Automatic tool changer comprehensive performance detection test stand

A technology of automatic tool change and comprehensive performance, which is applied to measuring devices, testing of machine/structural components, instruments, etc. It can solve the problems of difficult positioning accuracy detection, and achieve the effect of strong applicability and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

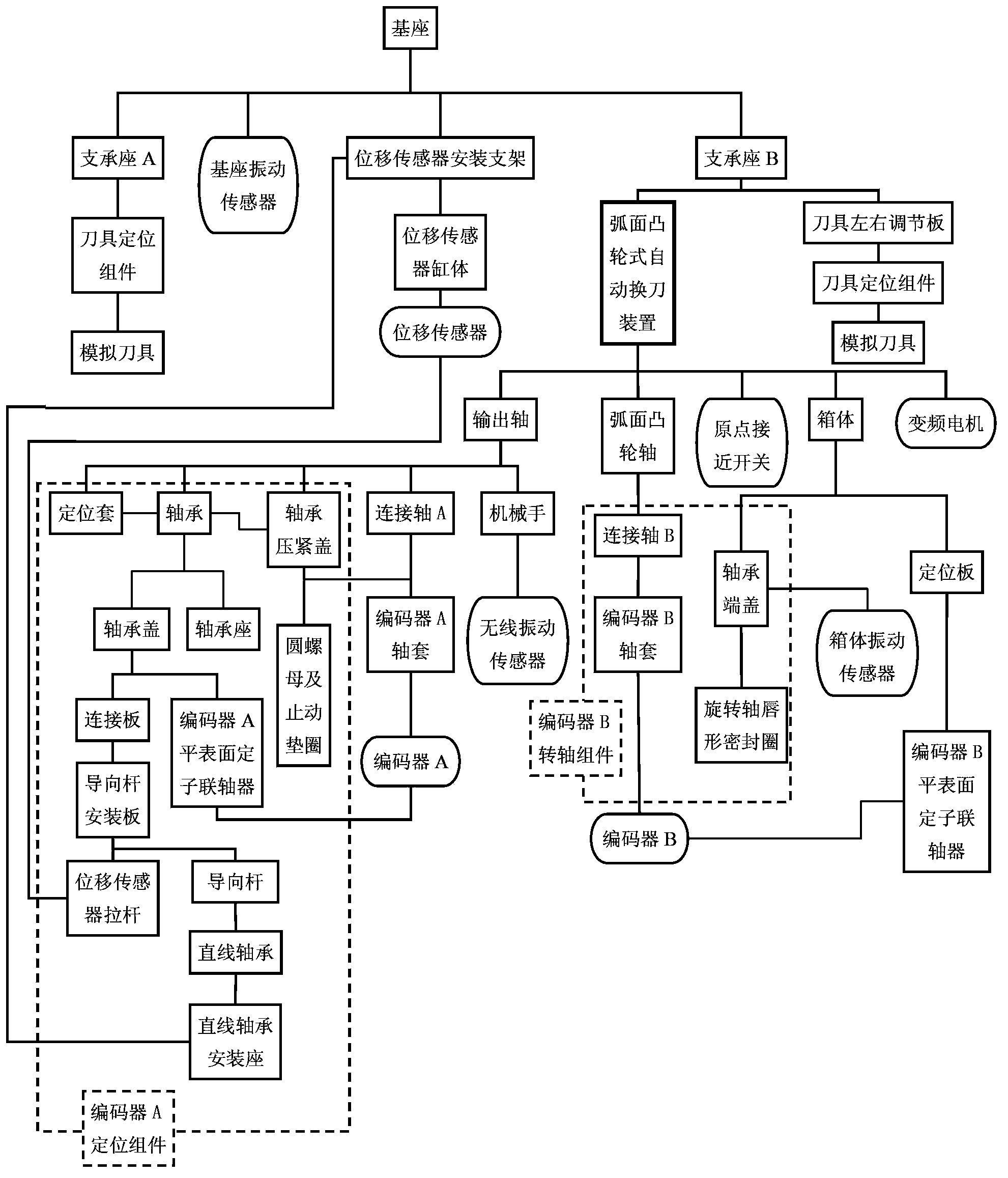

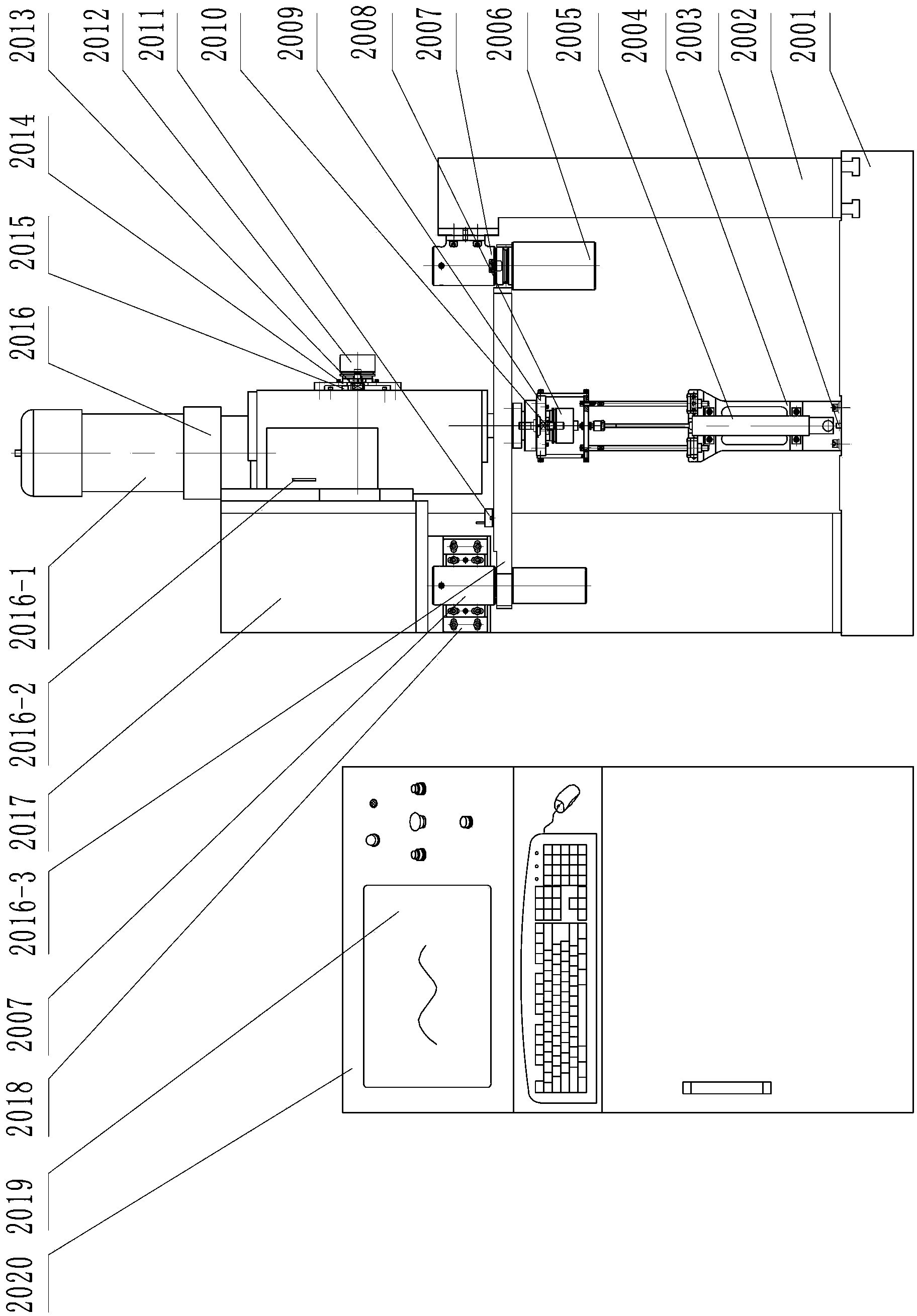

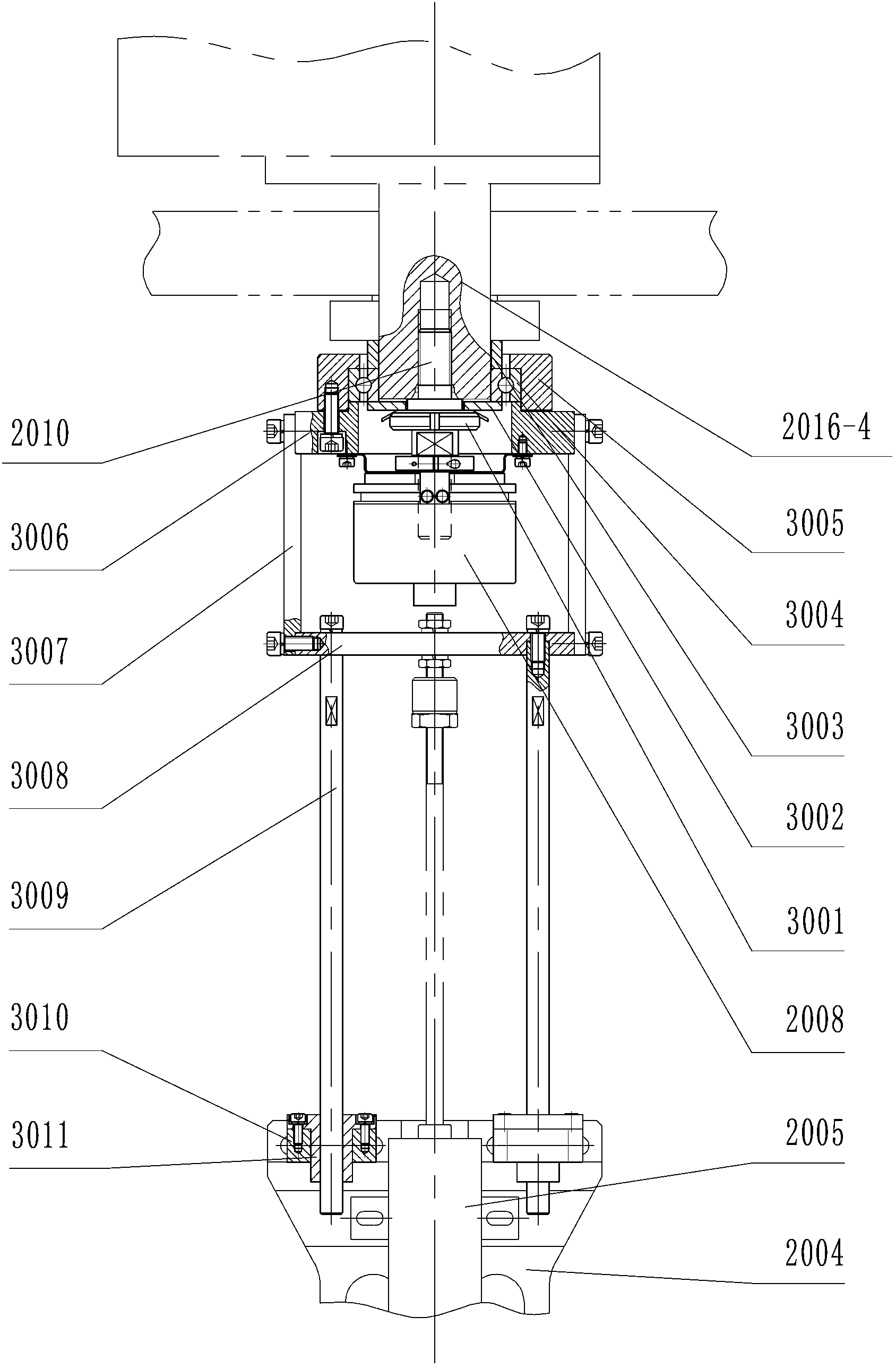

[0034] The present invention will be further described below in conjunction with accompanying drawing:

[0035] exist figure 2 Among them, support base A (2002) and support base B (2017) are installed on the base (2001), respectively located on both sides of the base, and the arc cam type automatic tool changer (2016) is installed on support base B (2017) the right side of the tool; the tool left and right adjustment plate (2018) is installed on the front side of the support seat B (2017); there are two sets of tool positioning components (2007), one set is installed on the tool left and right adjustment plate (2018), and the other The sleeve is installed on the left end surface of the support seat A (2002); the simulated tool (2006) is inserted into the tool sleeve (5002) of the tool positioning assembly (2007).

[0036] In order to meet the spatial position coordination requirements of the arc cam type automatic tool changer (2016) and the simulated tool (2006), to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com