Near-infrared laser spot field-of-view parameter measurement device and method

A laser parameter and laser spot technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large measurement errors, no automatic test of infrared laser spots, and difficulty in defining the edge of laser spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

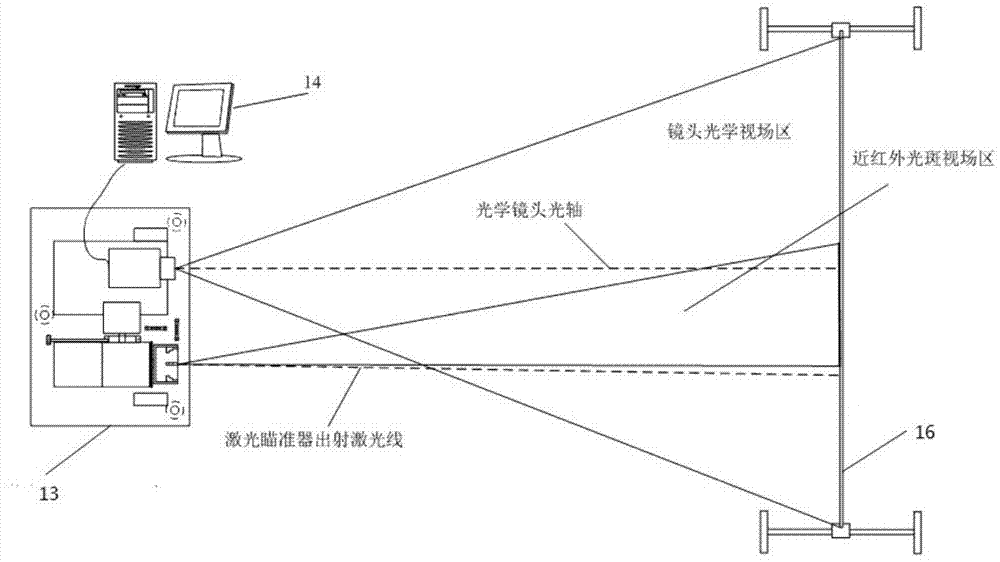

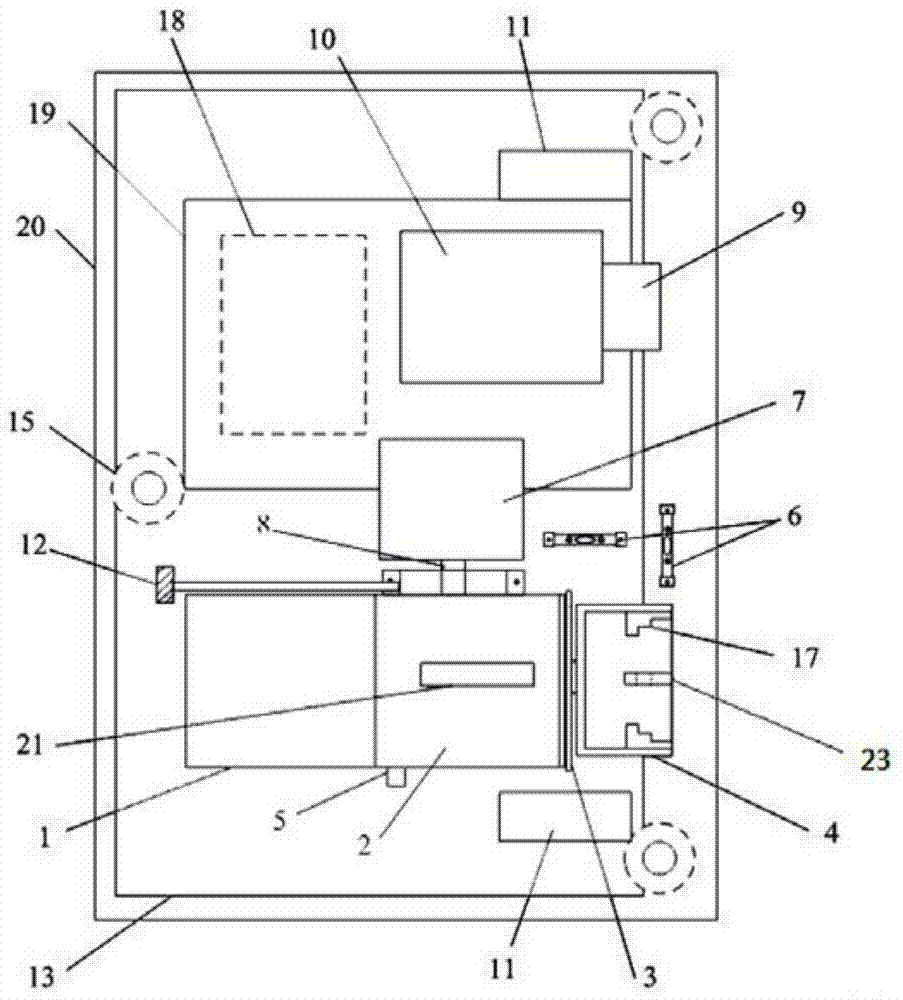

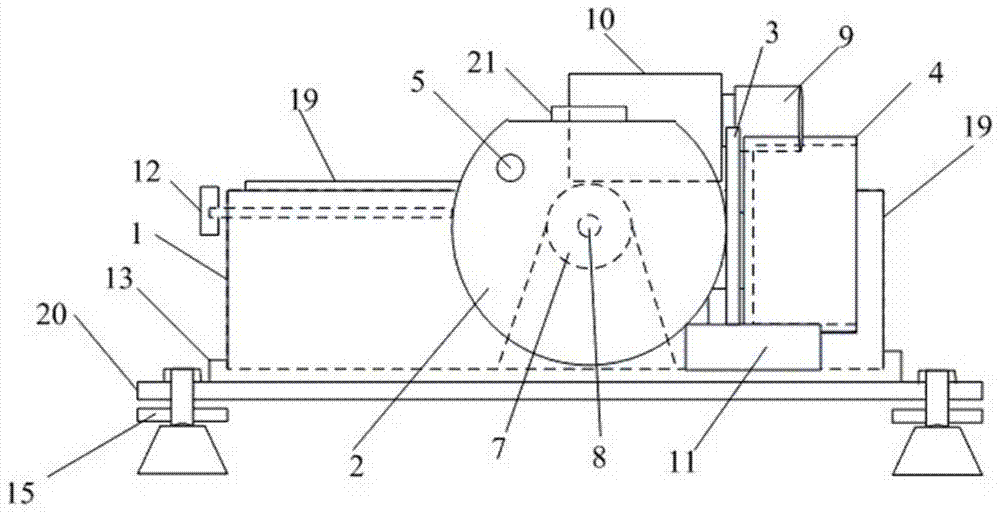

[0040] Such as Figure 1-4 As shown, a near-infrared laser spot field parameter measurement device is shown, which includes a near-infrared laser parameter test bench 13, a computer 14 and a calibration grid plate 16, wherein processing and calculation software are installed on the computer 14, and the near-infrared laser The parameter test bench 13 includes an emitting device capable of emitting near-infrared laser light. The measuring device also includes a chassis base 20 on which the near-infrared laser parameter test bench 13 can be fixed, and the chassis base 20 is placed horizontally by at least three horizontal adjustment bases 15 installed at its edge On the ground or on the platform, each level adjustment base 15 can be used to adjust the height of the chassis base 20 to ensure that the whole near-infrared laser parameter test bench 13 is in a horizontal state, and the chassis base 20 is also provided with two levels Observing the water bubbles is used to observe th...

Embodiment 2

[0063] According to the operation steps of Example 1, if the adjustment of the pitch direction rotation adjustment mechanism 2 and the concentric shaft rotation adjustment mechanism 4 in the specific step 5 are measured, the spot of the calibration laser 23 is located on the calibration grid plate 16, and the rotation adjustment of the pitch direction is recorded. The visible laser sight 21 above the mechanism 2 is marking the new coordinate point of the grid plate See Figure 5 , then ∠OFO 2 That is, the angle β between the centerline of the near-infrared laser exit spot and the main axis of the laser product. According to the coordinates O(x,y), o 0 (x 0 ,y 0 ) to obtain OO 2 and OO 0 Distance, by ΔOFO 2 , ΔO 2 o 0 F and ΔOO 0 F, combined with the pitch angle θ read by the 13-bit angle encoder 7, β can be calculated.

[0064] β = arccos OF 2 + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com