Quilting mechanism provided with double machine heads

A double-head, quilting technology, which is applied in the field of quilting machines, can solve the problems that the production efficiency cannot be greatly improved and the machine utilization rate is insufficient, and achieve the effect of improving production efficiency and simple and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

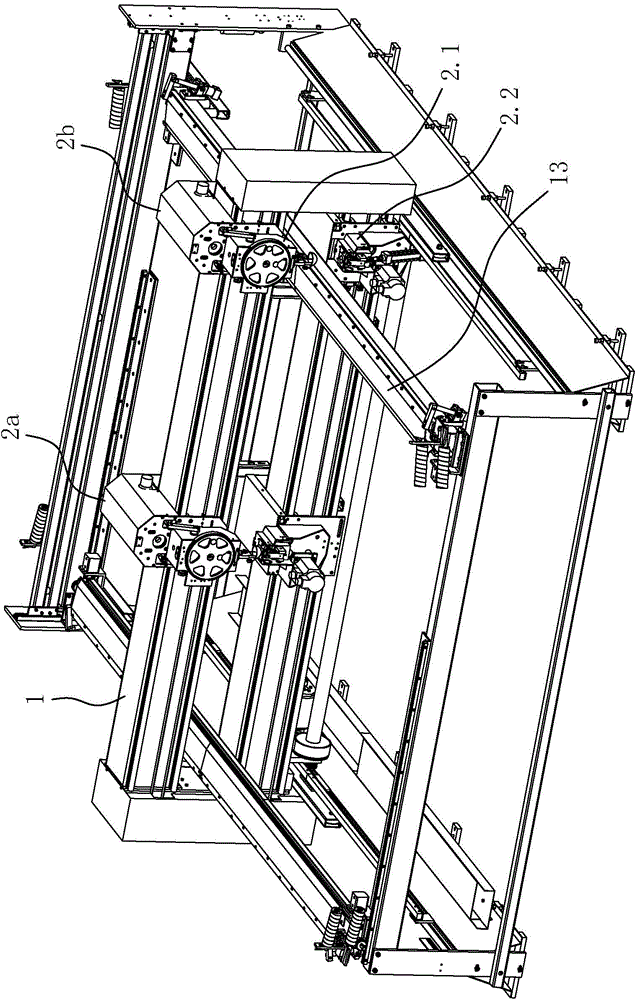

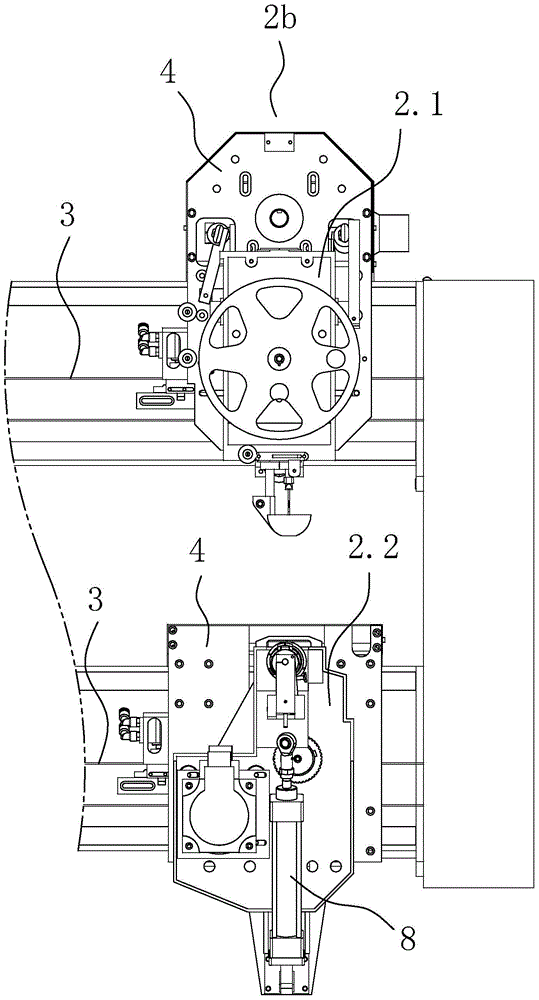

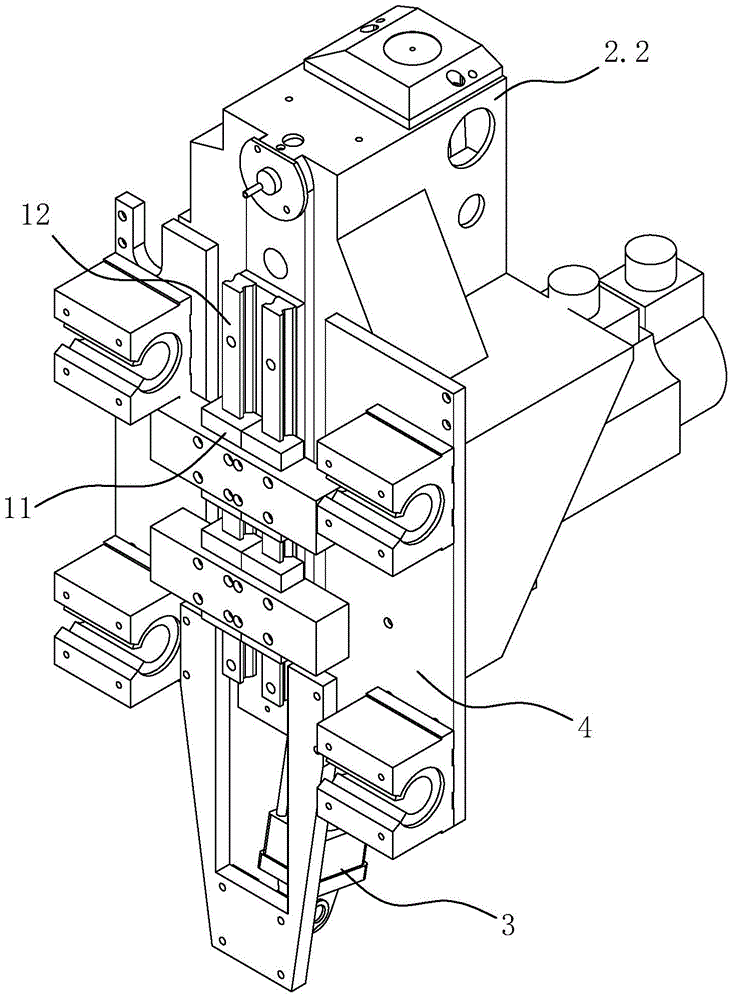

[0010] Such as Figure 1-4 As shown, a double-head quilting mechanism includes two sets of sewing heads 2a, 2b slidably mounted on the moving gantry 1, and two sets of sewing heads respectively installed on the moving gantry 1 to drive each group of sewing heads. The upper and lower sewing heads 2.1, 2.2 move the synchronous belt 3, wherein the upper and lower sewing heads 2.1, 2.2 of one group of sewing heads 2b are fixed with the upper side platen 5 of the synchronous belt on the installation side plate 4, and are provided with a synchronous belt. The lower side pressing plate 6, the lower side pressing plate 6 is driven up and down by the first cylinder 7, the first cylinder 7 is fixed on the installation side plate 4, the lower side pressing plate 6 is formed with synchronous teeth 6.1 meshing with the synchronous belt, and the set The lower sewing head 2.2 of the sewing head 2b is set to slide up and down with the installation side plate 4, and the second air cylinder 8 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com