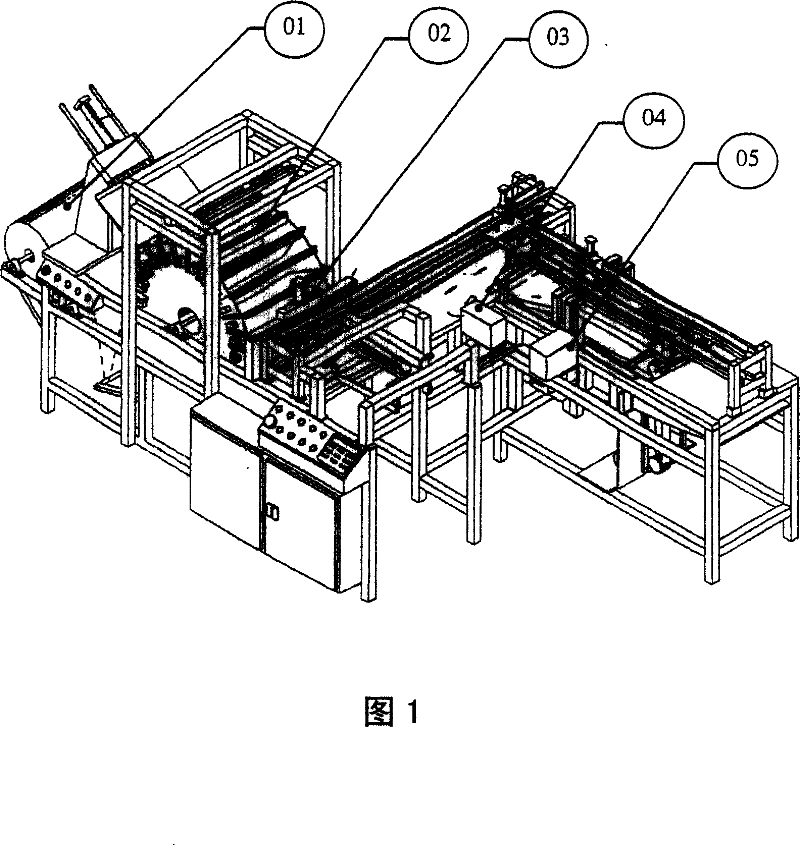

Machine for making textile bags

A technology for manufacturing machines and fabric bags, applied in the direction of textiles and papermaking, program-controlled sewing machines, sewing units, etc., can solve problems such as no machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

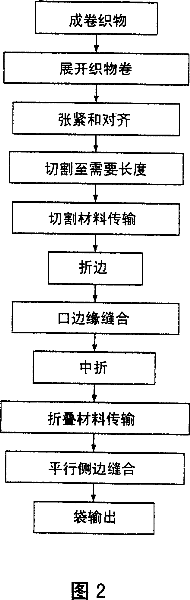

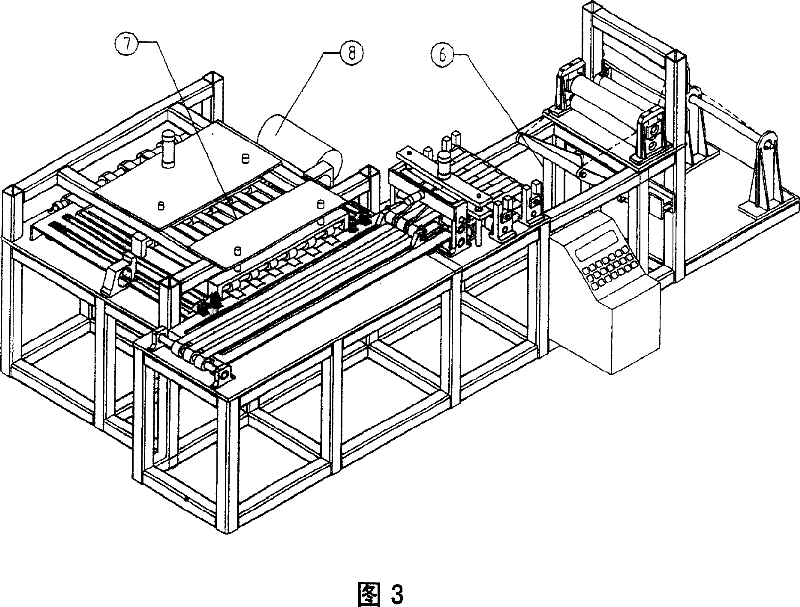

[0087] The embodiment of the bag making machine of the present invention as detailed above herein is used for bags made from jute fabric. Models of the Simultaneous Multi-Edge Folding and Sewing Unit (SMESU) feature a spiral-tapered double-edge folder, a double-strand seamer, one of which is oriented upside down for simultaneous seaming on two edges, and grouped Gripper and conveyor for pulling the fabric during the hemming operation. The different parameters and specifications of the bags produced by the machine of the invention are as follows:

[0088] Type of material entered; jute fabric

[0089] Width of jute fabric: 570mm

[0090] Type of Edge Fold: Double Fold

[0091] Pitch of chain stitch at mouth hem: 10mm

[0092] Pitch of overlock stitches at parallel sides: 12mm

[0093] Length of bag manufactured: 940mm

[0094] Width of bag produced: 570mm

[0095] Bags per hour: 150

[0096] The bags are made in a continuous process, so the throughput for making paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com