Device and method for detecting defect of transparent material

A defect detection and light transmittance technology, applied in measurement devices, optical devices, optical testing of flaws/defects, etc., can solve problems such as decreased defect detection accuracy, weak light, residual noise components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

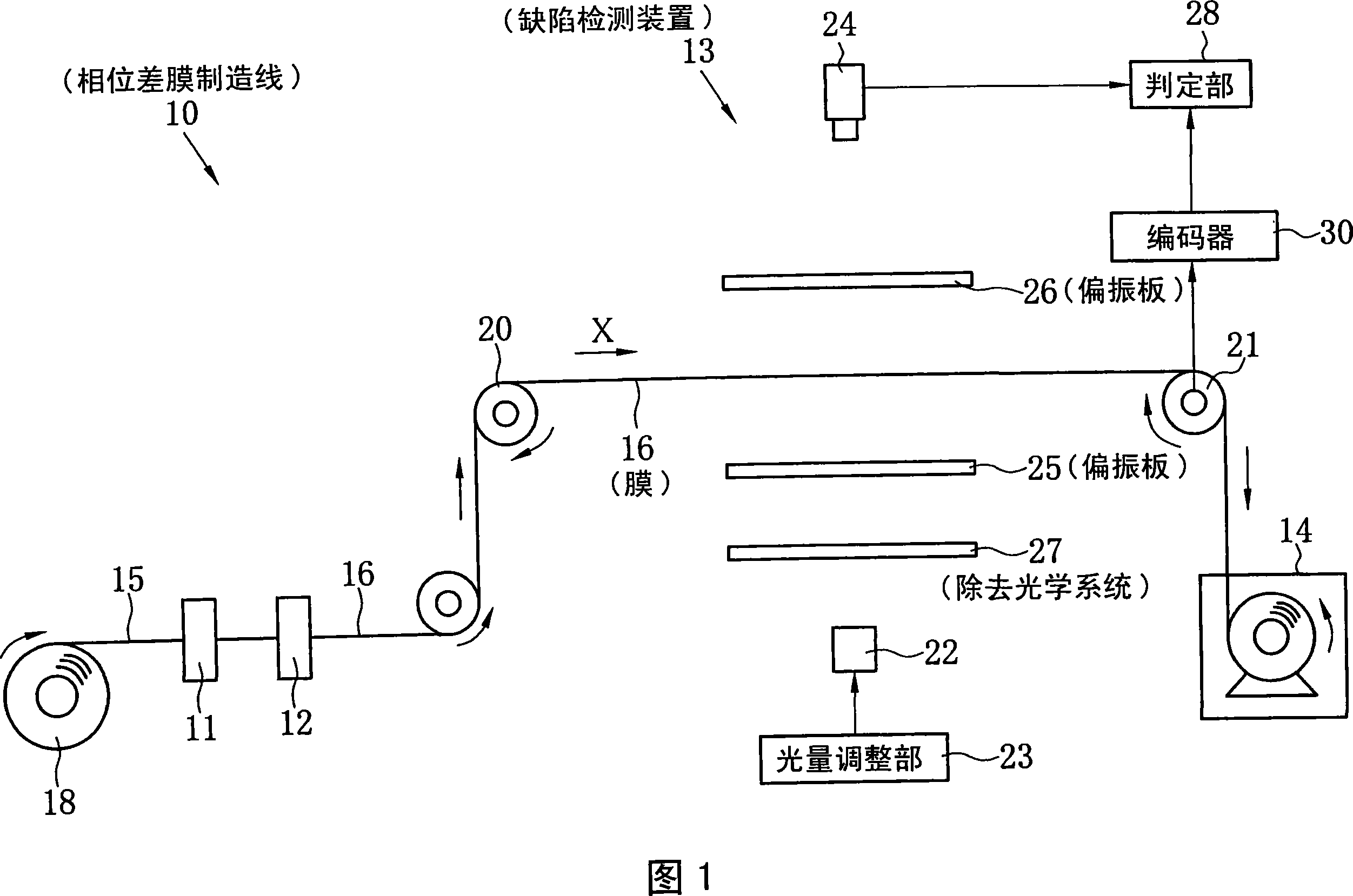

[0016] In FIG. 1 , a retardation film manufacturing line 10 includes an alignment film forming device 11 , a liquid crystal layer forming device 12 , a defect inspection device 13 , and a winding device 14 . The transparent resin film 15 and the retardation film 16 travel in the X direction in the figure by the winding by the winding device 14 .

[0017] The alignment film forming apparatus 11 applies a coating liquid containing a resin for forming an alignment film on the surface of the elongated transparent resin film 15 sent out from the film roll 18, and then heats and dries it. In this way, the resin layer for forming an alignment film is formed on the surface of the transparent resin film 15 . Then, the alignment film forming apparatus 11 performs a rubbing process on the resin layer for forming an alignment film of the transparent resin film 15 to form an alignment film.

[0018] The liquid crystal forming device 12 applies a coating liquid containing a liquid crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com