Towel machine

A towel machine and conveying mechanism technology, which is applied to sewing unit, cloth pressing mechanism, cloth feeding mechanism, etc., can solve the problems of high production cost, easy fatigue in operation time, and not suitable for mass production, so as to reduce production cost and improve The effect of production efficiency and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described below with reference to the drawings.

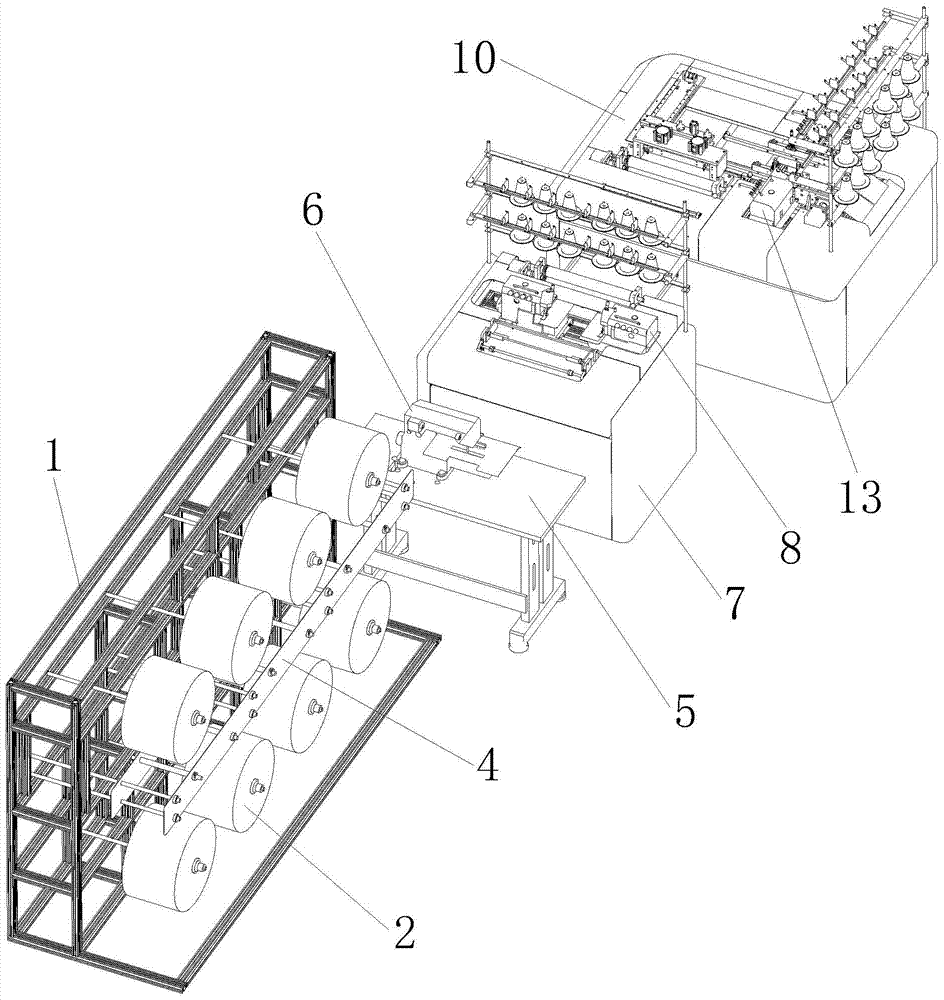

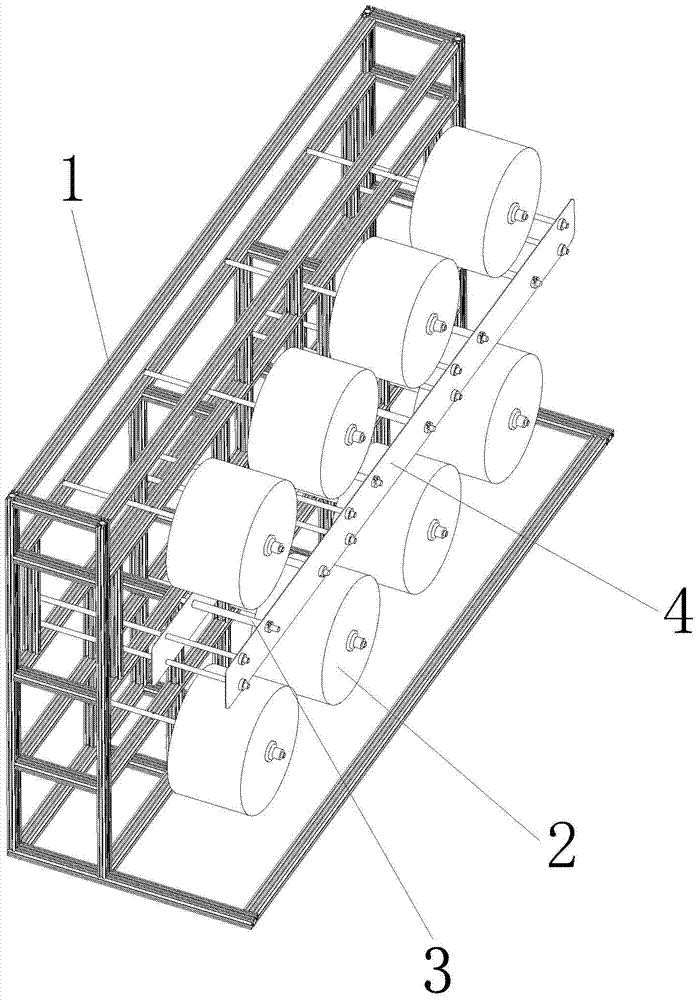

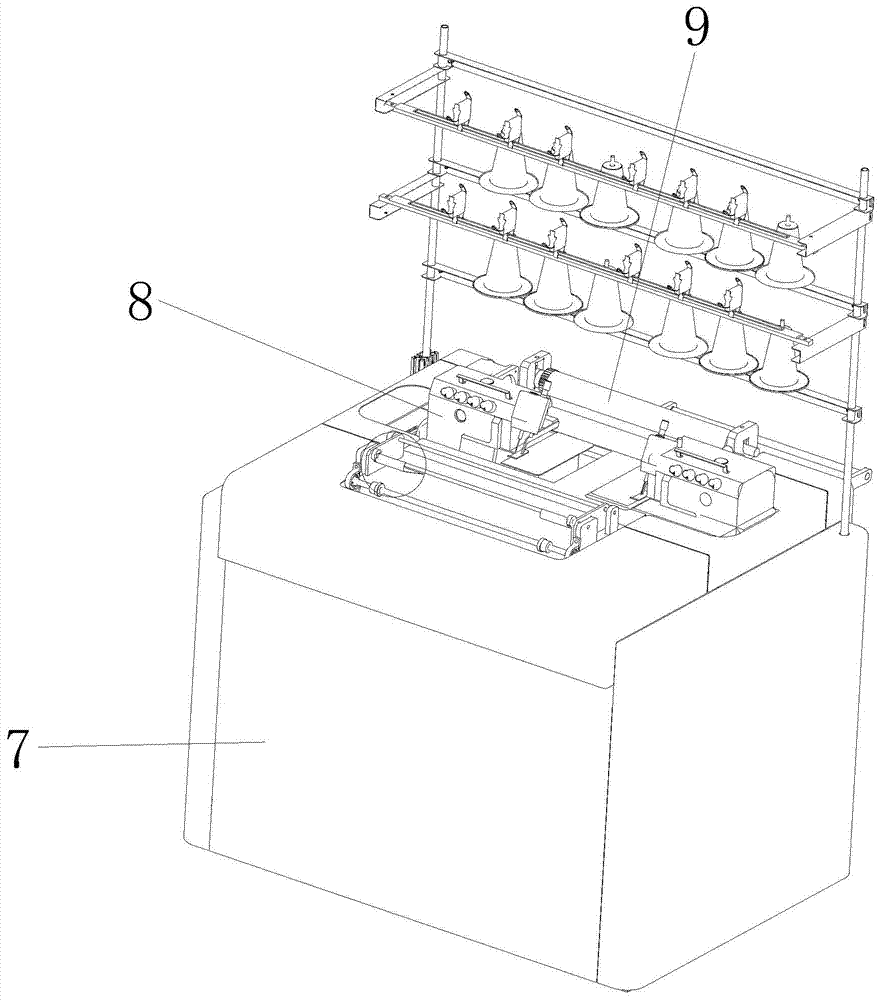

[0030] As attached Figure 1-11 The shown towel machine according to the present invention includes a feeding device, a first processing device, and a second processing device; the feeding device, the first processing device, and the second processing device are placed relatively and fixedly in sequence; the feeding device The fabric is fed into the first processing device; the first processing device performs a double edge over the fabric sent by the feeding device; the second processing device cuts the fabric sent from the first processing device and then performs a second time Double-sided overprinting; the feeding device includes a feeding frame 1, a roller 2, a rotating shaft 3 and a baffle 4; on one side of the feeding frame 1 there are two rows of symmetrical rollers 2; on the feeding frame 1 A plurality of rotating shafts 3 are also provided; the plurality of rotating shafts 3 are loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com