Clamp for machining round thin-walled workpiece

A thin-walled workpiece processing and fixture technology, which is applied in the field of circular thin-walled workpiece fixtures, can solve the problems of workpiece deformation, single force on circular thin-walled workpieces, and roundness that does not meet performance requirements, so as to improve the yield rate. , The effect of compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

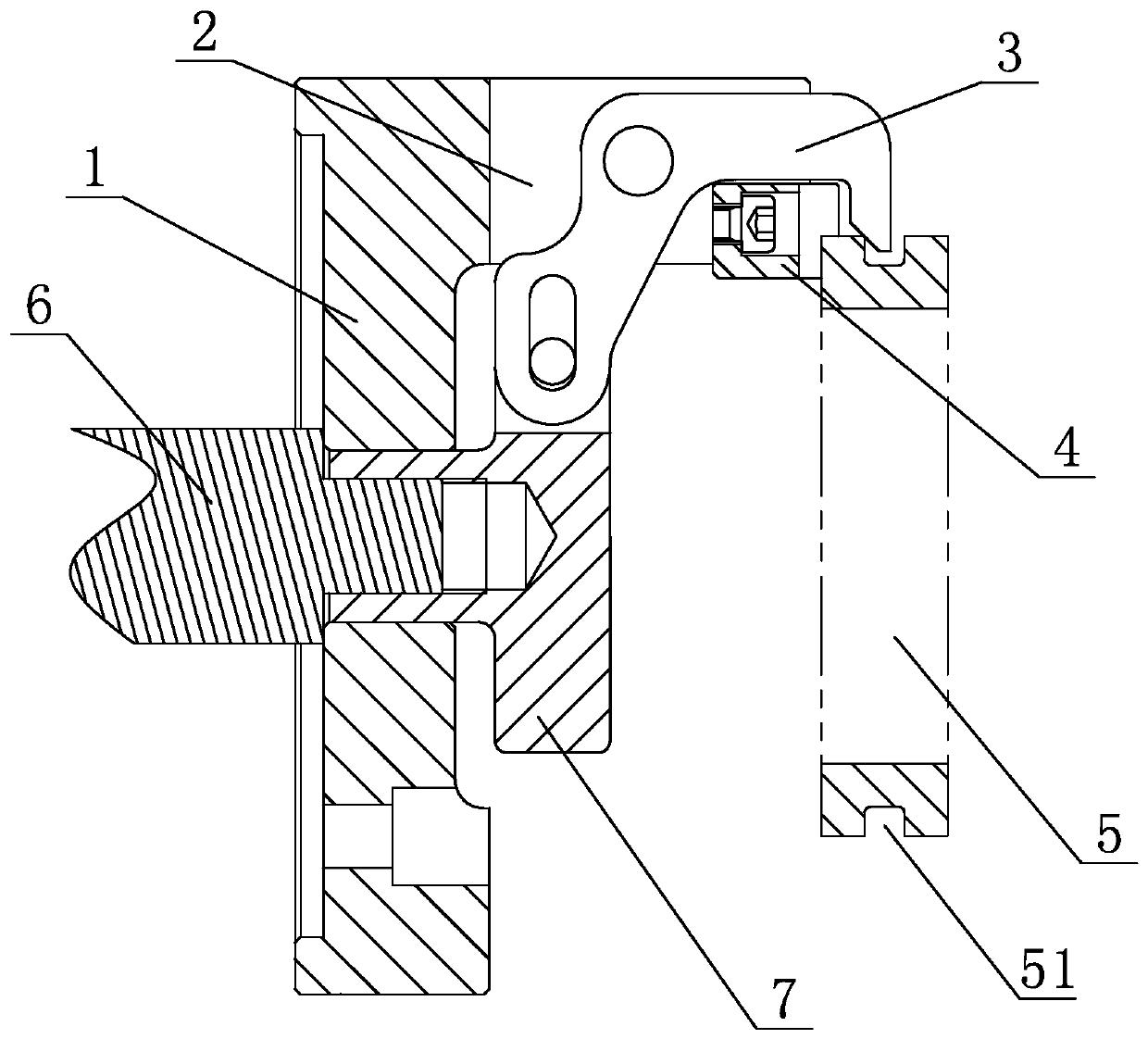

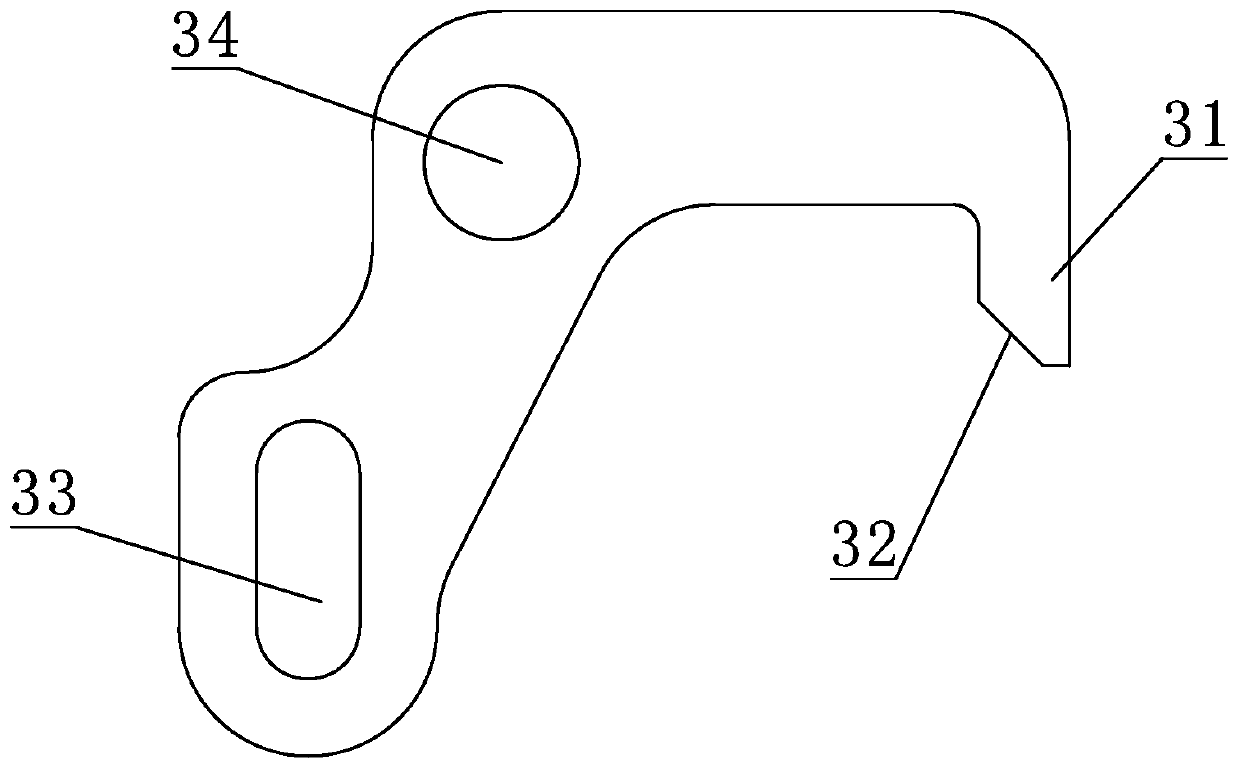

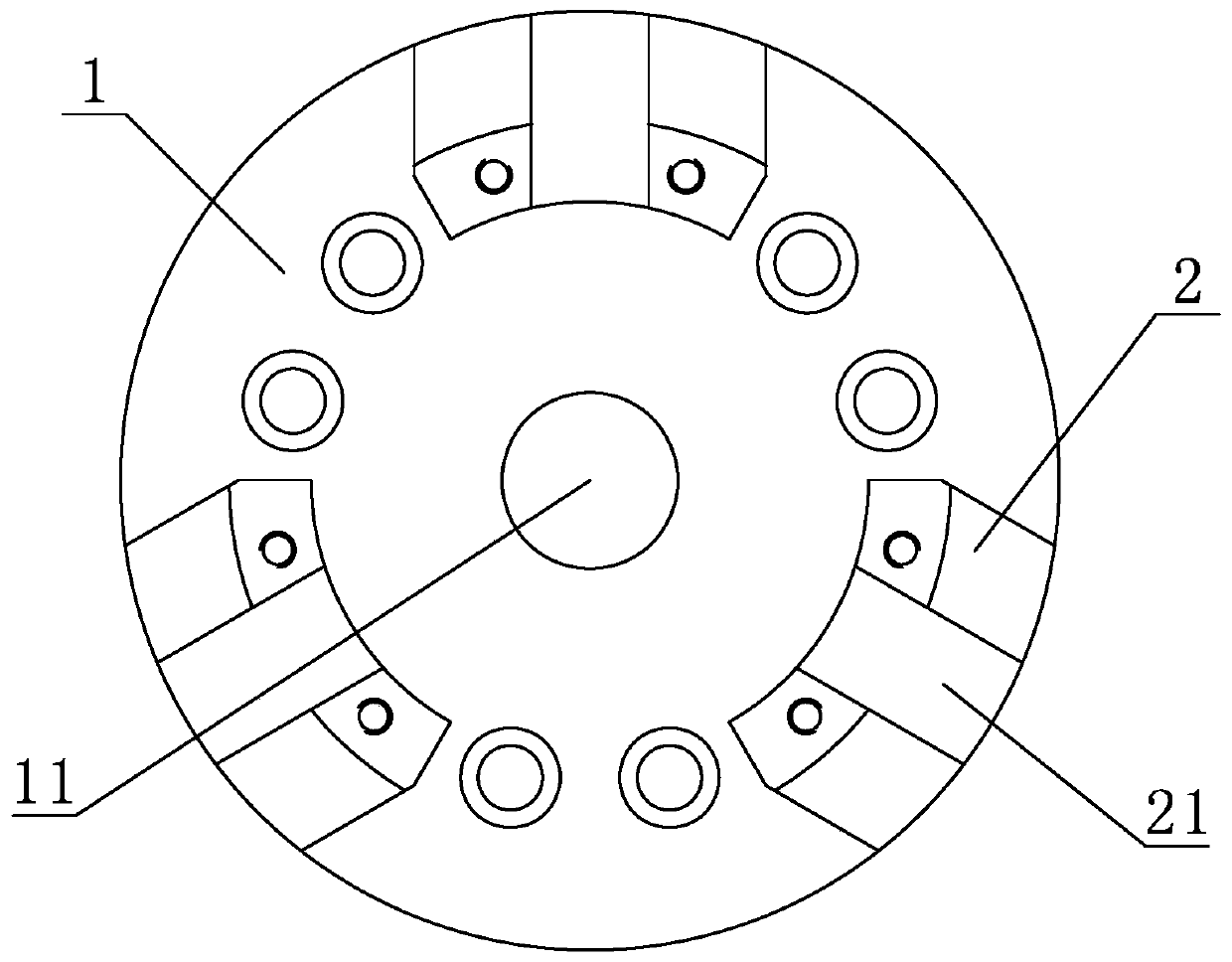

[0023] Such as figure 1 As shown, a fixture for a circular thin-walled workpiece 5 includes a disc-shaped disc body 1, a fixed seat 2 in an annular array and clamping jaws 3 arranged on the fixed seat 2 are integrally formed on the surface of the disc body 1 ; The front part of the jaw 3 is folded down to form a hook 31 for clamping; the end of the hook 31 has an inclined surface 32 . The inclined surface 32 is provided on the inner side of the hook 31 and is inclined from top to bottom and from inside to outside. A spacer 4 against the end face of the workpiece 5 is installed on the fixed seat 2 inside the hook 31; an annular groove 51 is provided on the side wall of the workpiece 5; the end of the hook 31 extends into the groove 51, the incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com