Alignment method

A technology for aligning marks and predetermined lines, which is applied in the direction of instruments, laser welding equipment, electrical components, etc., can solve the problems of time-consuming and other problems, and achieve the effect of reliable search and shortened alignment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

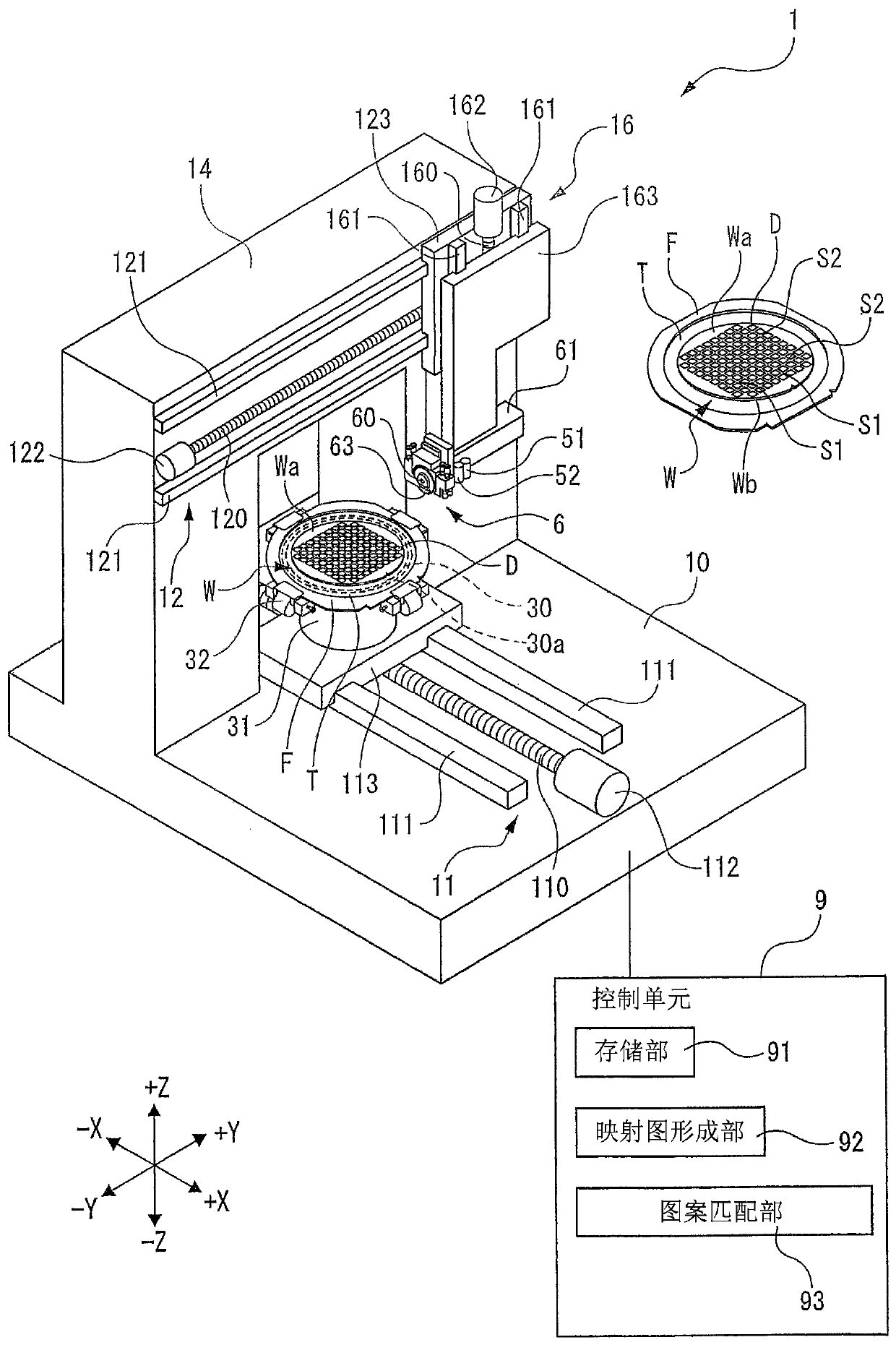

[0027] figure 1 The illustrated cutting device 1 is a device that rotates a cutting tool 63 included in the cutting unit 6 and cuts the wafer W into a plate-shaped workpiece held by the chuck table 30 to perform cutting processing.

[0028] The base 10 of the cutting device 1 is provided with a cutting feed unit 11 that reciprocates the chuck table 30 in the cutting feed direction (X-axis direction). The cutting and feeding unit 11 includes: a ball screw 110 having an axis in the X-axis direction; a pair of guide rails 111 arranged in parallel with the ball screw 110; a motor 112 that rotates the ball screw 110; and The movable plate 113 has an inner nut screwed with the ball screw 110, and the bottom of the movable plate 113 is in sliding contact with the guide rail 111. When the motor 112 rotates the ball screw 110, the movable plate 113 is guided by the guide rail 111 to move in the X-axis direction, and the chuck table 30 arranged on the movable plate 113 moves in the X-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com