A Method of Origin Positioning for Controlling Wafer Lifting Movement

A technology of origin positioning and lifting motion, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of poor module anti-electromagnetic interference, large positioning error between the boat stopping point and the starting origin, and potential safety hazards. To achieve the effect of powerful use and strong anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

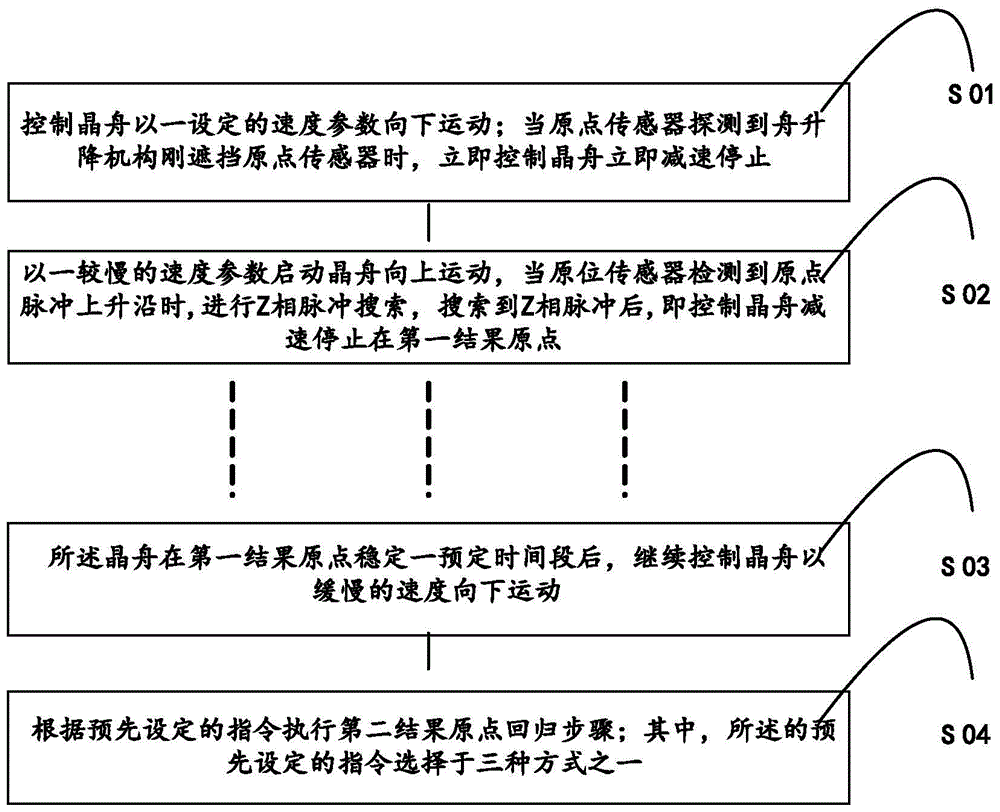

[0039] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

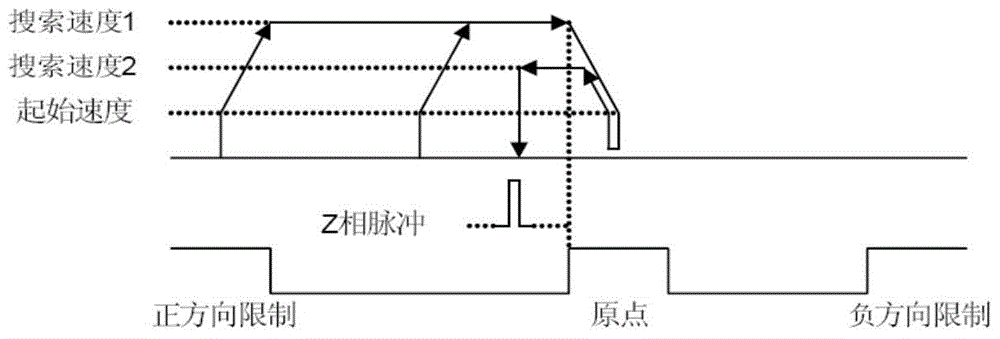

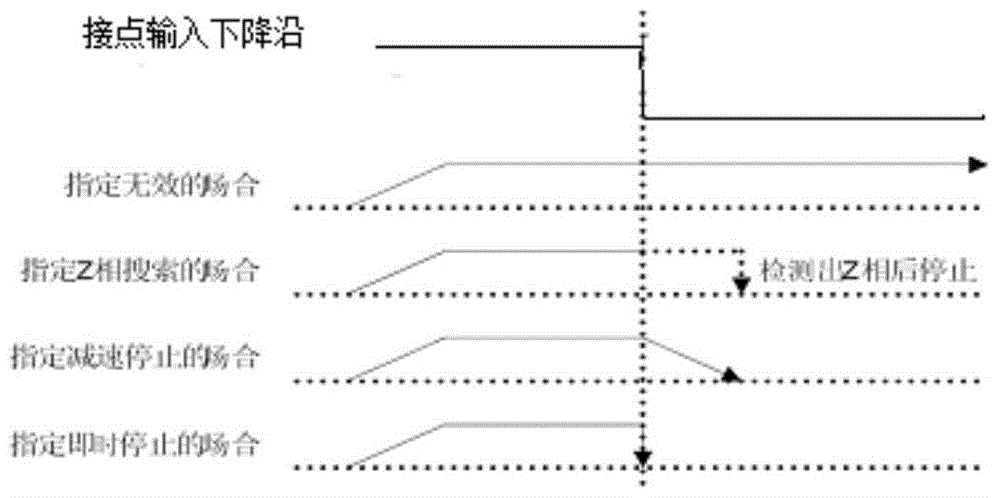

[0040] It should be noted that the system use environment of the origin positioning method for controlling the lifting movement of the wafer boat of the present invention includes usually setting three position sensors on the lifting shaft of the wafer boat, which are respectively the positive limit sensor set on the upper end of the lifting shaft of the wafer boat, A negative limit sensor arranged at the lower end of the wafer boat lifting shaft, and a home position sensor arranged between the positive and negative limit sensors. Different from other origin search methods, the origin search method of the present invention utilizes a pulse generated by a Z-phase pulse generator, thereby enabling more precise positioning.

[0041] In the embodiment of the present invention, the home position sensor is a digital sensor. Preferably, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com