Full-automatic top fly sewing machine

A sewing machine, fully automatic technology, applied in the field of garment machinery, can solve the problems of increasing costs, wasting human resources, manual feeding, etc., and achieve the effects of improving processing efficiency, saving human resources, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing.

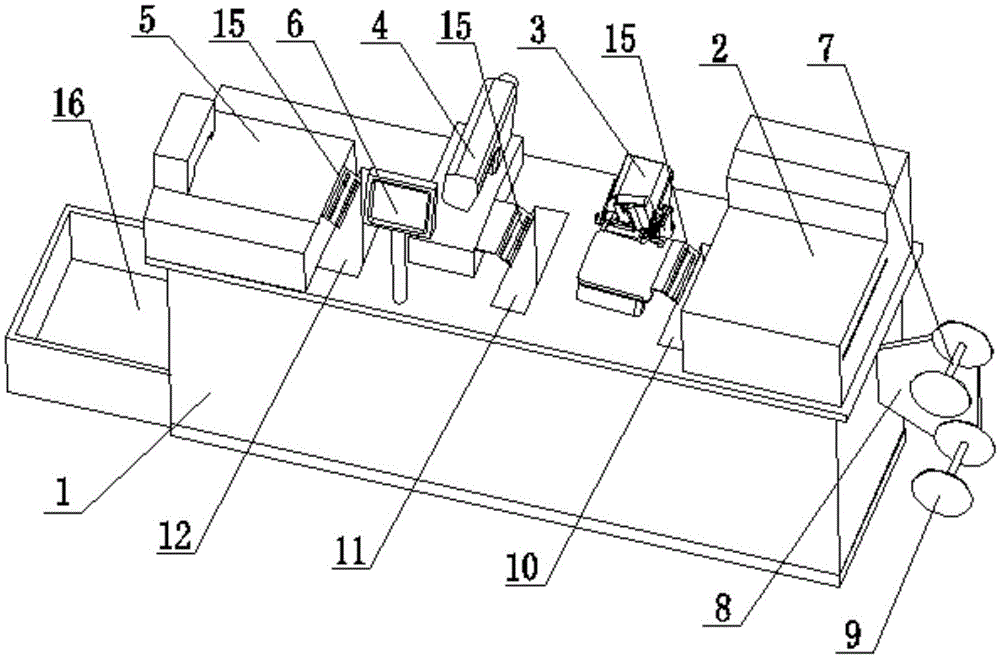

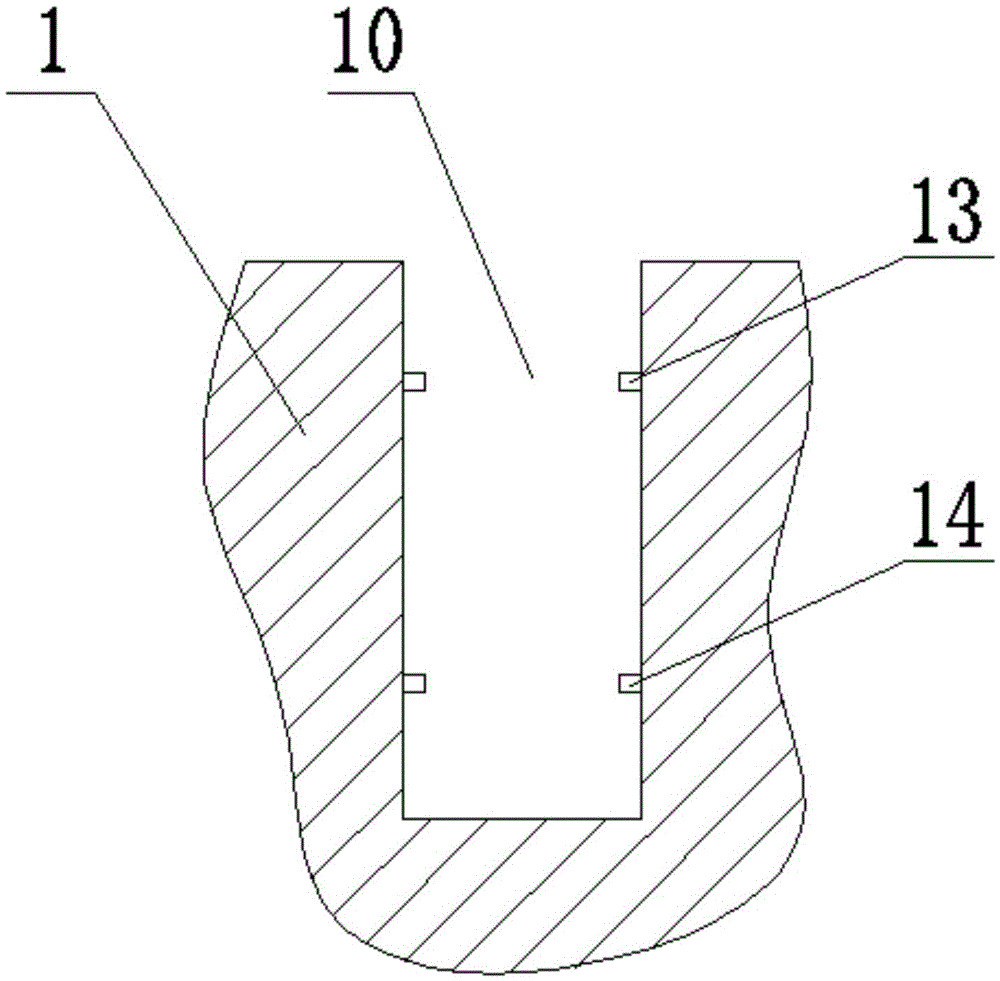

[0019] Fully automatic placket sewing machine of the present invention, as attached figure 1 , 2 Said, including frame 1, lining machine 2, overlay machine 3, interlock sewing machine 4, cutting machine 5, control device 6; machine 4 and cutting machine 5; the lining machine 2, edge machine 3, interlock sewing machine 4 and cutting machine 5 are sequentially fixed on the workbench on the upper surface of the frame 1; Cavities are respectively the first temporary storage space 10, the second temporary storage space 11 and the third temporary storage space 12; the first temporary storage space 10 is located in the middle of the lining machine 2 and the edge machine 3; The second temporary storage space 11 is located in the middle of the overlay machine 3 and the interlock sewing machine 4; the third temporary storage space 12 is located in the middle of the interlock sewing machine 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com