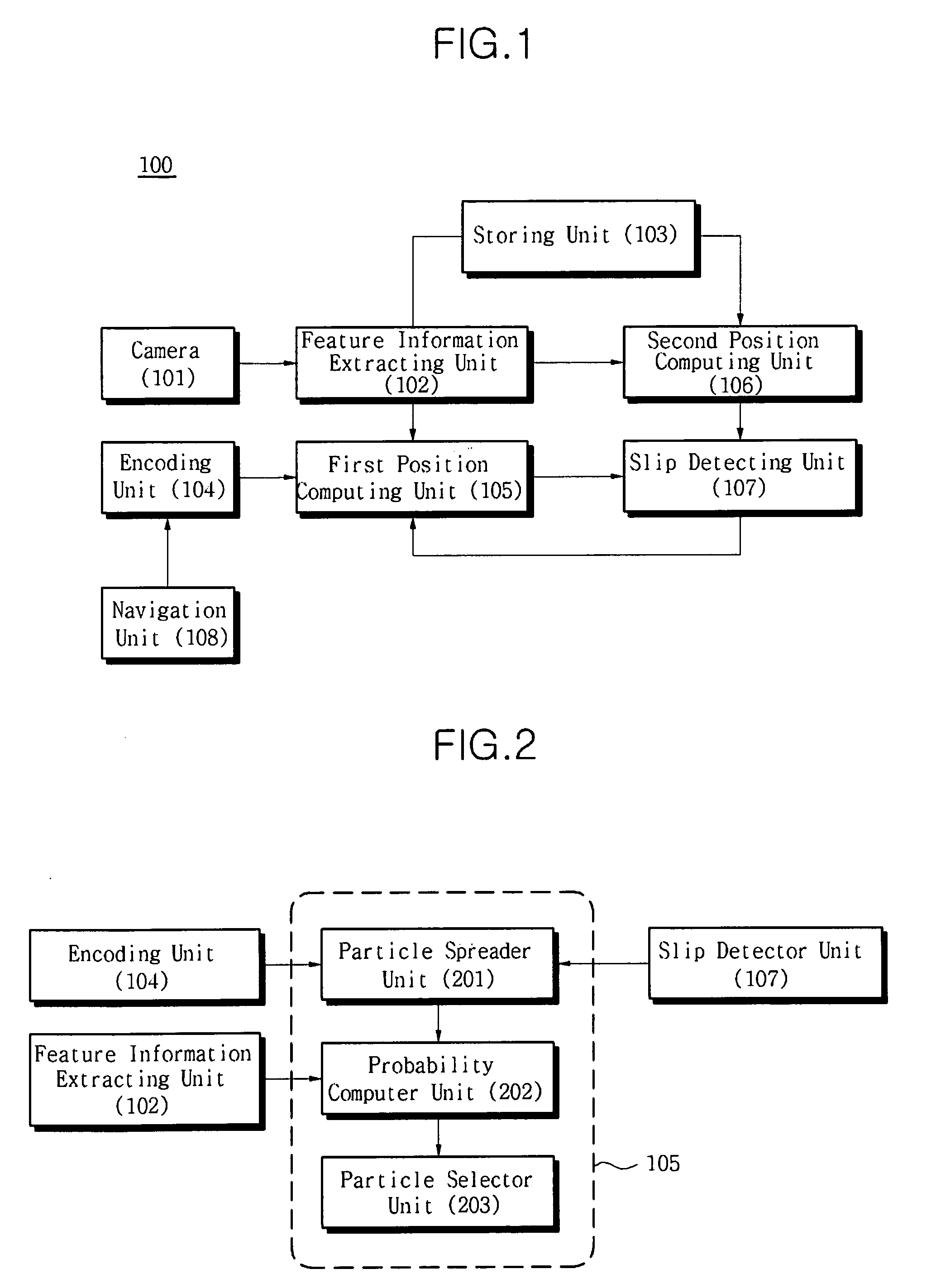

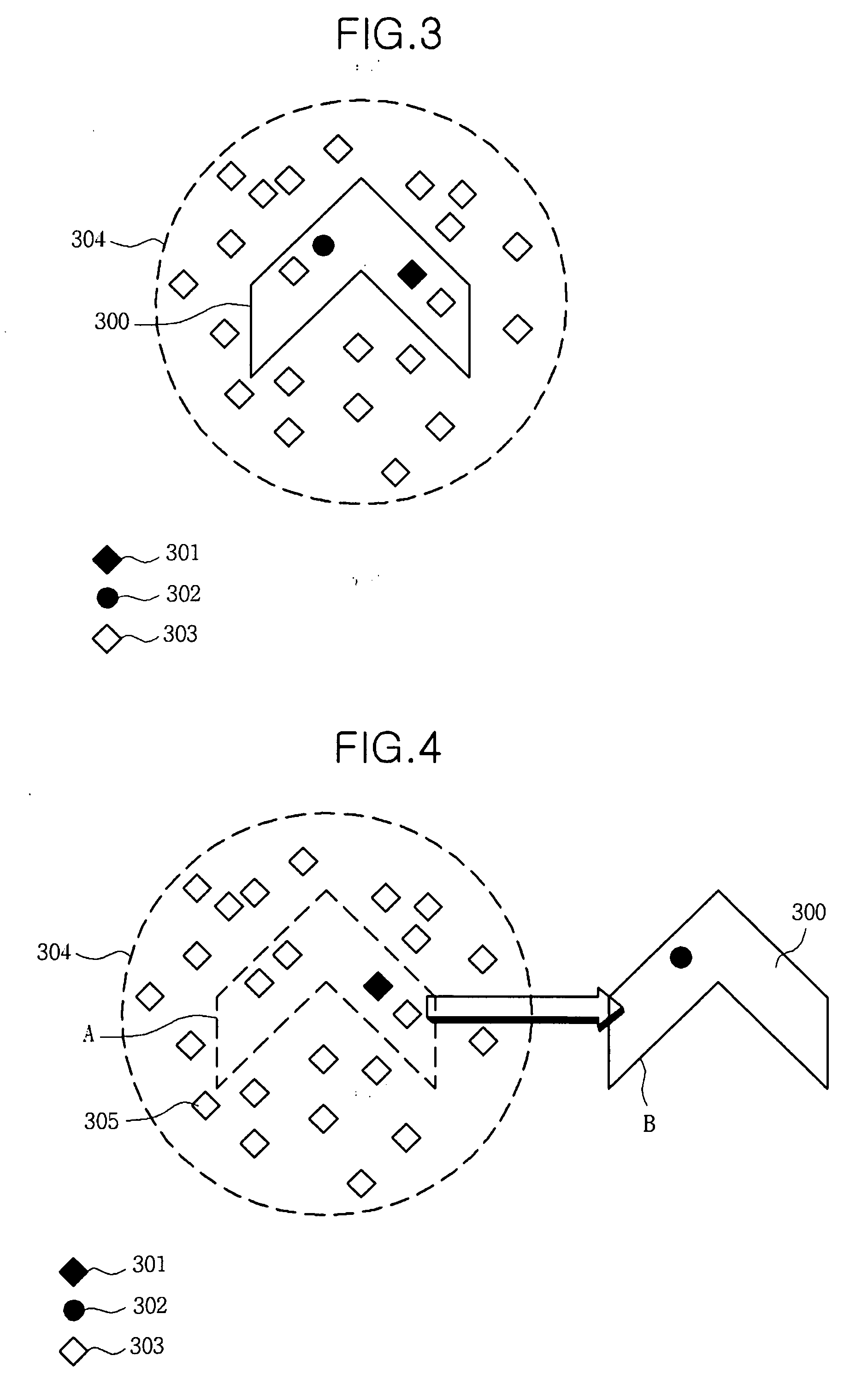

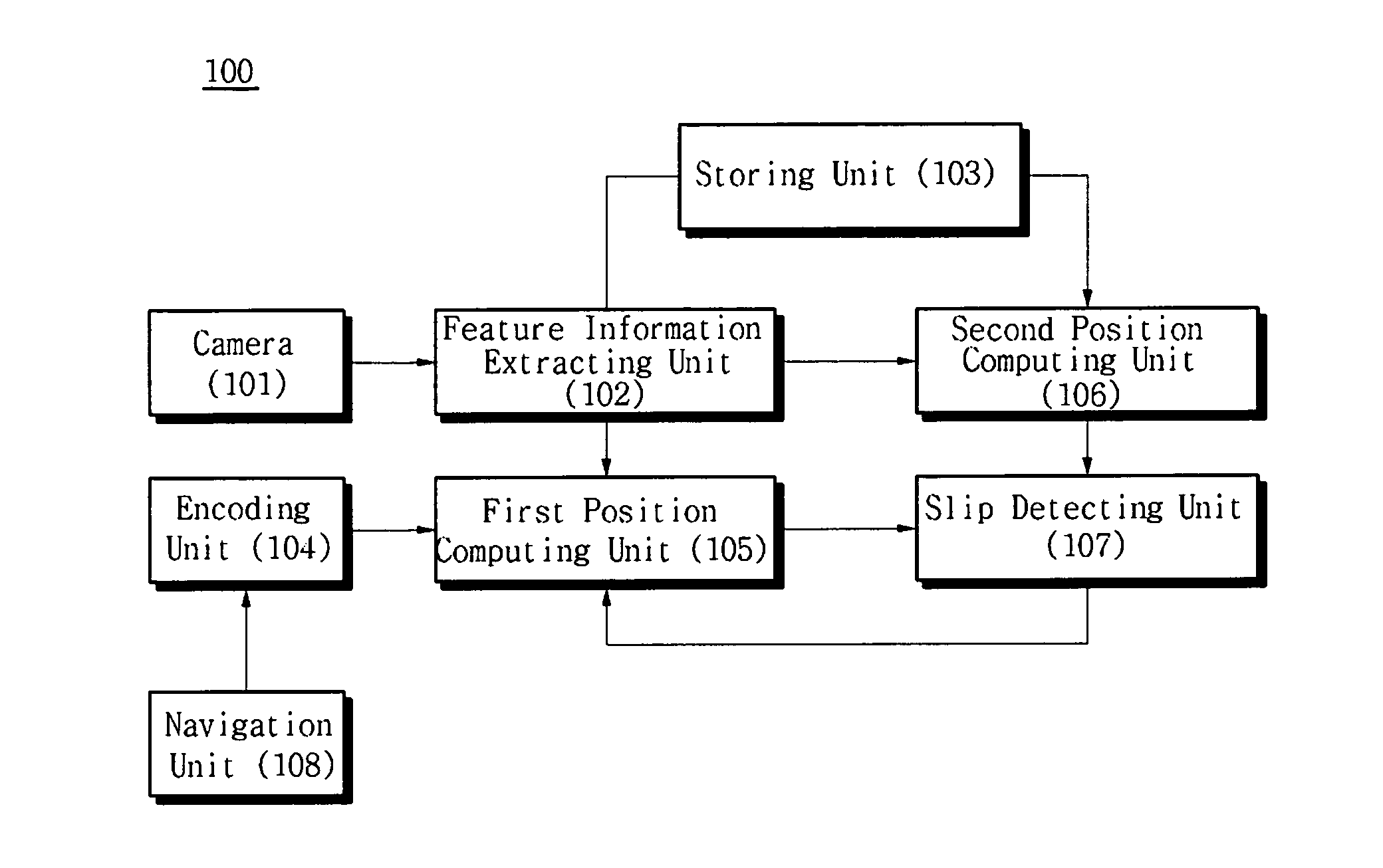

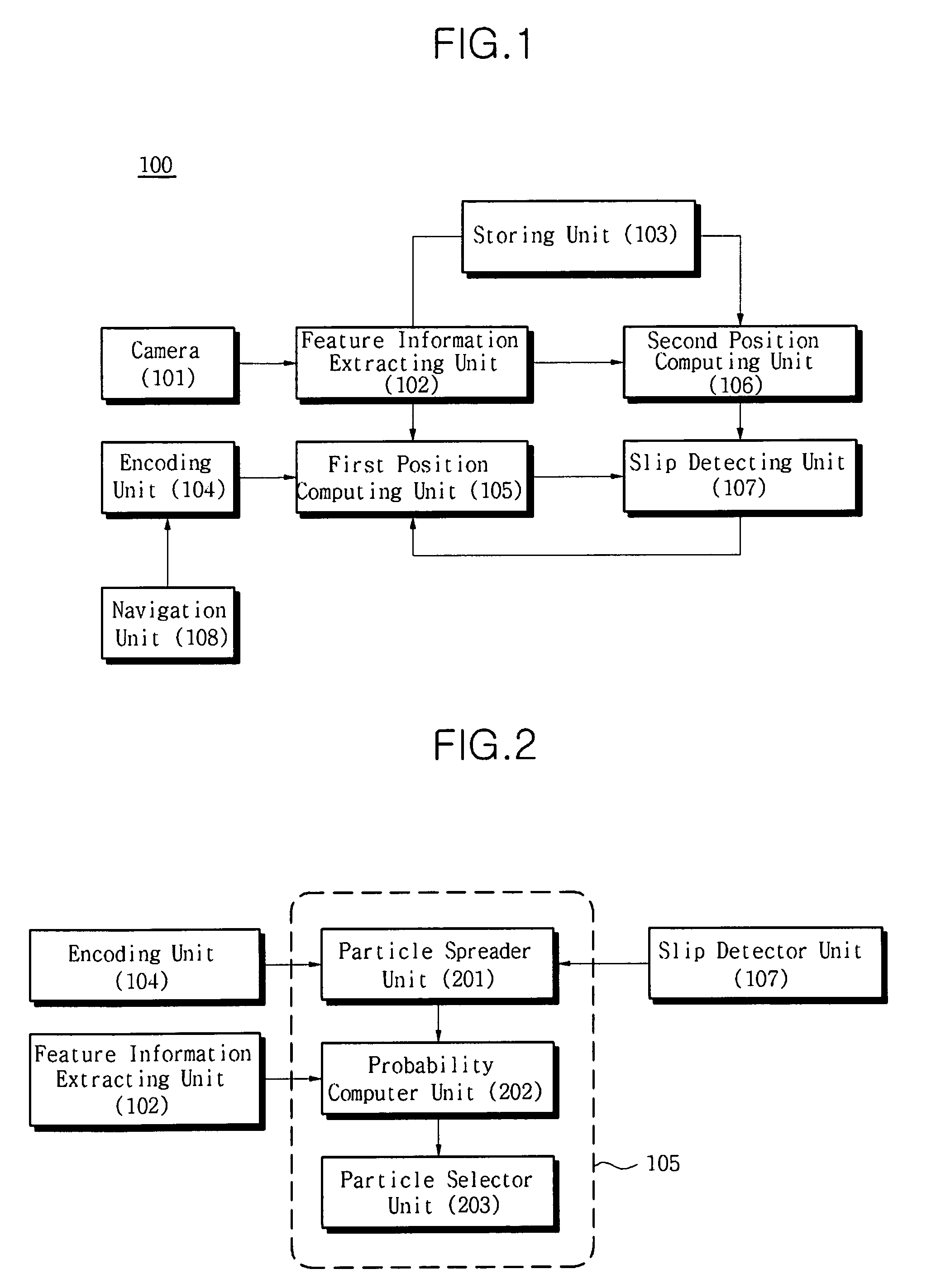

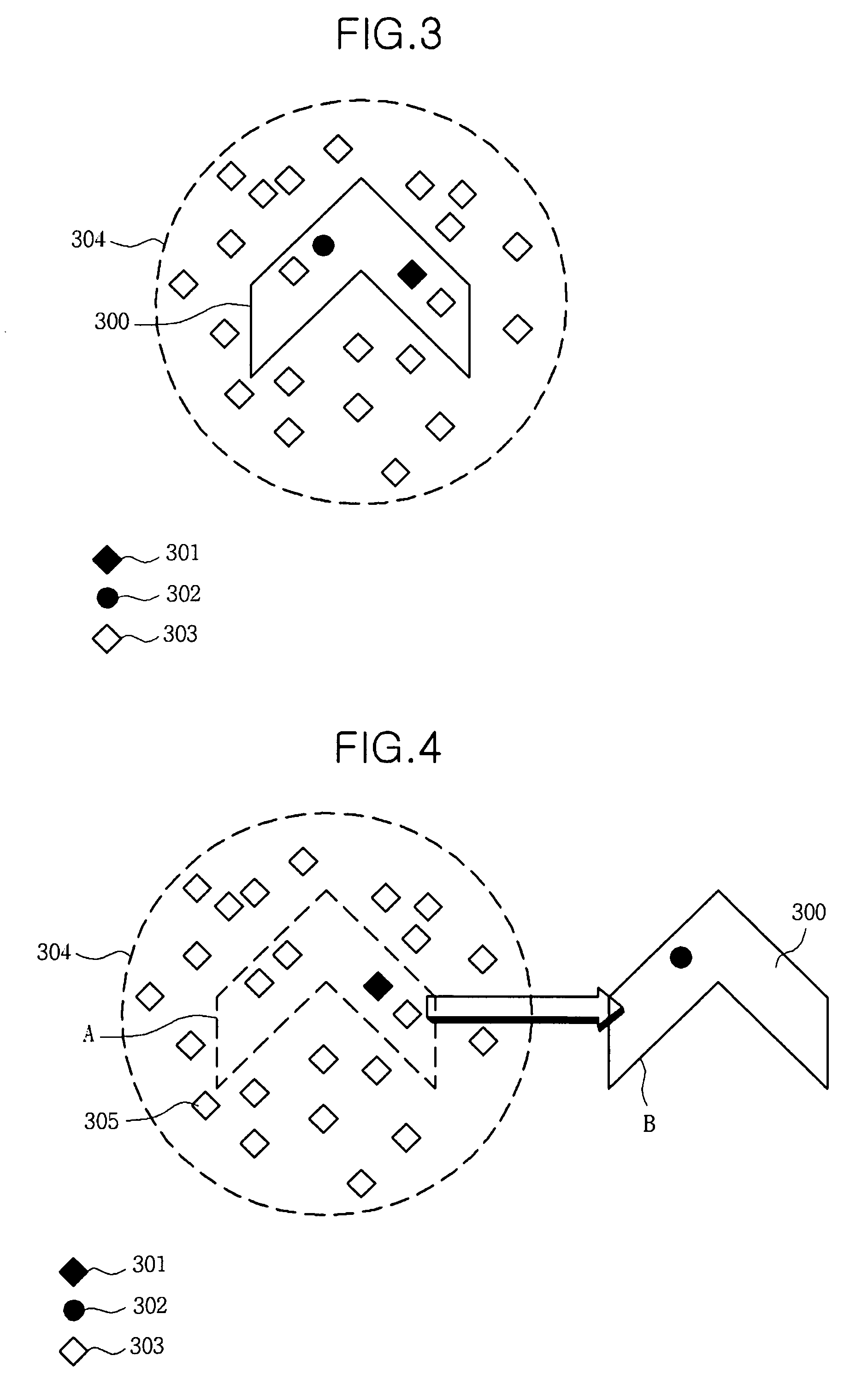

Robot slip detection apparatus and method

ActiveUS20100174409A1Improve accuracyDetection accuracy meetsProgramme controlComputer controlEngineeringParticle filter

A technique of detecting a slip of a robot using a particle filter and feature information of a ceiling image is disclosed. A first position of the robot is computed using a plurality of particles, a second position of the robot is computed using the feature information of the ceiling image, and whether a slip has occurred is determined based on a distance between the first position and the second position.

Owner:SAMSUNG ELECTRONICS CO LTD

Communication system using ARQ

ActiveUS7561893B2Improve accuracyGood estimatePower managementEnergy efficient ICTCommunications systemPrimary station

A communication system comprises a downlink data channel for the transmission of data packets from a primary station to a secondary station and two uplink control channels, a first channel for transmission of status signals to indicate the status of received data packets and a second channel for transmission of pilot information. In operation, on detection (402) of a data packet the secondary station increases (404) the transmission power of the second channel, thereby enabling the primary station to obtain a better estimate of uplink channel properties and hence increase the accuracy with which it can decode the status signal. The secondary station transmits (406) the status signal, typically either an acknowledgement (ACK) or negative acknowledgement (NACK), and decreases (408) the transmission power of the second control channel signal. The increase and decrease in power are not necessarily identical, for example as a result of the effects of power control.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

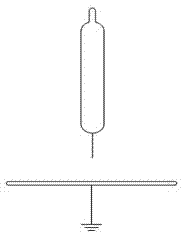

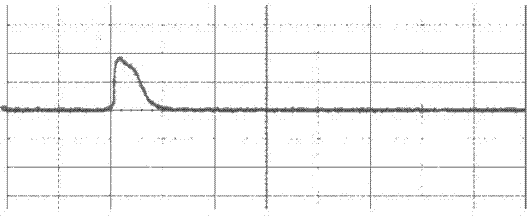

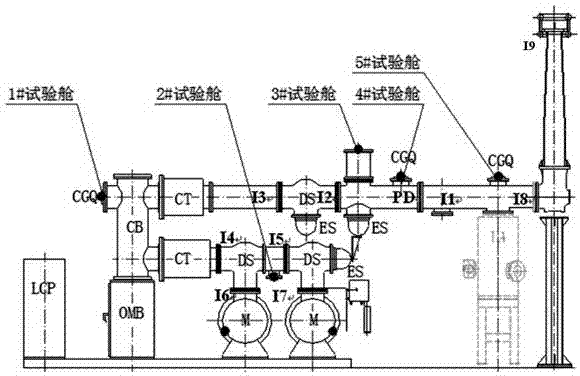

Global information system (GIS) partial discharge on-line monitoring calibration instrument and configuration authentication method thereof

ActiveCN103197212AAttenuation characteristics are similar toIncrease the effective measurement rangeTesting dielectric strengthGlobal information systemElectrical conductor

The invention relates to a global information system (GIS) partial discharge on-line monitoring calibration instrument and a configuration authentication method thereof. The calibration instrument is provided with a pulse signal source and a transmitting antenna. When the pulse signal source replacing a high-voltage conductor spike model injects signals of a simulation partial discharge source through an external sensor as the transmitting antenna into a GIS cavity, the calibration instrument carries out checking on sensitivity of a partial discharge ultra high frequency (UHF) detecting device in the process that the partial discharge UHF detecting device detects the signals on line on the basis of an ultrahigh frequency method. The configuration authentication method includes the steps of testing time domain waveform and spectrum characteristics of a UHF signal model radiated by a typical discharge source inside a GIS, providing technical parameters of the pulse signal source, injecting the pulse signals into the high-voltage conductor spike model on an entity GIS platform, injecting pulse signals into the GIS cavity through an internal sensor and the external sensor, and then carrying out equivalent checking.

Owner:STATE GRID CORP OF CHINA +2

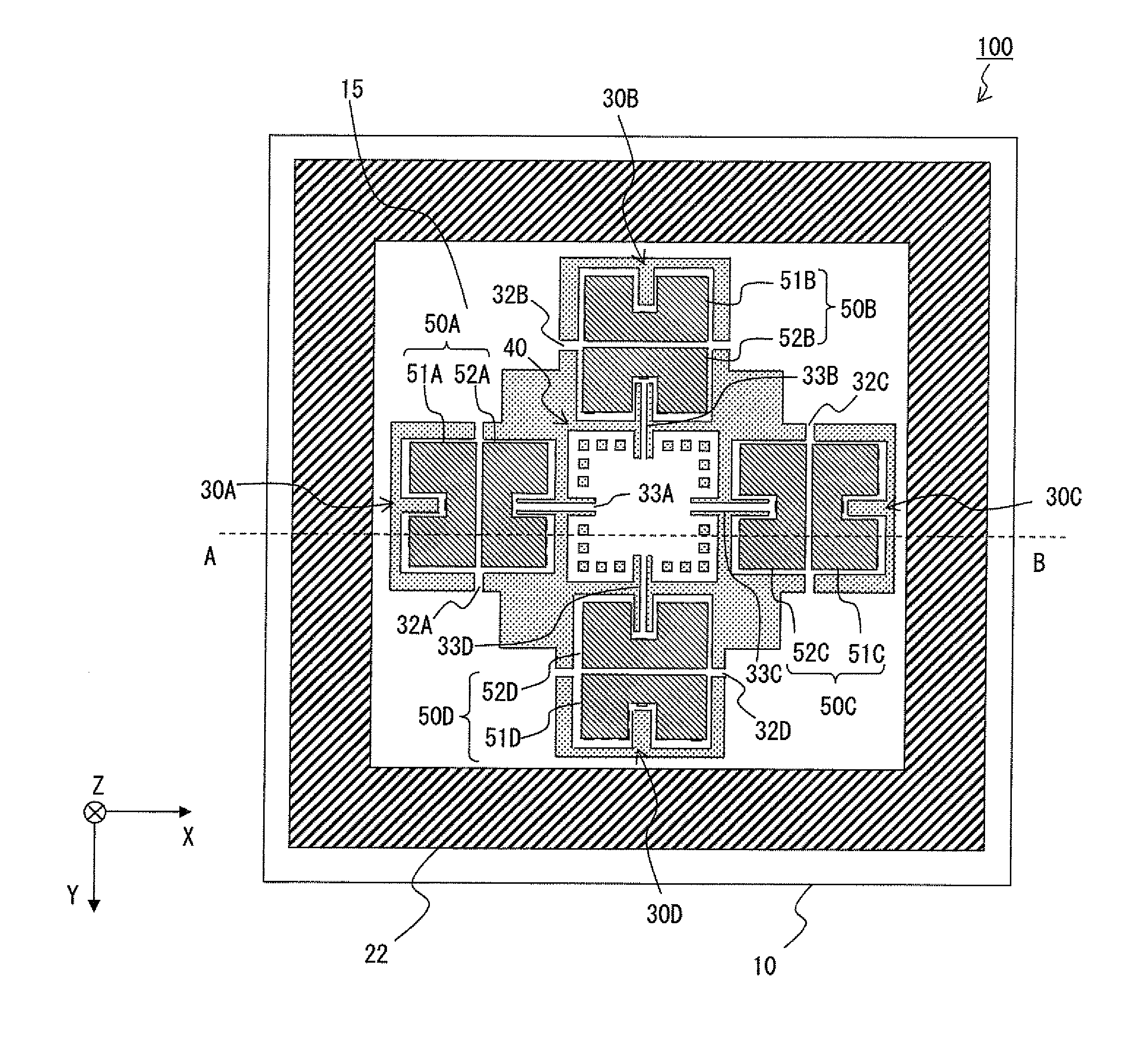

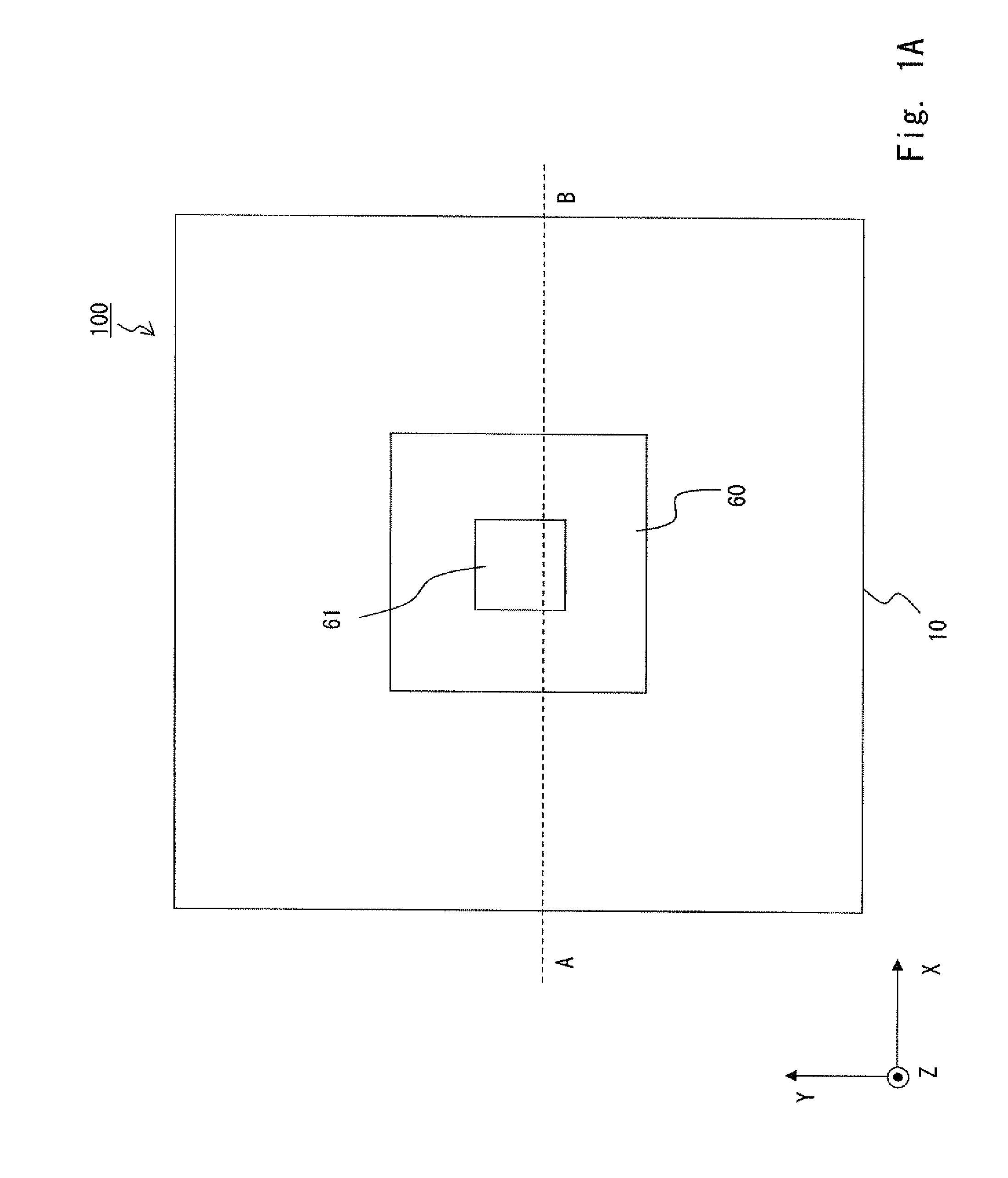

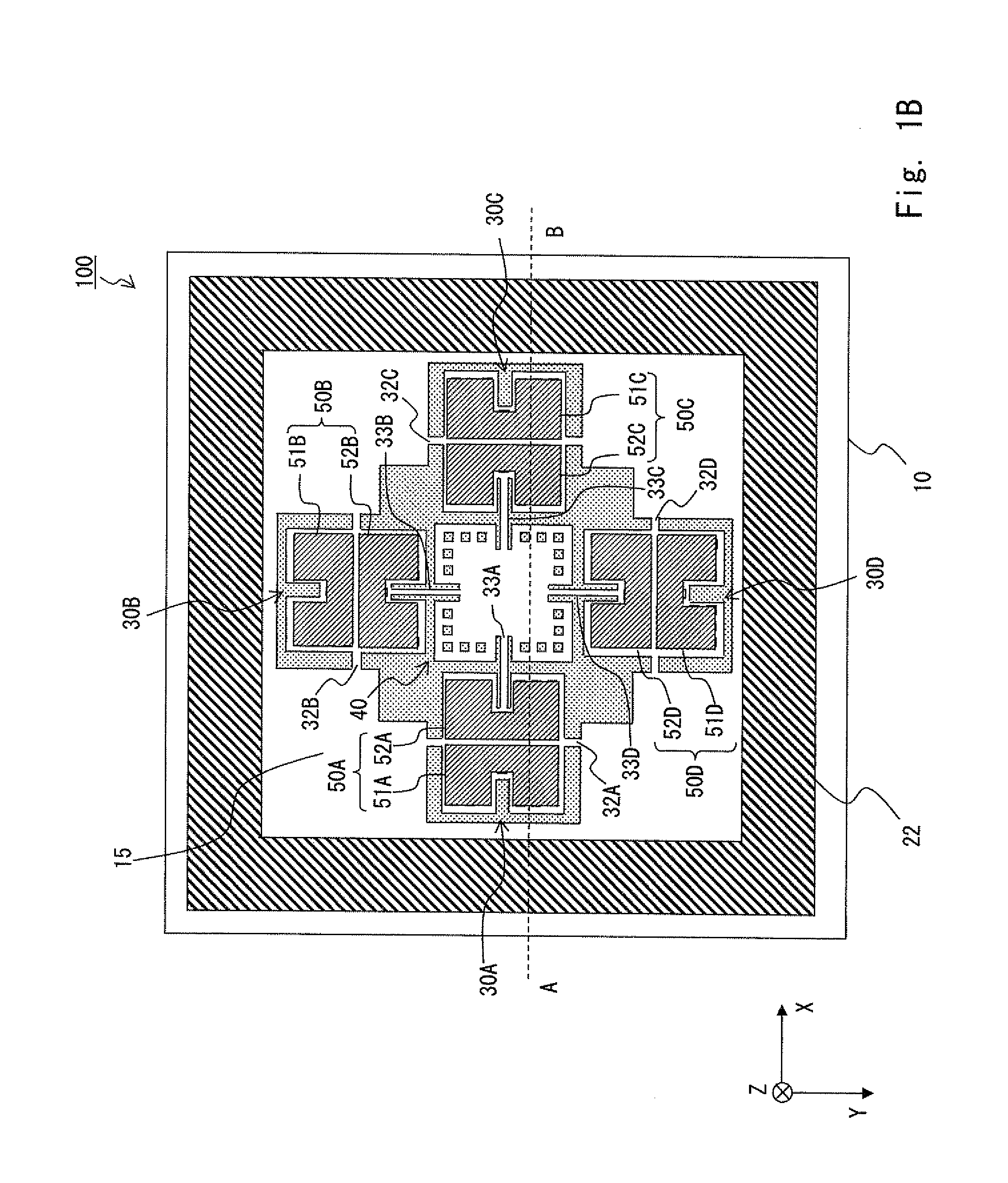

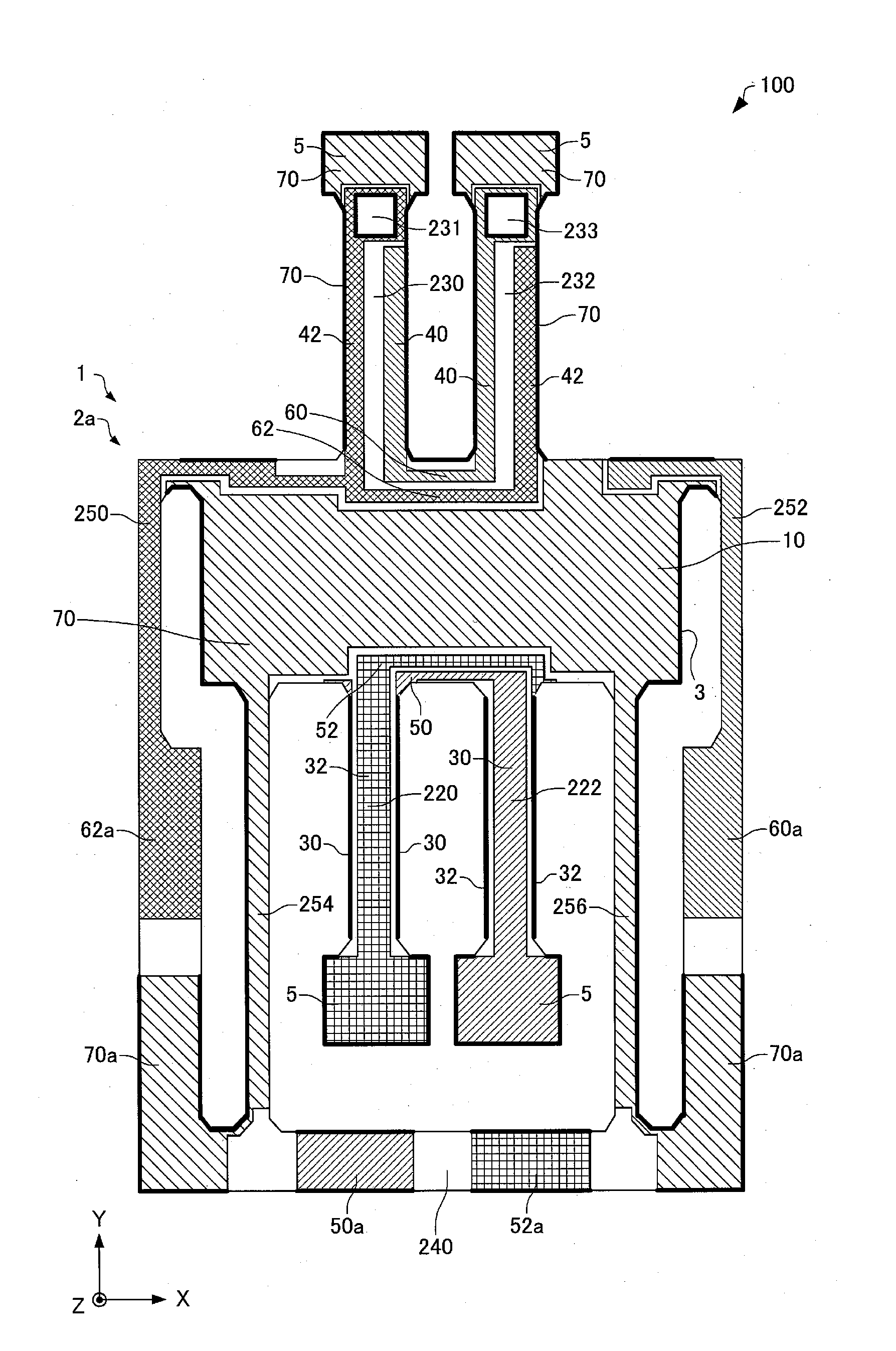

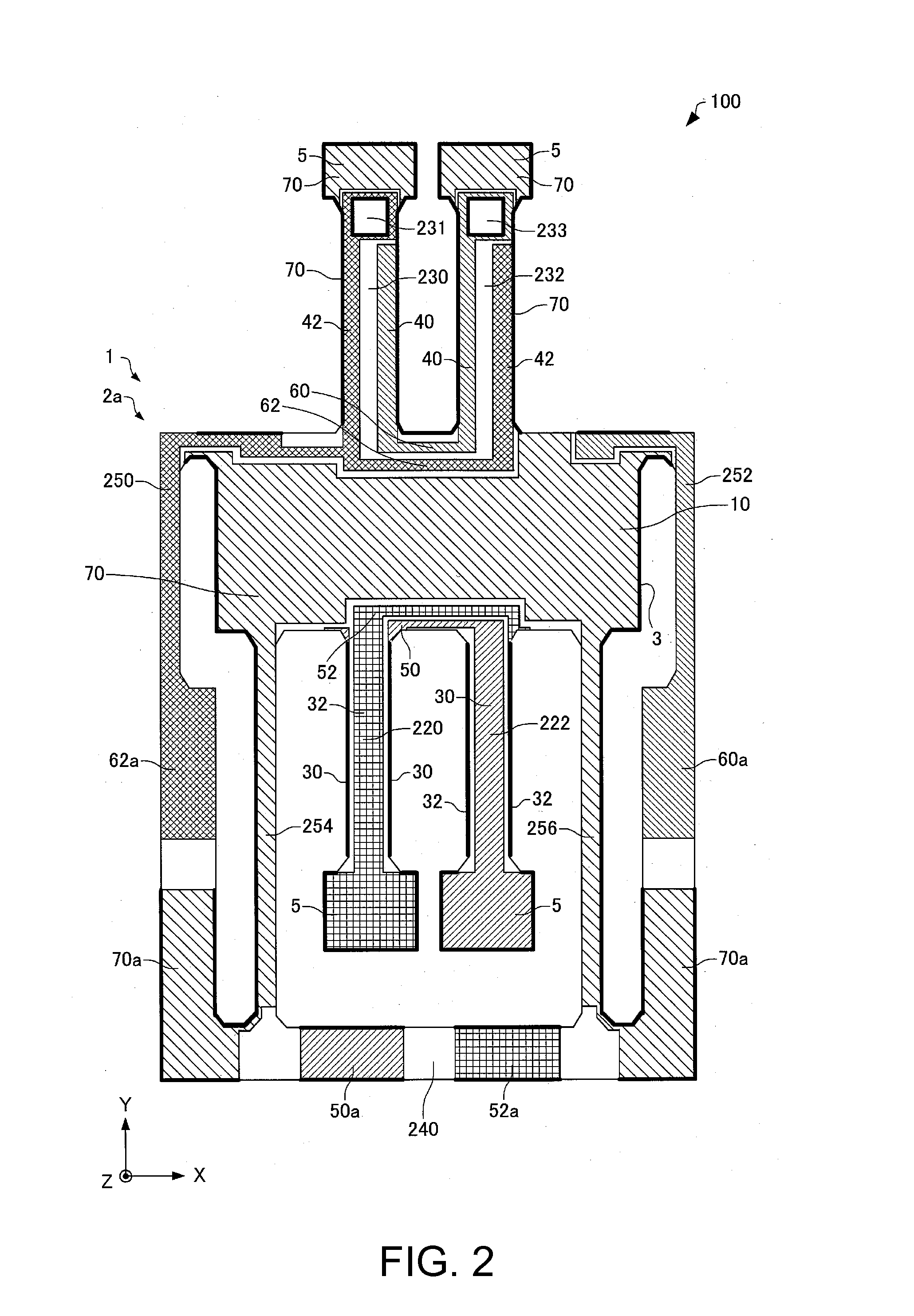

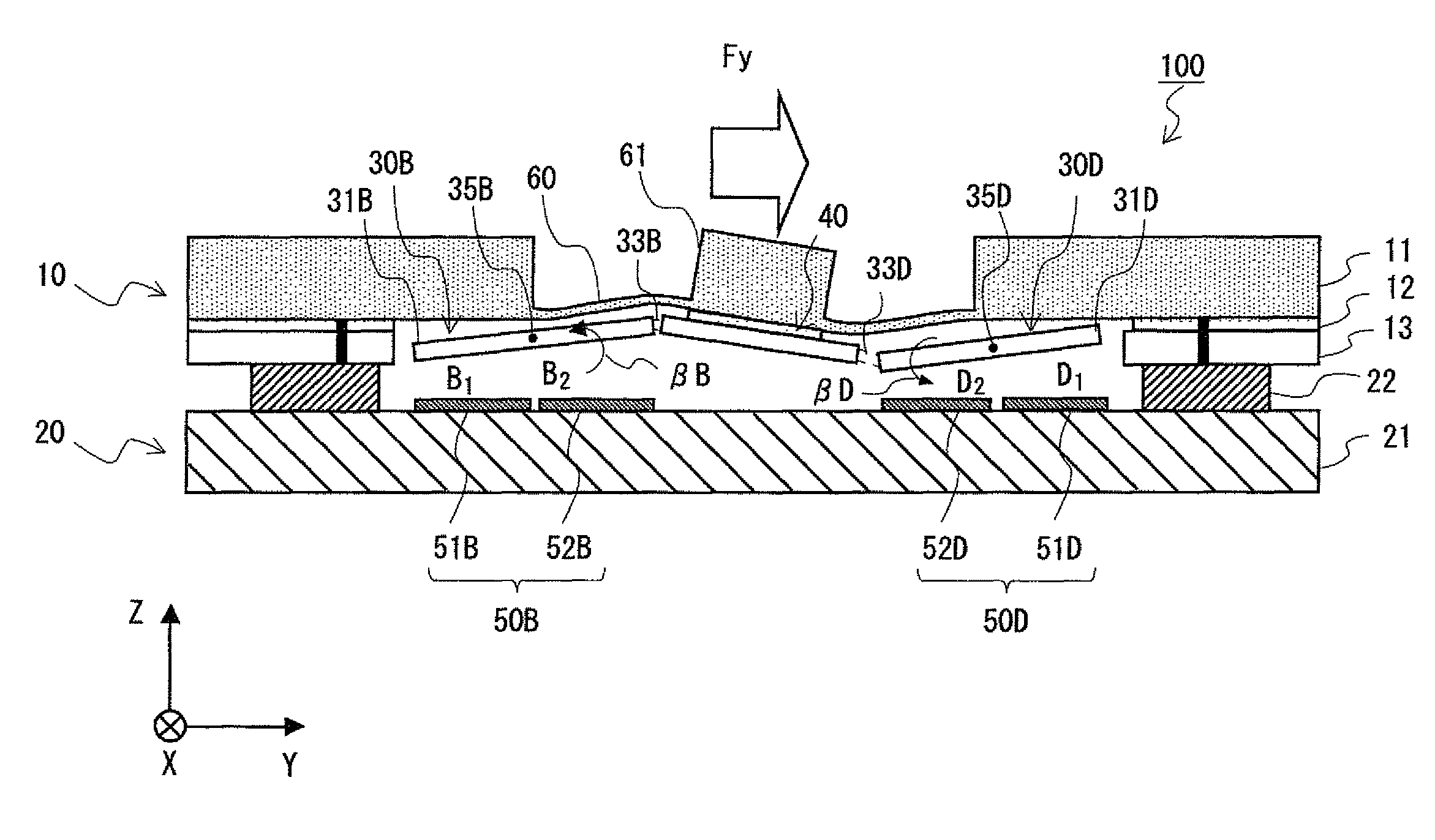

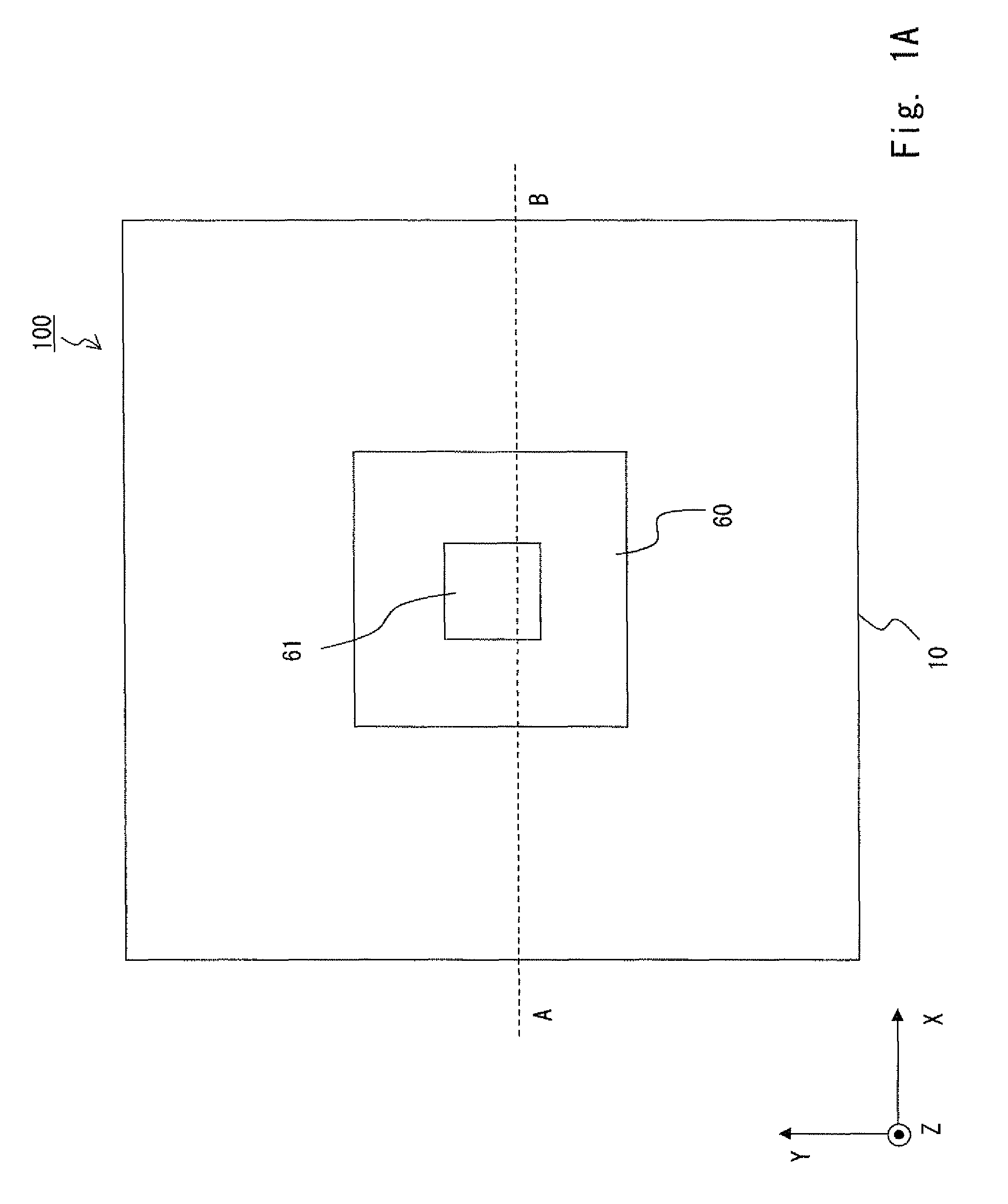

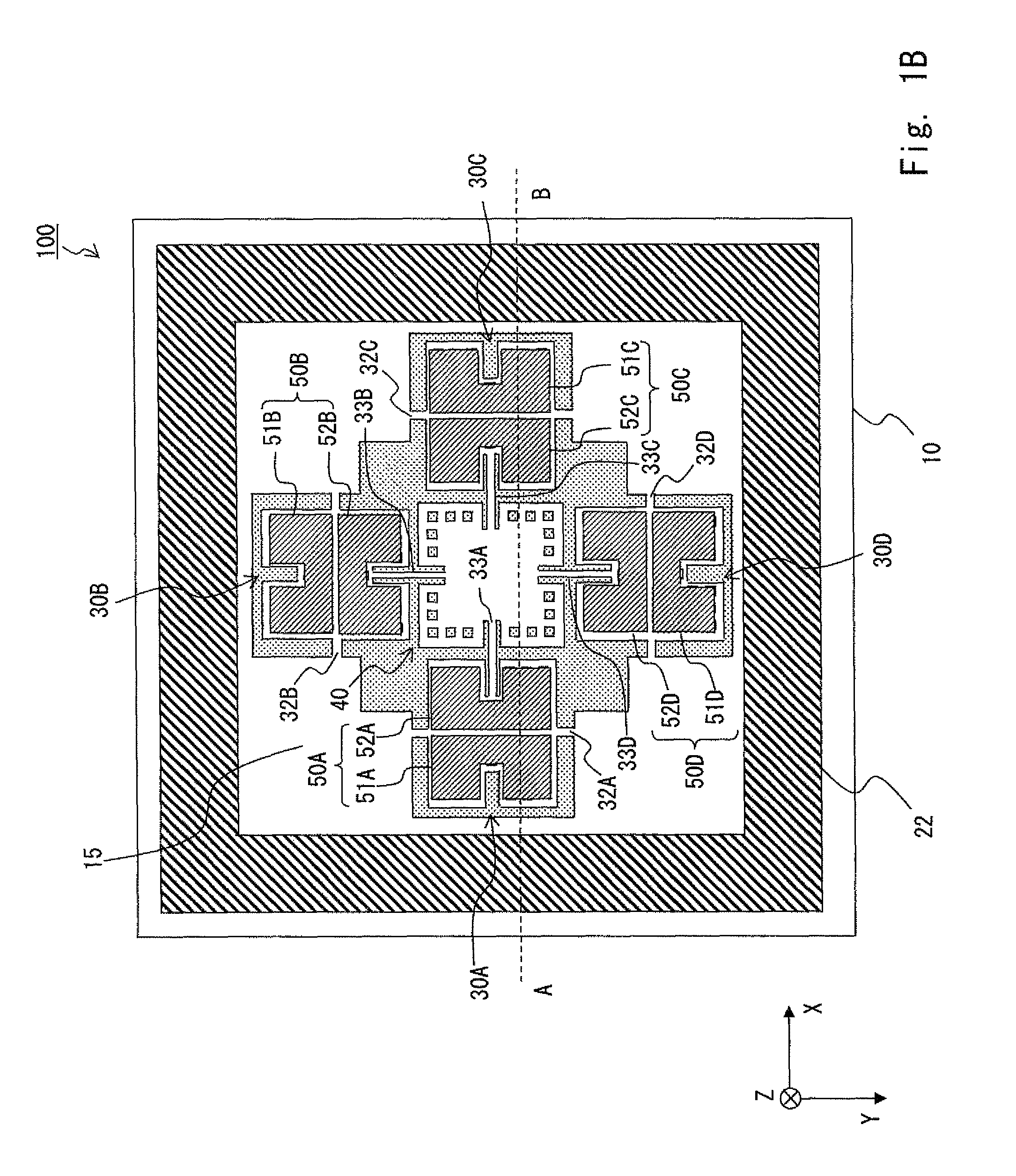

Dynamic quantity sensor and dynamic quantity sensor system

ActiveUS20140137670A1Reduce detection accuracySimple structureForce measurement by measuring frquency variationsApparatus for force/torque/work measurementRotational axisEngineering

A dynamic quantity sensor includes a force receiving portion, a first movable portion that rotates in a first rotational direction around a first rotational axis according to dynamic quantity in a first direction that the force receiving portion receives, and rotates in the first rotational direction around the first rotational axis according to dynamic quantity in a second direction different from the first direction that the force receiving portion receives; and a second movable portion that rotates in a second rotational direction around a second rotational axis according to the dynamic quantity in the first direction that the force receiving portion receives, and rotates in an opposite direction to the second rotational direction around the second rotational axis according to the dynamic quantity in the second direction that the force receiving portion receives.

Owner:TOYOTA CENT RES & DEV LAB INC +2

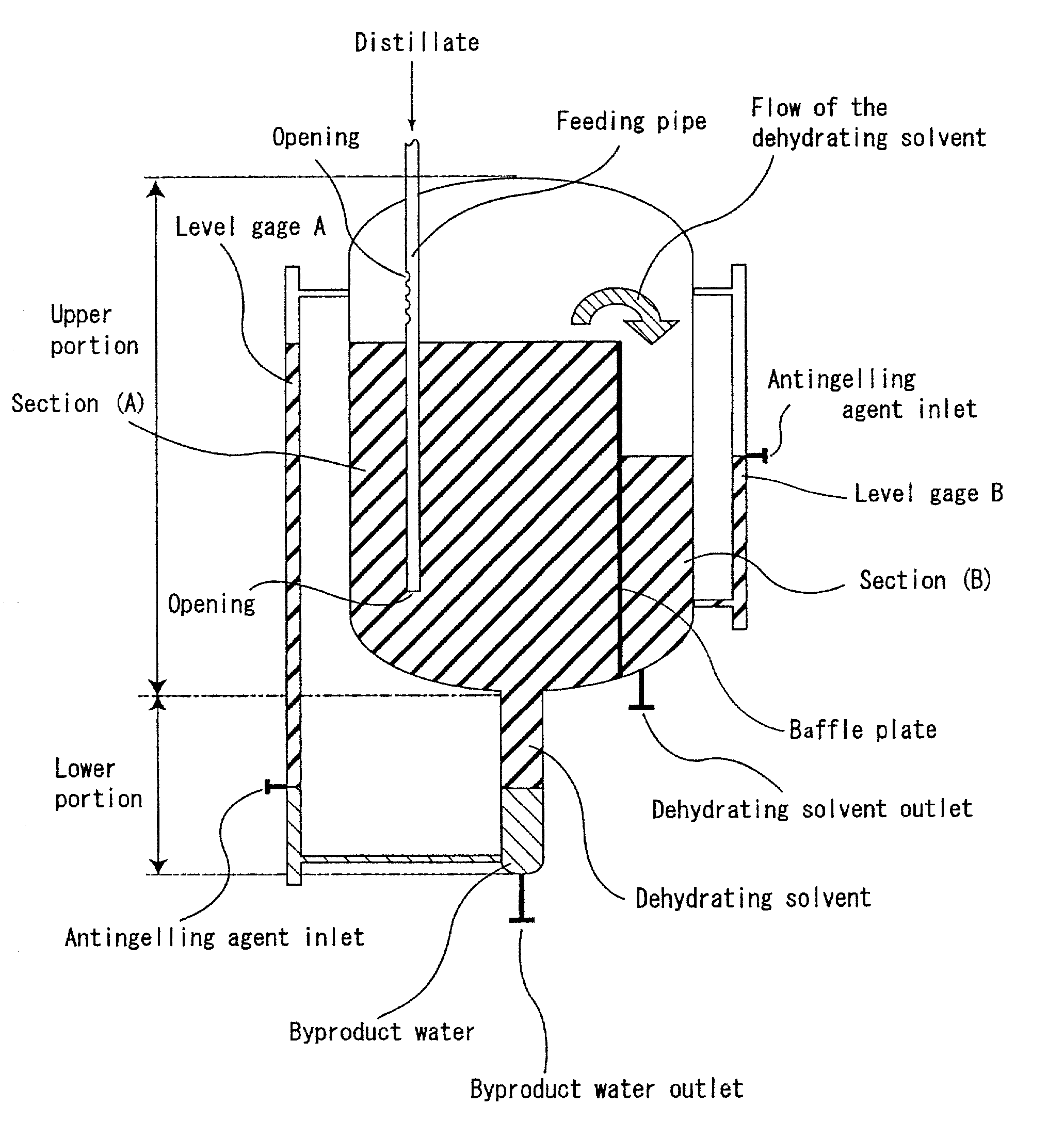

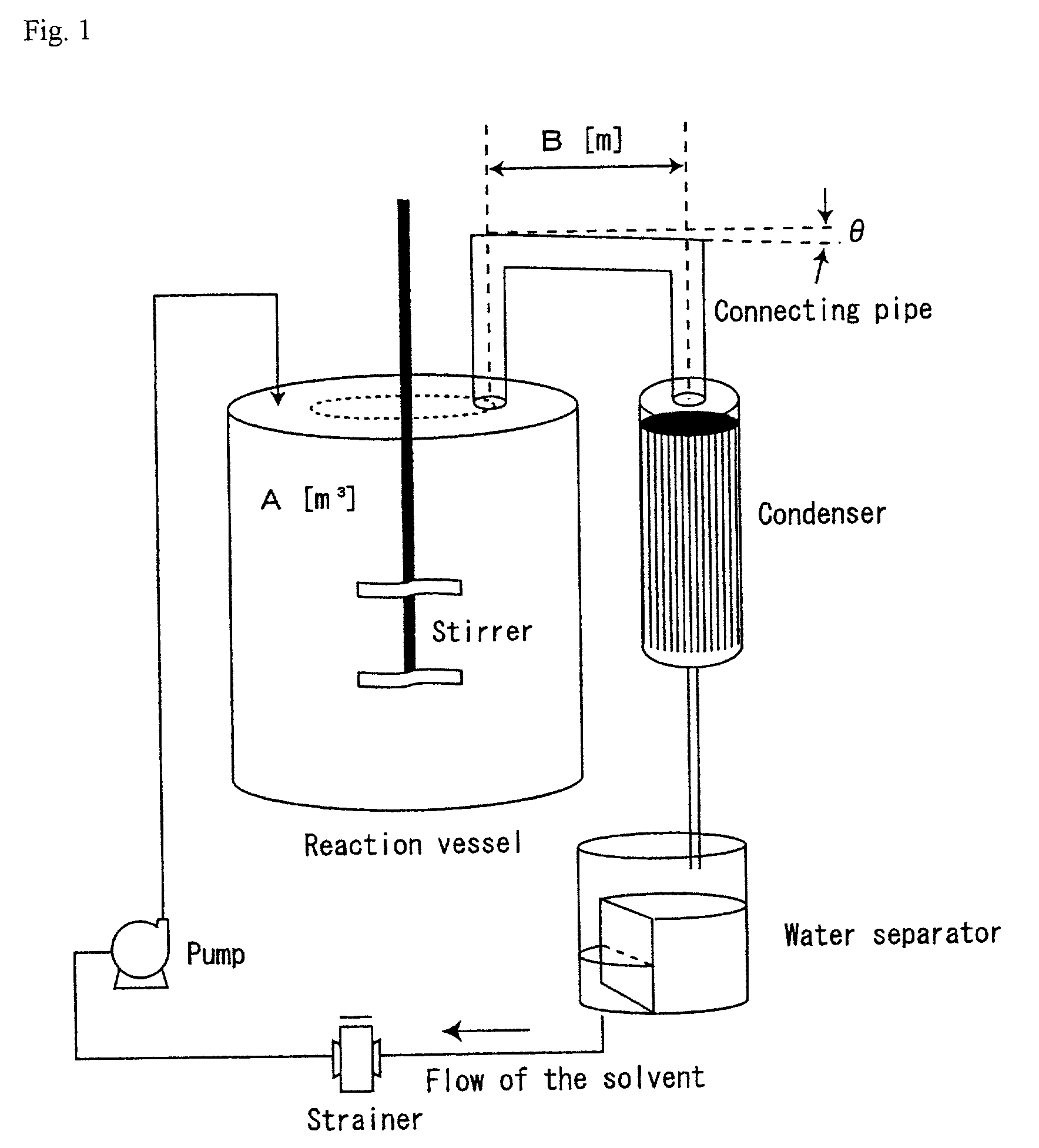

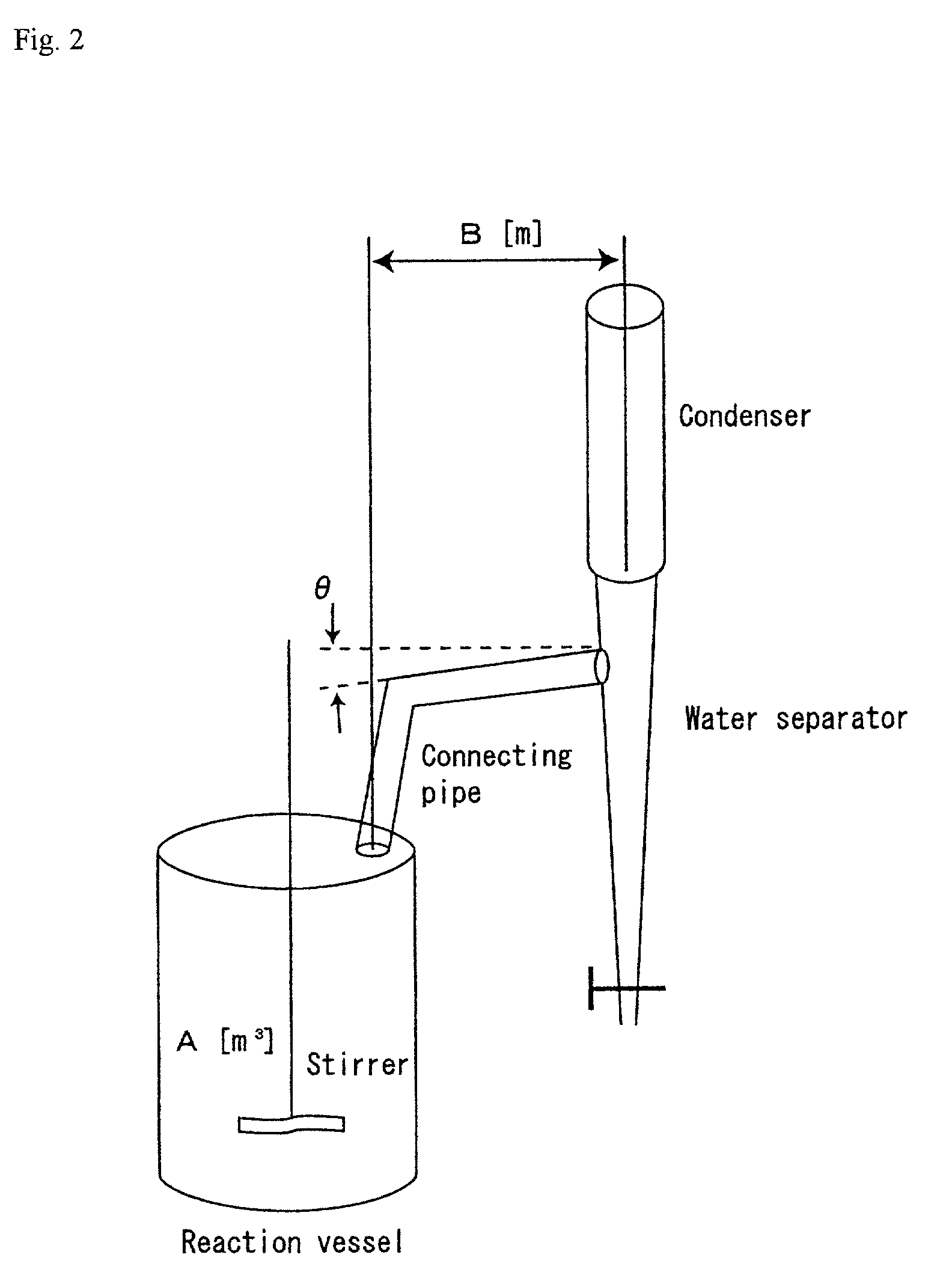

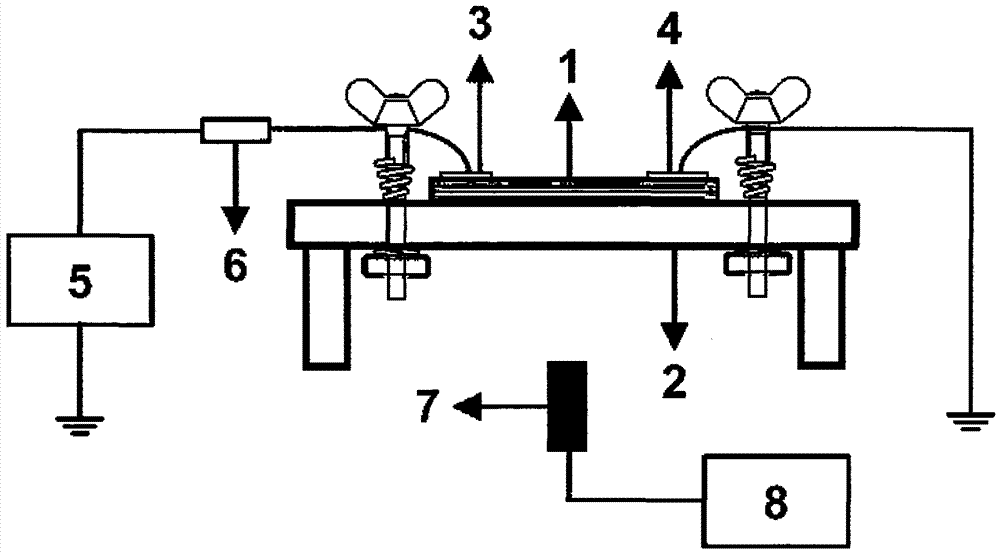

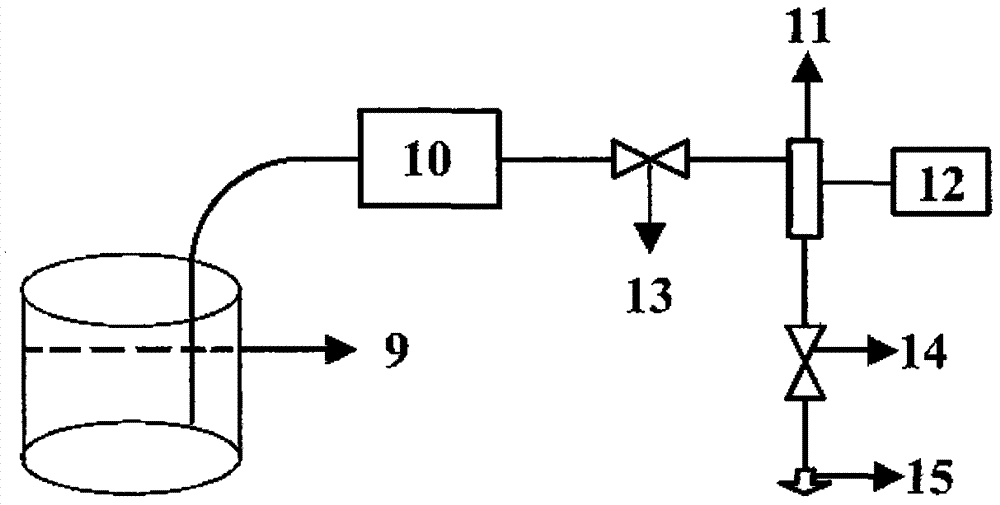

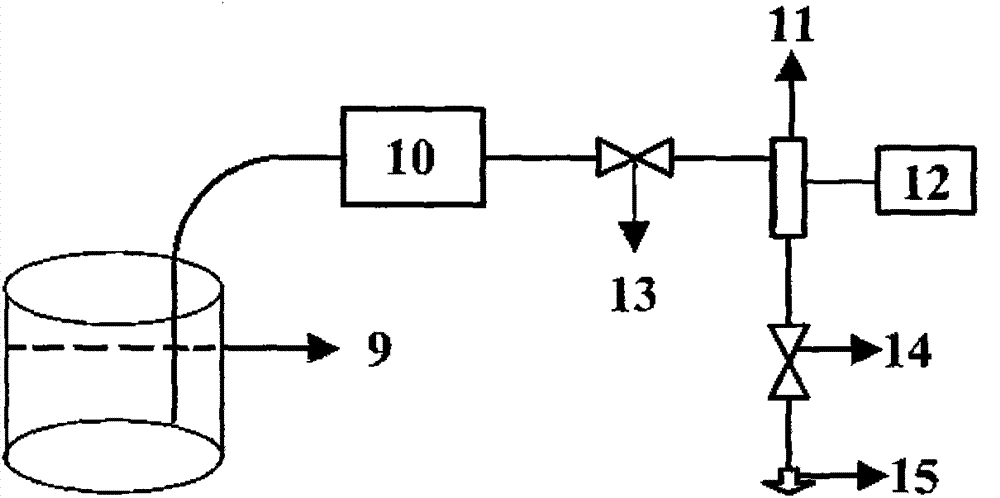

Production process for product of dehydration reaction and apparatus used for the production

InactiveUS7049462B2Prevent leakageEasy to installProductsReagentsCompound (substance)Chemical products

It is an object of the present invention to provide a production method of a dehydration reaction product by which the occurrence of troubles in the production step or the degradation in performance characteristics or quality of various chemical products can be suppressed to a satisfactory extent.A production method of a dehydration reaction productwhich comprises a dehydration reaction step of subjecting a reaction solution containing a polymerizable compound to the dehydration reaction,said dehydration reaction step comprising using a dehydration reaction apparatus,said dehydration reaction apparatus comprising a reaction vessel, a condenser and a connecting pipe joining said reaction vessel with said condenser andsatisfying the requirement:0.05<(B3 / A)<35where A is a capacity (m3) of said reaction vessel and B is a total length (m) of said connecting pipe on the horizontal basis.

Owner:NIPPON SHOKUBAI CO LTD

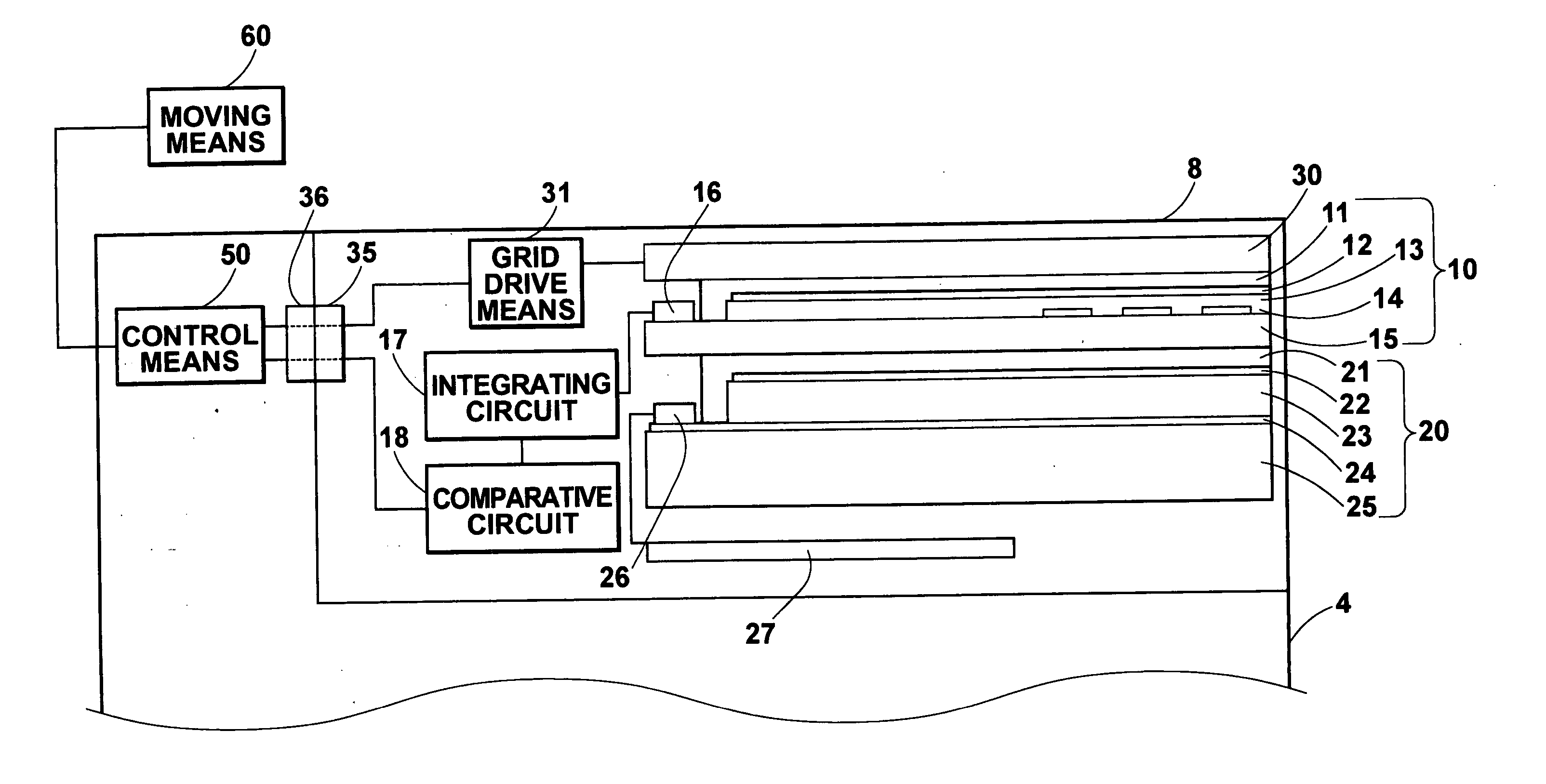

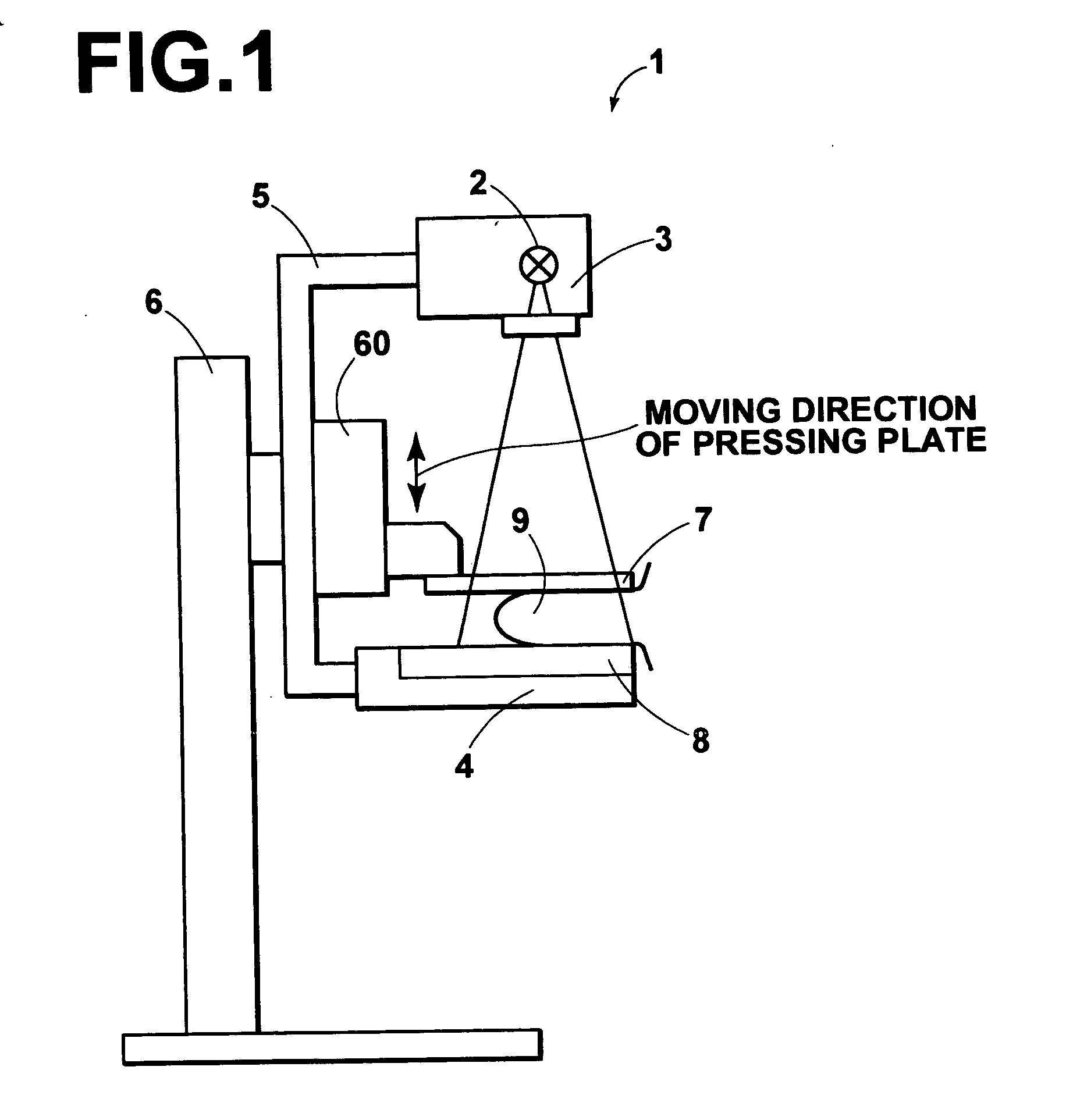

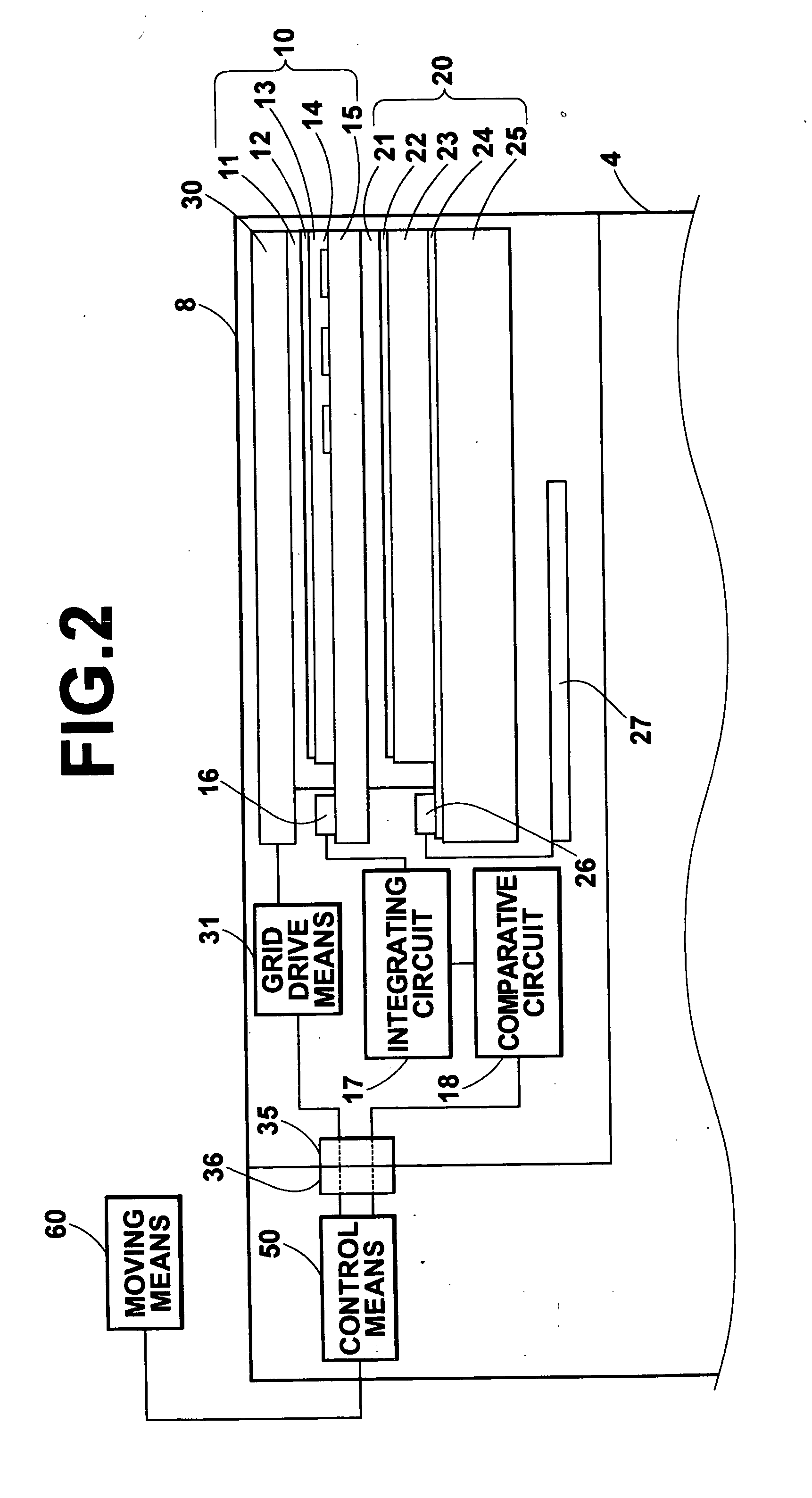

Mammography apparatus and detecting unit

InactiveUS20050111617A1Improve amount of controlDetection accuracyDosimetersPhotometrySolid state detectorX ray image

Detection accuracy of X-ray dosages, to be applied to control the amount of irradiated X-rays, is improved in a mammography apparatus that employs solid state detectors as X-ray image detecting means, and that is capable of interchangeably utilizing solid state detectors of various sizes, without adversely influencing detection of images by the solid state detector. A solid state detector, for recording image information by receiving irradiation of X-rays that bear the image information, and for outputting image signals that represent the recorded image information, an X-ray dosage detector, for detecting the amount of irradiated X-rays, and a moving grid, for removing scattered radiation, are housed within a detecting unit, stacked in this order. The detecting unit is configured to be removably attachable to an imaging table of a mammography apparatus. Thereby, interchangeable use of detecting units having solid state detectors of various sizes housed therein is enabled.

Owner:FUJIFILM HLDG CORP +1

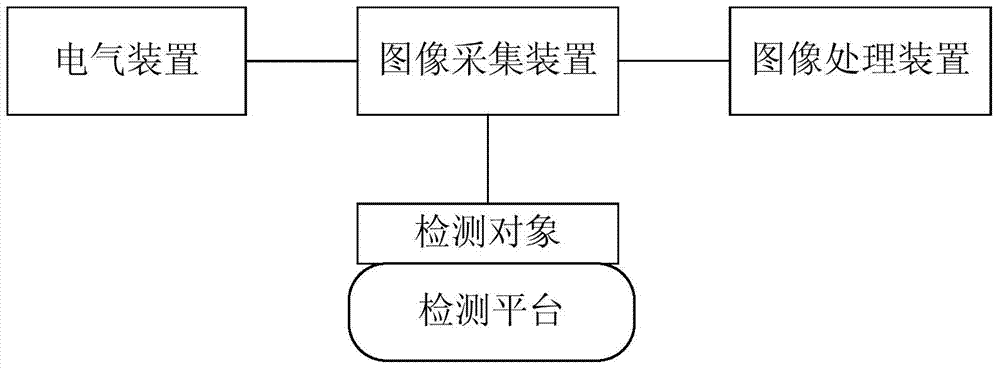

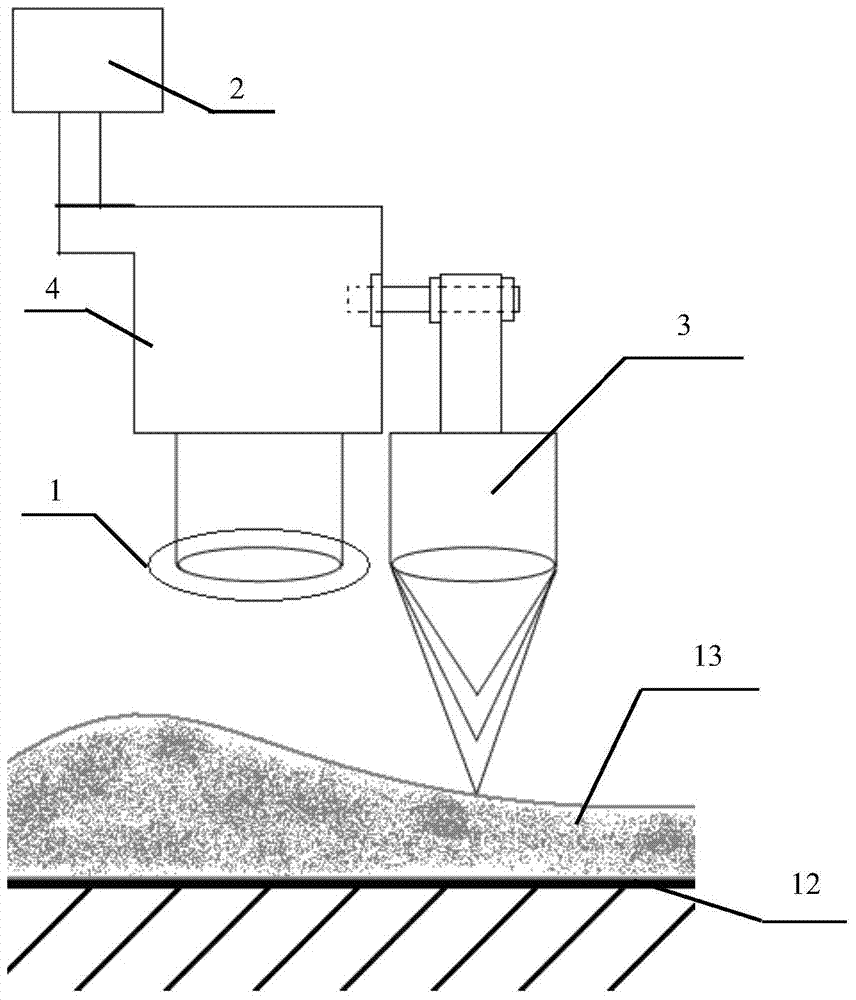

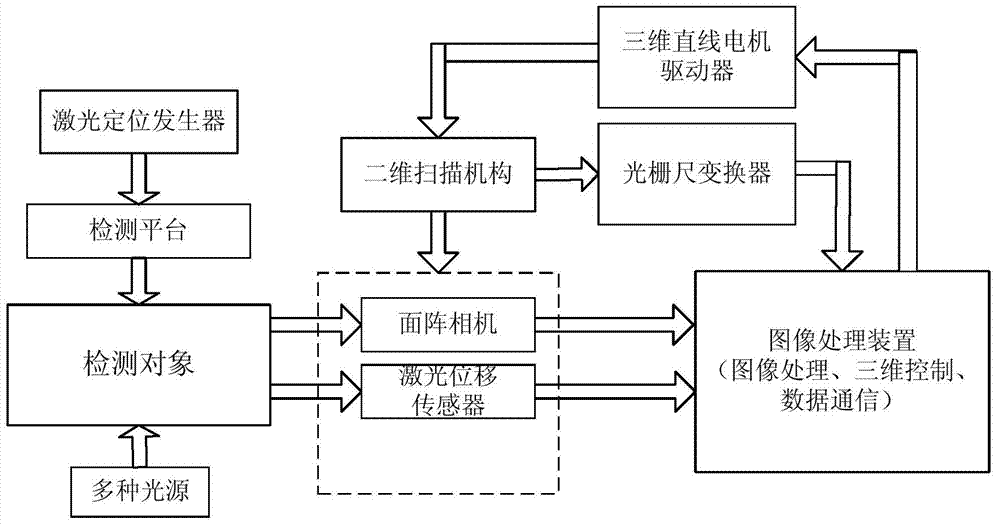

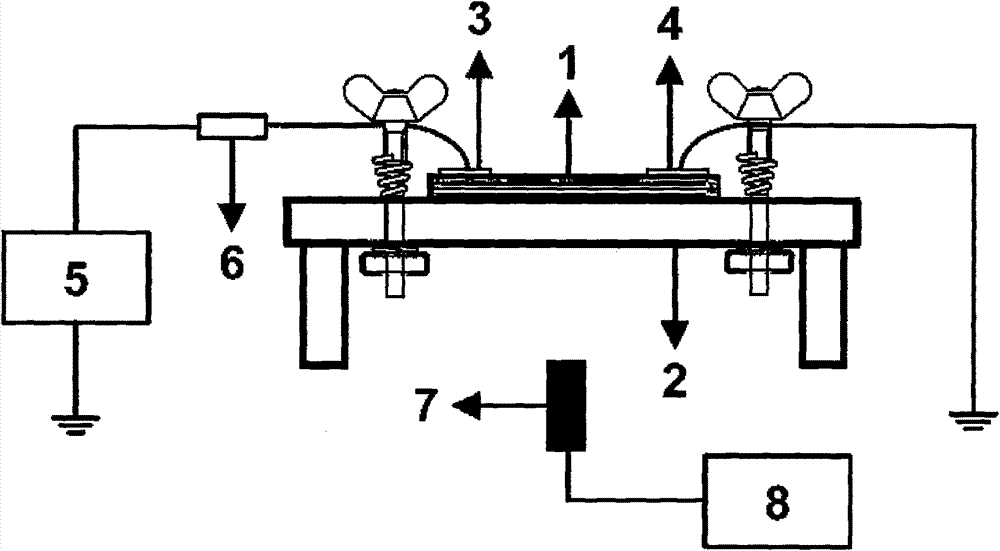

Printing plate quality detection system and method

ActiveCN103674962ARelatively high stabilityAccurate focusOptically investigating flaws/contaminationImaging processingHeat sink

The invention relates to a printing plate quality detection system and method. The system comprises a detection platform, an electric device, an image acquisition device and an image processing device, wherein the image acquisition device comprises an annular optical imaging light source, an area-array camera and a laser displacement sensor; the annular optical imaging light source comprises an annular frame body, a heat radiation sheet arranged on the outer side wall of the annular frame body and a plurality of LED (Light Emitting Diode) light sources arranged on the inner wall of the annular frame body; the annular optical imaging light source is used for uniformly illuminating in a focal plane of the area-array camera; the area-array camera is used for automatically scanning a detection object which is horizontally arranged on the detection platform under the irradiation of the annular optical imaging light source to acquire a high-quality image in the horizontal plane and carry out image pattern detection; the area-array camera or the laser displacement sensor is used for acquiring the depth of the detection object in the vertical direction so as to carry out depth measurement; the image processing device is used for carrying out data processing and analysis on image information to finish the quality detection. The system and the method have the advantages of high detection precision, high detection speed and high reliability.

Owner:BEIJING BANKNOTE CURRENCY DESIGNING & PLATING +2

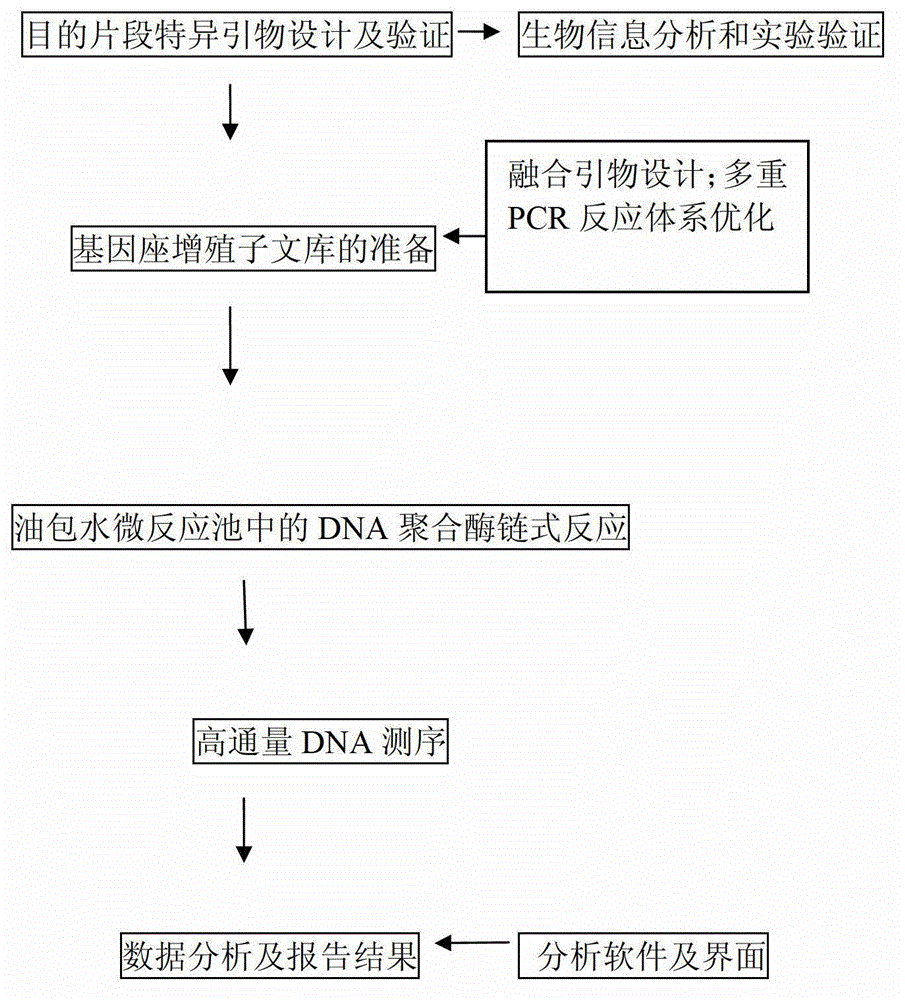

Application of high-pass DNA (Deoxyribonucleic Acid) sequencing method on determination of short tandem repeat gene locus in human genome and method

ActiveCN102943111AAccurate measurementSimultaneous sequencingMicrobiological testing/measurementHuman genomeTandem repeat

The invention discloses application of a high-pass DNA (Deoxyribonucleic Acid) sequencing method on determination of a short tandem repeat gene locus in human genome and a method, belonging to the technical field of biology. The method comprises the following steps of: preparing a multi-sample gene locus proliferation sublibrary; sequencing high-pass DNA; and analyzing data and reporting the result. According to the application and the method disclosed by the invention, the high-pass DNA sequencing technology is applied to determination of the human short tandem repeat (STR) gene locus for the first time and the resolving power and the sensitivity of the STR locus as individual human recognition are remarkably improved; and meanwhile, the detection pass of the STR is greatly improved.

Owner:IPE BIOTECHNOLOGY CO LTD

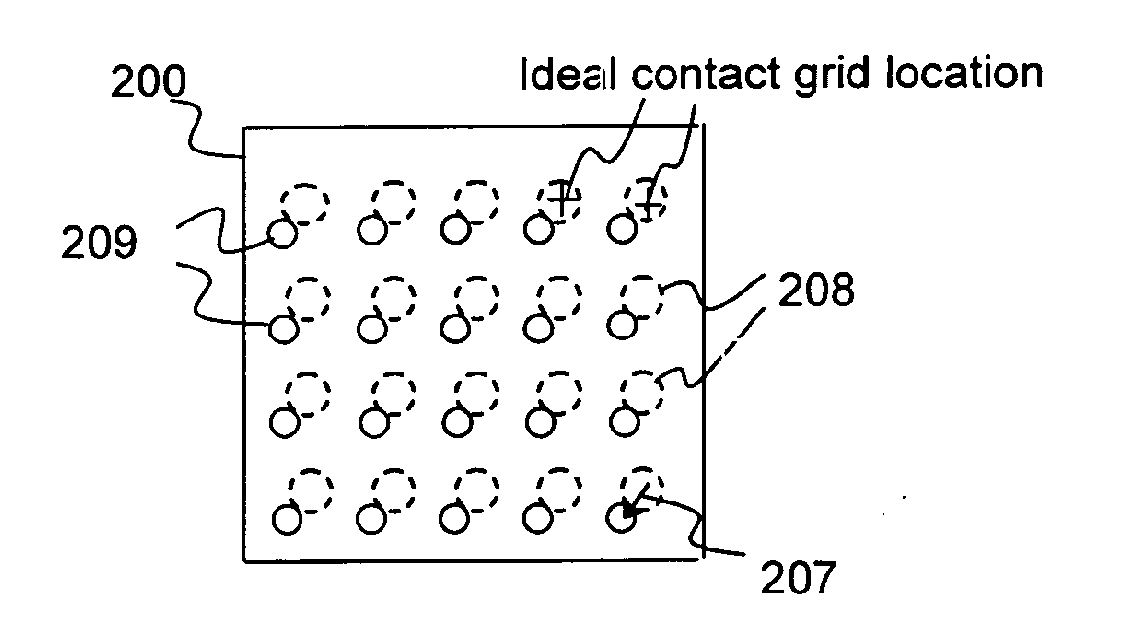

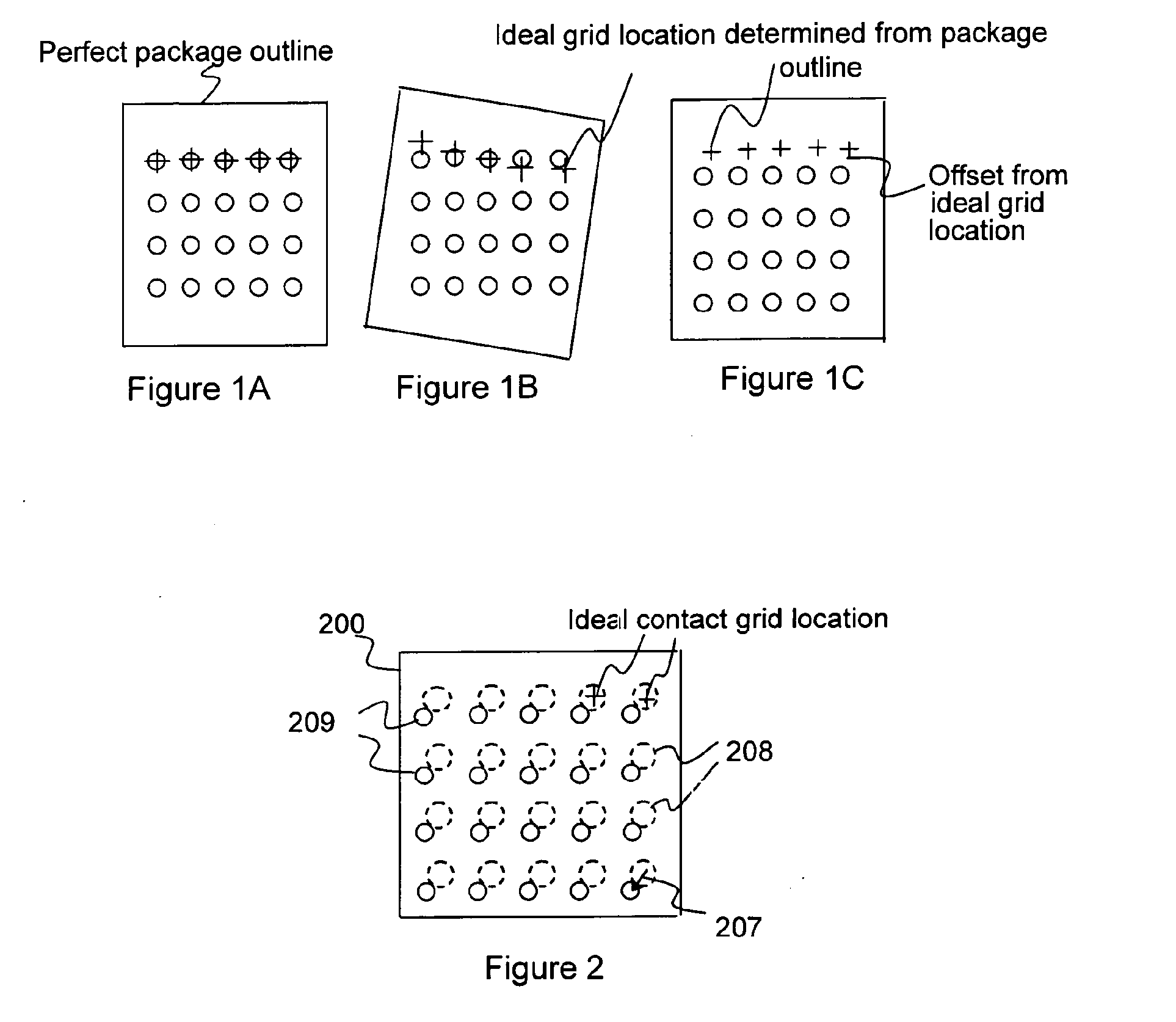

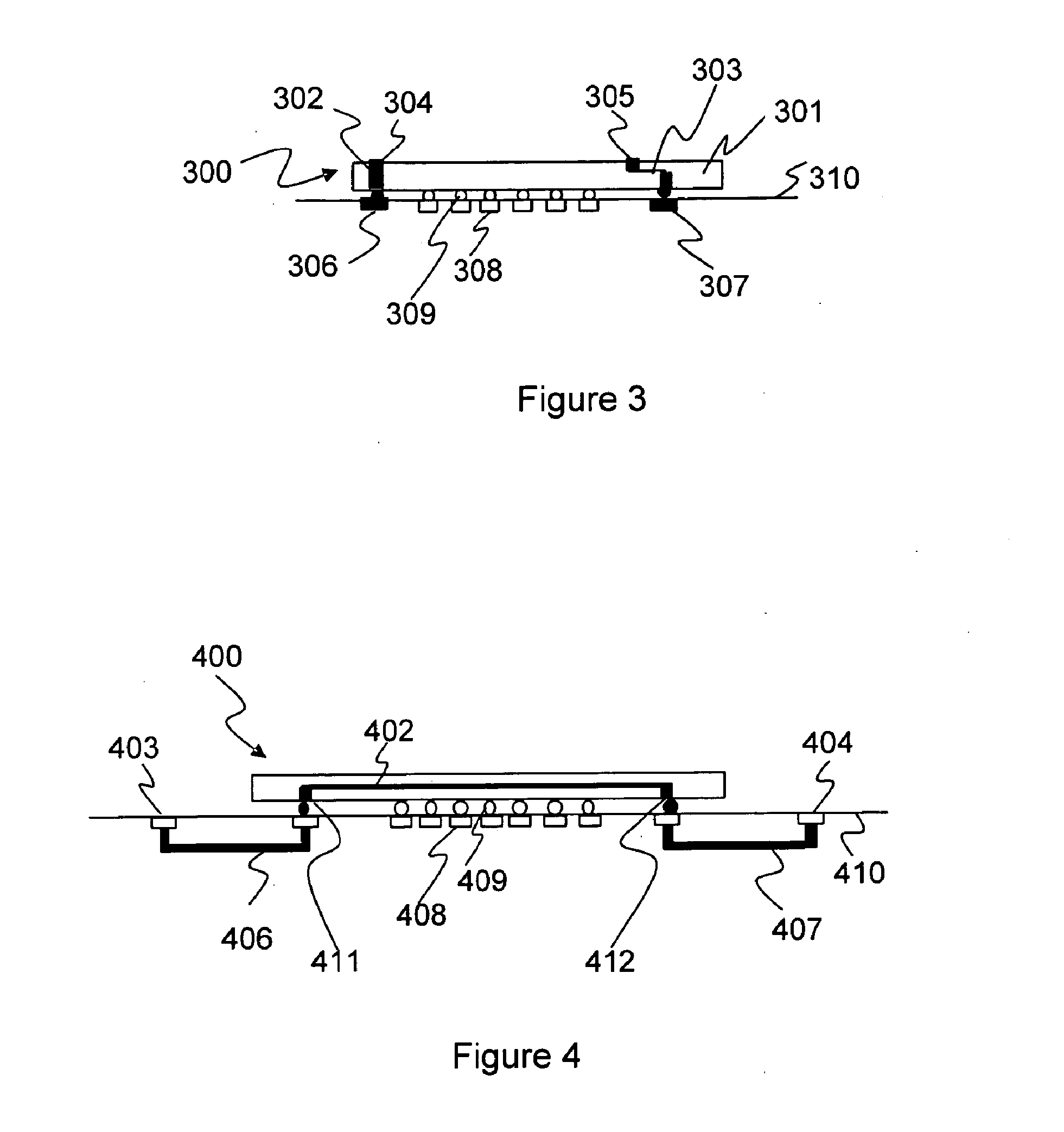

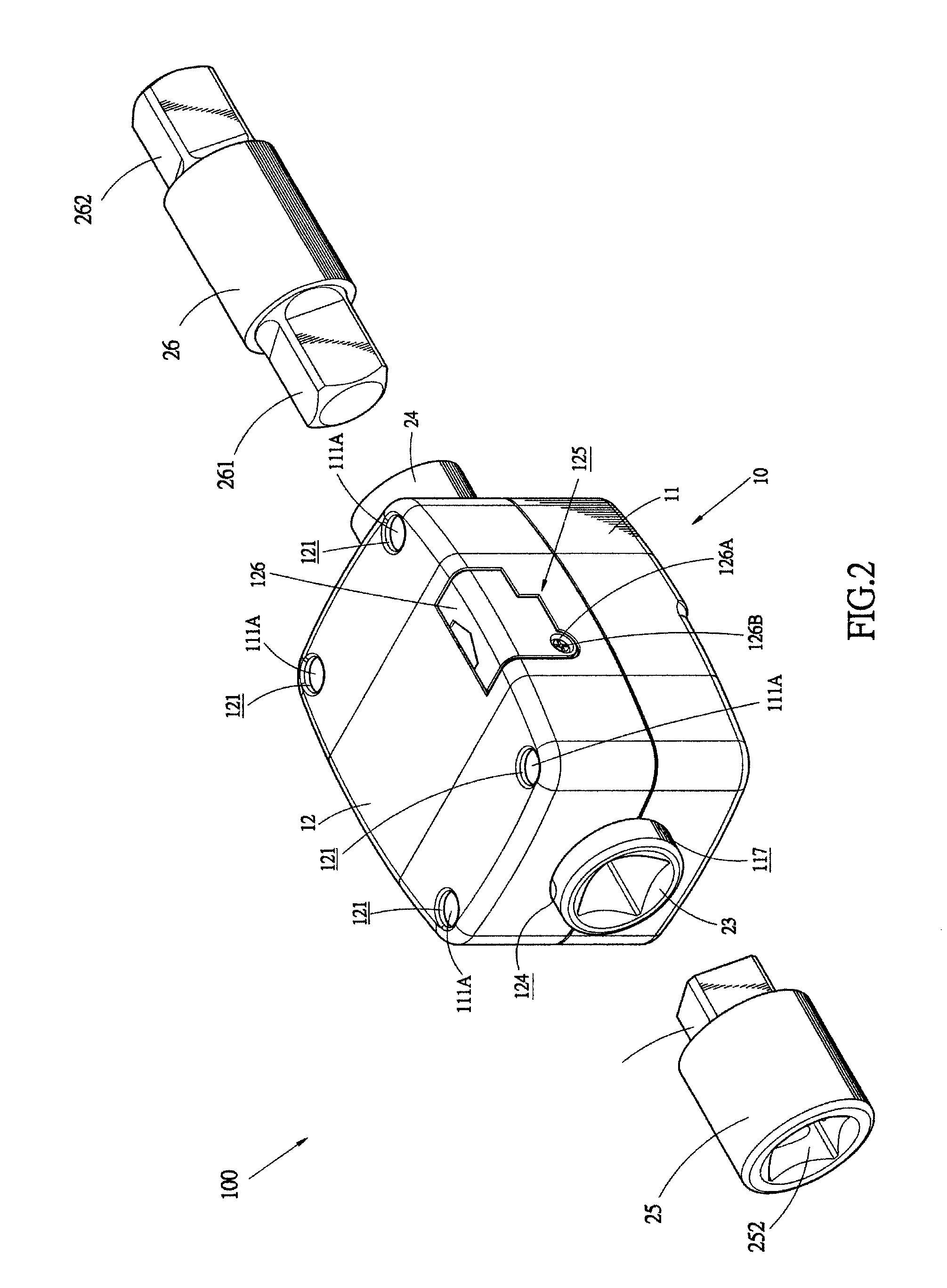

Apparatus and method for predetermined component placement to a target platform

InactiveUS20110121841A1Improve accuracyEasy to detectForce measurement by measuring frquency variationsSemiconductor/solid-state device testing/measurementMultiple sensorEngineering

The present invention relates generally to assembly techniques. According to the present invention, the alignment and probing techniques to improve the accuracy of component placement in assembly are described. More particularly, the invention includes methods and structures to detect and improve the component placement accuracy on a target platform by incorporating alignment marks on component and reference marks on target platform under various probing techniques. A set of sensors grouped in any array to form a multiple-sensor probe can detect the deviation of displaced components in assembly.

Owner:WINTEC IND INC

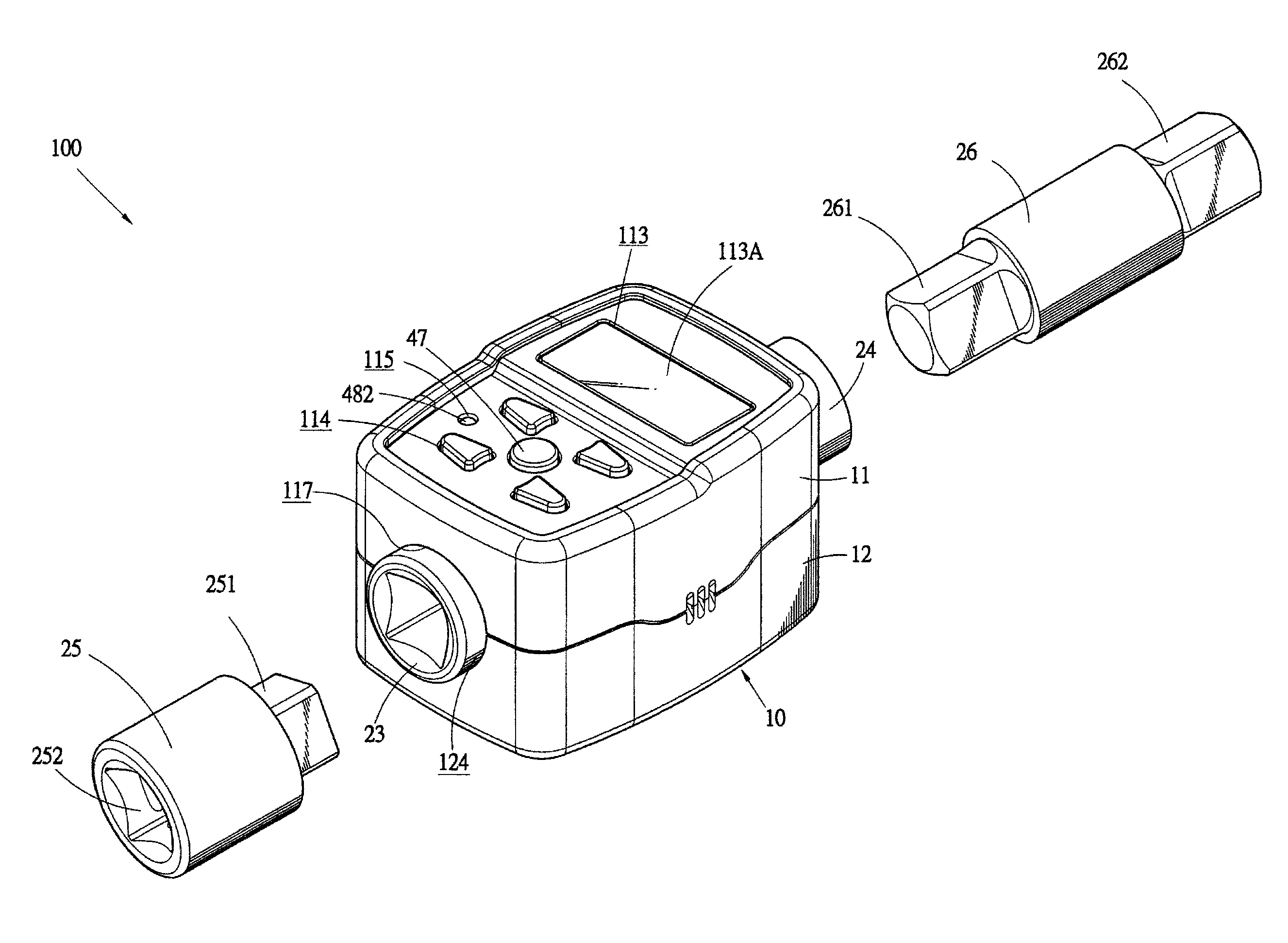

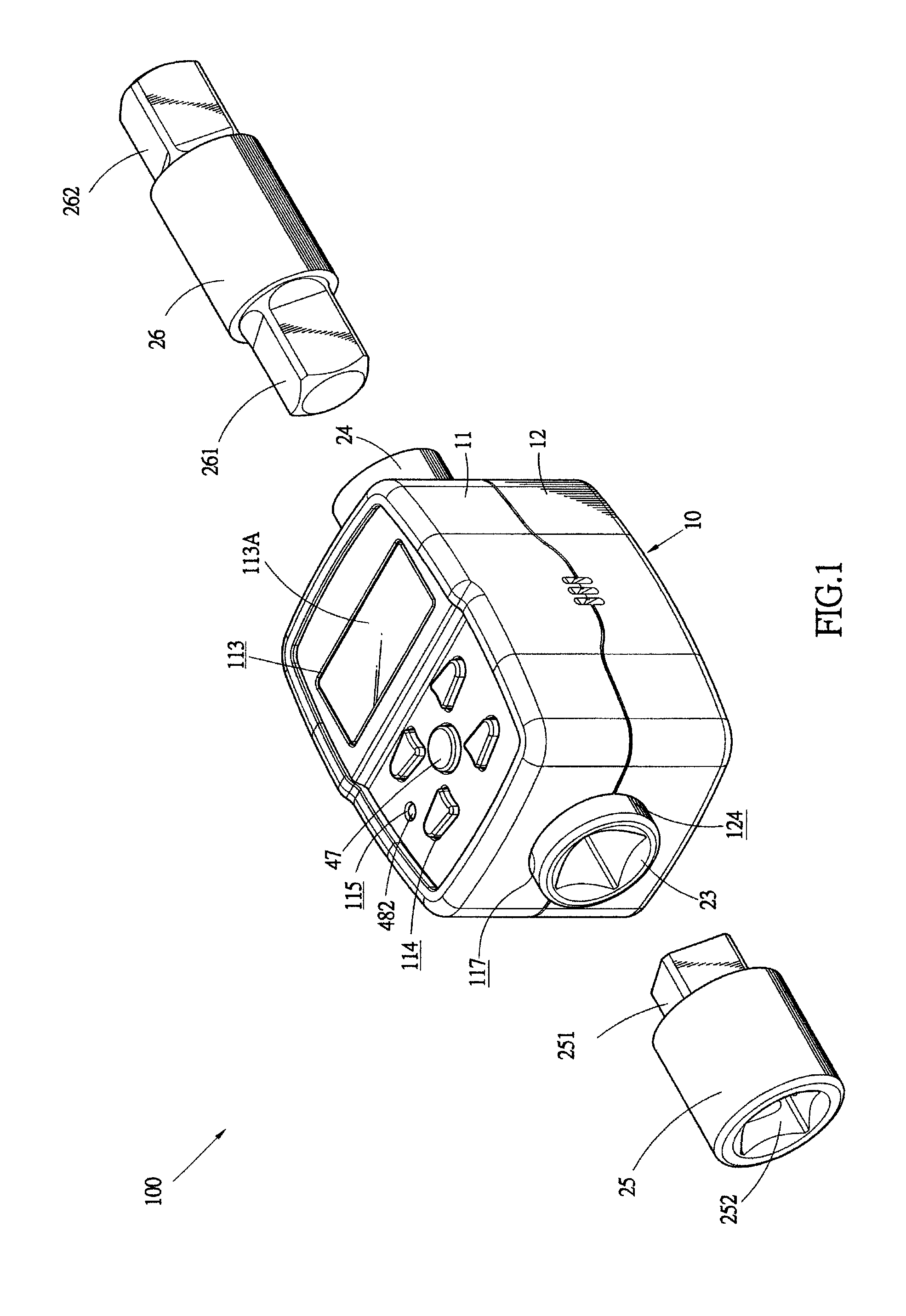

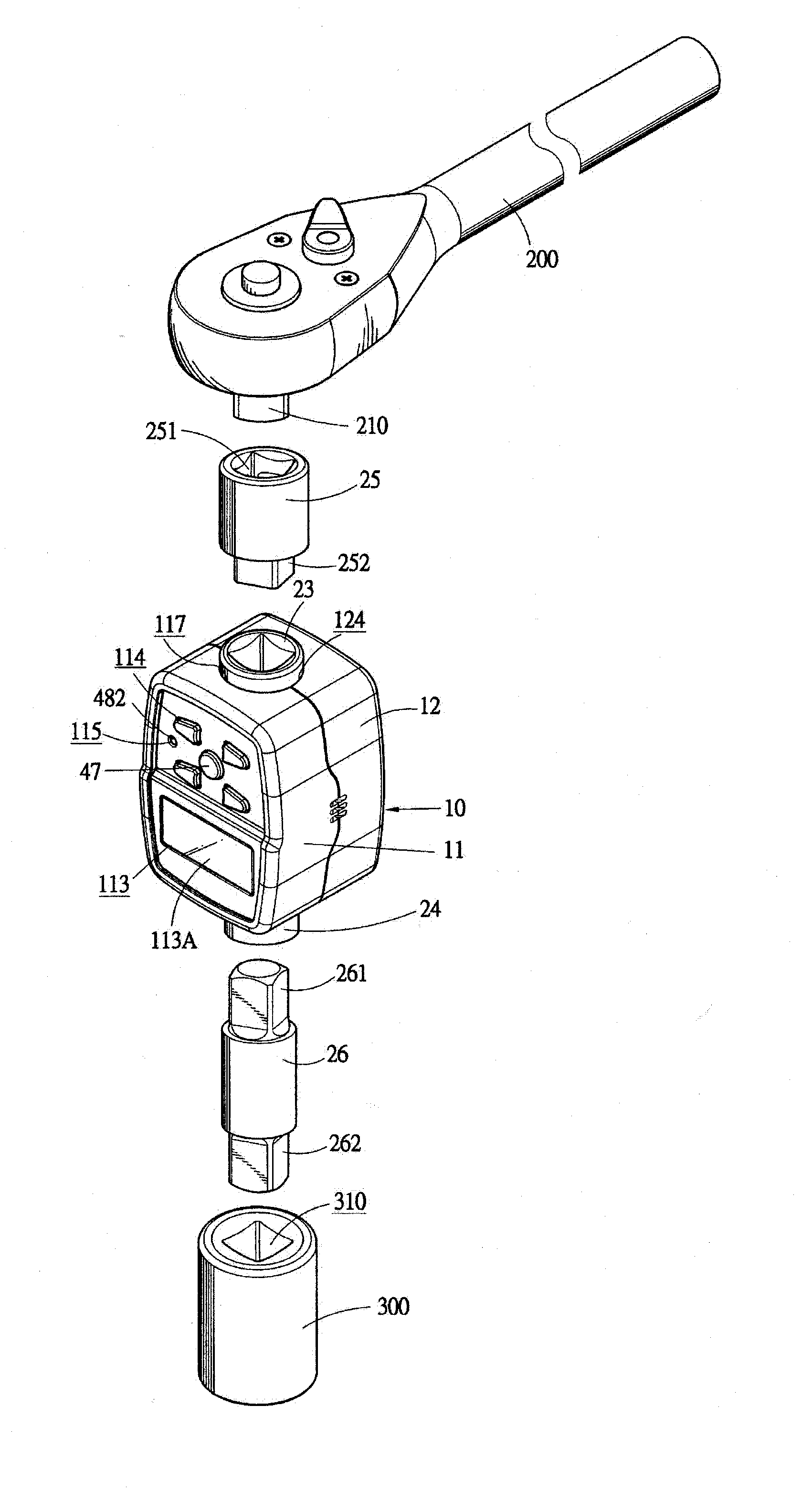

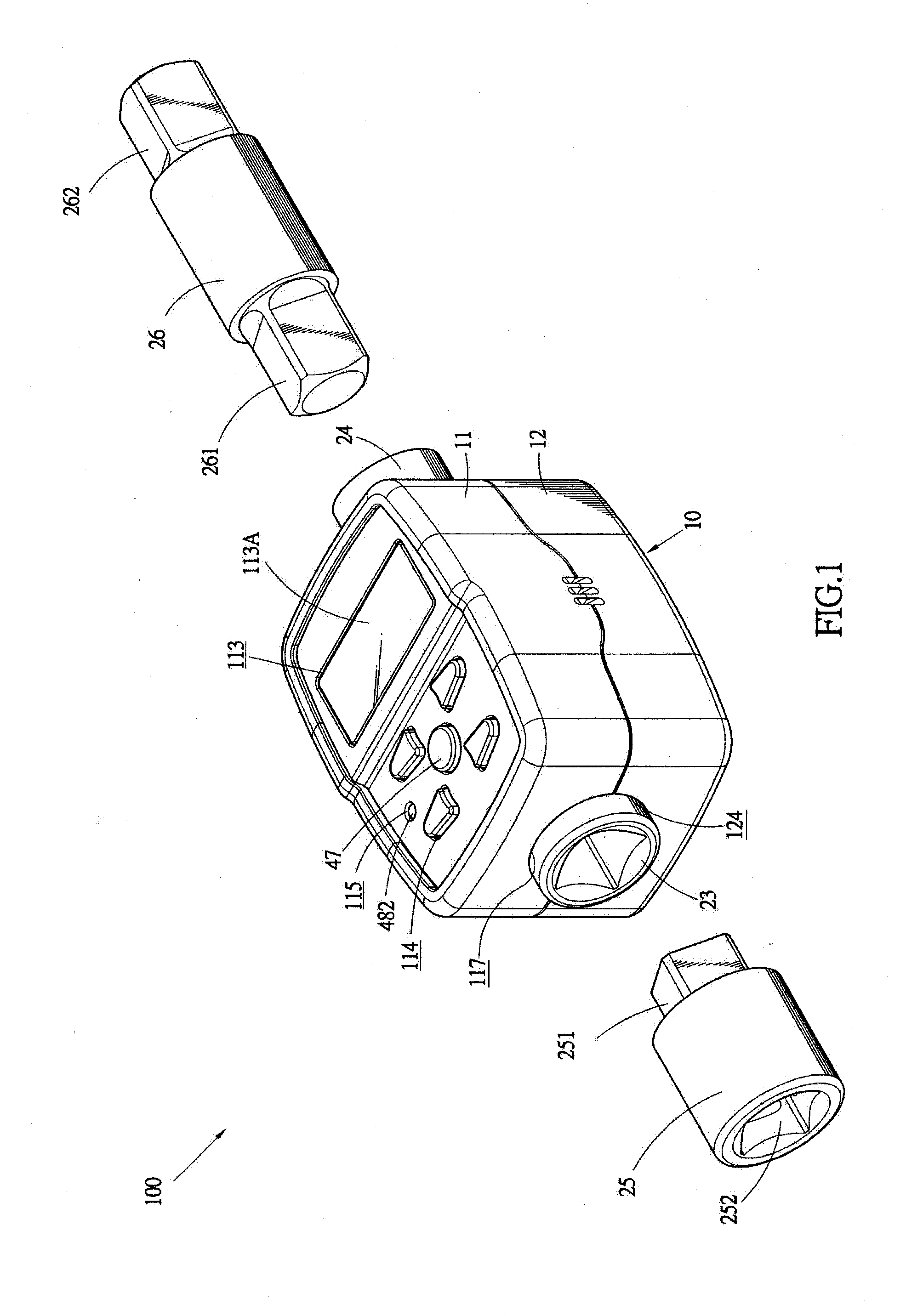

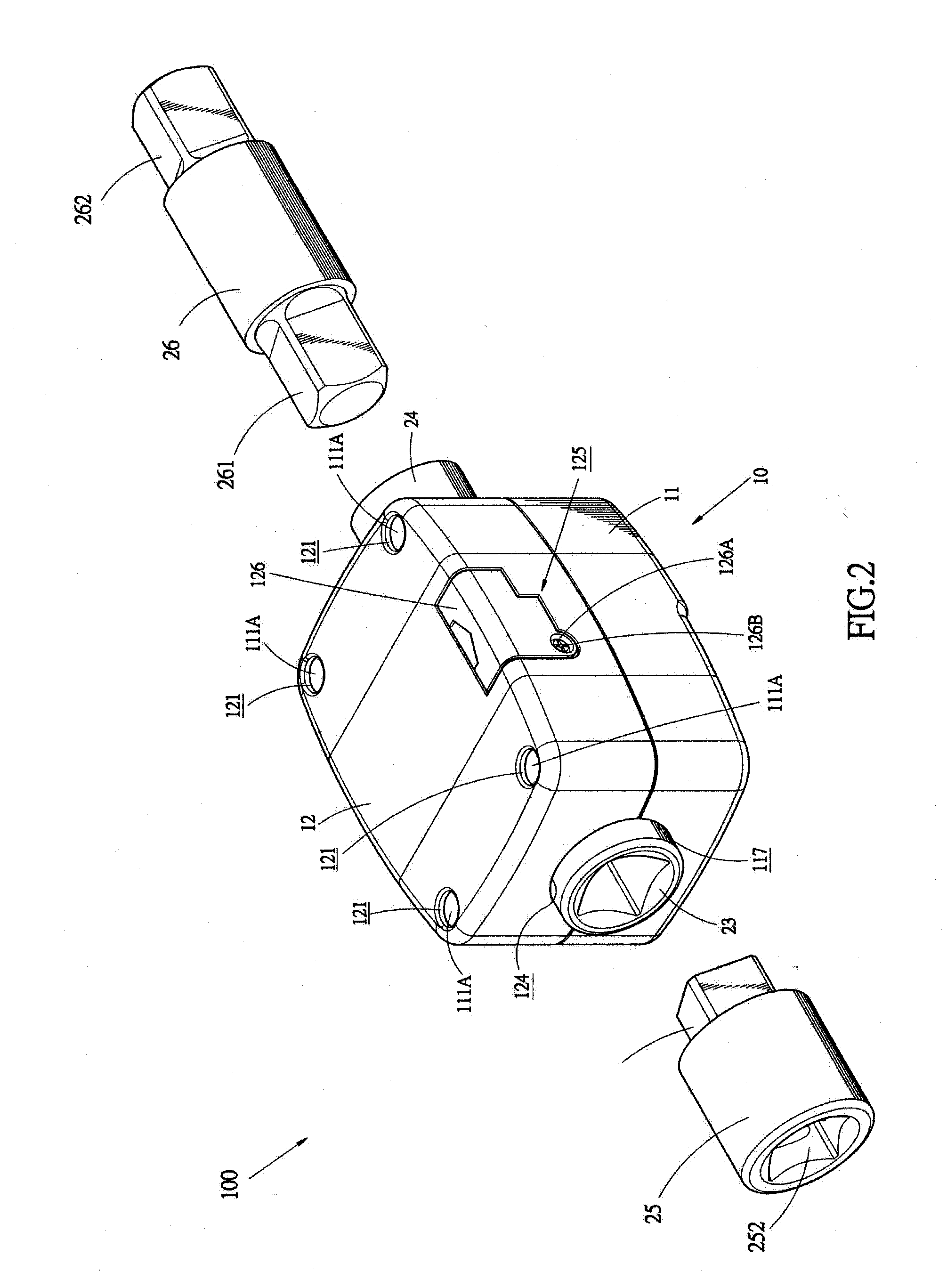

Torque detection device

ActiveUS8215187B2Improve operational convenienceEasy to readMeasurement of torque/twisting force while tighteningWork measurementPneumatic toolPower tool

A torque detection device includes an enclosure, at least one torque-strain bar, at least one adaptor, a coupler, at least one strain gauge, and a torque display unit. The torque-strain bar is enclosed by the enclosure and has opposite ends respectively forming coupling terminals for coupling with the adaptor and the coupler in either direction. The adaptor is connectable to a torque device, such as a hand tool, an electric tool, or a pneumatic tool. The coupler is connectable to a tool piece, such as a wrench socket. The strain gauge is directly mounted to the torque-strain bar to detect the value of a torque applied thereto and to convert the torque value into a torque value signal, which can be outputted in either wired or wireless manner. The torque display unit is mounted to the enclosure and receives the torque value signal from the stain gauge, whereby the torque display unit may perform displaying of torque value, alarming, and storage according to the torque value signal.

Owner:LEGEND LIFESTYLE PRODS CORP

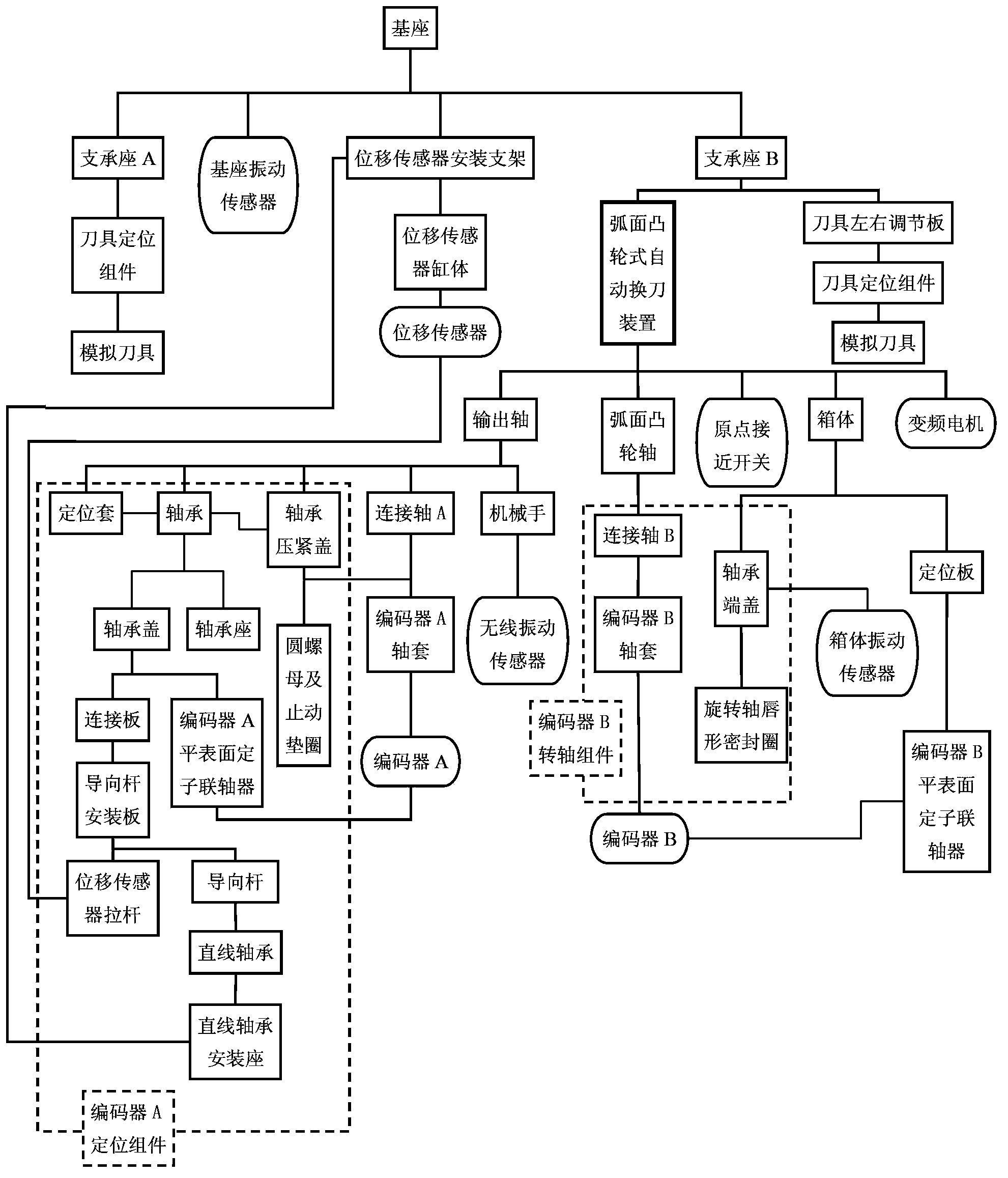

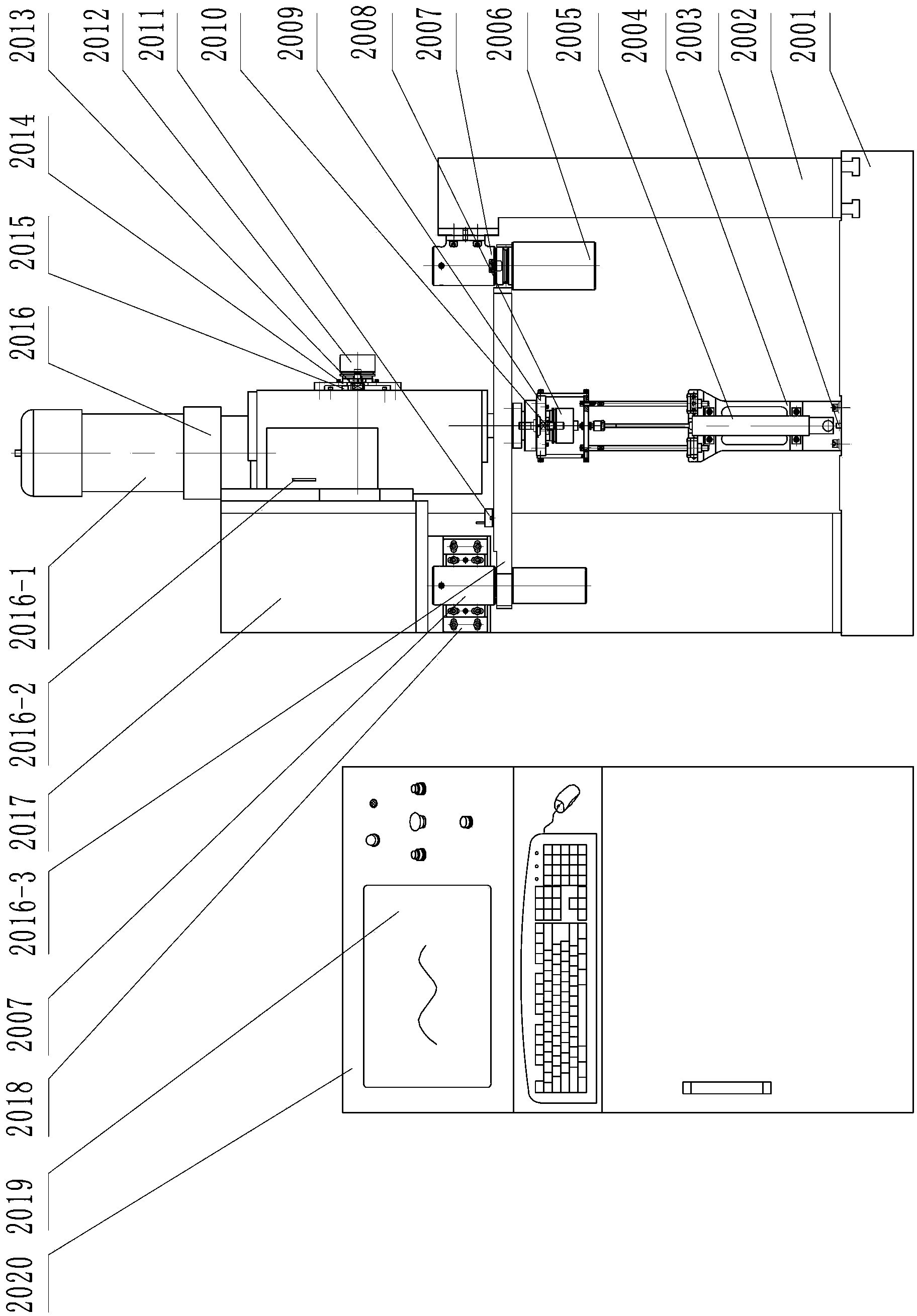

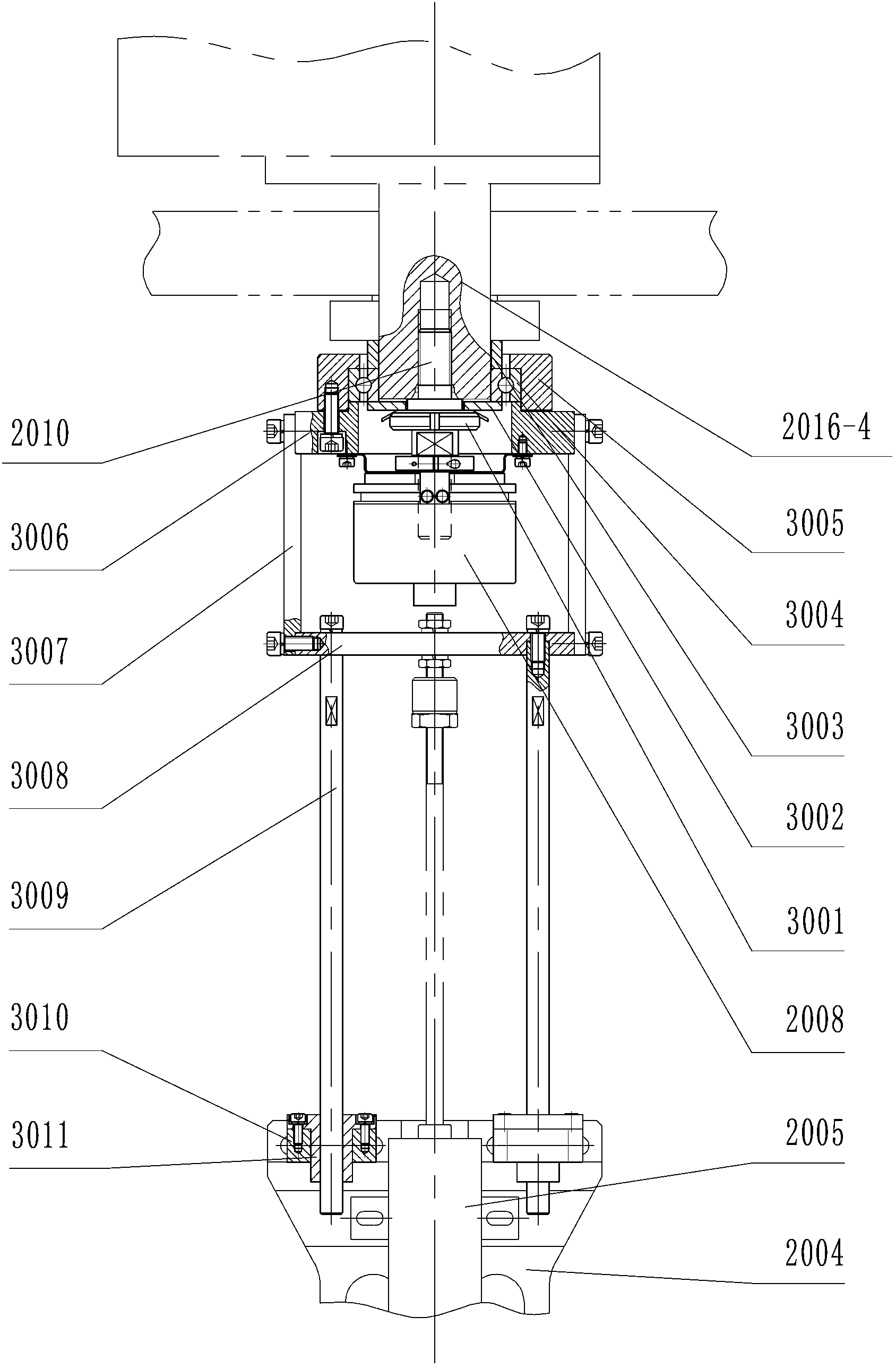

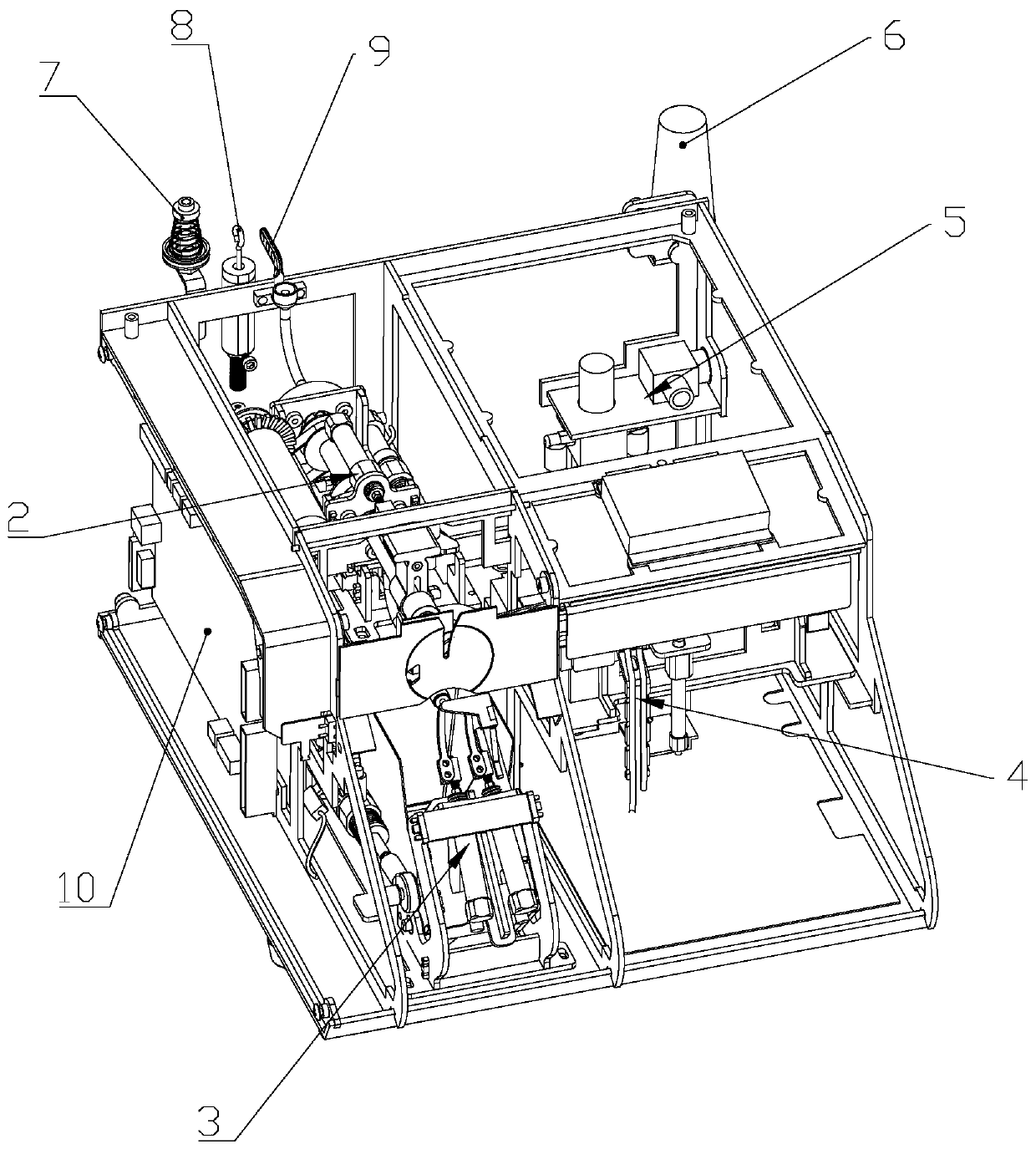

Automatic tool changer comprehensive performance detection test stand

InactiveCN103383315ASimple designImprove performanceStructural/machines measurementLinear motionNumerical control

The invention discloses an automatic tool changer comprehensive performance detection test stand, and belongs to the field of numerical control machine tool functional unit performance detection. The automatic tool changer comprehensive performance detection test stand integrates the mechanical technology and the sensor technology and virtual instruments, and accomplishes detection of all the following performances: tool change time, output shaft positioning accuracy (tool-capture-in-place accuracy, tool-change-in-place accuracy, returning accuracy, linear displacement accuracy and repetitive positioning accuracy), mechanical arm vibration, ATC operation stability, tool change success rate, globoidal indexing cam mechanism comprehensive indexing accuracy and dynamic characteristics. The technical problem that positioning accuracy is difficult to detect due to the fact that compound motion (rotary motion and linear motion) of the output shaft is solved by a positioning component of an encoder A; input and output parameters of a globoidal indexing cam mechanism are directly detected by the encoder A and an encoder B, and the comprehensive indexing accuracy and the dynamic characteristic detection accuracy of the globoidal indexing cam mechanism are improved. The automatic tool changer comprehensive performance detection test stand provides a comprehensive performance detection scheme for a professional manufacturing plant, and has significant practical meanings for a functional unit professional manufacturing plant.

Owner:BEIJING UNIV OF TECH

Torque detection device

ActiveUS20110107882A1Reduce manufacturing costImprove operational convenienceMeasurement of torque/twisting force while tighteningWork measurementPneumatic toolPower tool

A torque detection device includes an enclosure, at least one toque-strain bar, at least one adaptor, a coupler, at least one strain gauge, and a torque display unit. The toque-strain bar is enclosed by the enclosure and has opposite ends respectively forming coupling terminals for coupling with the adaptor and the coupler in either direction. The adaptor is connectable to a torque device, such as a hand tool, an electric tool, or a pneumatic tool. The coupler is connectable to a tool piece, such as a wrench socket. The strain gauge is directly mounted to the toque-strain bar to detect the value of a torque applied thereto and to convert the torque value into a torque value signal, which can be outputted in either wired or wireless manner. The torque display unit is mounted to the enclosure and receives the torque value signal from the stain gauge, whereby the torque display unit may perform displaying of torque value, alarming, and storage according to the torque value signal.

Owner:LEGEND LIFESTYLE PRODS CORP

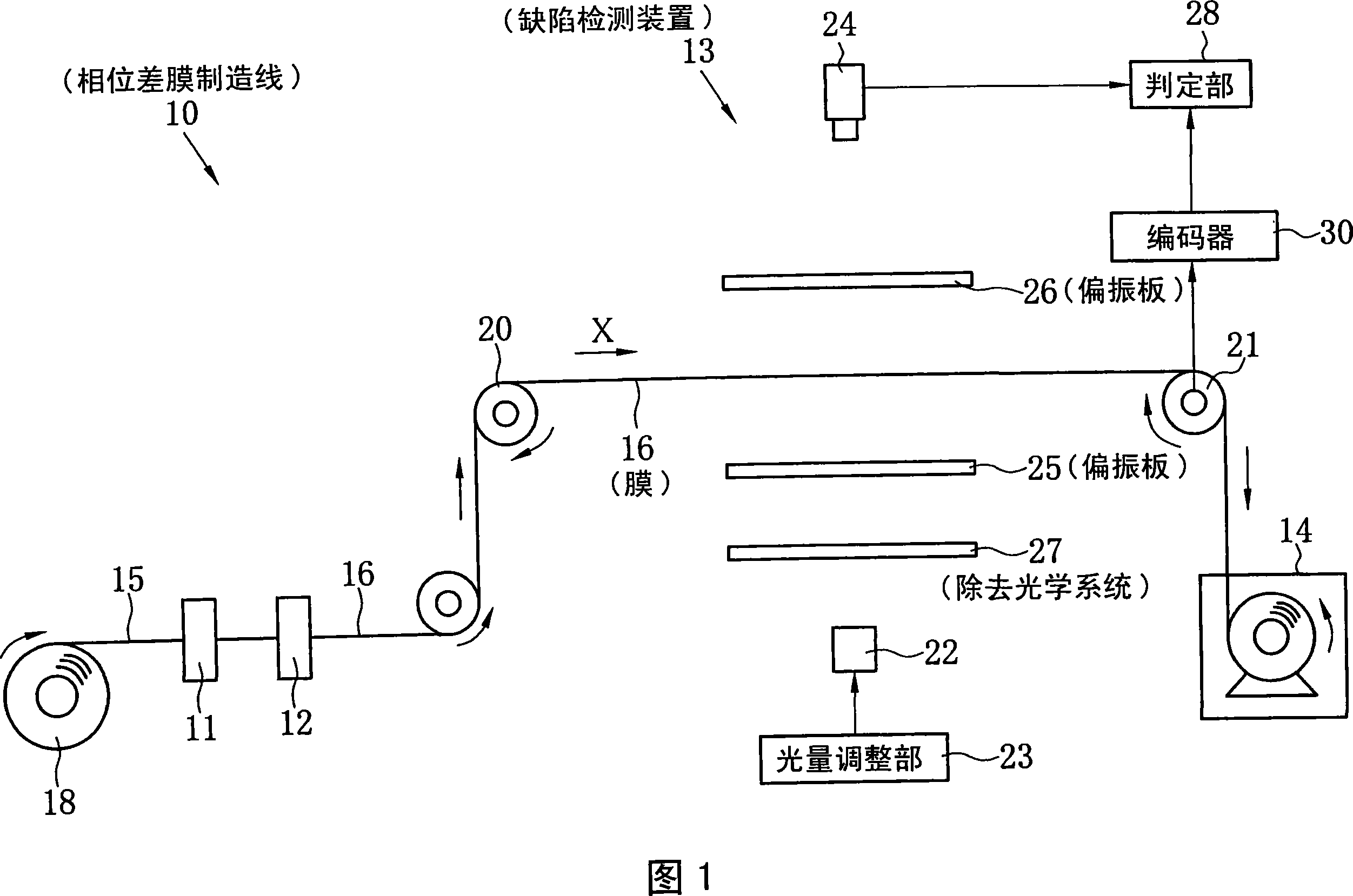

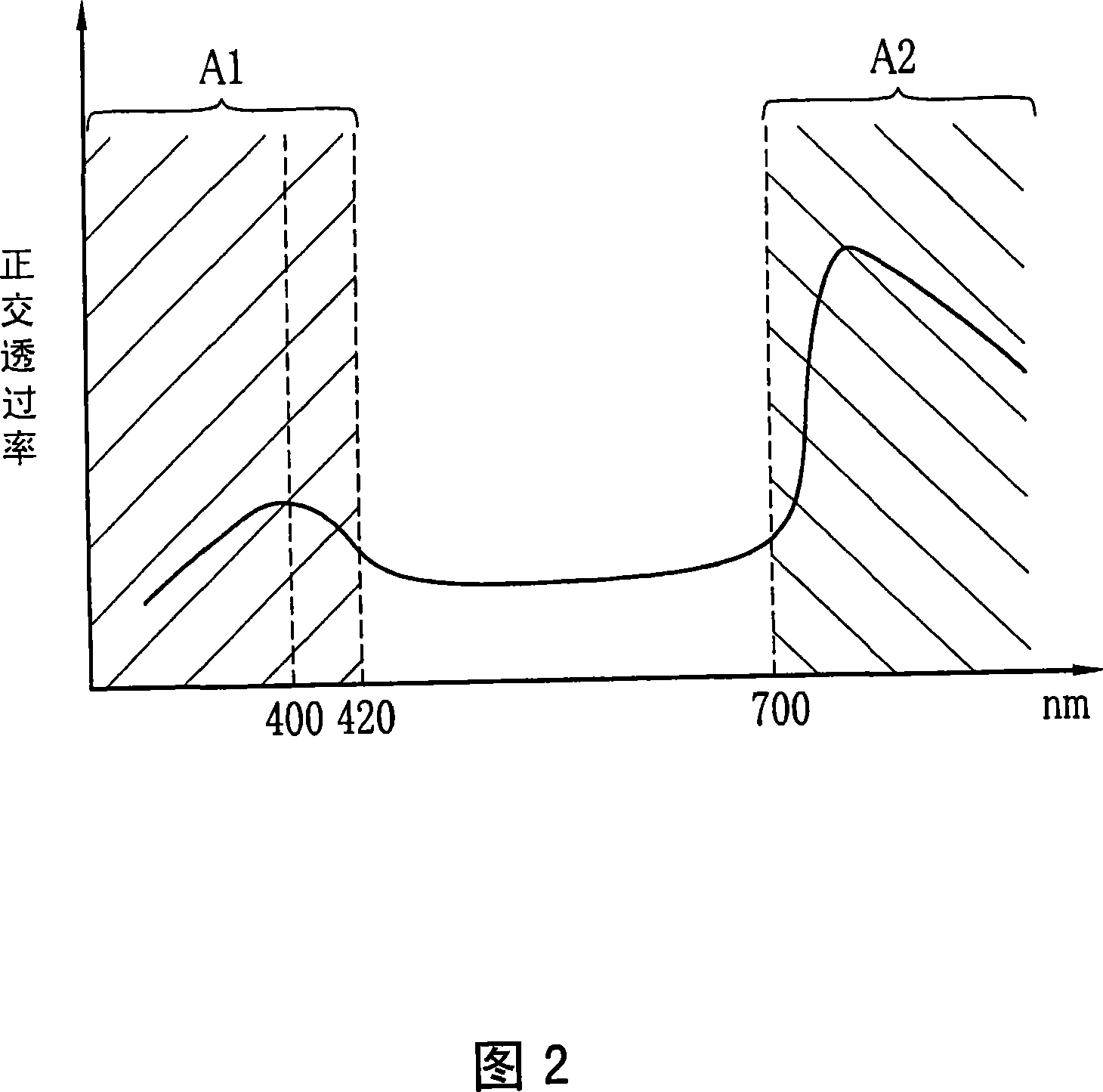

Device and method for detecting defect of transparent material

InactiveCN101226158ADetection accuracy meetsPolarising elementsOptically investigating flaws/contaminationBand-pass filterOptoelectronics

The invention provides a flaw detecting device of transparent material. A first and second polarization plates are arranged above and below the film in orthogonal polarization mode. A projector irradiates light through the first polarization plate and a light receiving device receives light from the second polarization plate, therefore the flaw of the film is detected. A band filter is set between the first polarization plate and projector. The band filter removes the light of wave band below 420nm and above 700nm. There is no light of needless wave band into the light receiving device, thus the flaw detecting accuracy is increased.

Owner:FUJIFILM CORP

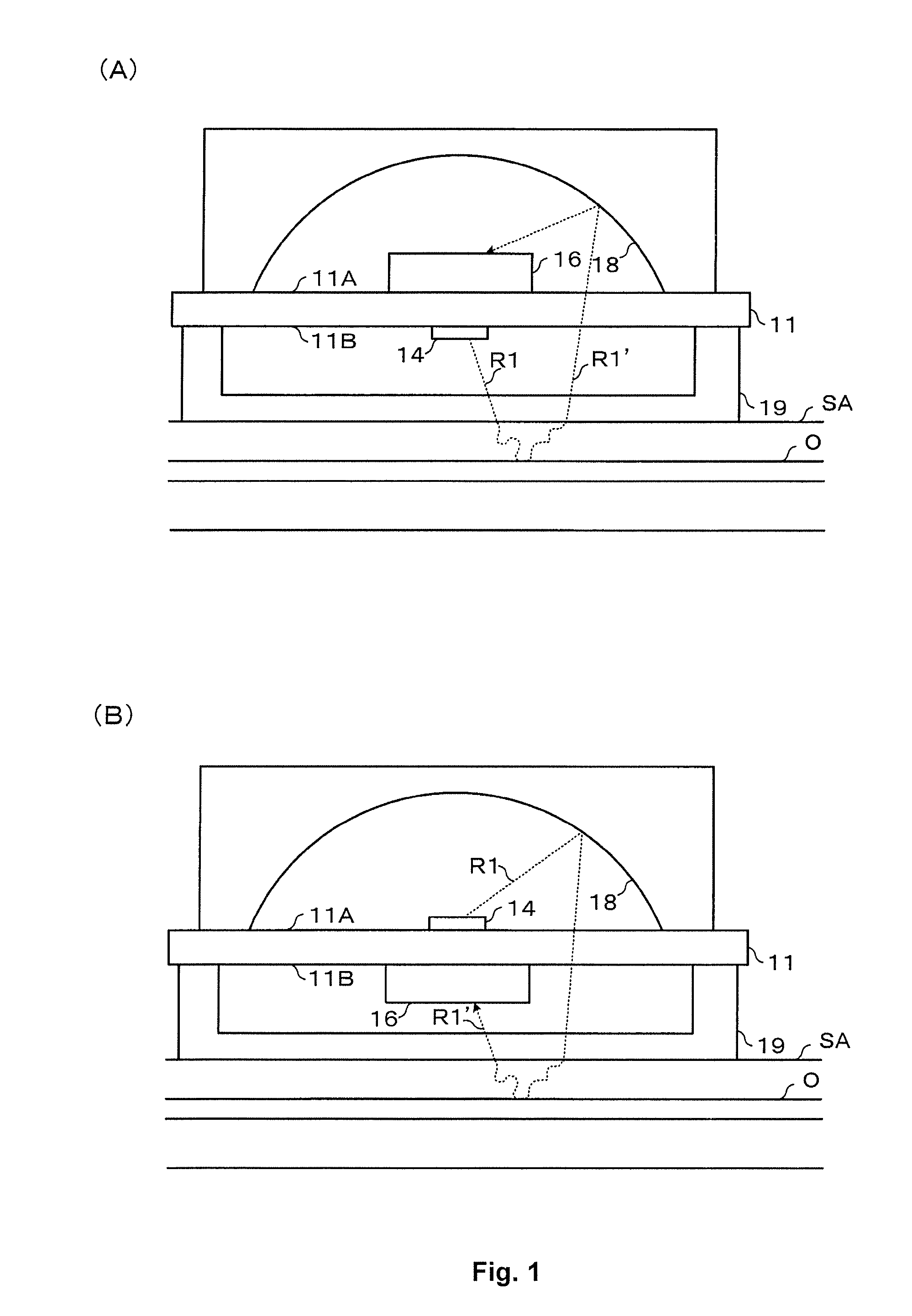

Radiation detection device, radiation image acquiring system, and method for detecting radiation

ActiveUS8280005B2Improve detection accuracyImprove claritySolid-state devicesMaterial analysis by optical meansForeign matterHigh energy

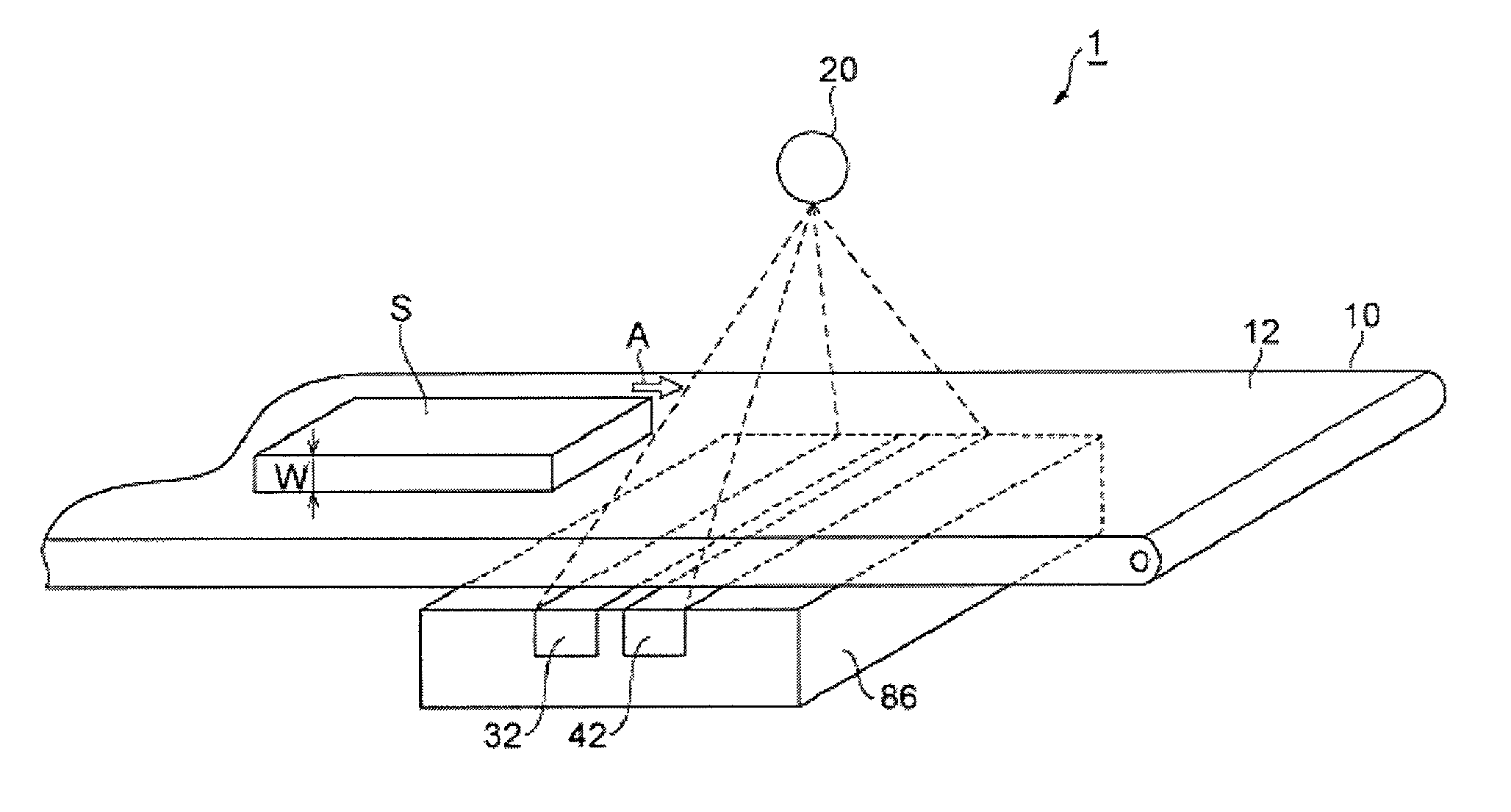

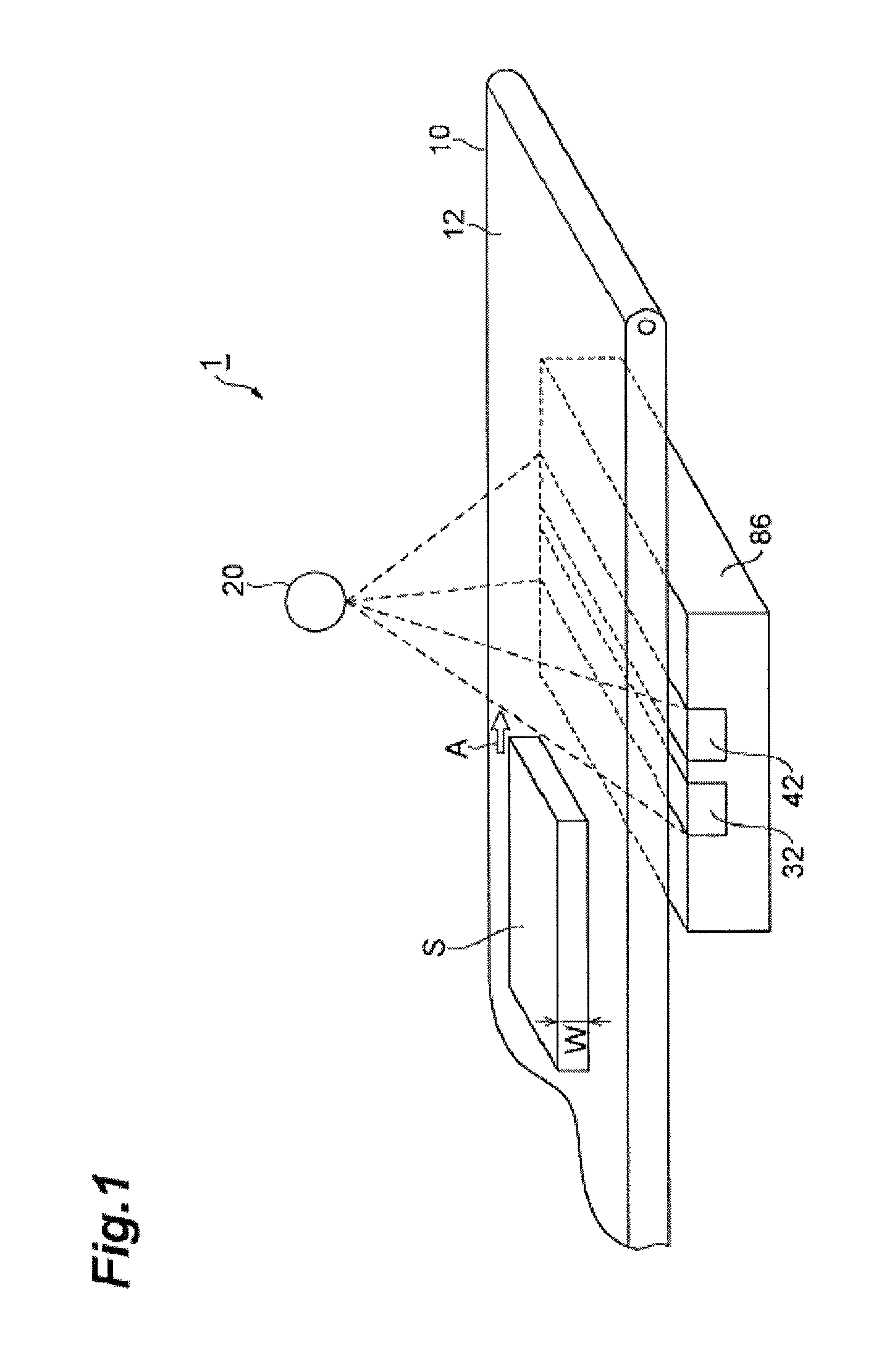

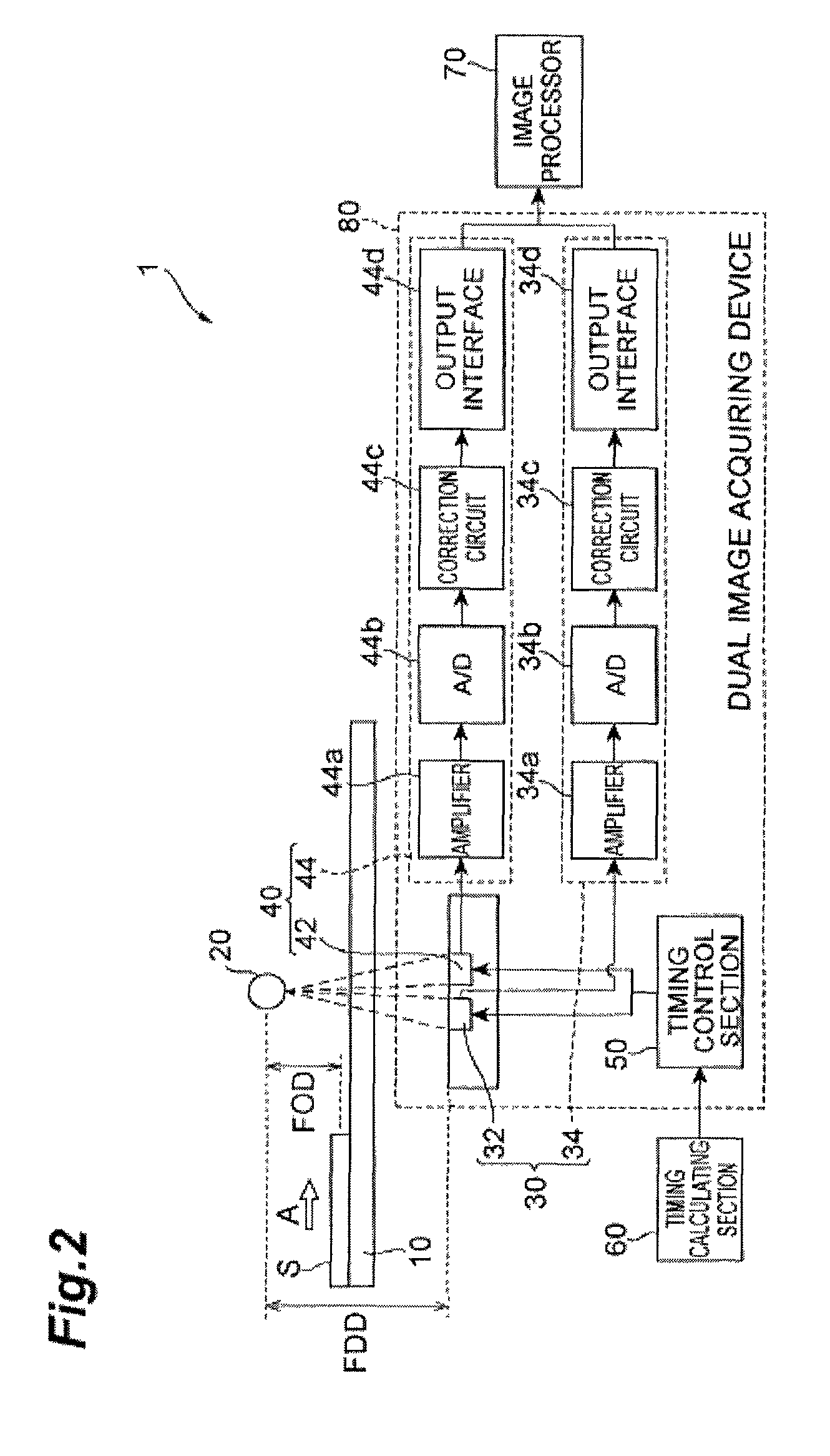

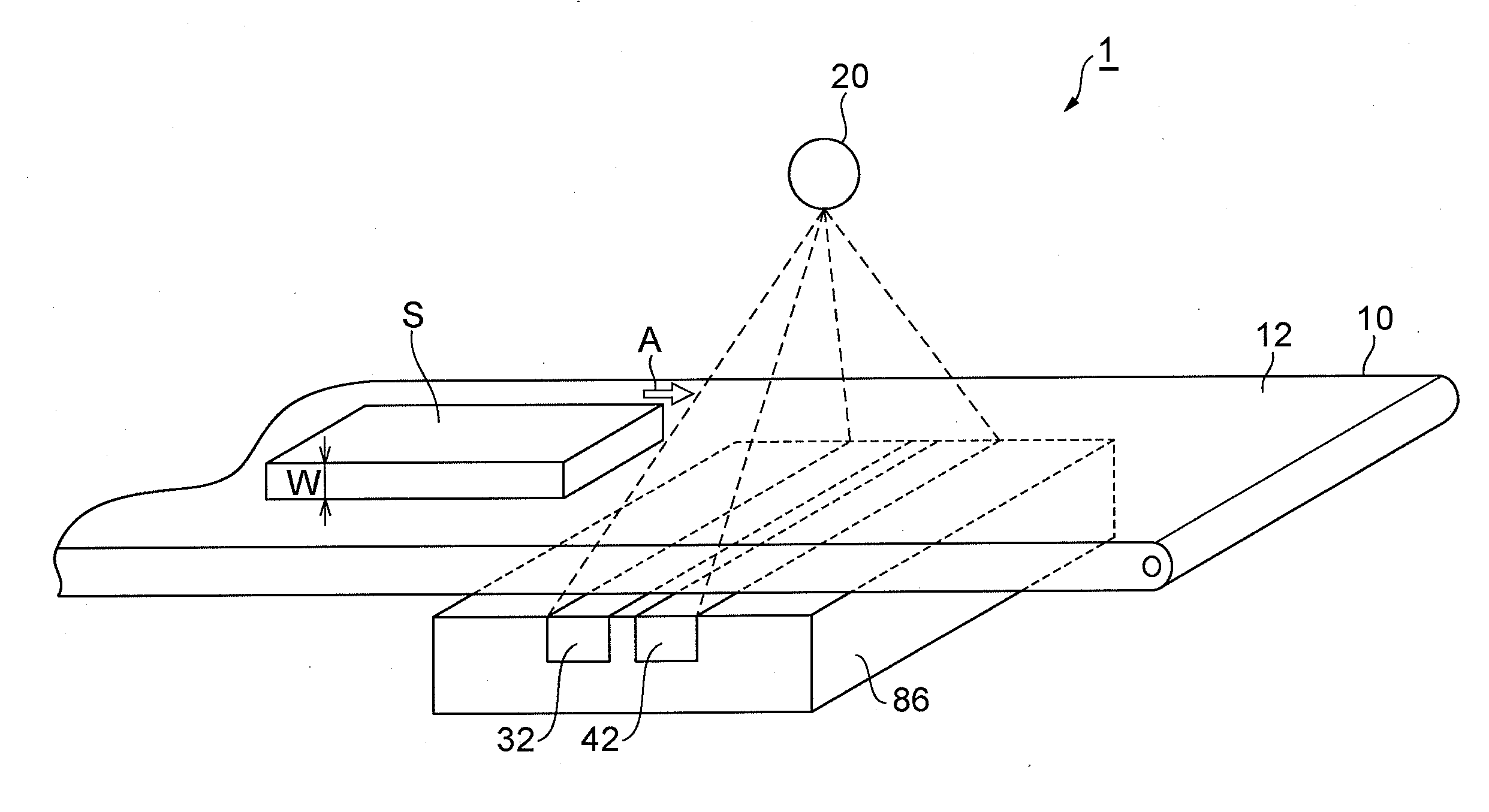

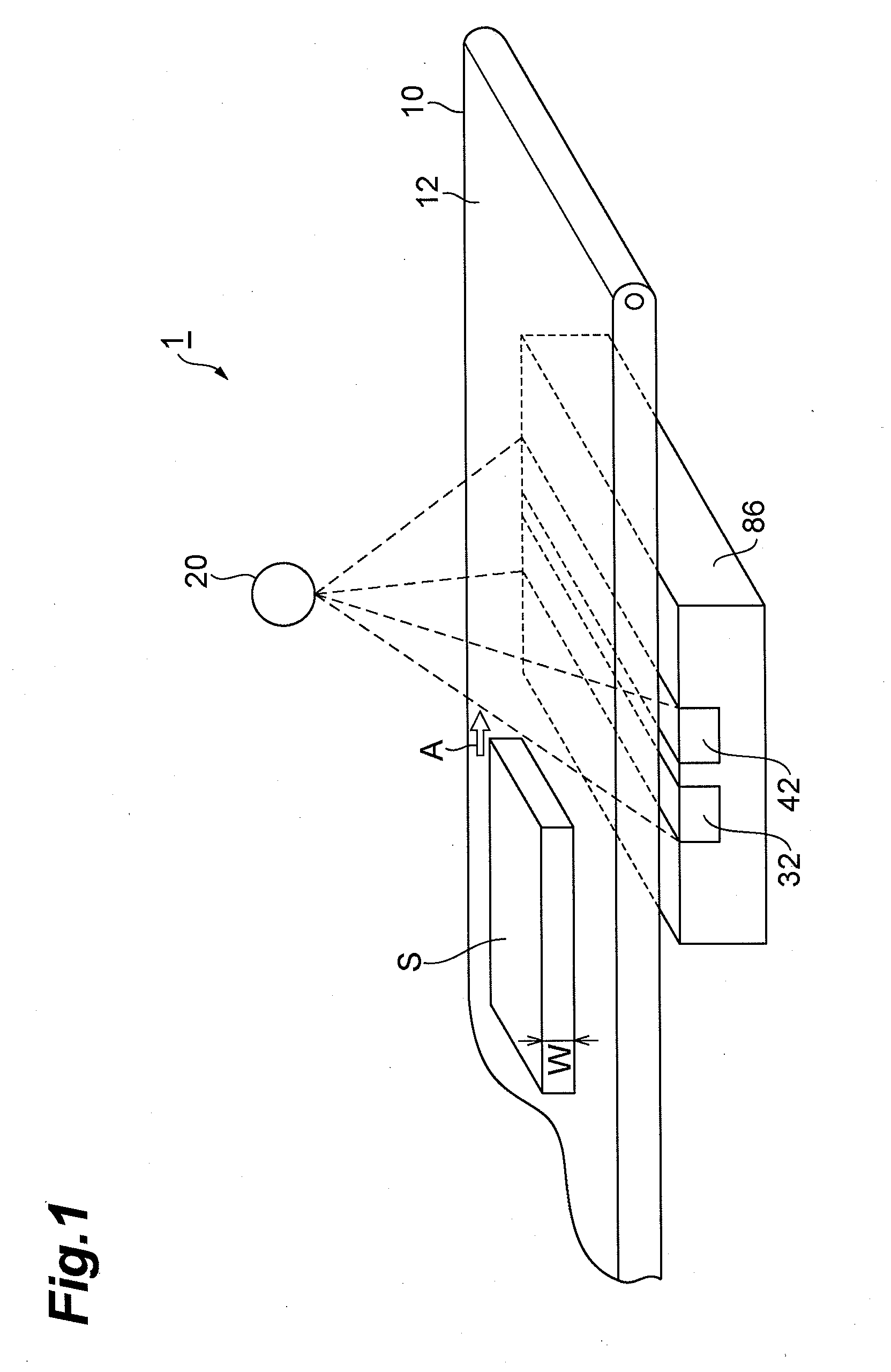

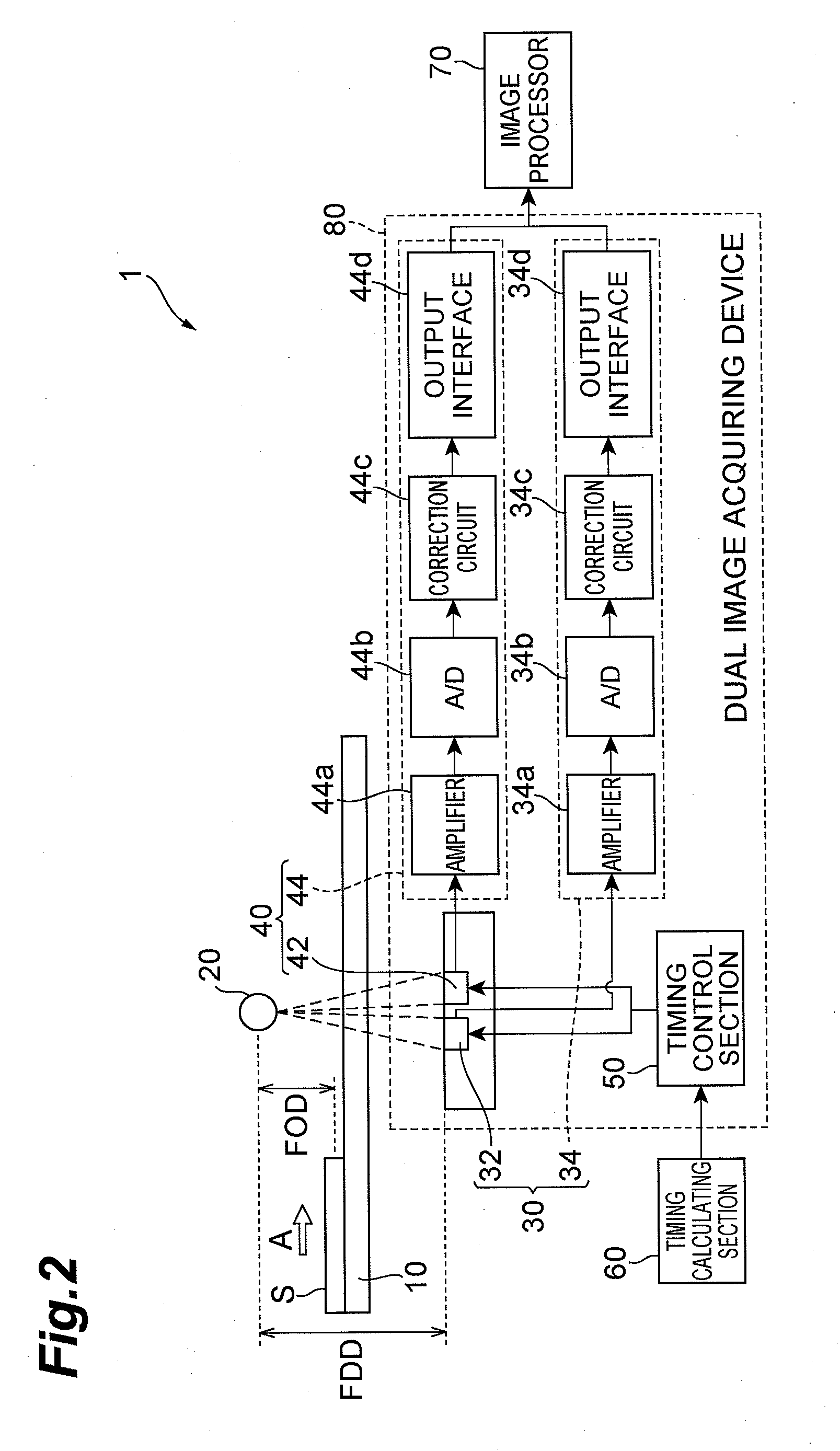

An X-ray image acquiring system capable of improving the detection accuracy of a foreign substance contained in a subject is provided. An X-ray image acquiring system 1 irradiates X-rays to a subject S having a predetermined thickness W from an X-ray source, and detects X-rays transmitted through the subject S in a plurality of energy ranges. The X-ray image acquiring system 1 includes a low-energy detector 32 for detecting, in a low-energy range, X-rays having been transmitted through a region R1 extending in a thickness direction within the subject S, a high-energy detector 42 for detecting, in a high-energy range, X-rays having been transmitted through a region R2 extending in a thickness direction within the subject S, and a timing control section 50 for controlling detection timing of X-rays in the low-energy detector 32 and the high-energy detector 42 so that an inspecting region E located at a predetermined site within the subject S is included in the region R1 and the region R2.

Owner:HAMAMATSU PHOTONICS KK

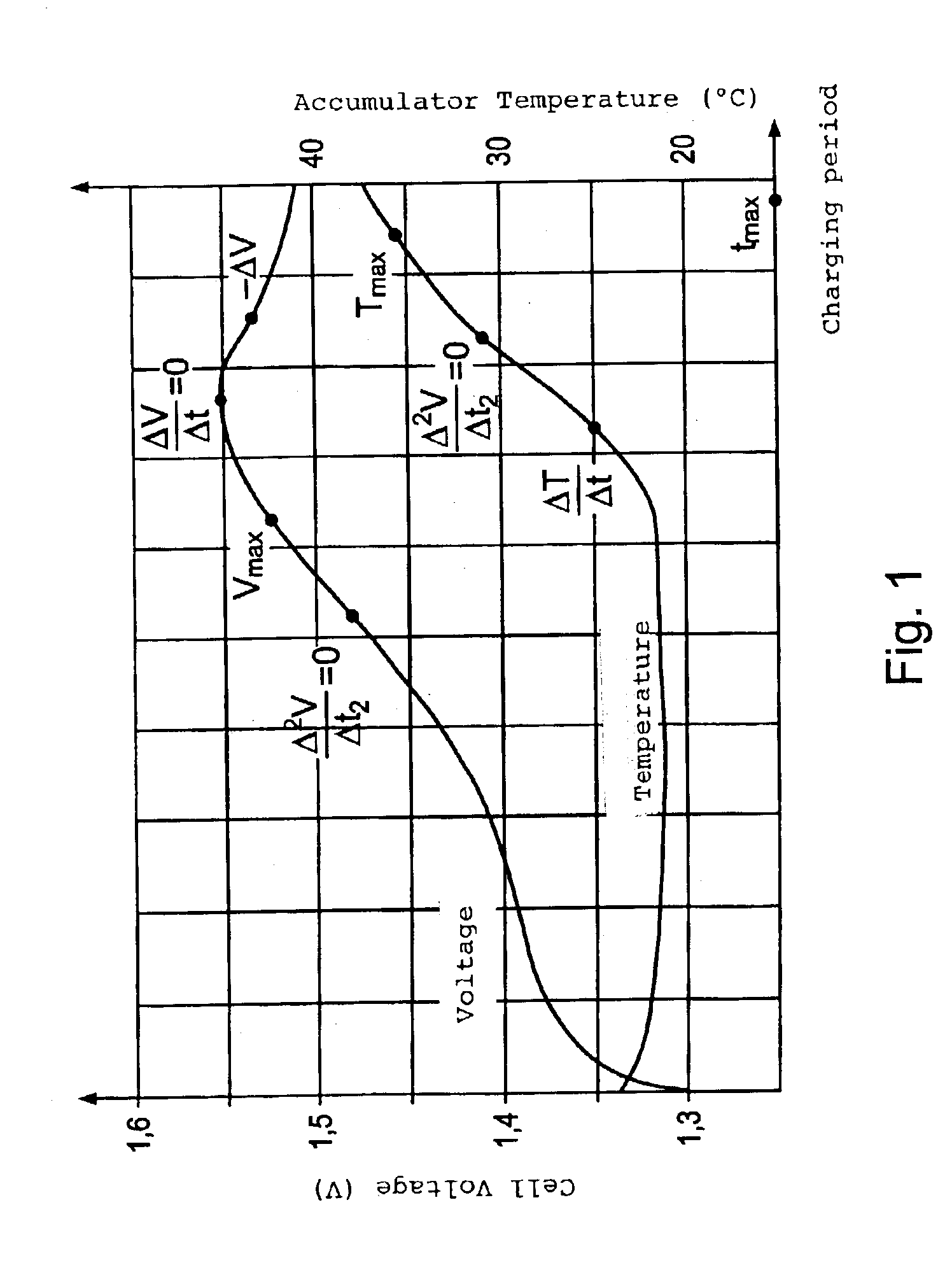

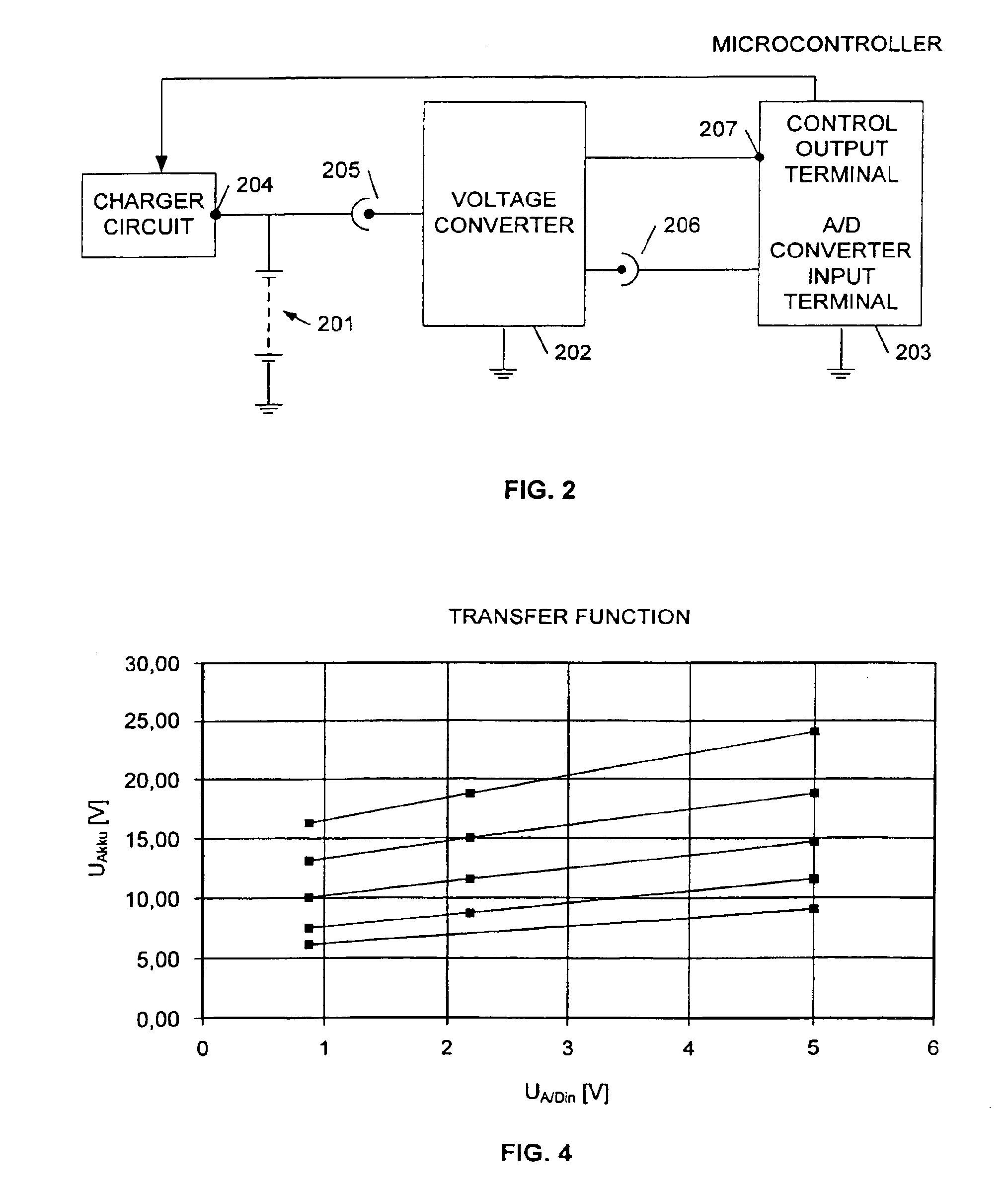

Device and method for the detection of a charging voltage

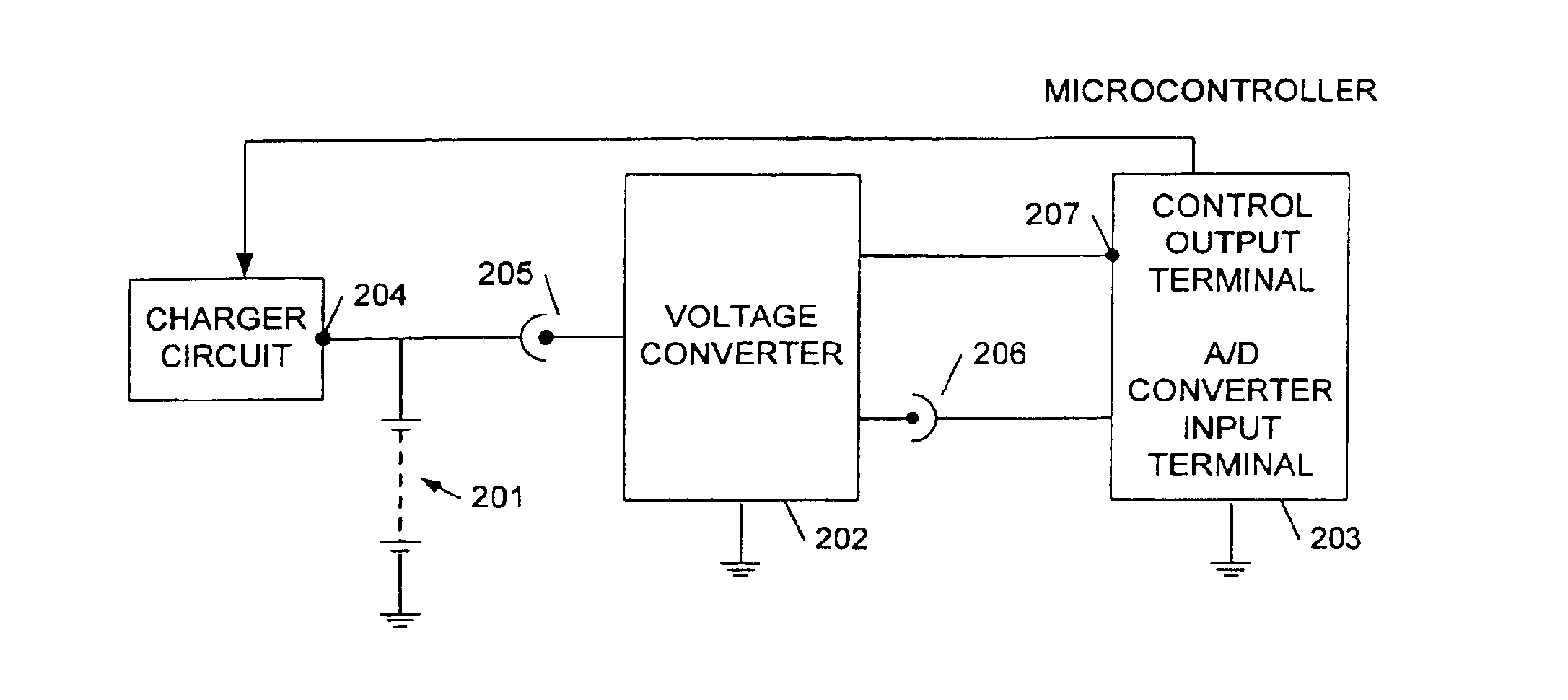

ActiveUS6906498B2Compact and inexpensive to manufactureComplex analog circuitsCircuit monitoring/indicationCurrent/voltage measurementVoltage converterAudio power amplifier

The present invention relates to a device and a method for the detection of a charging voltage of at least one rechargeable battery comprising a voltage converter for converting the charging voltage of the at least one rechargeable battery into a voltage signal, an analog / digital converter for converting the voltage signal of the voltage converter into a digital signal, and an evaluation and control device for evaluating the digital signal of the analog / digital converter as well as for controlling the charging process of the at least one rechargeable battery on the basis of the evaluation of the digital signal of the analog / digital converter. The voltage converter comprises an amplifier circuit with a variable gain controlled by at least one control output terminal of the evaluation and control device such that the gain applied for the generation of the voltage signal is adjusted to the input voltage range of the analog / digital converter according to a transfer function.

Owner:FRIWO GERAETEBAU GMBH

Robot slip detection apparatus and method

ActiveUS8938319B2Detection accuracy meetsImprove accuracyComputer controlSimulator controlEngineeringParticle filter

A technique of detecting a slip of a robot using a particle filter and feature information of a ceiling image is disclosed. A first position of the robot is computed using a plurality of particles, a second position of the robot is computed using the feature information of the ceiling image, and whether a slip has occurred is determined based on a distance between the first position and the second position.

Owner:SAMSUNG ELECTRONICS CO LTD

Device for hydrophobicity detection and aging evaluation of composite insulator

InactiveCN103941120AEnhanced electric fieldDetection securitySurface/boundary effectElectrical testingEarly detectionSupply and distribution

The invention provides a device for hydrophobicity detection and aging evaluation of a composite insulator based on ultraviolet optical characteristics of liquid drop discharge. On the premise of guaranteeing safe operation of electric transmission and transformation equipment, the ultraviolet optical characteristics of discharge of liquid drops on the surface of the composite insulator are obtained effectively and used for reflecting the existing state and distribution of the liquid drops on the surface of the composite insulator and the aging conditions of the composite insulator, and corresponding aging evaluation criteria are provided. By means of the device, hydrophobicity reducing factors causing external insulation flashover accidents can be subjected to early detection and diagnosis, the resolution and accuracy of surface hydrophobicity detection of the composite insulator are improved, and continuity and reliability of power supply and distribution of an electric power system are effectively guaranteed.

Owner:STATE GRID TIANJIN ELECTRIC POWER

Radiation detection device, radiation image acquiring system, and method for detecting radiation

ActiveUS20100119040A1Improve detection accuracyImprove clarityX/gamma/cosmic radiation measurmentX-ray apparatusForeign matterHigh energy

An X-ray image acquiring system capable of improving the detection accuracy of a foreign substance contained in a subject is provided. An X-ray image acquiring system 1 irradiates X-rays to a subject S having a predetermined thickness W from an X-ray source, and detects X-rays transmitted through the subject S in a plurality of energy ranges. The X-ray image acquiring system 1 includes a low-energy detector 32 for detecting, in a low-energy range, X-rays having been transmitted through a region R1 extending in a thickness direction within the subject S, a high-energy detector 42 for detecting, in a high-energy range, X-rays having been transmitted through a region R2 extending in a thickness direction within the subject S, and a timing control section 50 for controlling detection timing of X-rays in the low-energy detector 32 and the high-energy detector 42 so that an inspecting region E located at a predetermined site within the subject S is included in the region R1 and the region R2.

Owner:HAMAMATSU PHOTONICS KK

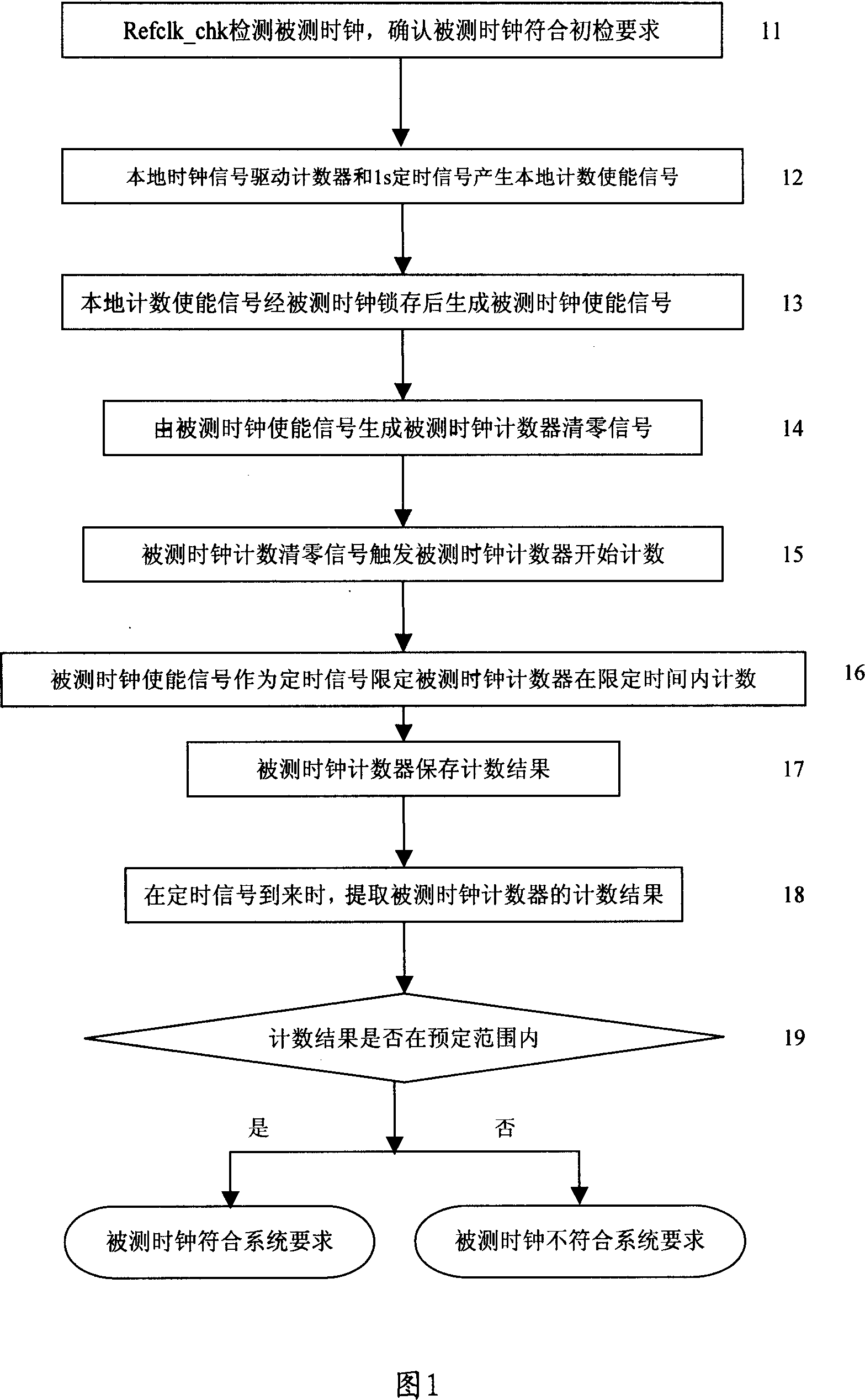

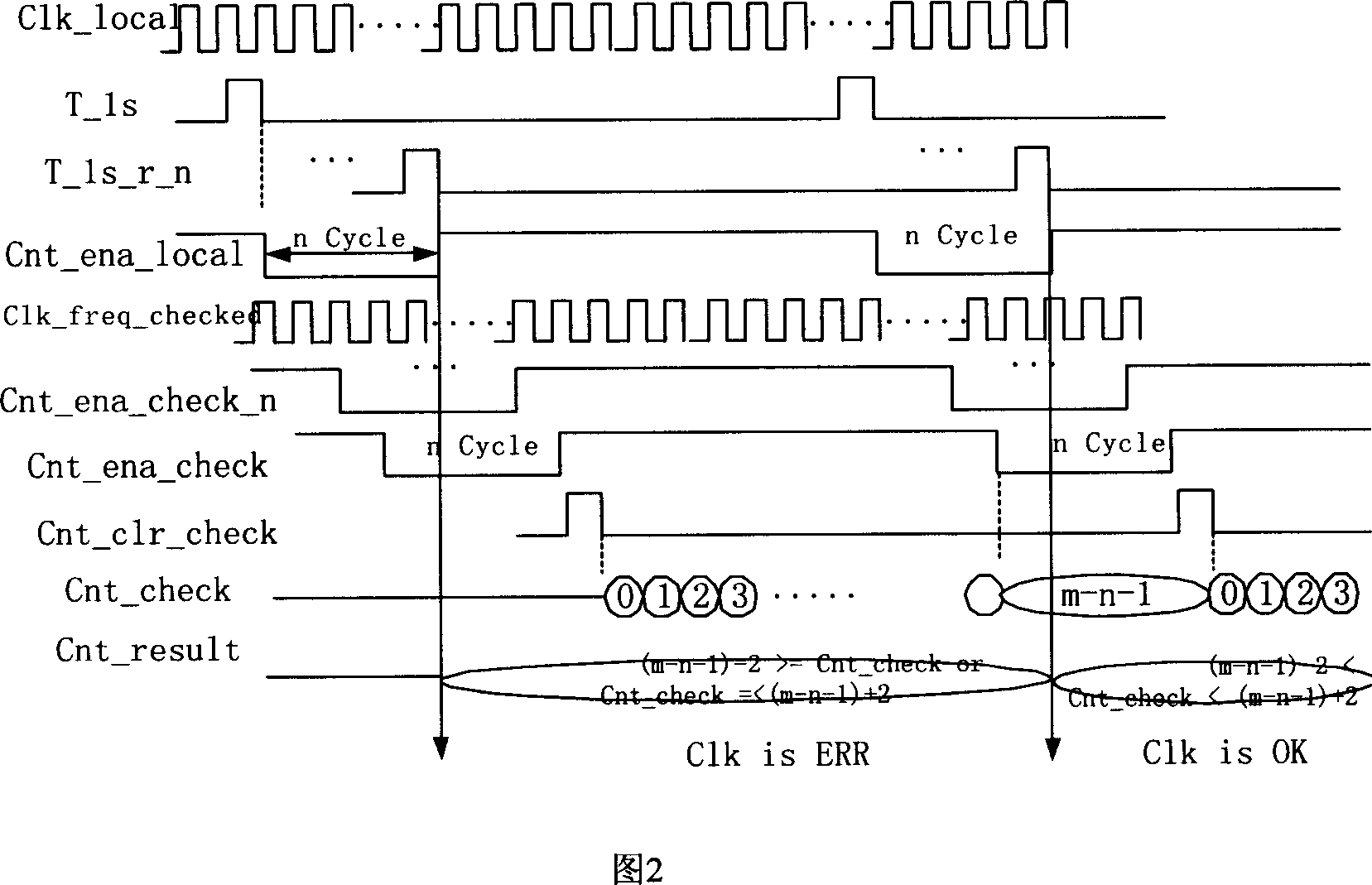

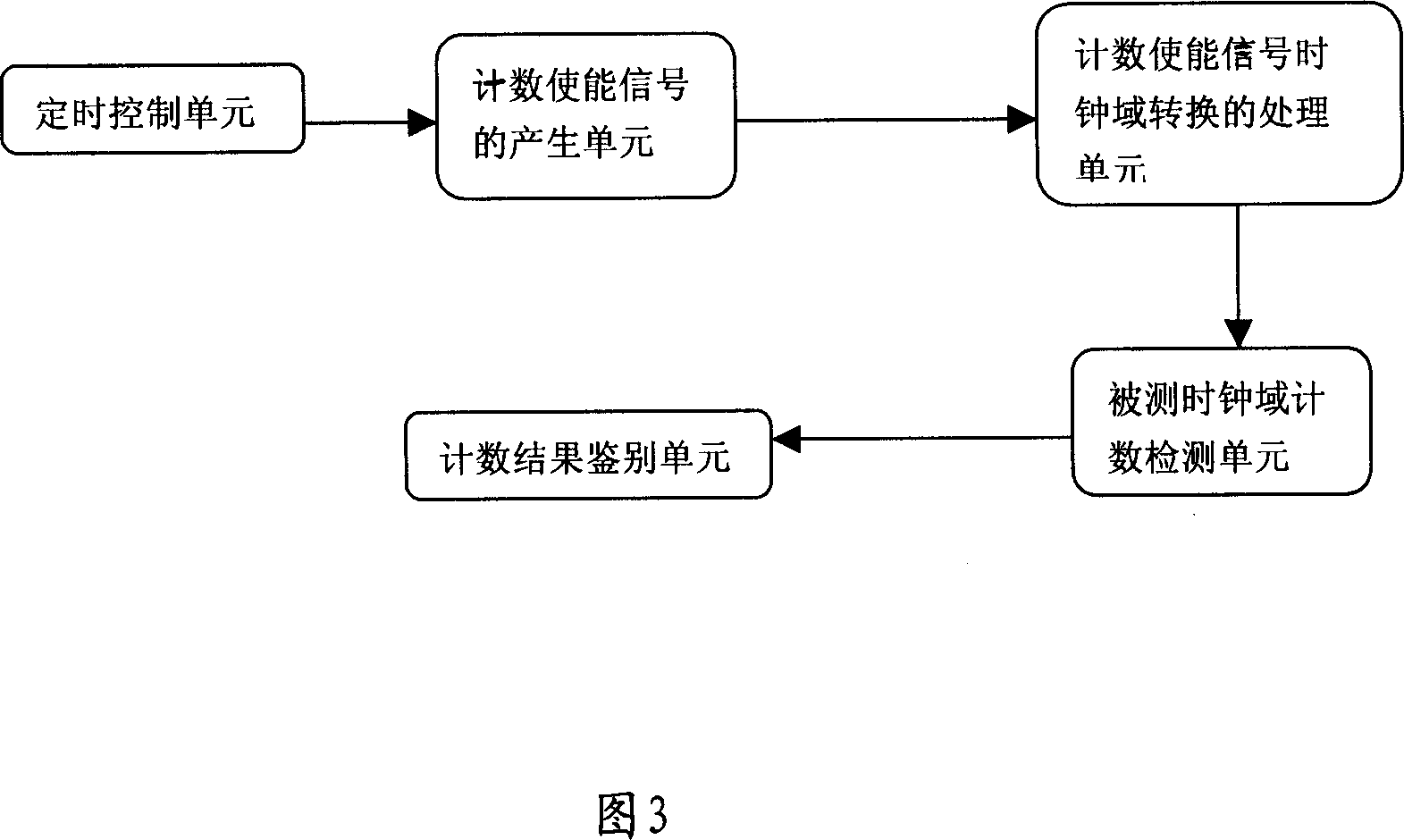

Method and device for clock detection

InactiveCN1925329ADetection accuracy meetsReliable servicePulse train pattern monitoringError detection/correctionClock rateTimer

This invention relates to one clock test method and device, which comprises the following steps: firstly generating meter energy signals according to local timing mechanism and the meter can transfer the tested signals into the clock zone to be tested to generate clock timer energy signals of zero and triggering the tested clock zone meter by signal and to start metering at fixed time circle; observing meter results to judge the accuracy of the clock to be tested.

Owner:HUAWEI TECH CO LTD

Method for hydrophobicity detection and aging evaluation of composite insulator

InactiveCN103884972APrecise control of pollution levelPrecise position controlTesting dielectric strengthElectric dischargeComposite insulators

The invention provides a method for hydrophobicity detection and aging evaluation of a composite insulator based on the ultraviolet optical characteristics of liquid drop electric discharge. According to the method, on the premise that safe operation of electric transmission and transformation equipment is guaranteed, the ultraviolet optical characteristics of liquid drop electric discharge on the surface of the composite insulator are effectively obtained and are used for reflecting the existing state and the distribution of the surface liquid drop of the composite insulator and the aging condition of the composite insulator, a corresponding aging evaluation basis is provided, hydrophobicity lowering factors causing an external insulation flashover accident can be detected and judged early, the definition and the accuracy of the surface hydrophobicity detection of the composite insulator are improved, and the continuity and the reliability of power supply and distribution of a power system are effectively guaranteed.

Owner:TIANJIN UNIV

Polishing pad and method of producing semiconductor device

InactiveUS8845852B2Detection accuracy meetsHigh measurement accuracySemiconductor/solid-state device manufacturingFlexible-parts wheelsIn planeTransmittance

A polishing pad enabling a highly precise optical endpoint sensing during the polishing process and thus having excellent polishing characteristics (such as surface uniformity and in-plane uniformity) is disclosed. A polishing pad enabling to obtain the polishing profile of a large area of a wafer is also disclosed. A polishing pad of a first invention comprises a light-transmitting region having a transmittance of not less than 50% over the wavelength range of 400 to 700 nm. A polishing pad of a second invention comprises a light-transmitting region having a thickness of 0.5 to 4 mm and a transmittance of not less than 80% over the wavelength range of 600 to 700 nm. A polishing pad of a third invention comprises a light-transmitting region arranged between the central portion and the peripheral portion of the polishing pad and having a length (D) in the diametrical direction which is three times or more longer than the length (L) in the circumferential direction.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

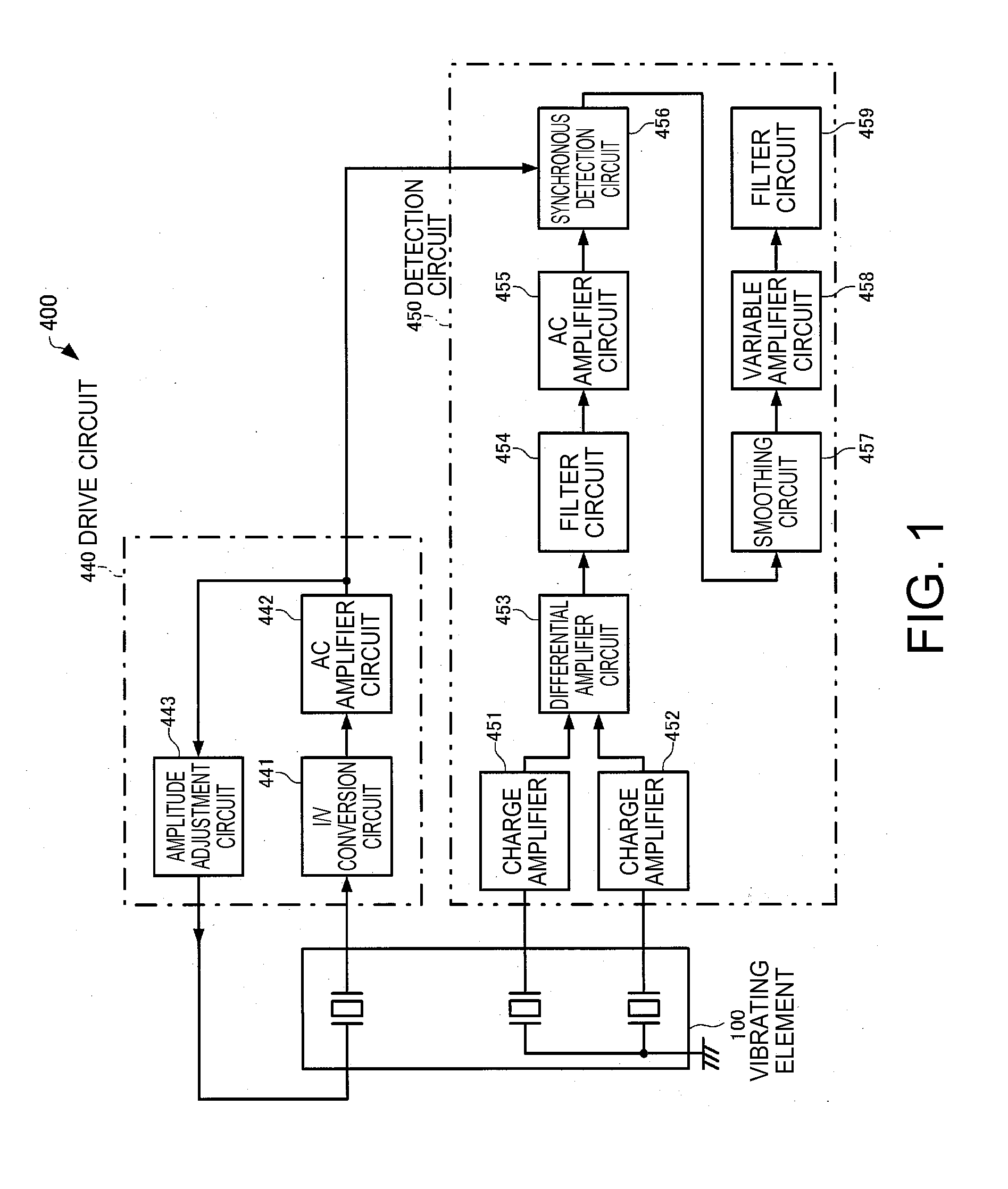

Physical quantity detection circuit, physical quantity detecting device, electronic apparatus, and moving object

InactiveUS20150276404A1Reduce the possibilityReduce detection accuracyAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsResonanceEngineering

A physical quantity detection circuit includes a filter circuit, and a synchronous detection circuit that is provided at a downstream of the filter circuit and detects a signal in response to a physical quantity contained in an output signal of a vibrating element based on a drive signal for driving the vibrating element. The filter circuit has a cutoff frequency between a resonance frequency in a drive mode and a resonance frequency in a detection mode of the vibrating element and contains the resonance frequency in the drive mode in a passband.

Owner:SEIKO EPSON CORP

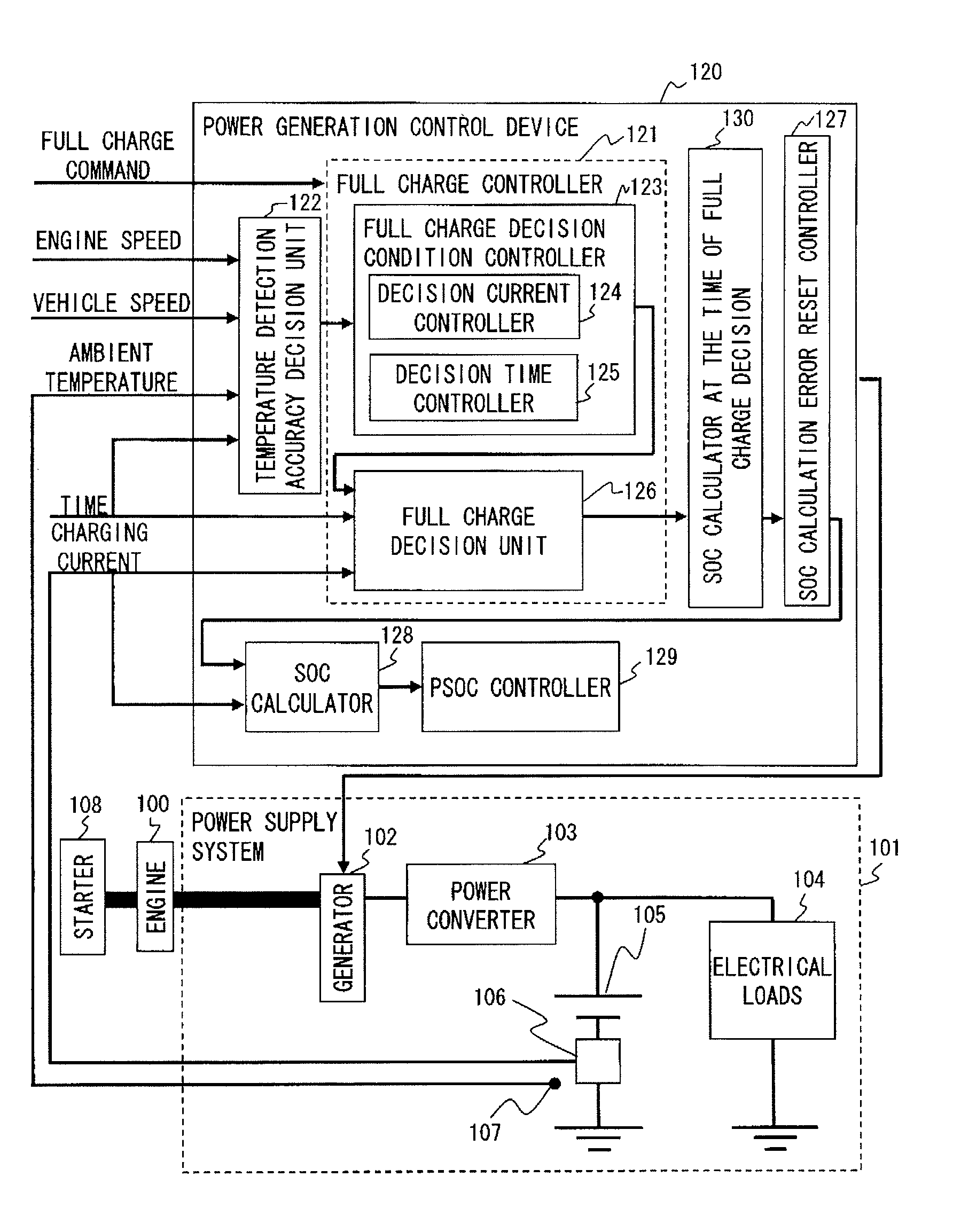

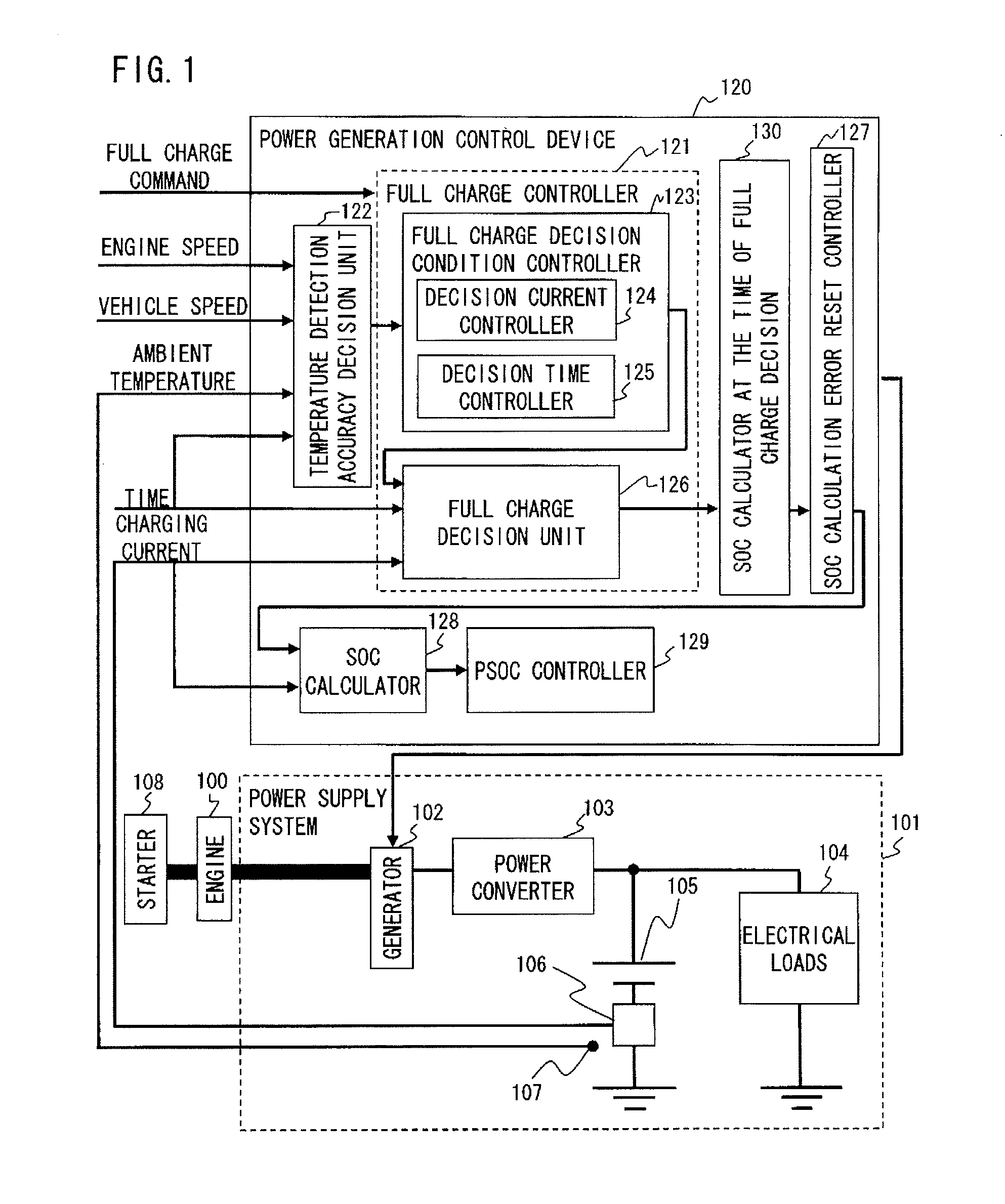

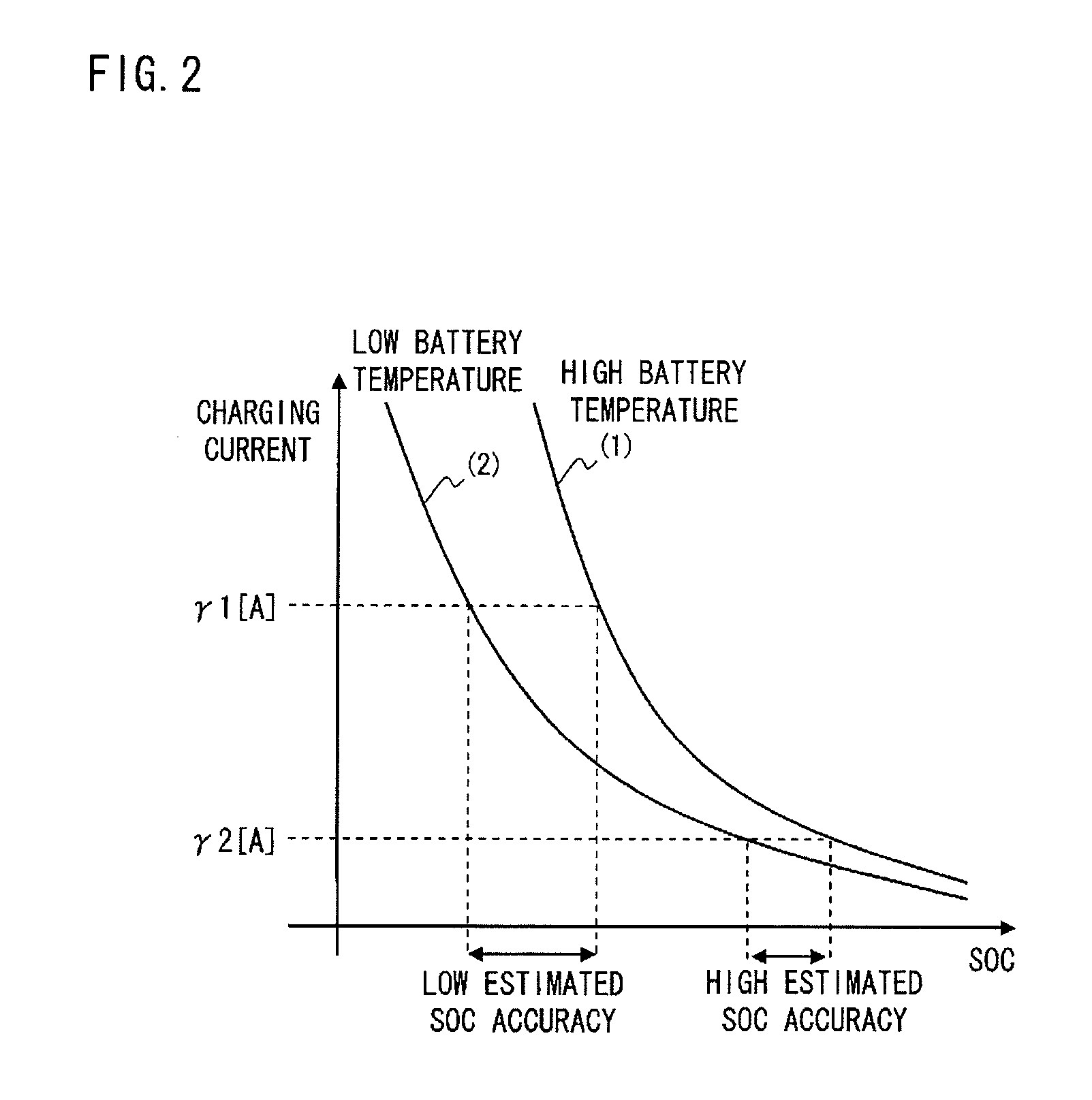

Full charge control apparatus for onboard battery

InactiveUS20120293121A1Inhibit deteriorationDetection accuracy meetsBatteries circuit arrangementsElectrical testingCharge controlEngineering

A full charge control apparatus includes a temperature detection accuracy decision unit and a full charge decision unit. The temperature detection accuracy decision unit detects an engine speed, a vehicle speed and an ambient temperature and, based on these surrounding conditions, determines whether the difference between the temperature of the battery estimated from a measurement by a temperature sensor and a true battery temperature falls within a specified accuracy range. If the battery temperature measurement accuracy is not within the specified range, the criteria for judging the fully charged state of the battery are modified to ensure that the battery will not be under-charged.

Owner:MITSUBISHI ELECTRIC CORP

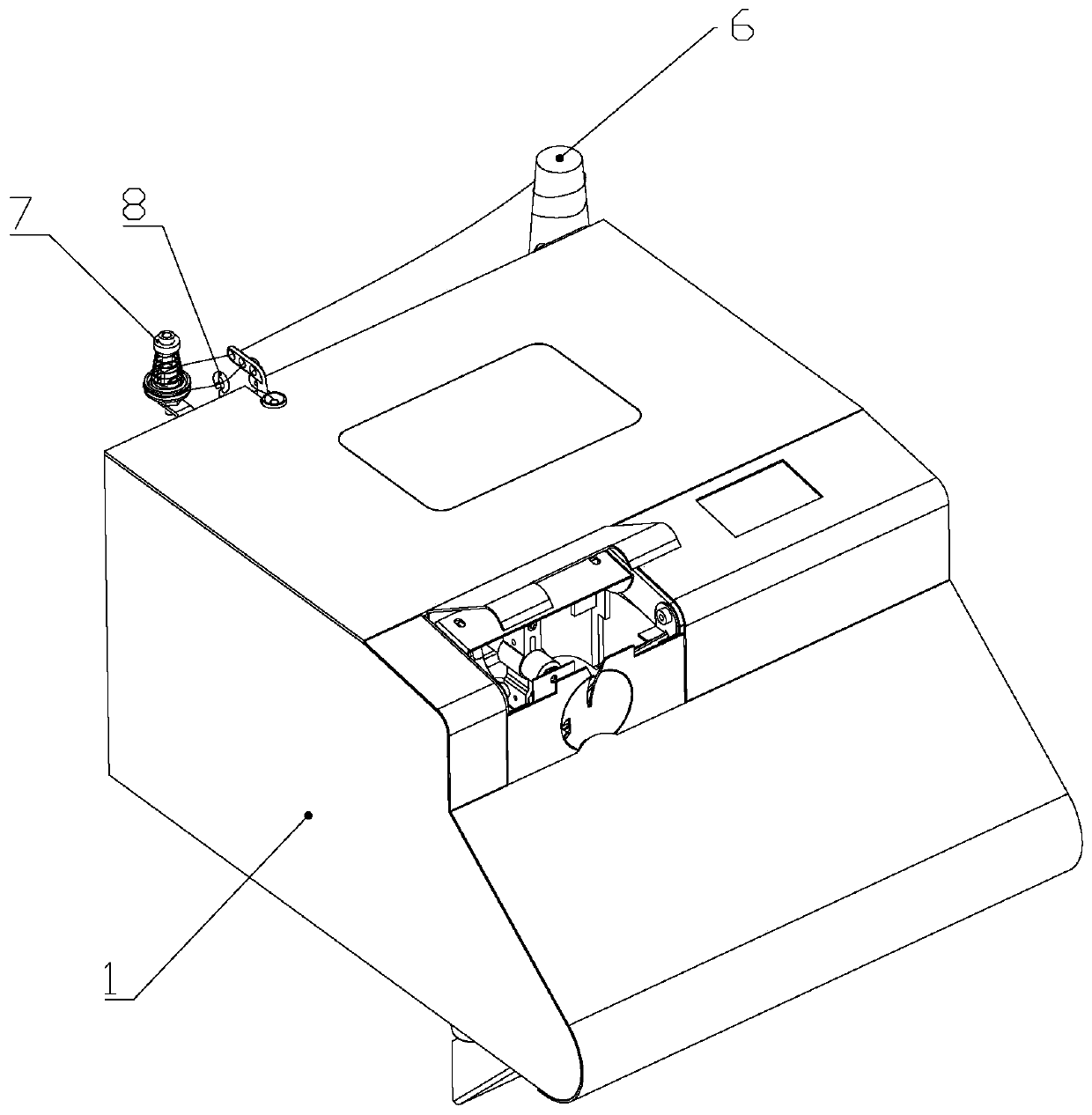

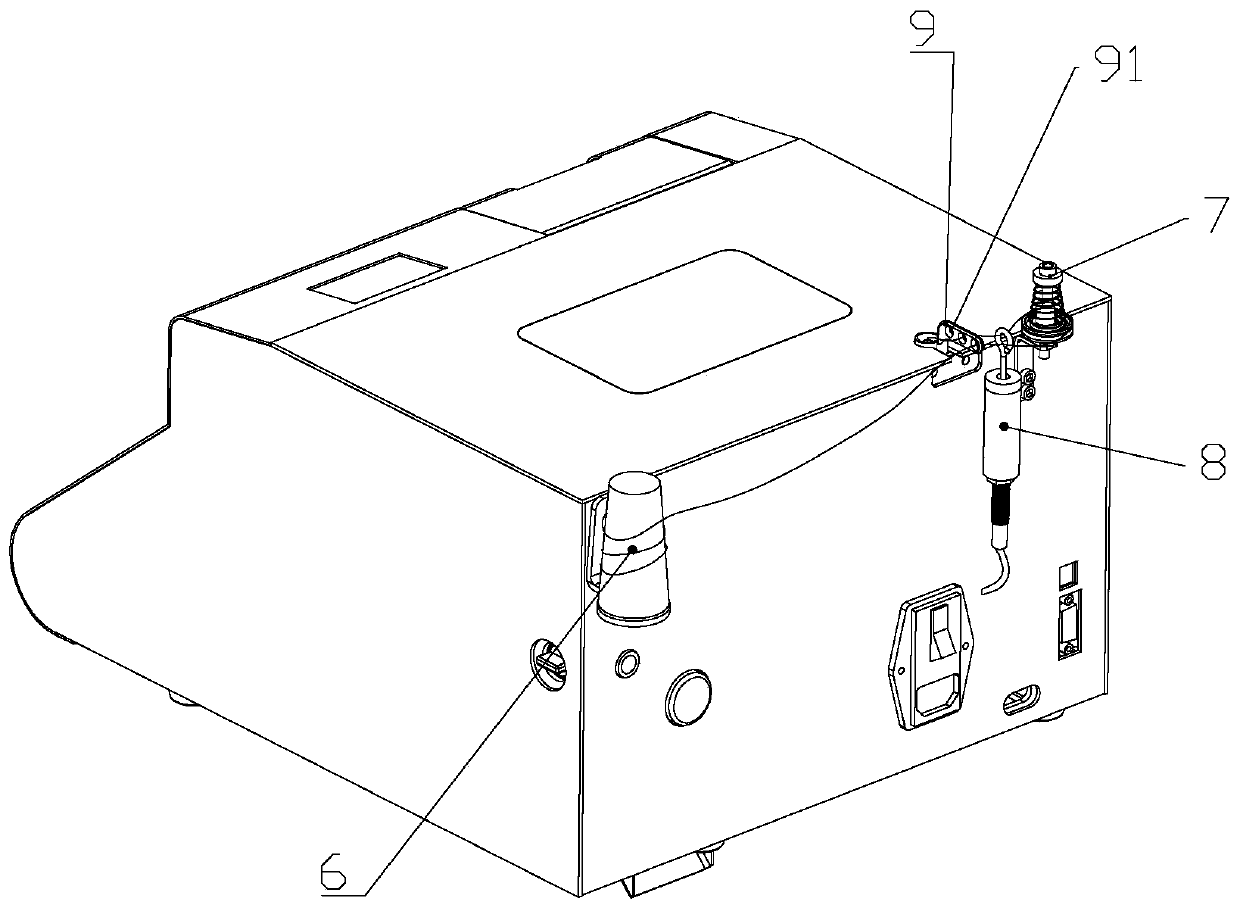

Intelligent full-automatic hot-melting button wrapping machine

PendingCN110820187AAvoid wastingAvoid pulling out and droppingSewing-machine control devicesSpool-pin assembliesWinding machineControl system

The invention discloses an intelligent full-automatic hot-melting button wrapping machine. The intelligent full-automatic hot-melting button wrapping machine comprises a frame and is characterized inthat a winding mechanism, a thread pulling and breaking mechanism, a thread melting and fixing mechanism and a drive device are arranged in the frame, a control system in control connection with the drive device is arranged on the frame, a spool seat for mounting a spool is arranged on the frame, a button wrapping thread tightness adjuster is arranged between the spool seat and the winding mechanism, a thread breaking detecting alarm device is arranged between the button wrapping thread tightness adjuster and the winding mechanism, and the output end of the thread breaking detecting alarm device is connected with the control system. The intelligent full-automatic hot-melting button wrapping machine the thread breaking detecting alarm device is arranged on the frame, the thread breaking detecting alarm device transmits thread breaking information to the control system when the button wrapping thread entering the winding mechanism breaks to guarantee that the machine stops working duringthread breaking, the thread breaking detecting alarm device can also emits notification to notify staff immediately after the thread breaking occurs, and manpower and material resource waste can be avoided.

Owner:谭英

Dynamic quantity sensor and dynamic quantity sensor system

ActiveUS9134189B2Improve accuracyLinearity of output is poorAcceleration measurement using interia forcesForce measurement by elastic gauge deformationRotational axisEngineering

A dynamic quantity sensor includes a force receiving portion, a first movable portion that rotates in a first rotational direction around a first rotational axis according to dynamic quantity in a first direction that the force receiving portion receives, and rotates in the first rotational direction around the first rotational axis according to dynamic quantity in a second direction different from the first direction that the force receiving portion receives; and a second movable portion that rotates in a second rotational direction around a second rotational axis according to the dynamic quantity in the first direction that the force receiving portion receives, and rotates in an opposite direction to the second rotational direction around the second rotational axis according to the dynamic quantity in the second direction that the force receiving portion receives.

Owner:TOYOTA CENT RES & DEV LAB INC +2

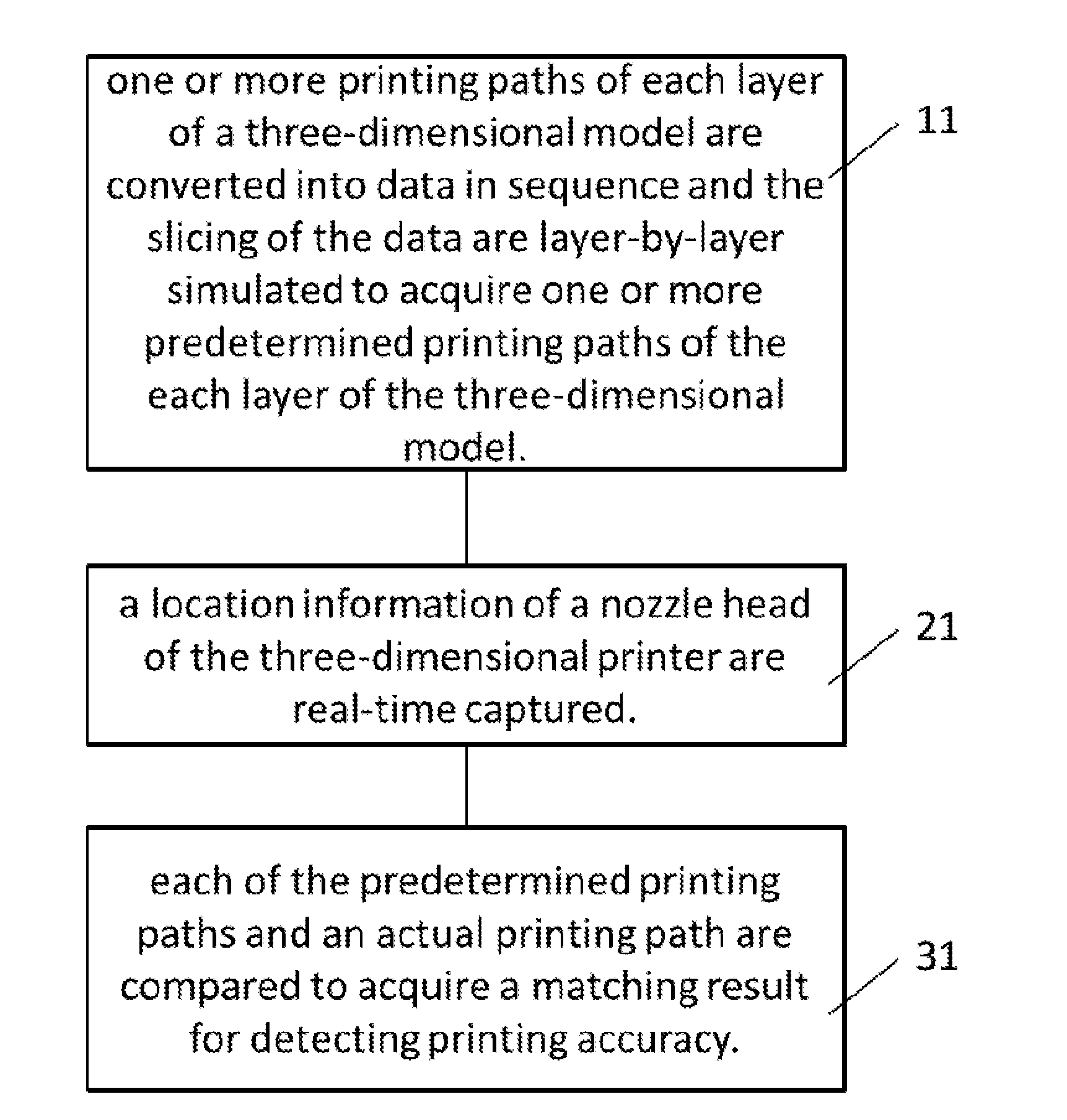

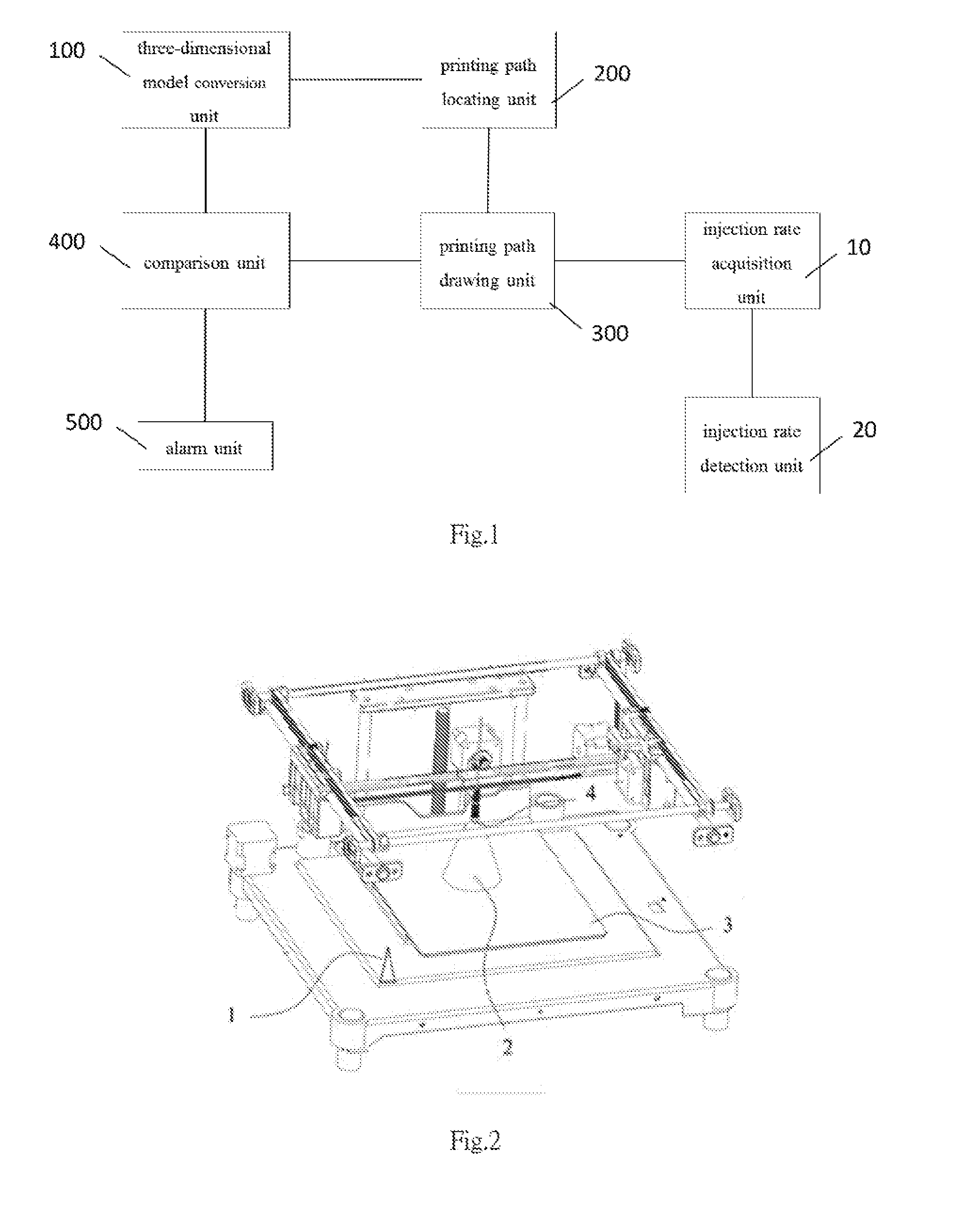

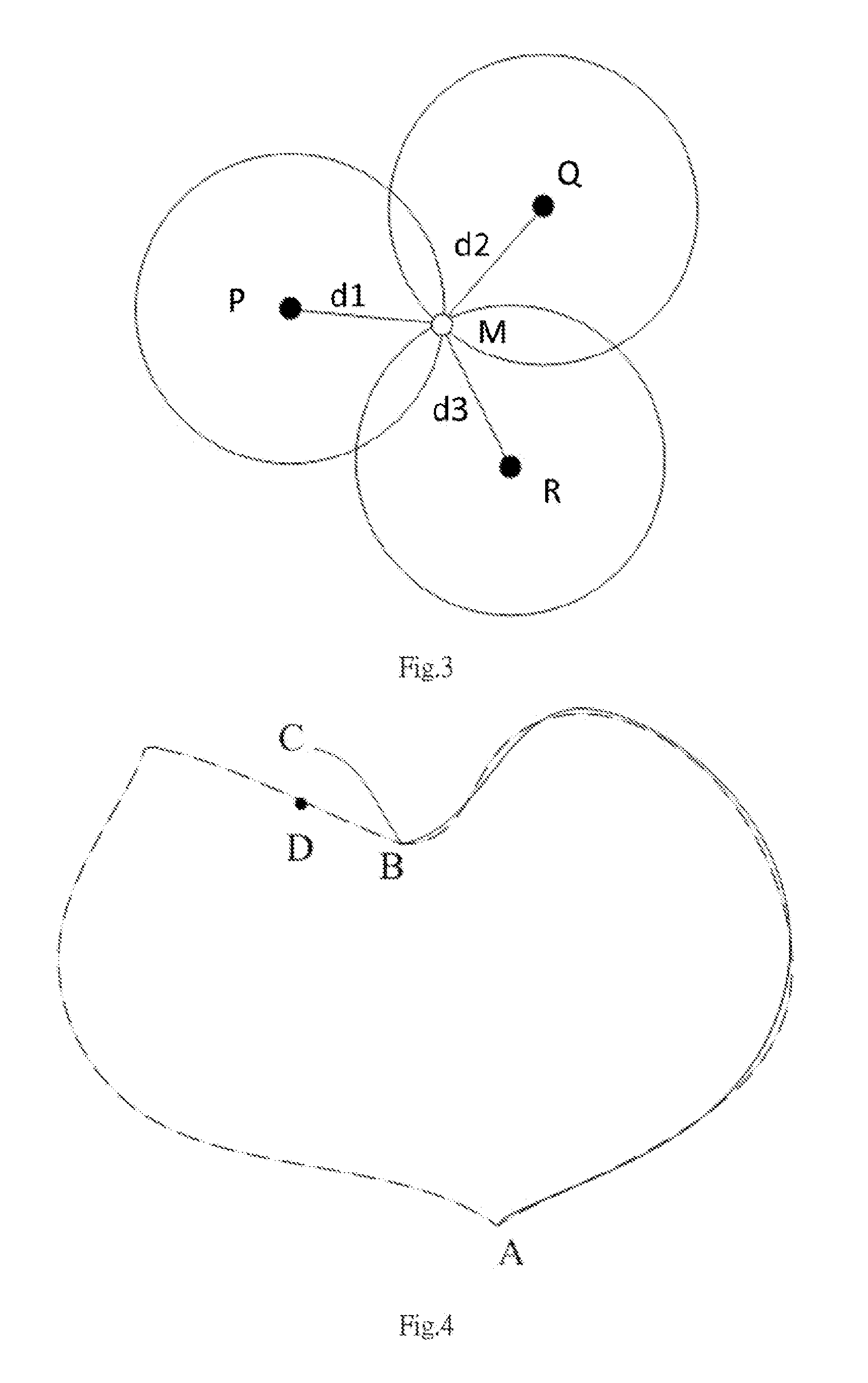

Three-Dimensional Printer and Printing Accuracy Detection Method

ActiveUS20170001378A1Implement detectionDetection accuracy meetsProgramme controlAdditive manufacturing apparatusSpray nozzleThree dimensional model

A three-dimensional printer with detecting printing accuracy and a method for detecting printing accuracy is provided. The three-dimensional printer with printing accuracy detection includes a three-dimensional model conversion unit, a printing path locating unit, a printing path drawing unit, and a comparison unit. An actual printing path is drawn according to the real-time captured location information of a nozzle head of the three-dimensional printer and compared with a predetermined printing path, which may implement the detection of printing accuracy. The method for detecting printing accuracy may implement the accuracy detection of the three-dimensional printer and be capable of detecting the accuracy for the three-dimensional printer. The method for detecting printing accuracy also reminds an operator to check and maintain printing accuracy of the three-dimensional printer.

Owner:INVENTECSHANGHAI TECH +2

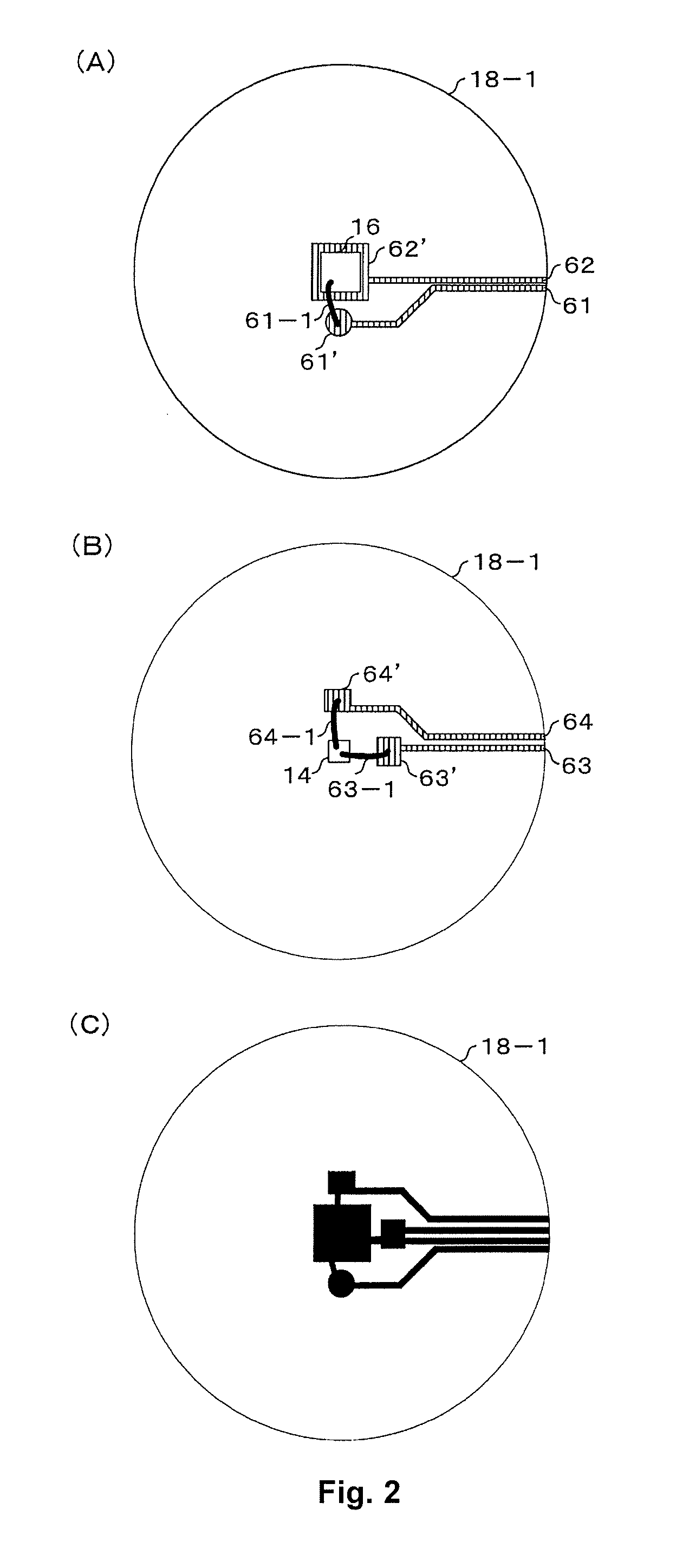

Giological information detector and biological information measuring device

InactiveUS20110178414A1Improve accuracyDetection accuracy meetsBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansPhysicsTest object

A biological information detector includes a light-emitting part, a light-receiving part, a reflecting part, and a substrate. The light-receiving part is for receiving light having biological information, where the light is emitted by the light-emitting part and reflected at a detection site of a test subject. The reflecting part is for reflecting the light emitted by the light-emitting part or the light having biological information. The substrate has a first surface and a second surface facing the first surface, formed from a material that is transparent with respect to a wavelength of the light emitted by the light-emitting part, at least one of the first surface and the second surface of the substrate has a light-blocking region containing wiring leading to at least the other of the light-emitting part and the light-receiving part.

Owner:SEIKO EPSON CORP

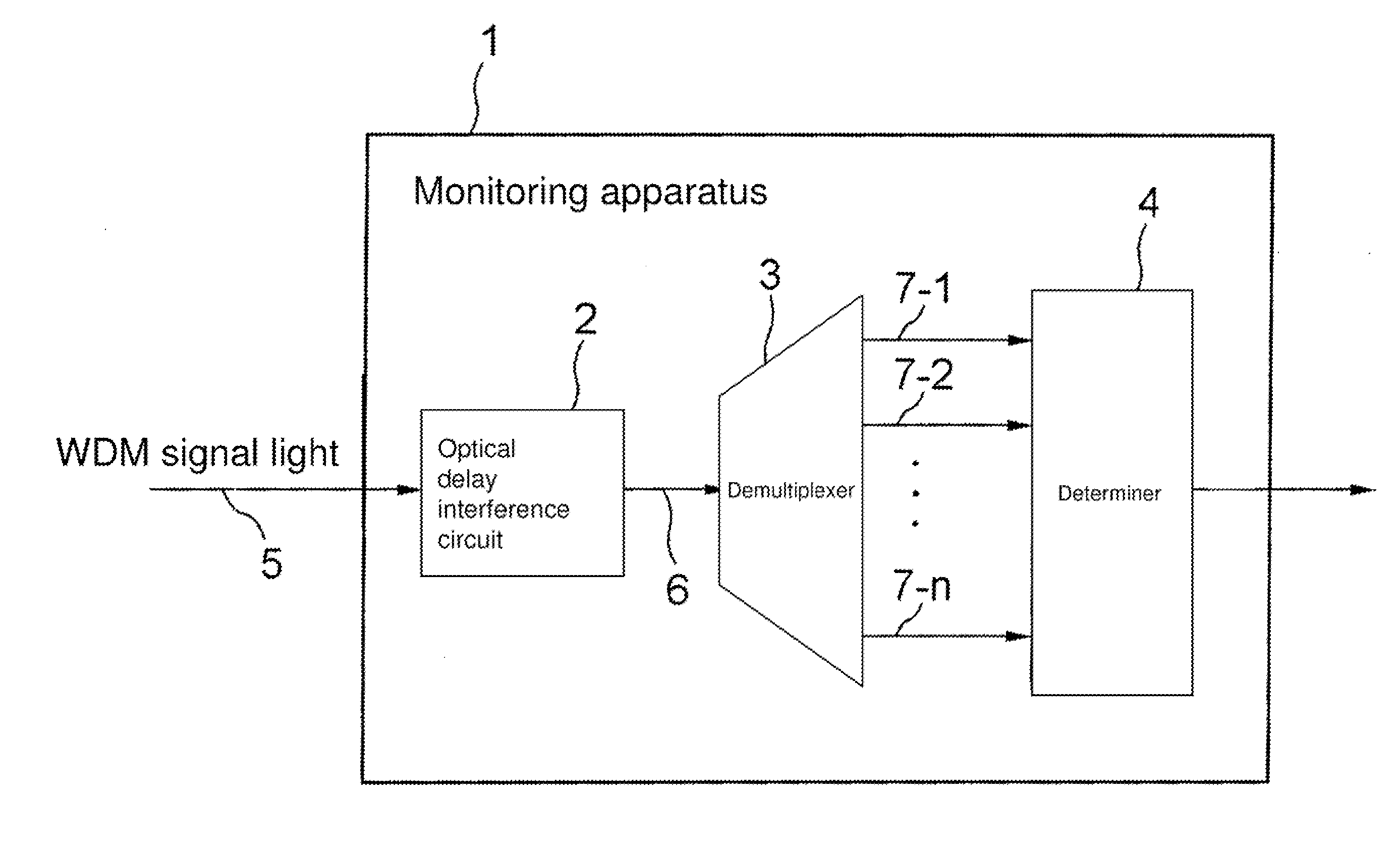

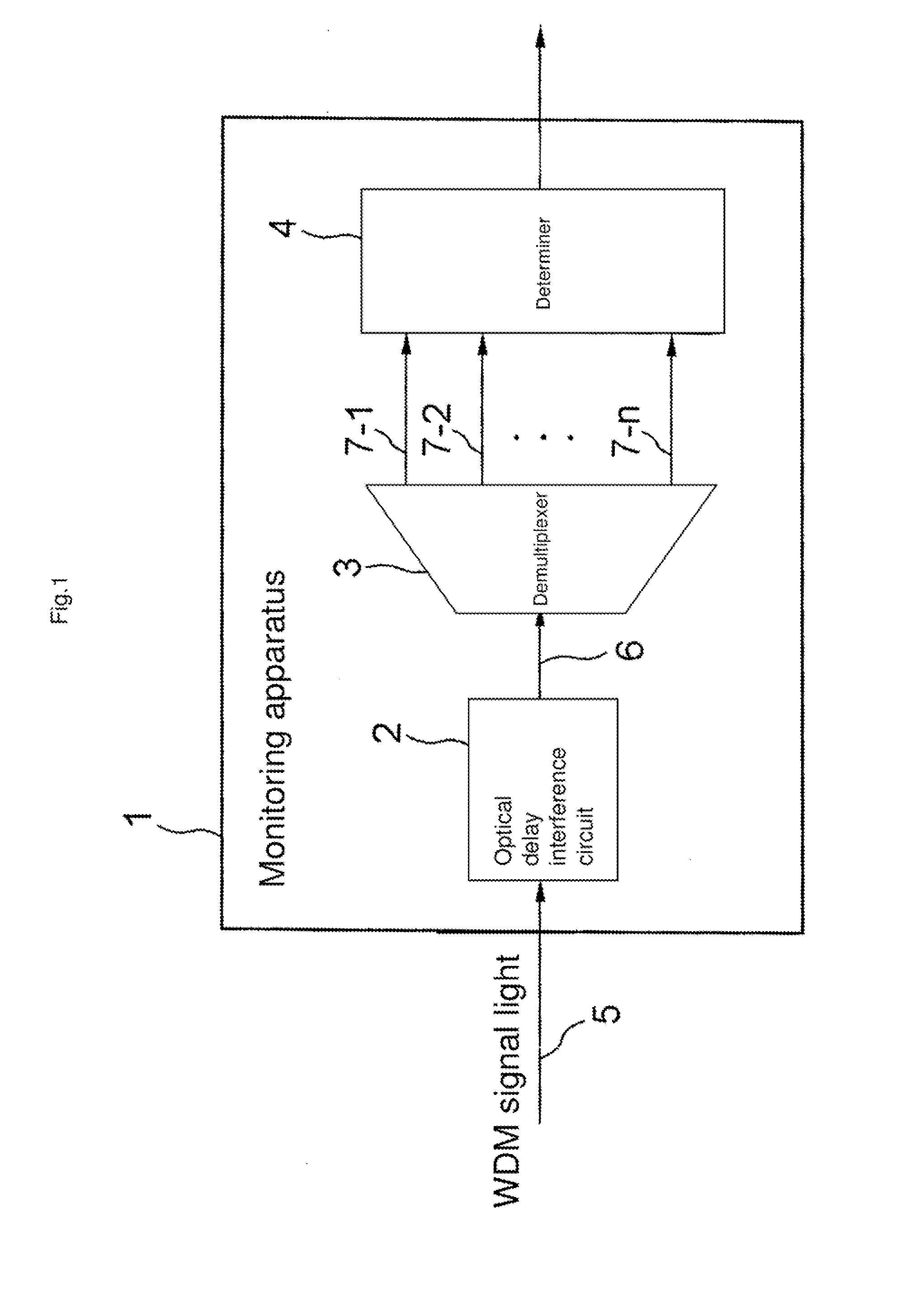

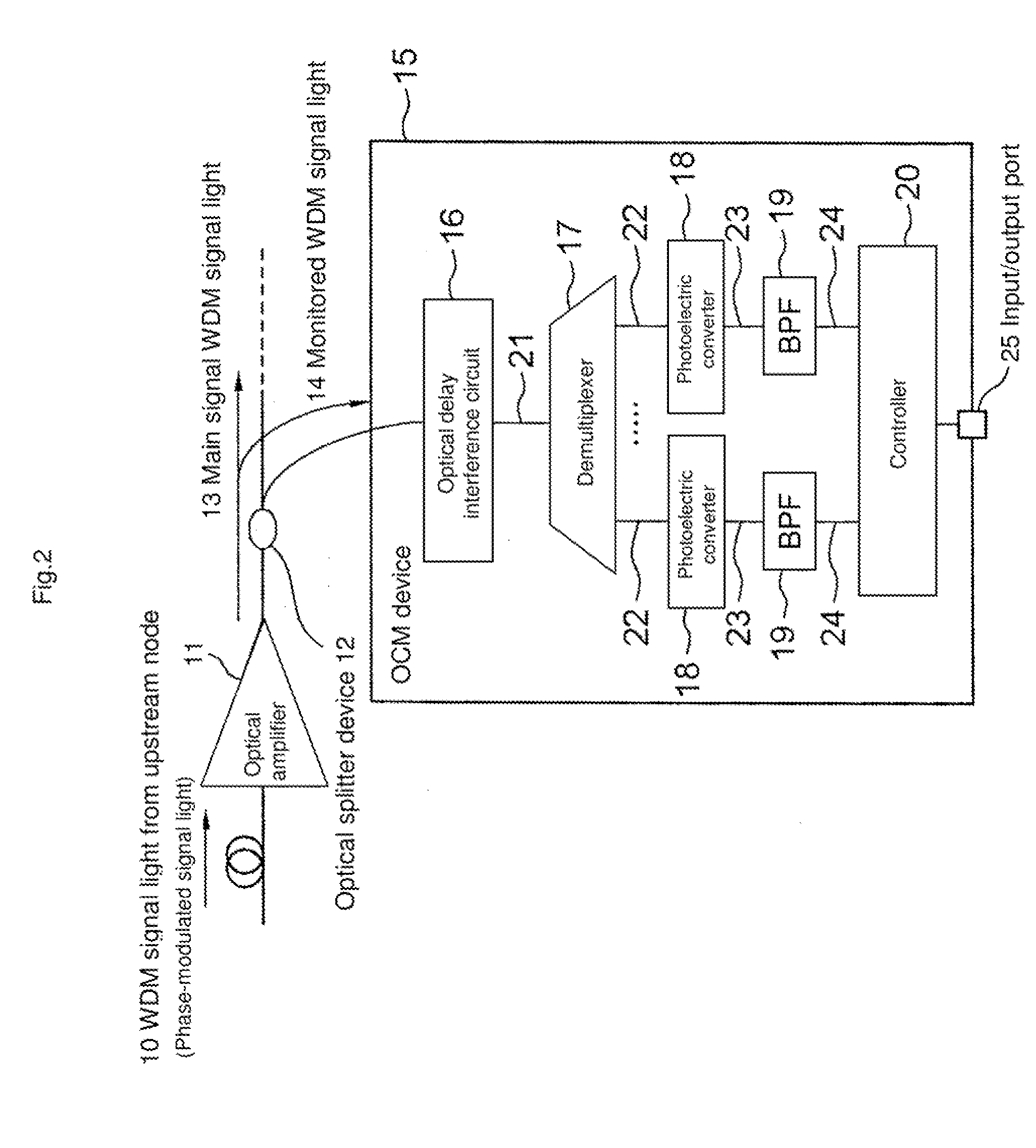

WDM signal light monitoring apparatus, WDM system and WDM signal light monitoring method

InactiveUS20120002962A1Detection accuracy meetsConvenient and accurateWavelength-division multiplex systemsTransmission monitoringSignal lightIntensity modulation

A WDM signal light monitoring apparatus includes an optical delay interference circuit, a demultiplexer and a determiner. The optical delay interference circuit demultiplexes a phase-modulated WDM signal light, gives a delay difference to the demultiplexed WDM signal lights, then multiplexes the demultiplexed WDM signal lights, and thereby generates an intensity-modulated WDM signal light. The demultiplexer demultiplexes the intensity-modulated WDM signal light into signal lights of respective channels, and outputs the demultiplexed signal lights. The determiner determines the presence or absence of the signal light of each of the channels, based on the signal lights outputted from the demultiplexer.

Owner:NEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com