Patents

Literature

30results about How to "Guarantee the quality of the workpiece" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

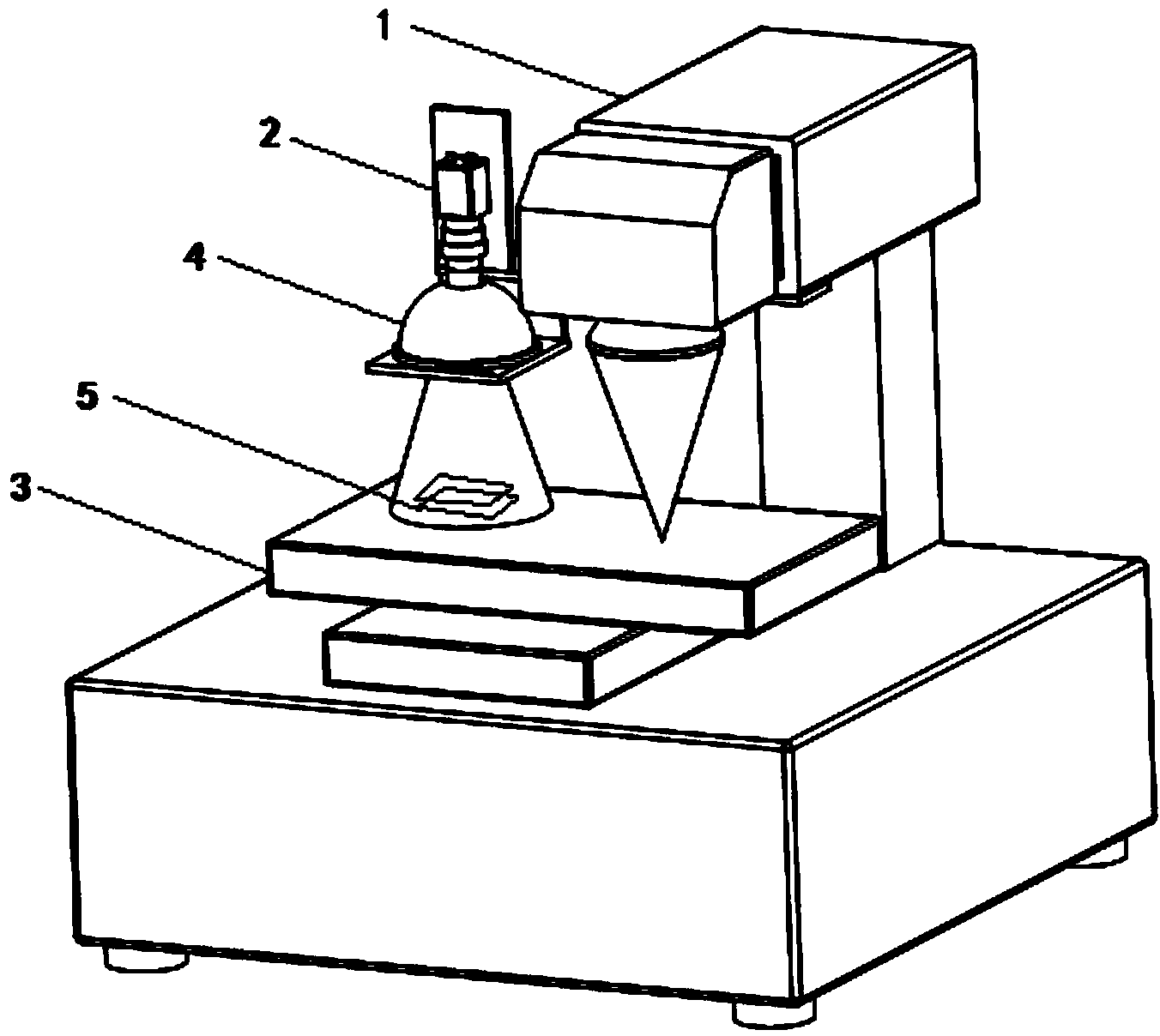

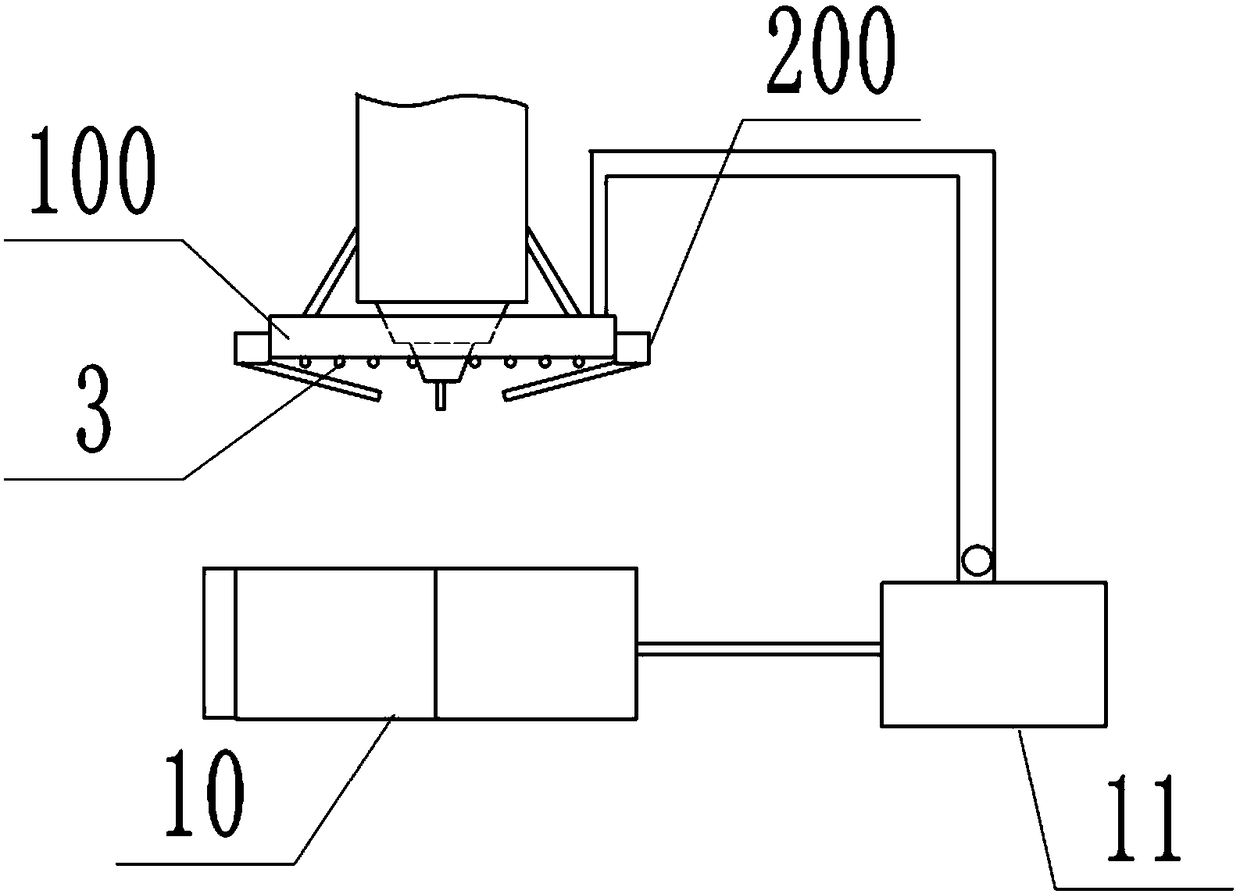

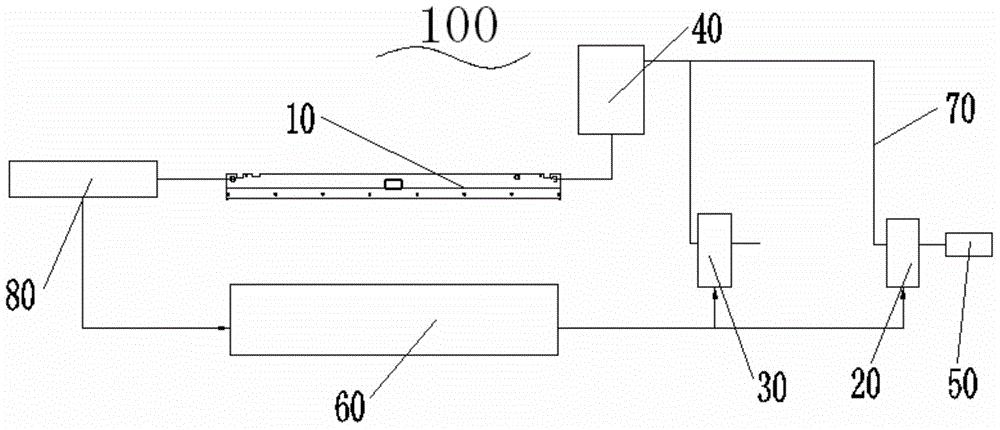

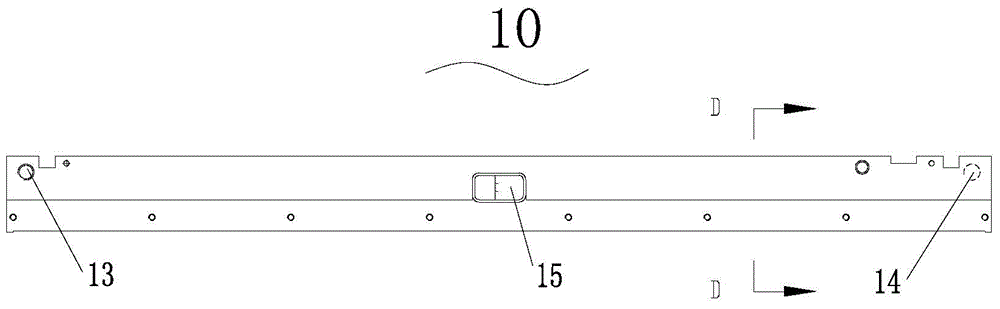

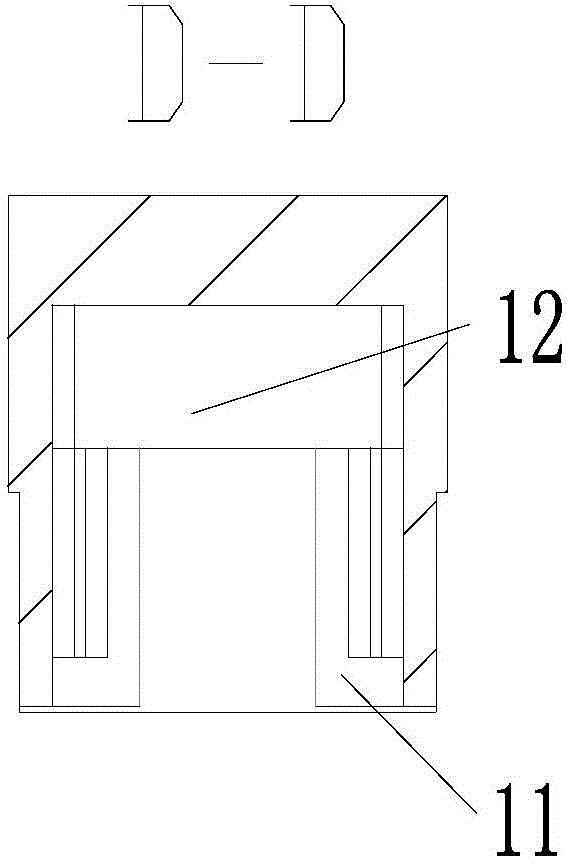

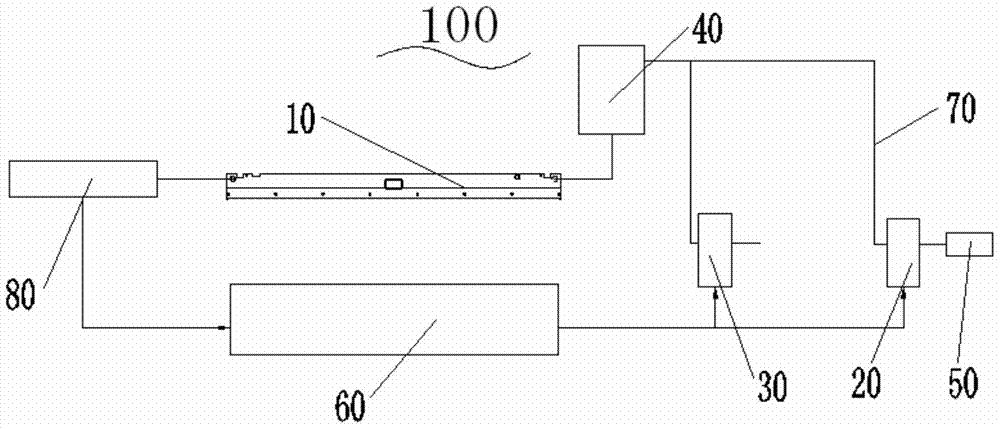

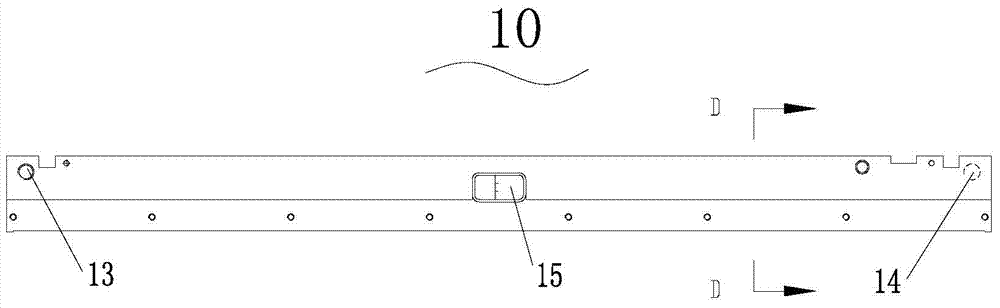

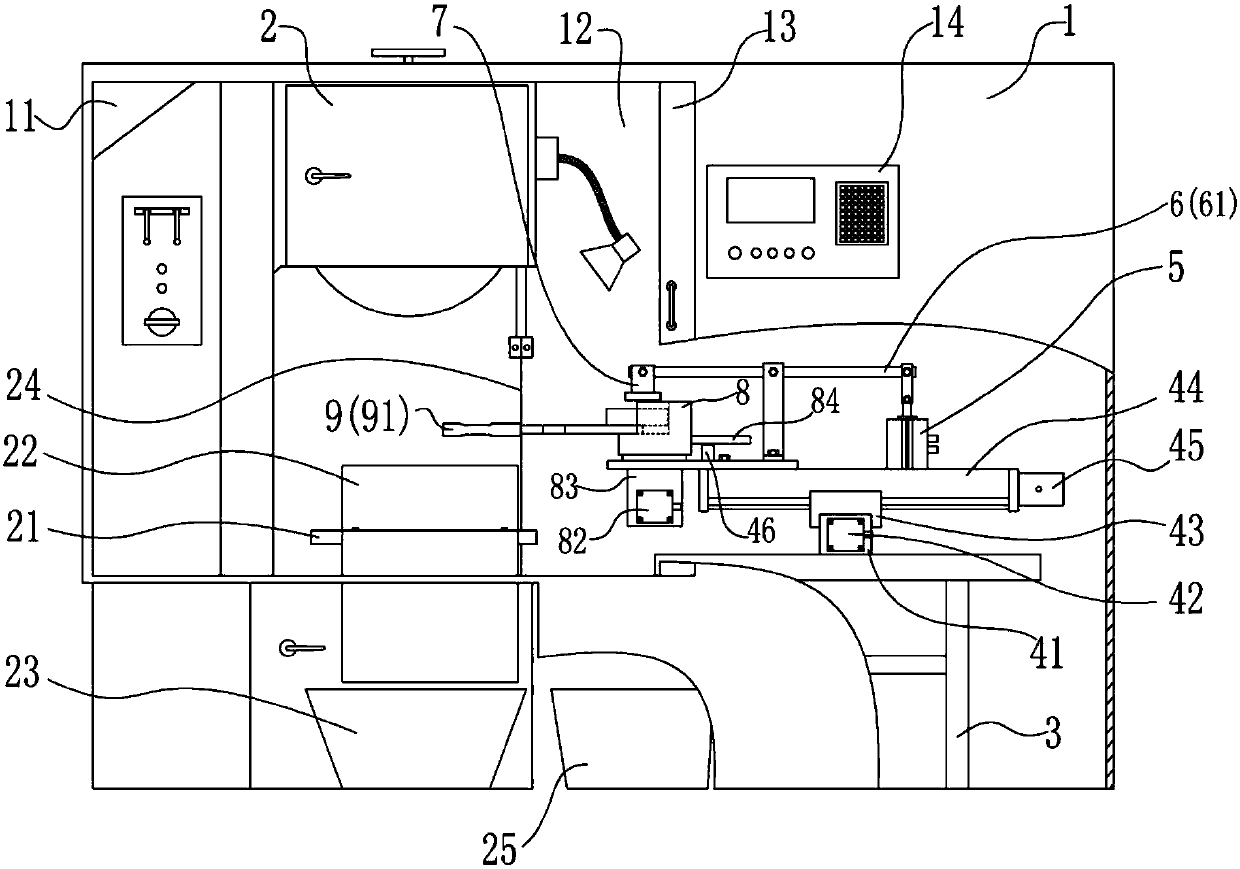

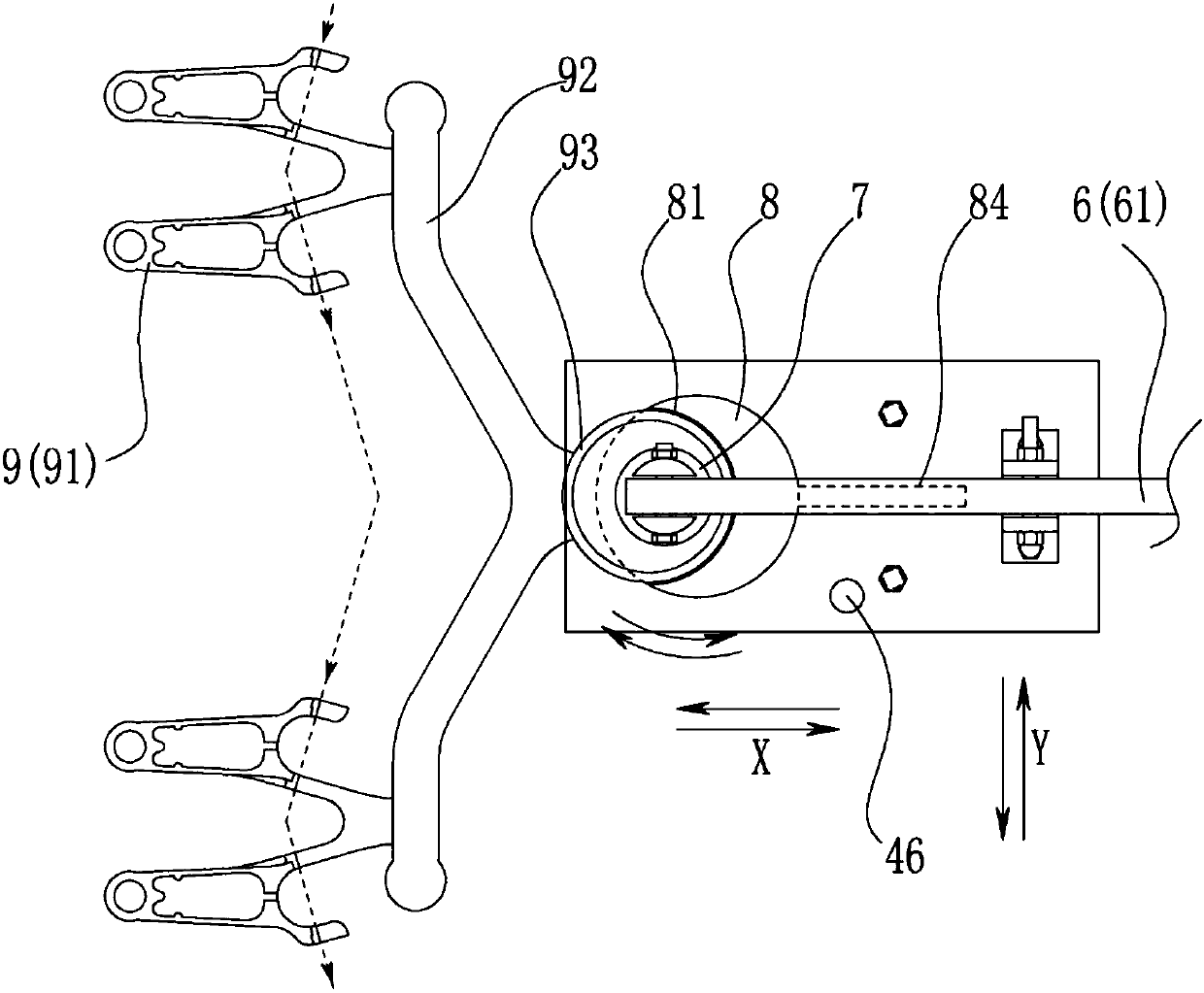

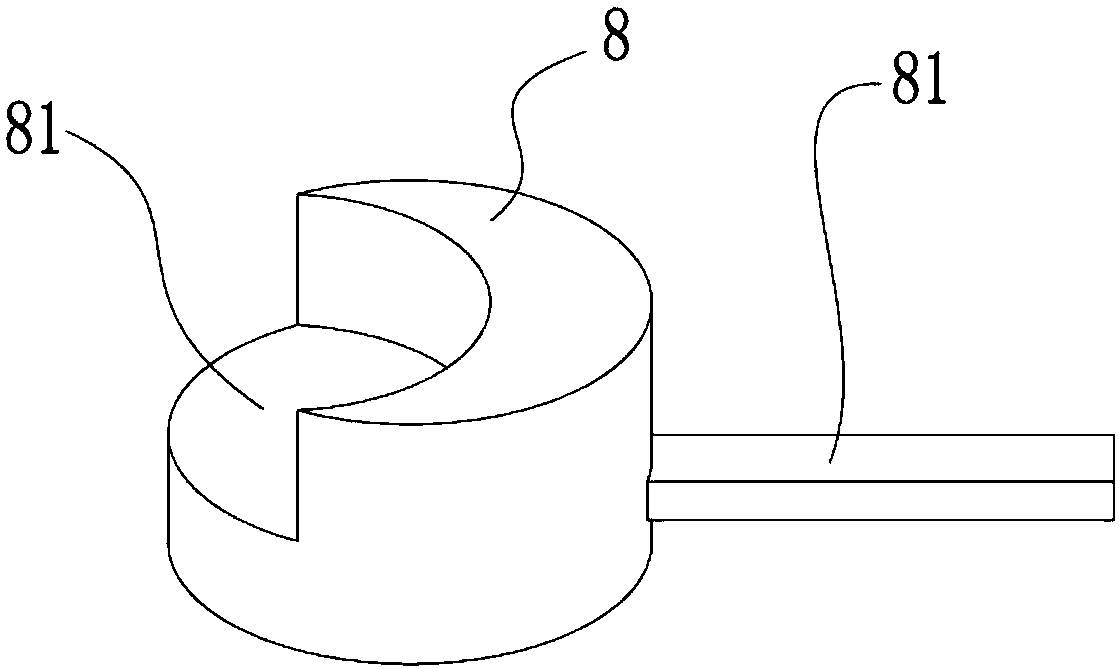

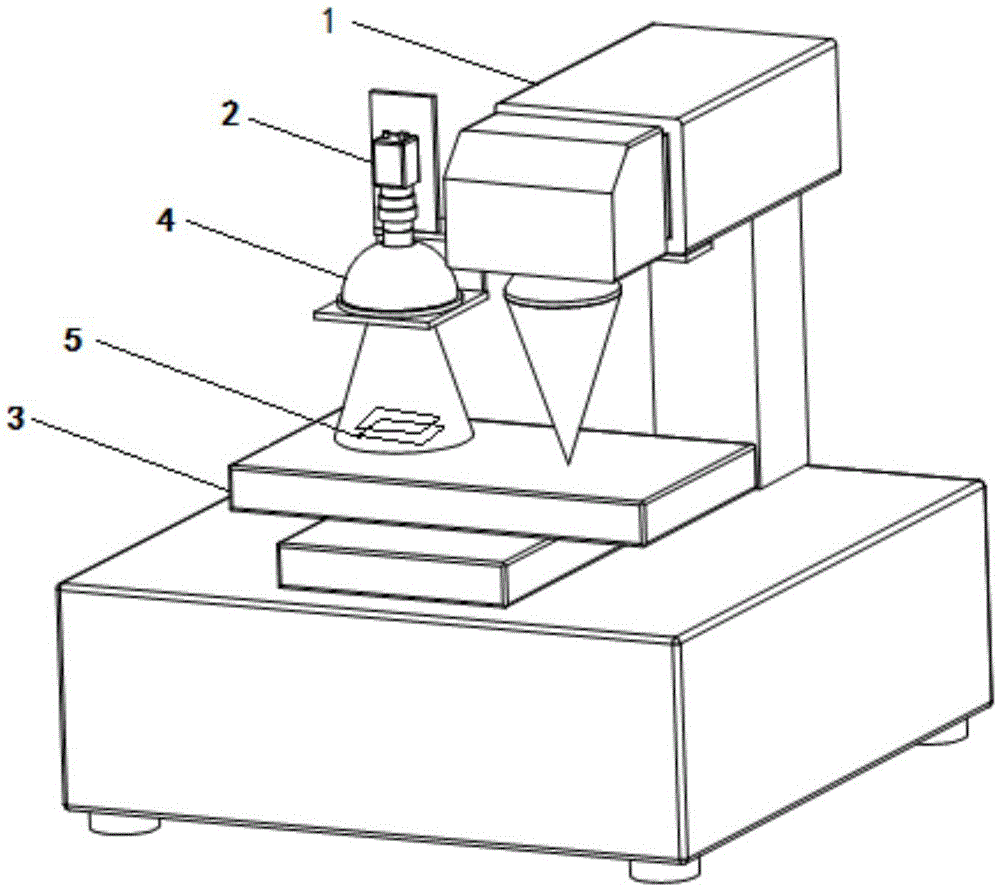

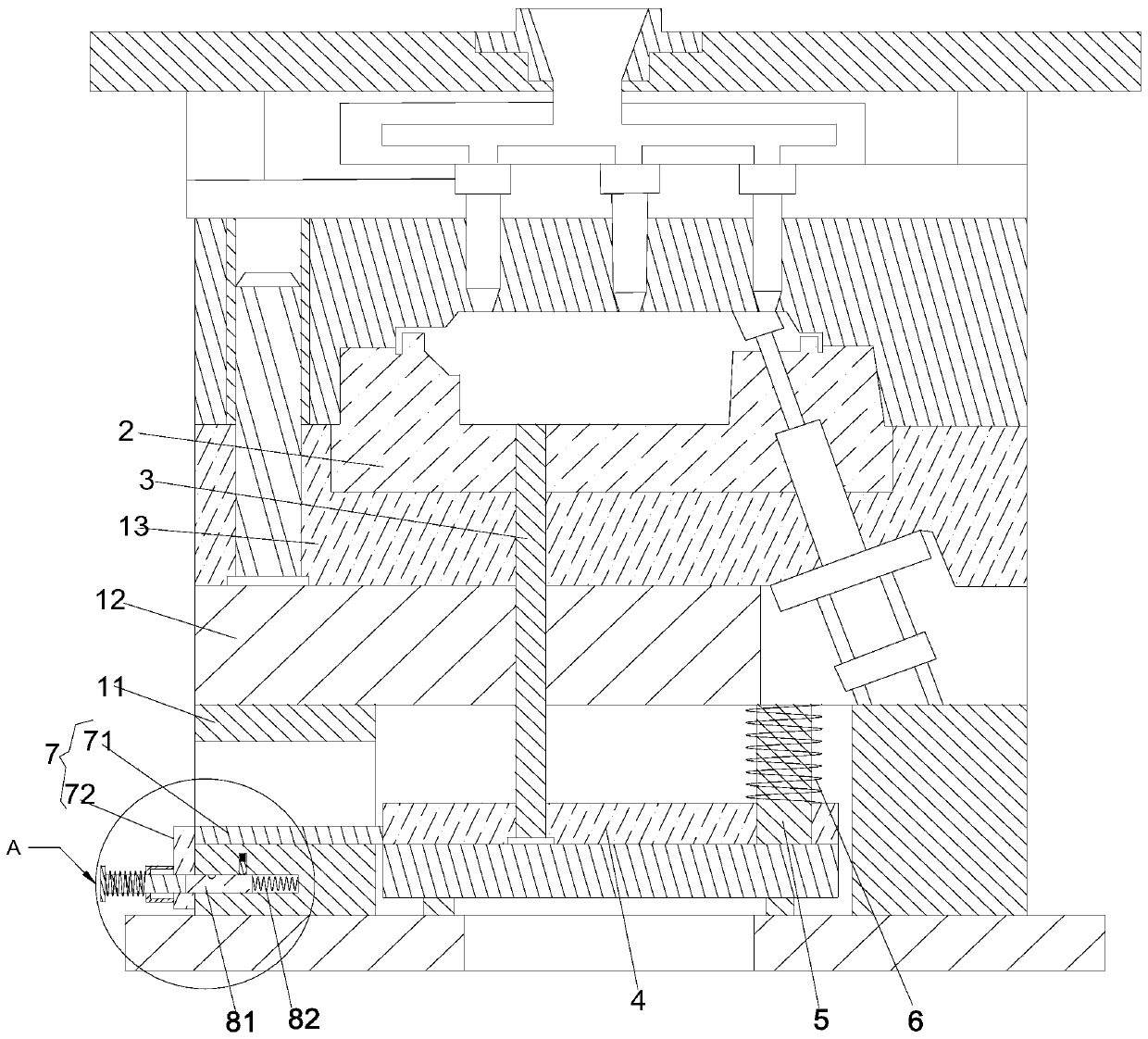

Laser deburring system and method

ActiveCN103639599AImprove efficiencyGuarantee the quality of the workpieceLaser beam welding apparatusComputer scienceLaser

The invention relates to the technical field of laser machining and provides a laser deburring method which comprises the following steps of: acquiring an actual outline of a workpiece and a burr outline through a workpiece image, determining a start point coordinate and an end point coordinate according to a distance between the actual outline of the workpiece and the burr outline, and cutting the burr according to the start point coordinate and the end point coordinate of the burr of the workpiece. With the adoption of the method, a part with the burr is only required to be cut, and deburring treatment is not required to be performed on the whole outline of an object, so that the deburring efficiency is improved. Simultaneously, the workpiece quality is ensured since parts without the burrs on the workpiece are not influenced by laser heat.

Owner:HANS LASER TECH IND GRP CO LTD +1

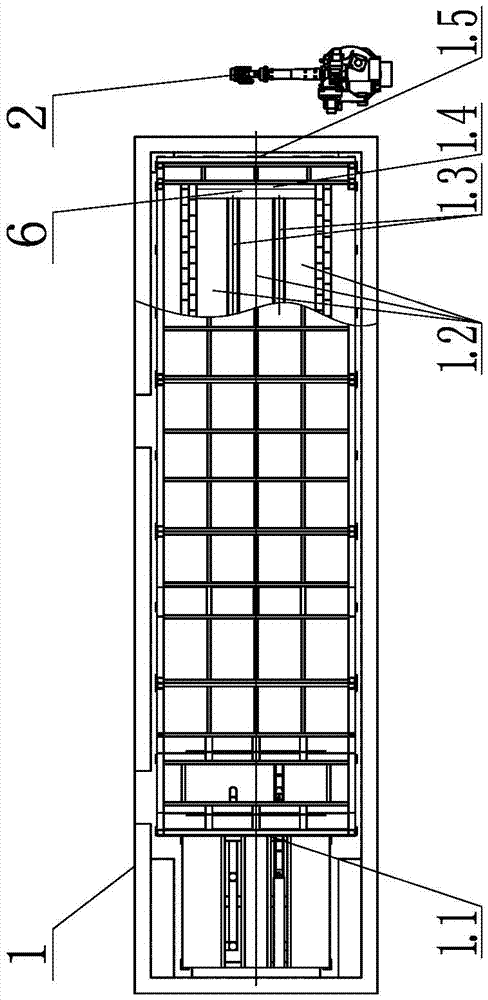

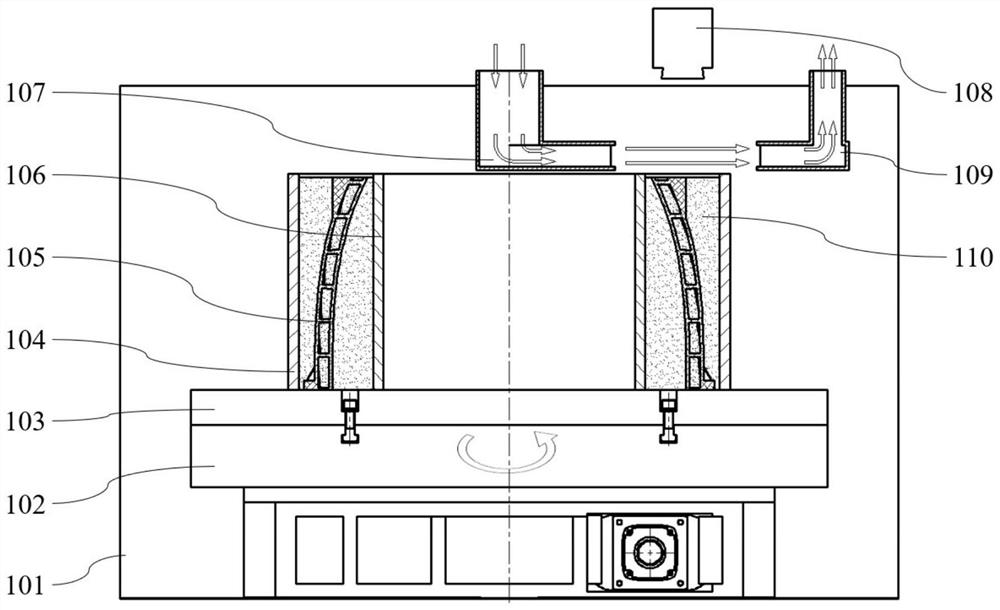

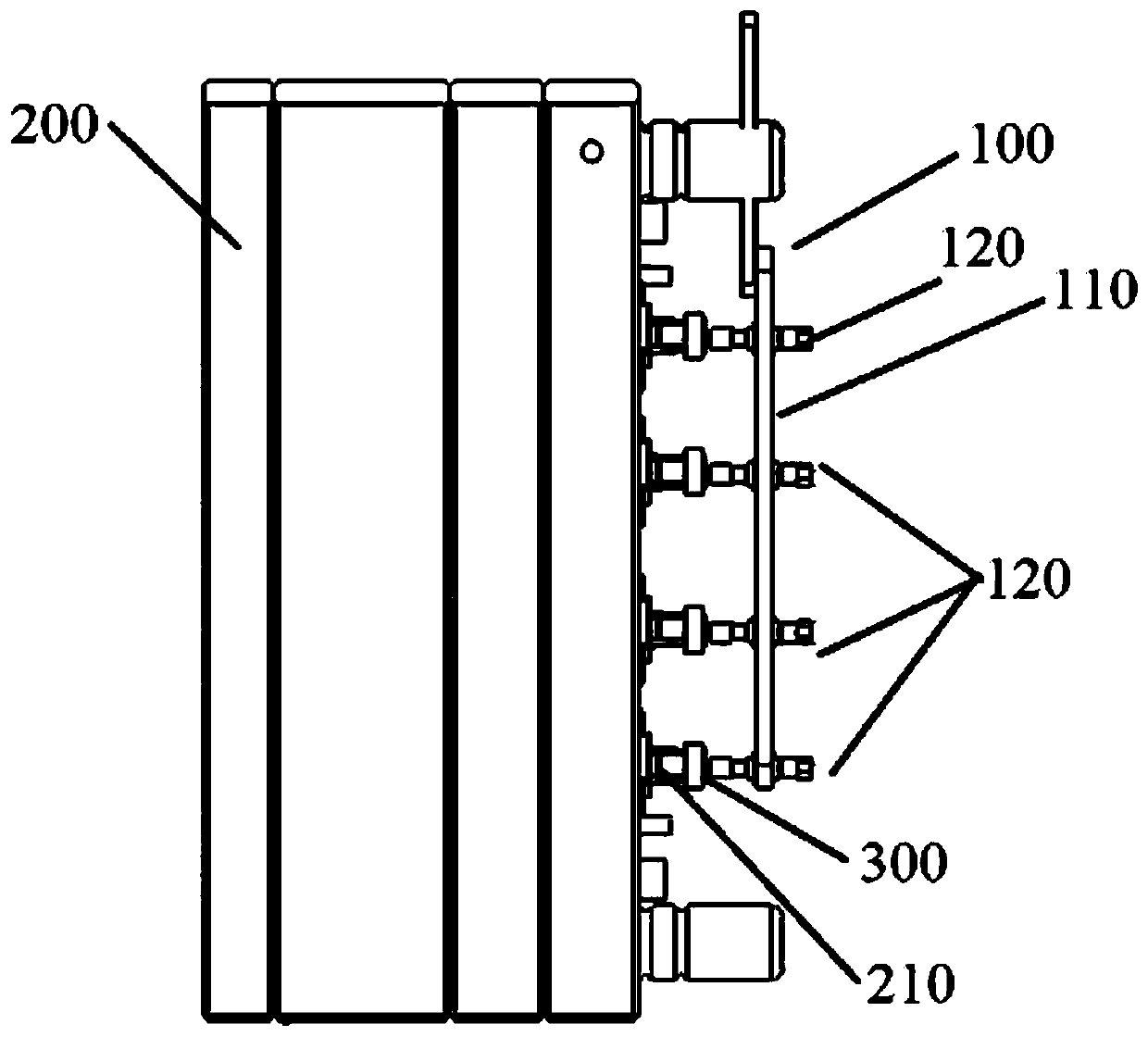

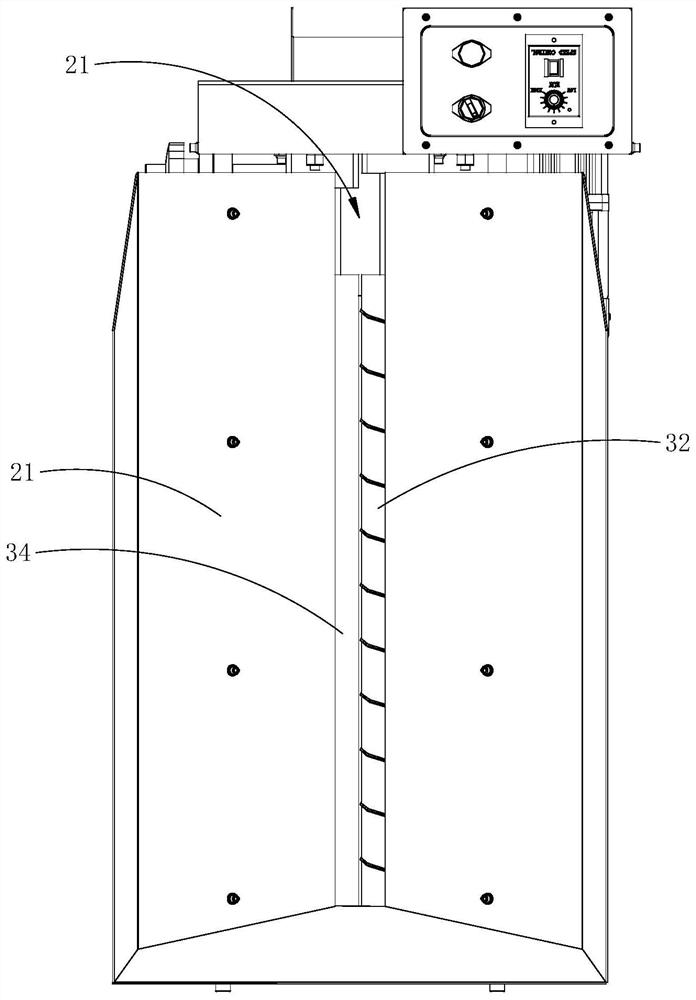

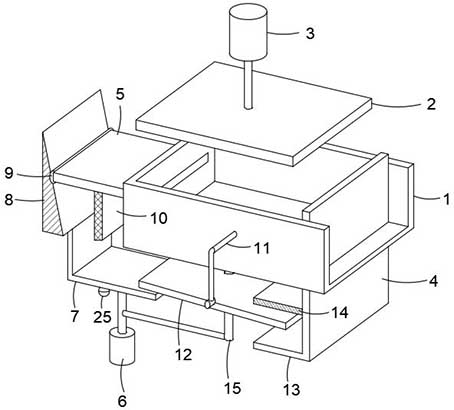

Cooling system for numerically-controlled machine tool

ActiveCN108857568AGuaranteed effective coolingGuarantee the quality of the workpieceMeasurement/indication equipmentsMaintainance and safety accessoriesEngineeringMachining process

The invention discloses a cooling system for a numerically-controlled machine tool and relates to the field of numerically-controlled machine tool equipment. The cooling system comprises an annular guide rail and a moving mechanism. Multiple temperature sensors are arranged on the lower portion of the annular guide rail. The annular guide rail is internally provided with a cavity. A liquid inlet pipe is arranged on the annular guide rail, wherein the liquid inlet pipe communicates with the cavity. The wall of the cavity is provided with a first solenoid valve. An infrared sensor is arranged atone side of the first solenoid valve. A buckling ring is internally provided with an inner cavity. A conveying channel is formed in the buckling ring and a connecting plate. The conveying channel enables a spray head to communicate with the inner cavity. A water pump is arranged at the connection position of the conveying channel and the inner cavity. The inner cavity is internally provided witha liquid level sensor. The wall of the inner cavity of the buckling ring is provided with a second solenoid valve. The second solenoid valve can be opposite to the first solenoid valve in position. Bymeans of the cooling system, the problem that in the workpiece machining process of a traditional numerically-controlled machine tool, the spray flow of cooling liquid cannot be adjusted automatically according to the machining heat quantity is solved; and the cooling system is mainly used for guaranteeing the cooling effect and workpiece quality.

Owner:温州市职业中等专业学校

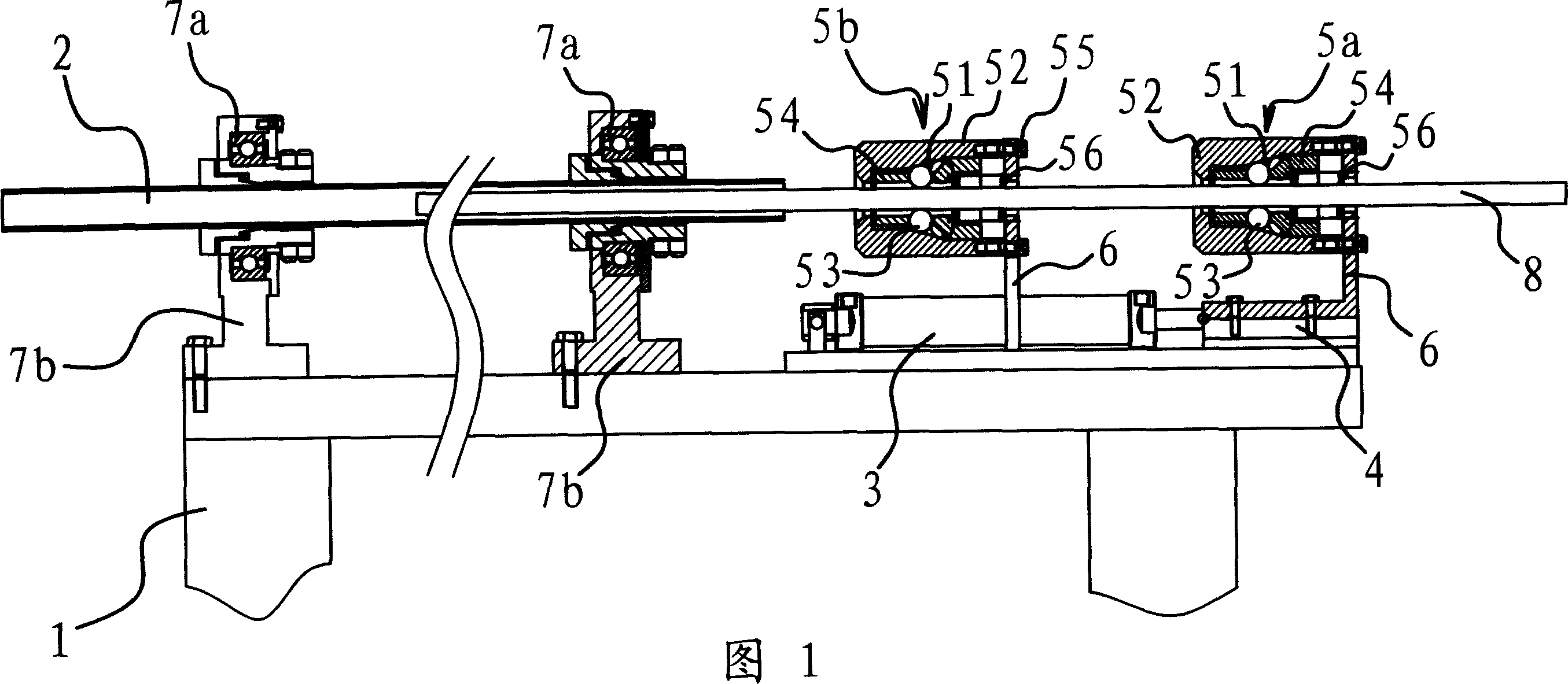

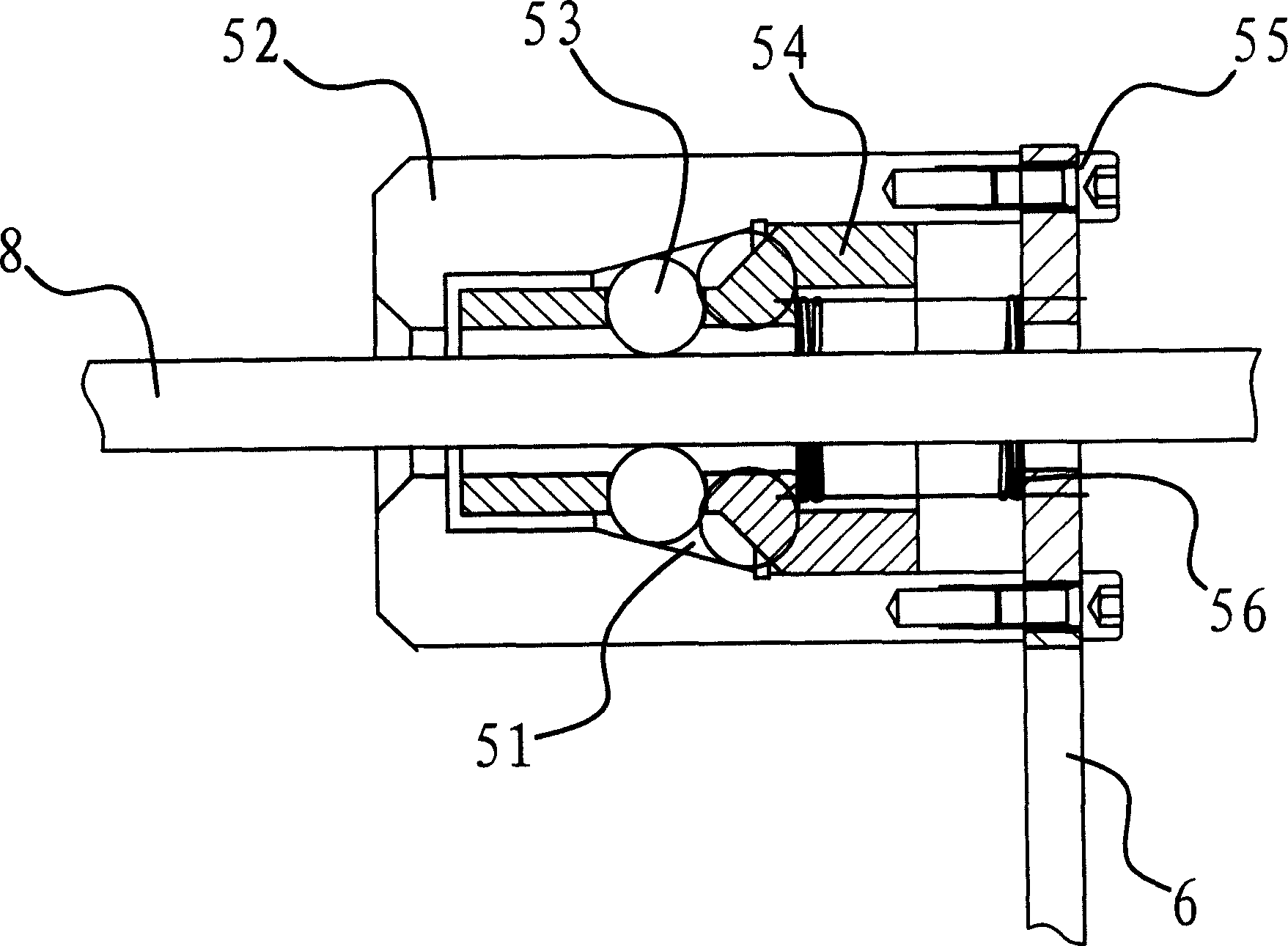

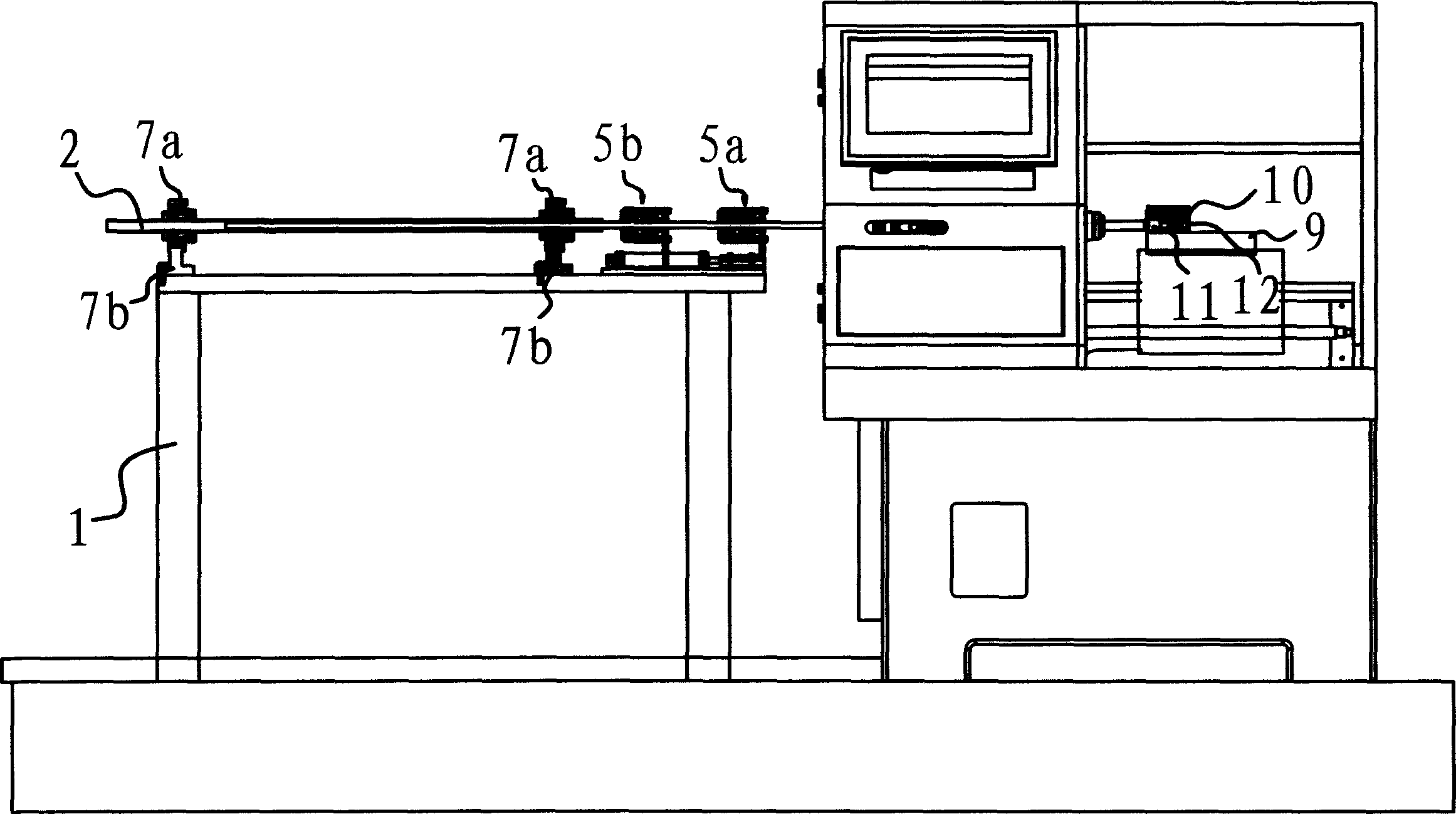

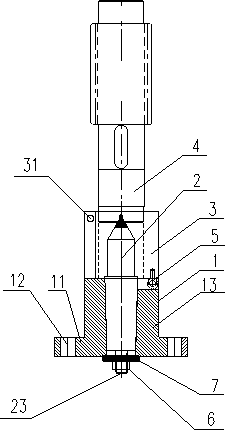

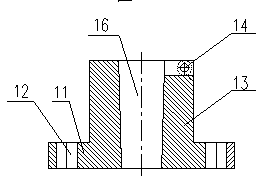

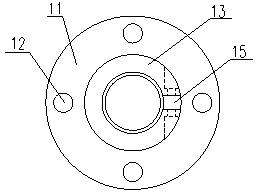

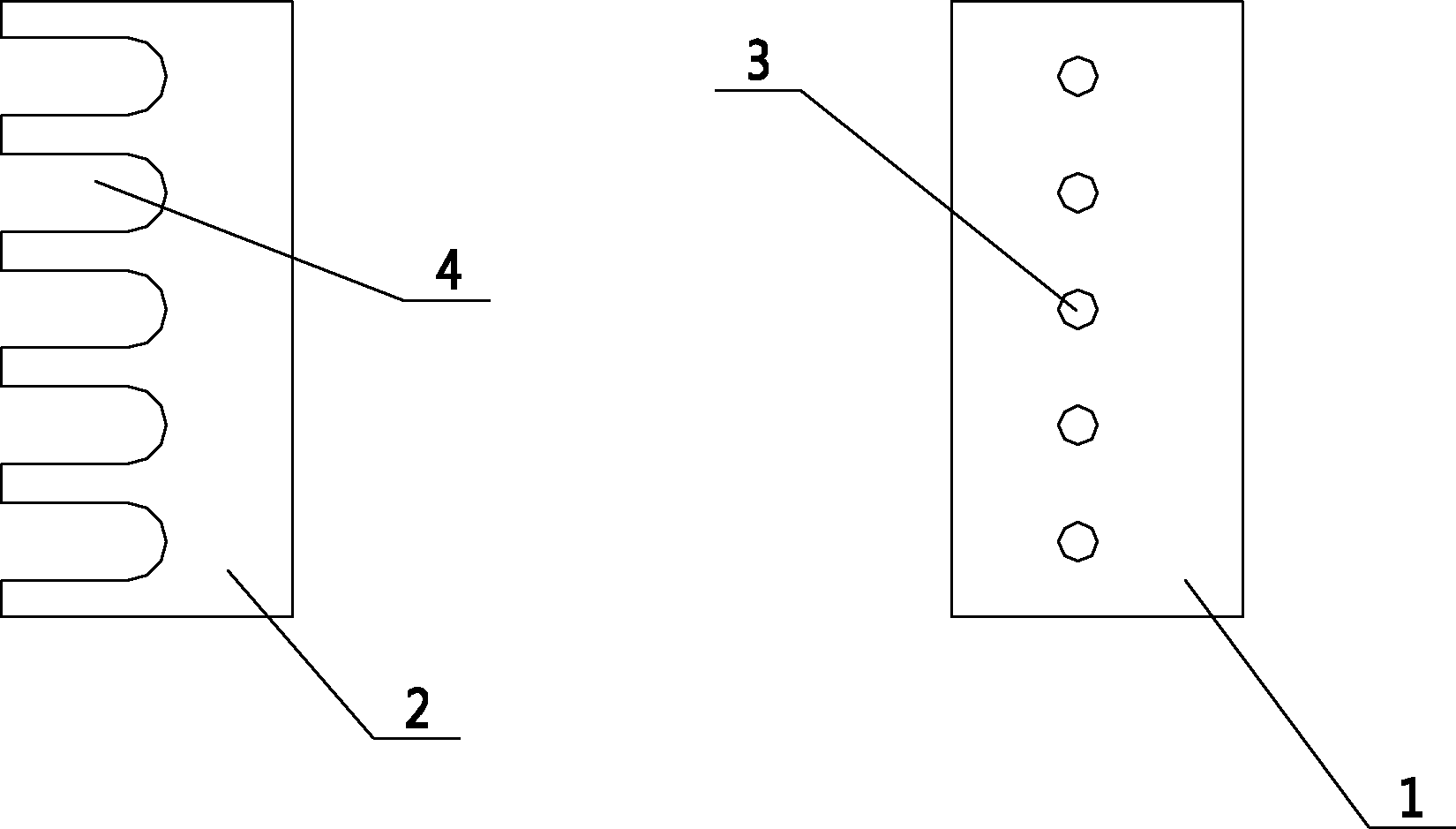

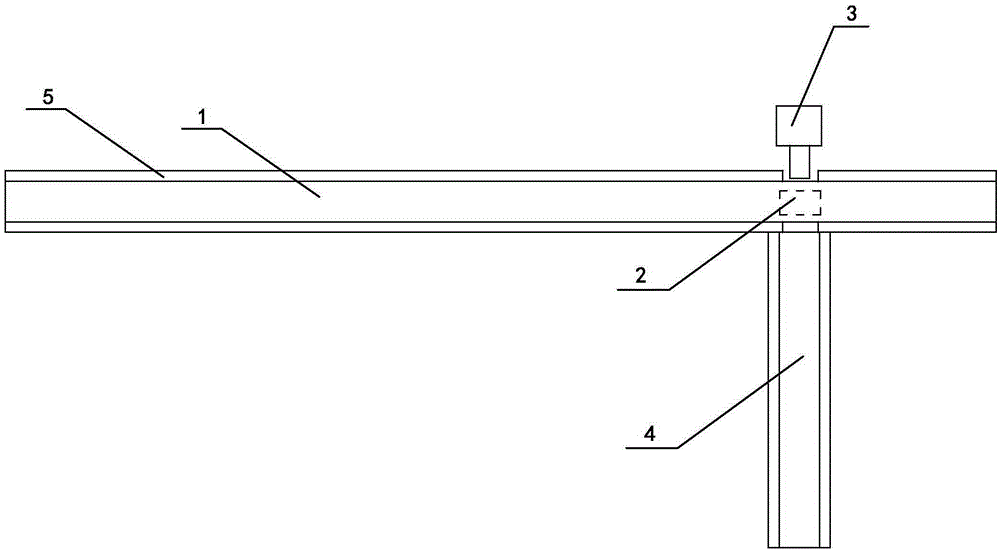

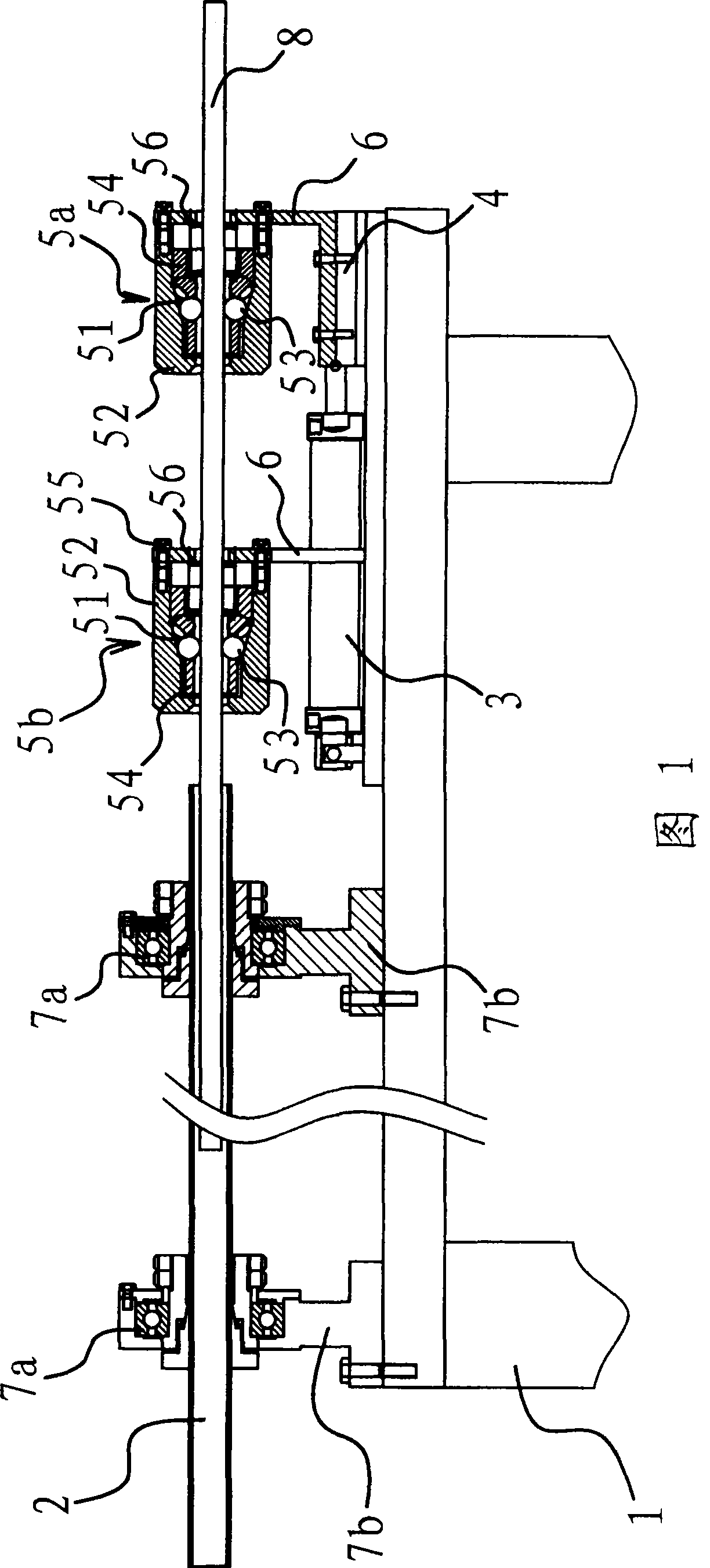

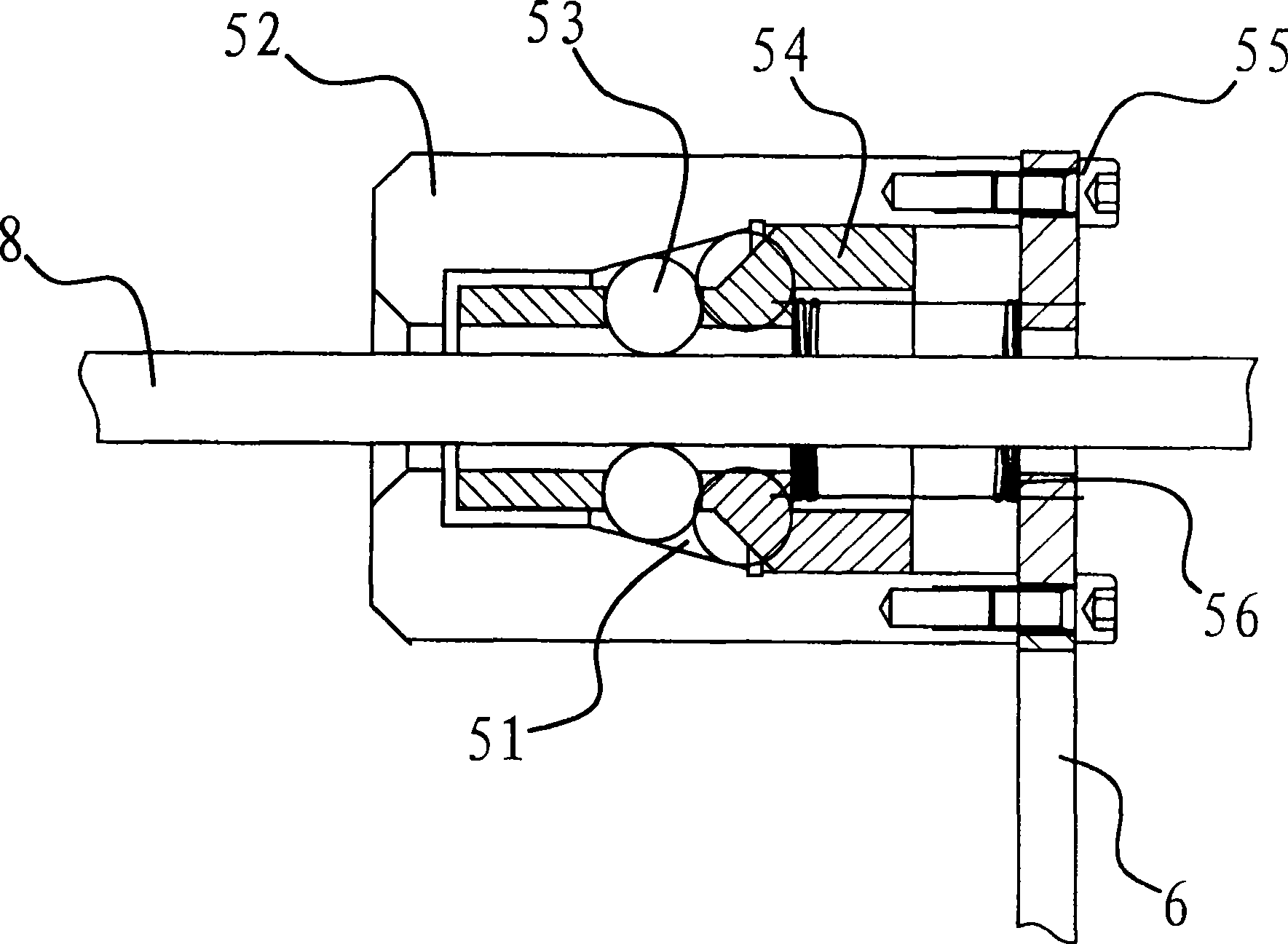

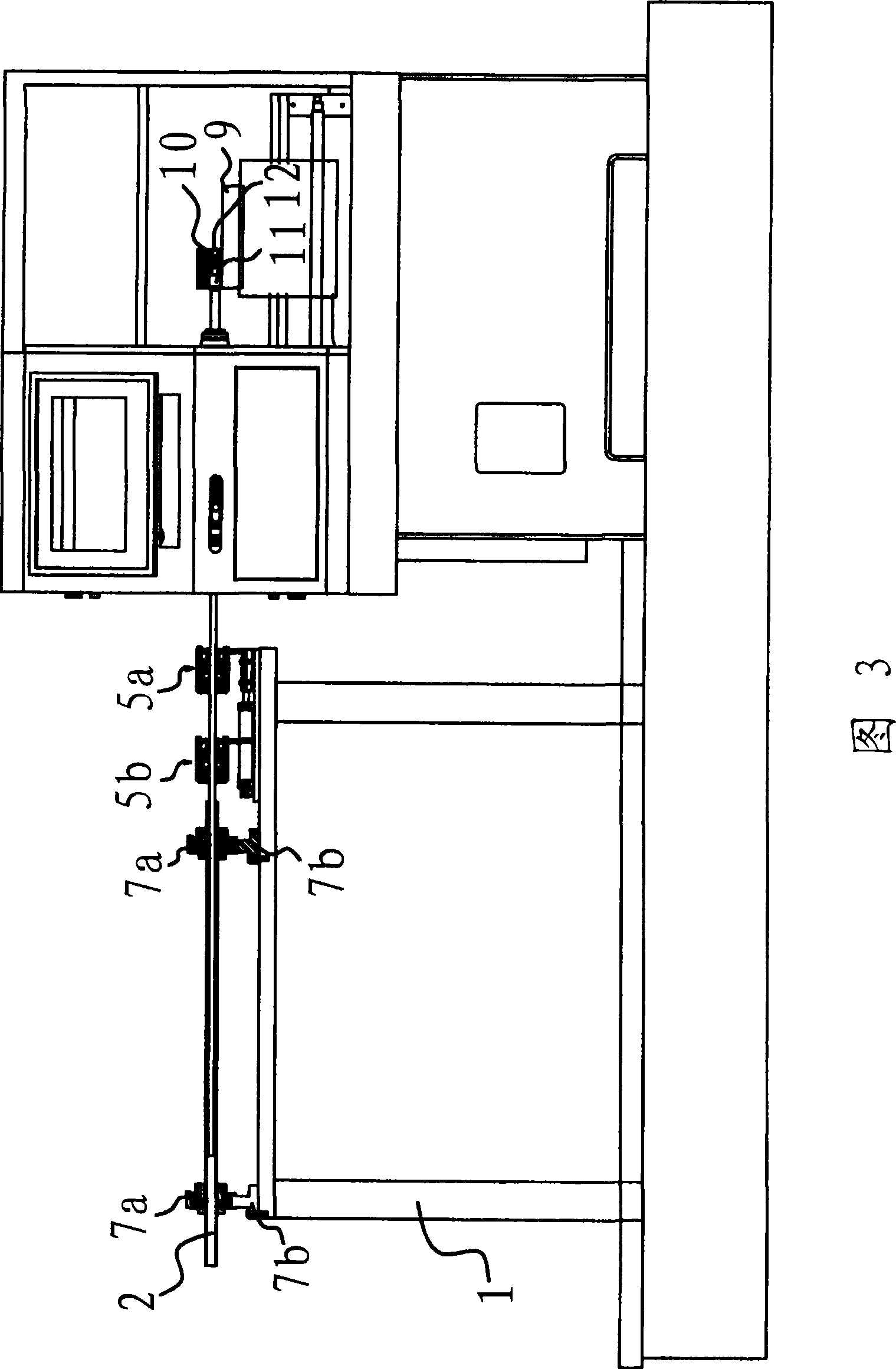

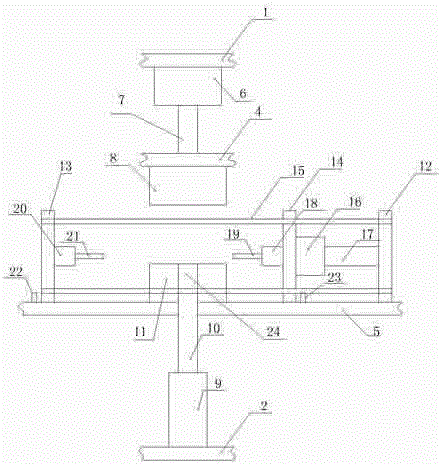

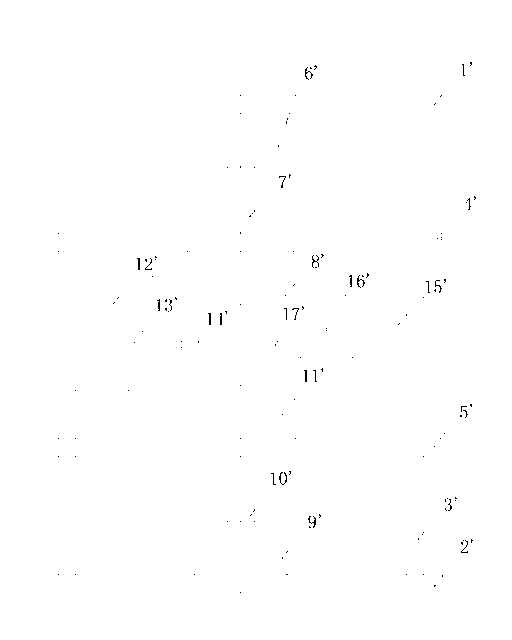

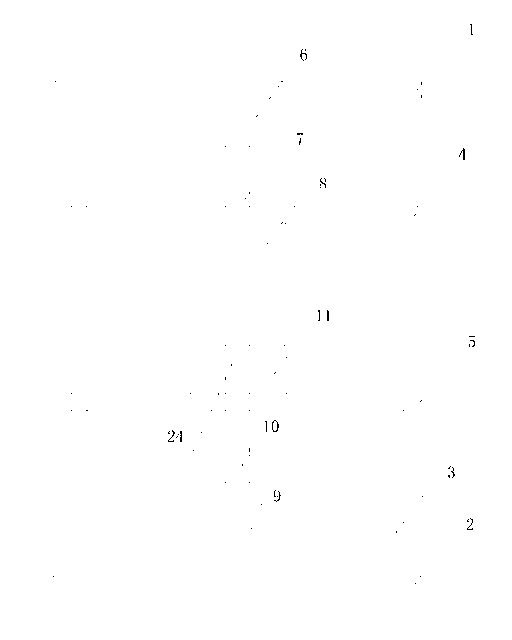

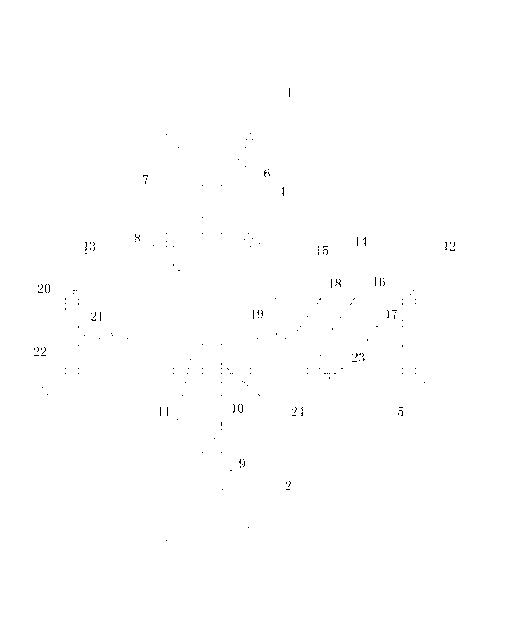

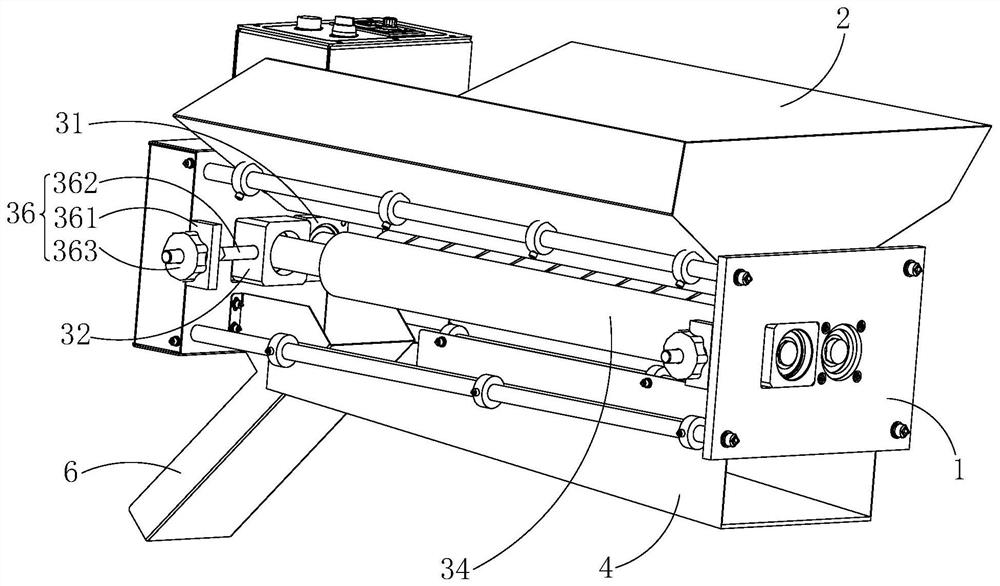

Automatic feeding device for lathe

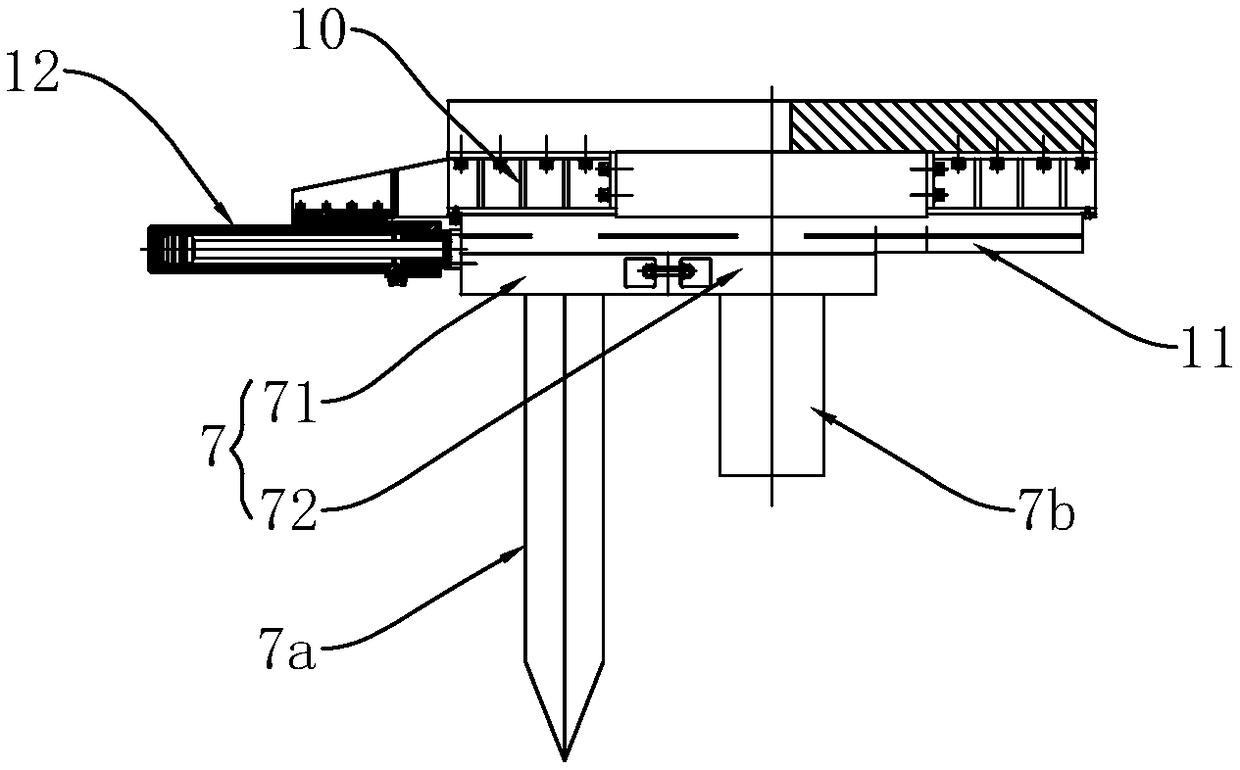

ActiveCN1850400AReduce disturbanceGuaranteed rotation accuracyAutomatic conveying/guiding stockSlide plateEngineering

The present invention provides an automatic feeder device for lathe. Said automatic feeder device is placed by workpiece holder of lathe, and includes the following several portions: material-supporting pipe placed on the machine frame, material-feeding cylinder placed at one side of said material-supporting pipe, slide plate fixedly connected on said material-feeding cylinder and can be axially moved along the material-supporting pipe and two material-feeding devices through which the rod material can be passed are placed on the machine frame. Said two material-feeding devices include one mobile material-feeding device and one fixed material-feeding device. Its operation is convenient, stable and reliable.

Owner:浙江海德曼智能装备股份有限公司

Scraper pressure stabilizing system and control method thereof

ActiveCN104626584AEfficient removalGuaranteed printing success rateAdditive manufacturing apparatusSolenoid valveClosed loop

The invention provides a scraper pressure stabilizing system. The scraper pressure stabilizing system comprises a scraper as well as a vacuum box for regulating gas pressure of an inner cavity of the scraper, a first solenoid valve, a second solenoid valve, a vacuum pump and a central controller, wherein the central controller is connected with a pressure sensor, the first solenoid valve and the second solenoid valve which are communicated with the inner cavity of the scraper respectively; the central controller comprises a data processing module and an instruction sending module, can be used for regulating the first solenoid valve and the second solenoid valve according to a gas pressure value measured by the pressure sensor to control the gas pressure in the inner cavity of the scraper to be kept at a stable value. Through the closed-loop stable control, the scraper pressure stabilizing system keeps the constant pressure of the inner cavity of the scraper, so that the stabilization of resin liquid level in the inner cavity of the scraper and effective removal of gas bubbles are realized, and the printing success rate during printing and the quality of the printed workpieces of a laser photocuring molding printer which adopts the scraper pressure stabilizing system are guaranteed.

Owner:SHINING 3D TECH CO LTD

Hobbing assembly clamp for gear shaft

InactiveCN104227148AEasy to processGuarantee the quality of the workpieceGear-cutting machinesGear teethHobbingEngineering

The invention discloses a hobbing assembly clamp for a gear shaft. The hobbing assembly clamp comprises a clamp body, a tip, a clamping sleeve and a baffle block, wherein the tip is located in the clamp body; the clamping sleeve is fixed on the clamp body through the baffle block; the clamping sleeve is arranged as an open type annular sleeve; thread holes are formed in two annular ends on the upper part of the annular sleeve; a bolt mounting step position is arranged on a sleeve wall at one end; a bolt can be conveniently screwed into the thread holes from the bolt mounting step position, so that the two ends of the annular sleeve are connected with each other; two longitudinal technical slots are arranged on the outer side of the sleeve wall at an interval. During a use process, the clamp body is fixedly mounted on a working turntable of a hobbing machine through a plurality of mounting through holes in a lug boss on the lower part of the clamp body by using the bolt, one end of the to be processed gear shaft is inserted into the clamping sleeve, the center hole in an end face of the gear shaft is aligned with the tip, and then the bolt on the upper part of the clamping sleeve is tightened, so that the outer surface of the gear shaft is tightly held by the clamping sleeve and the gear shaft is firmly fixed on the clamp.

Owner:HENGSHAN GEAR

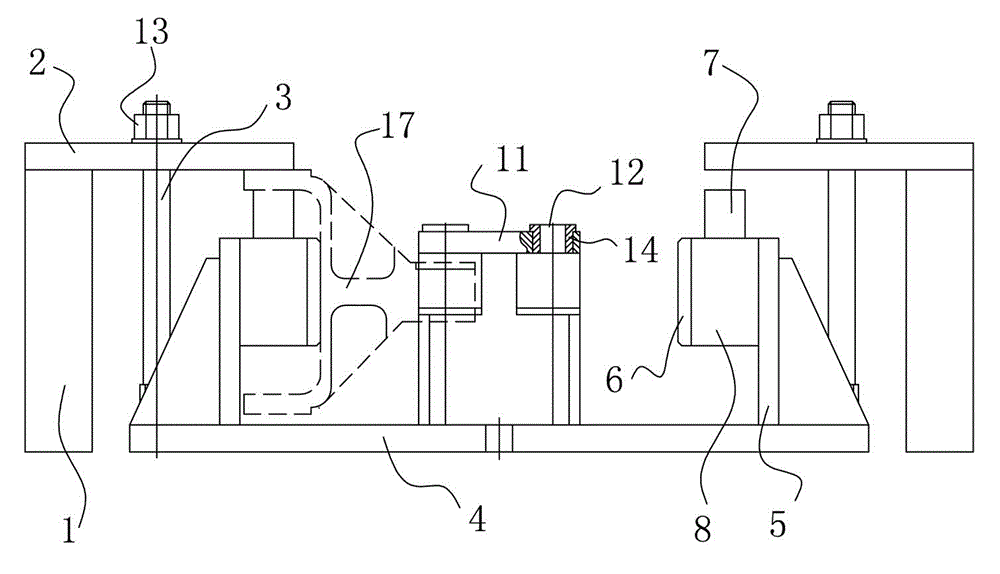

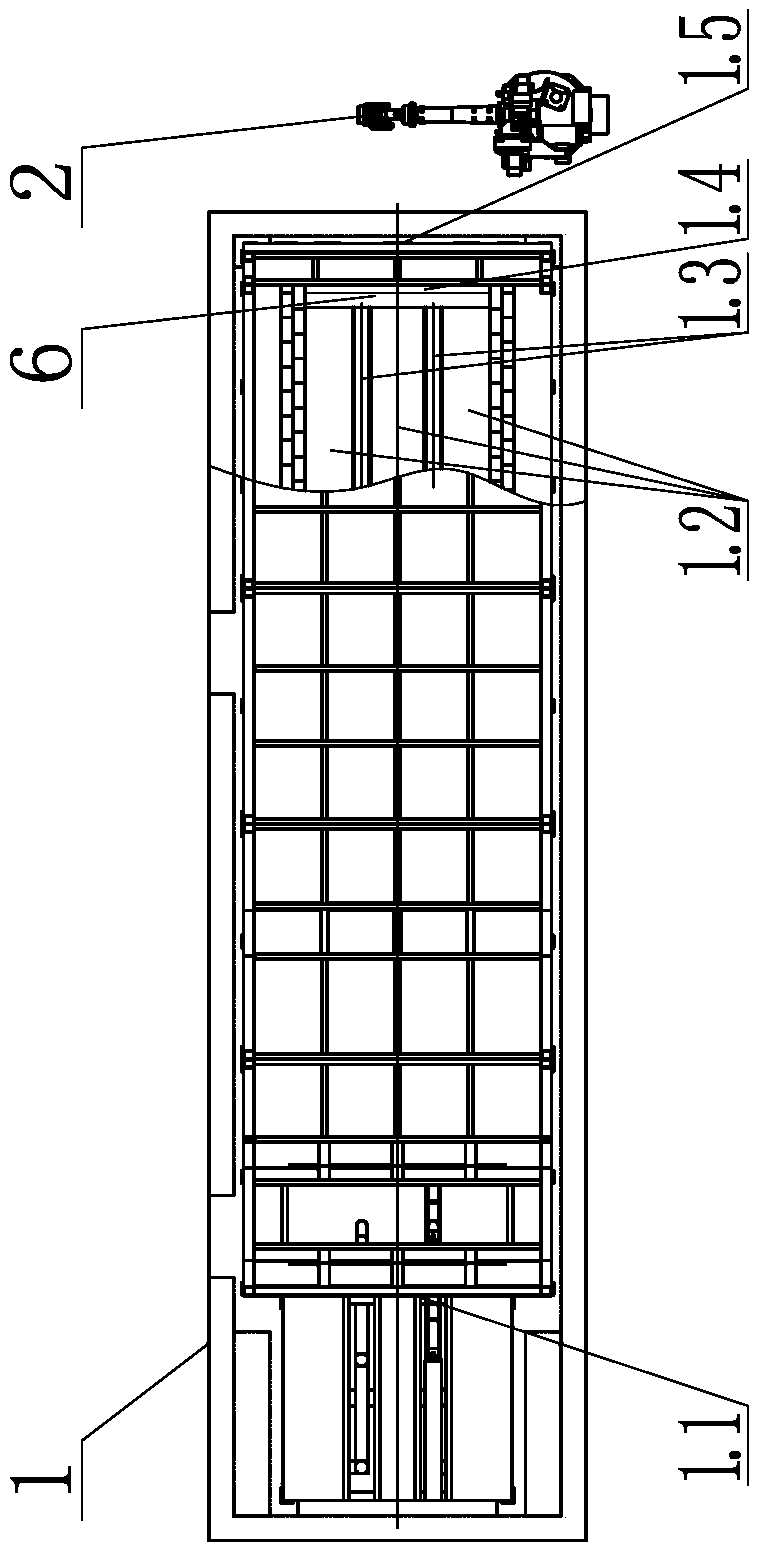

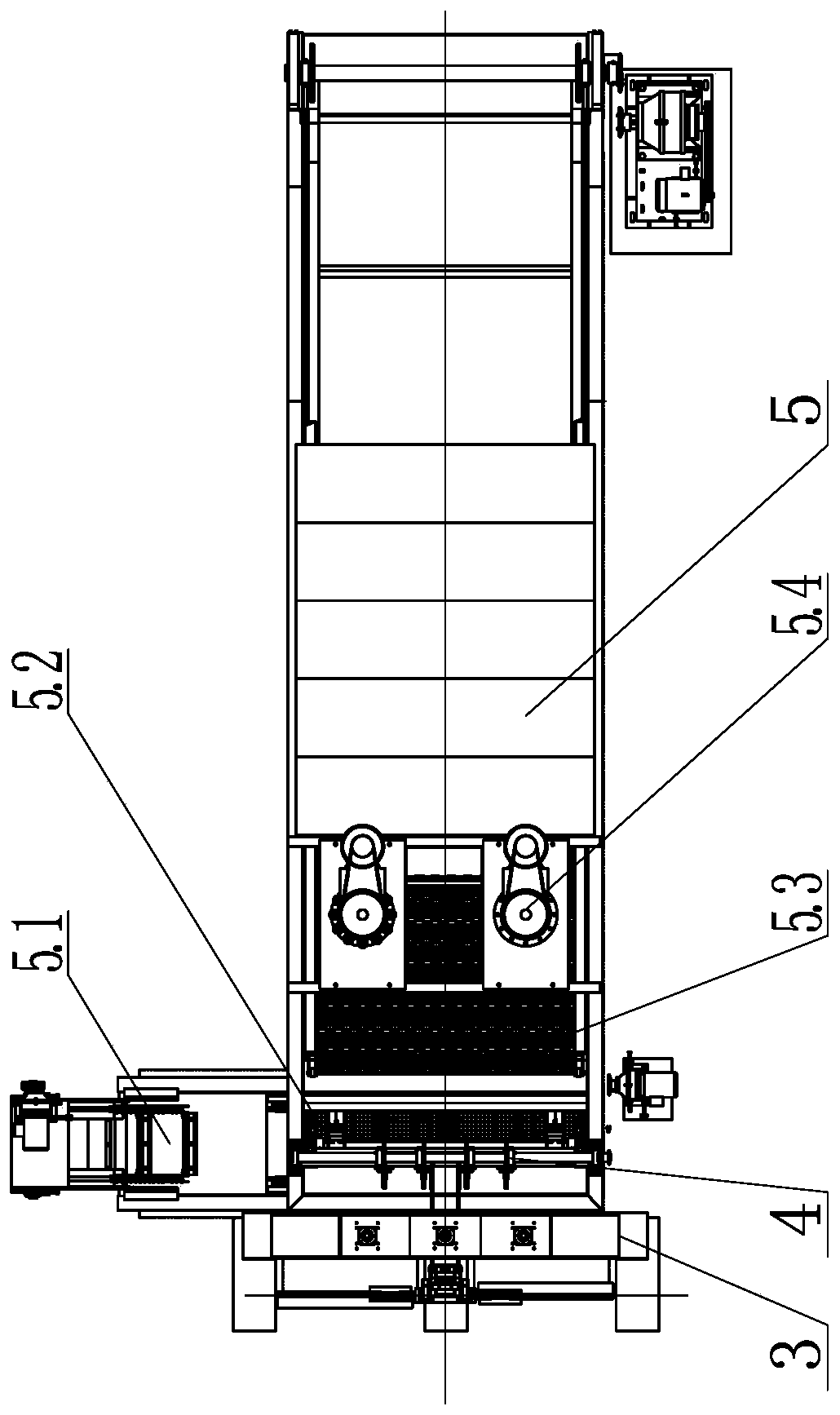

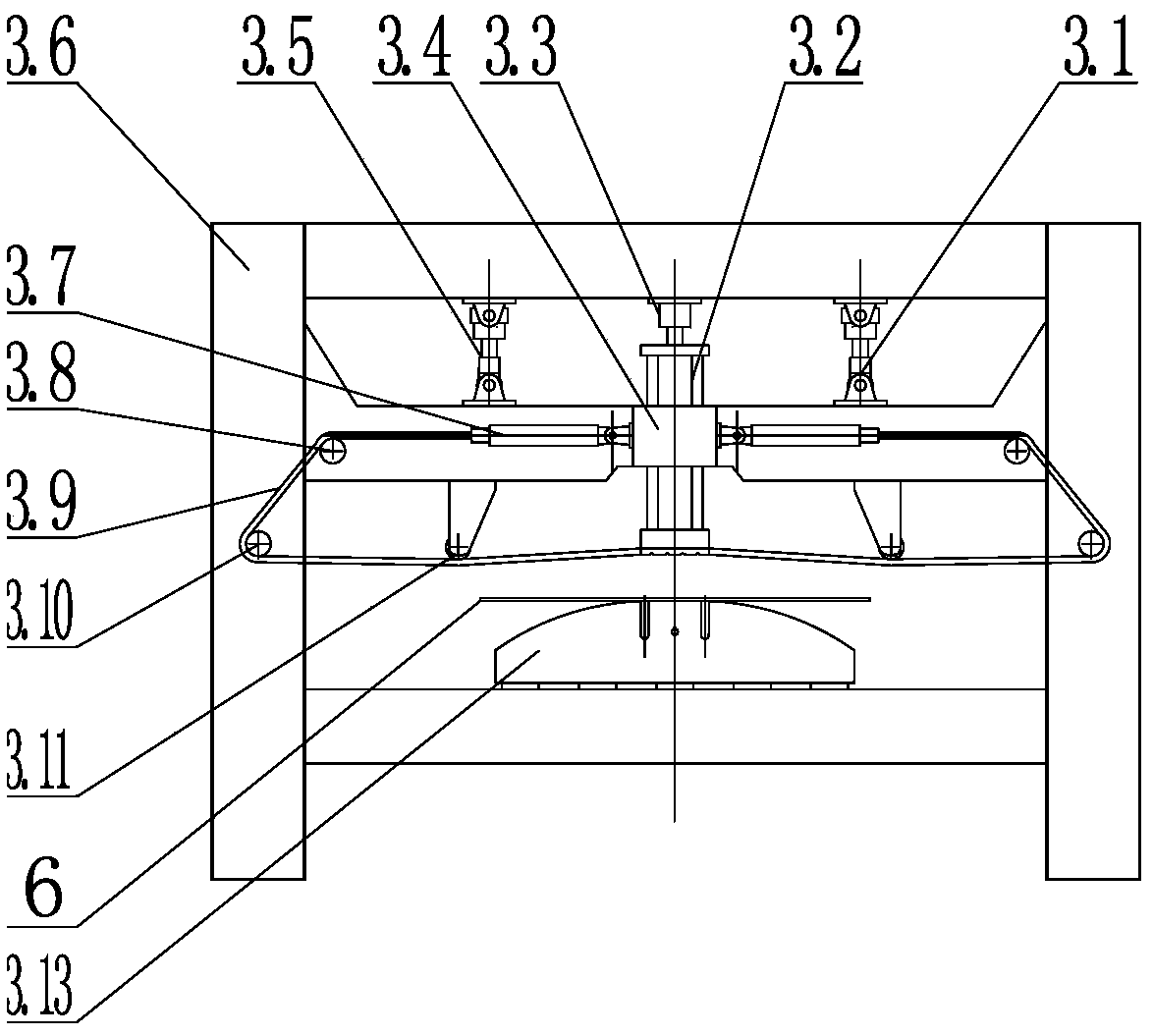

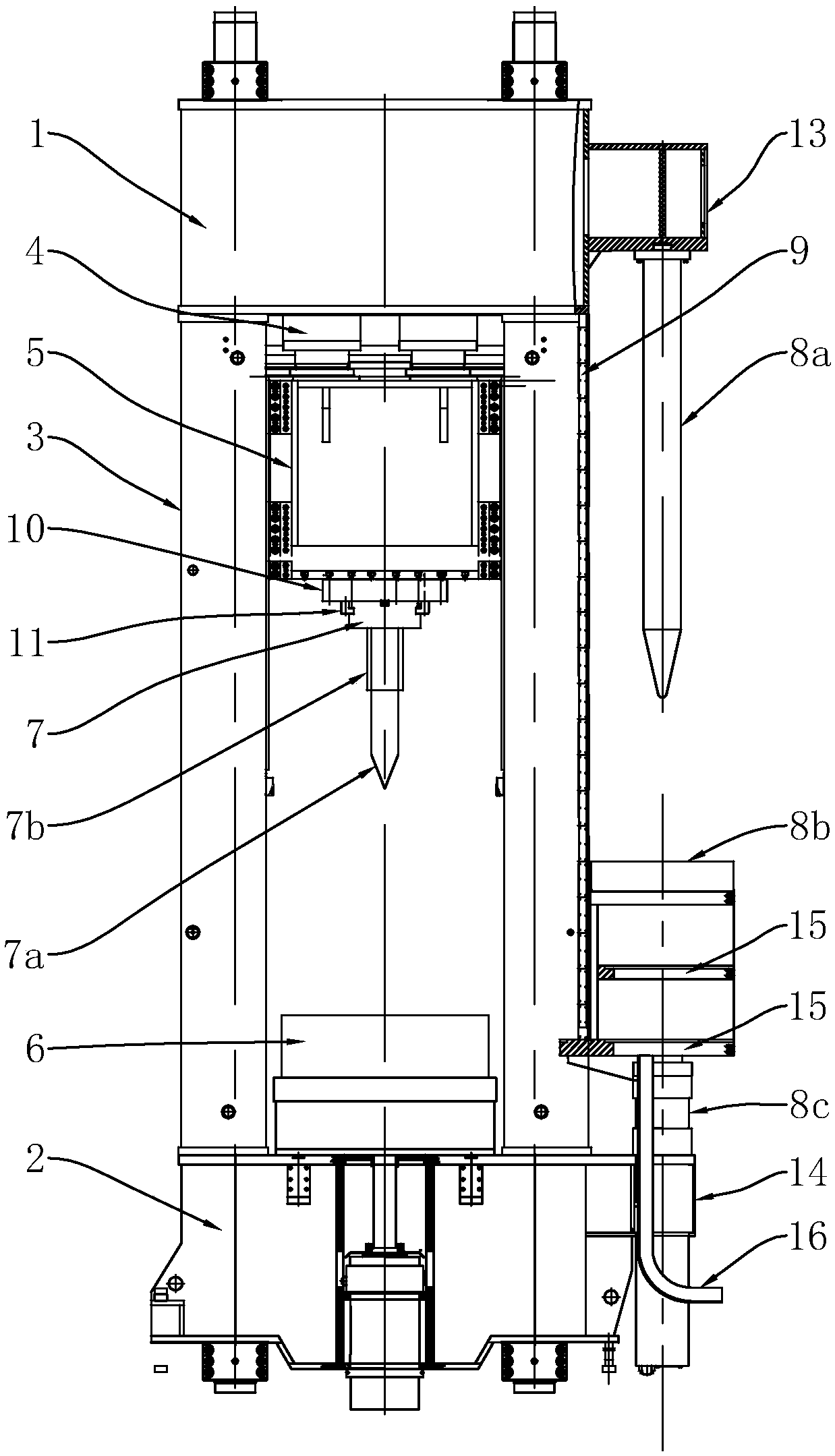

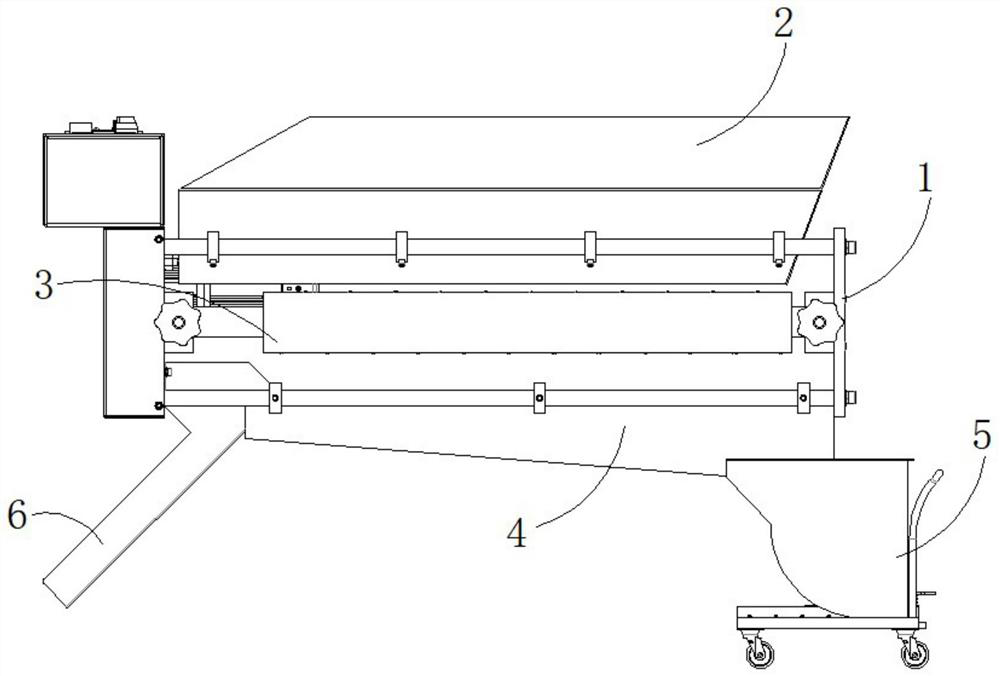

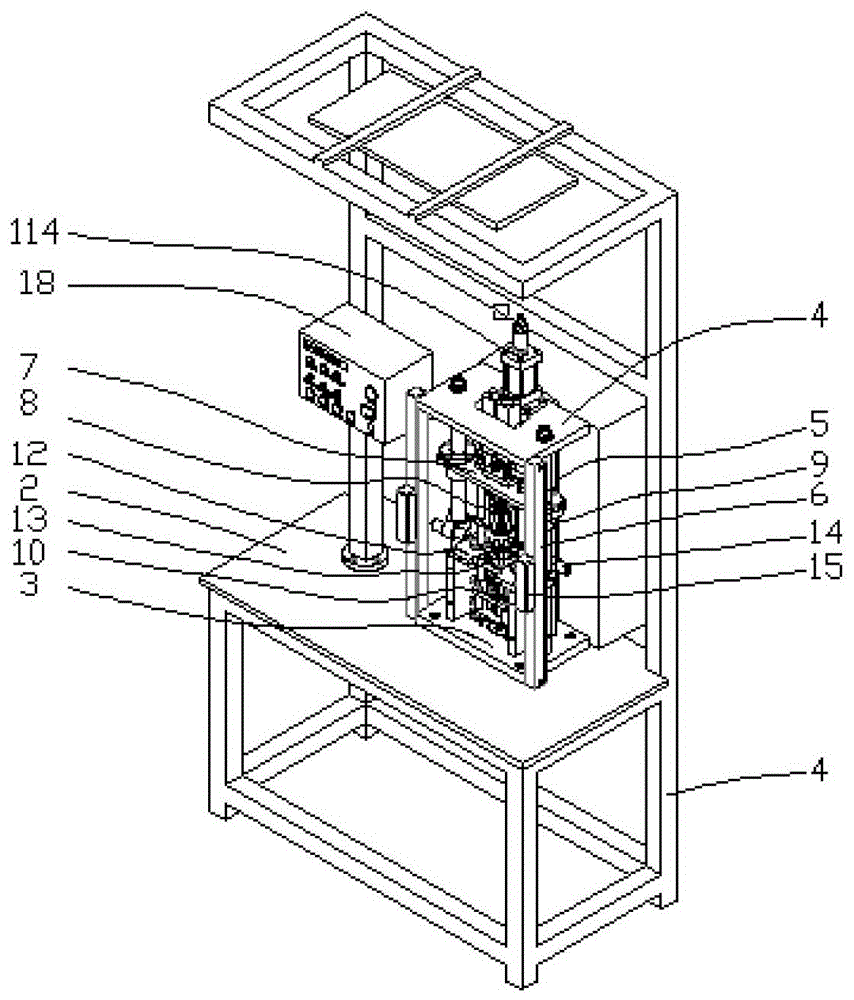

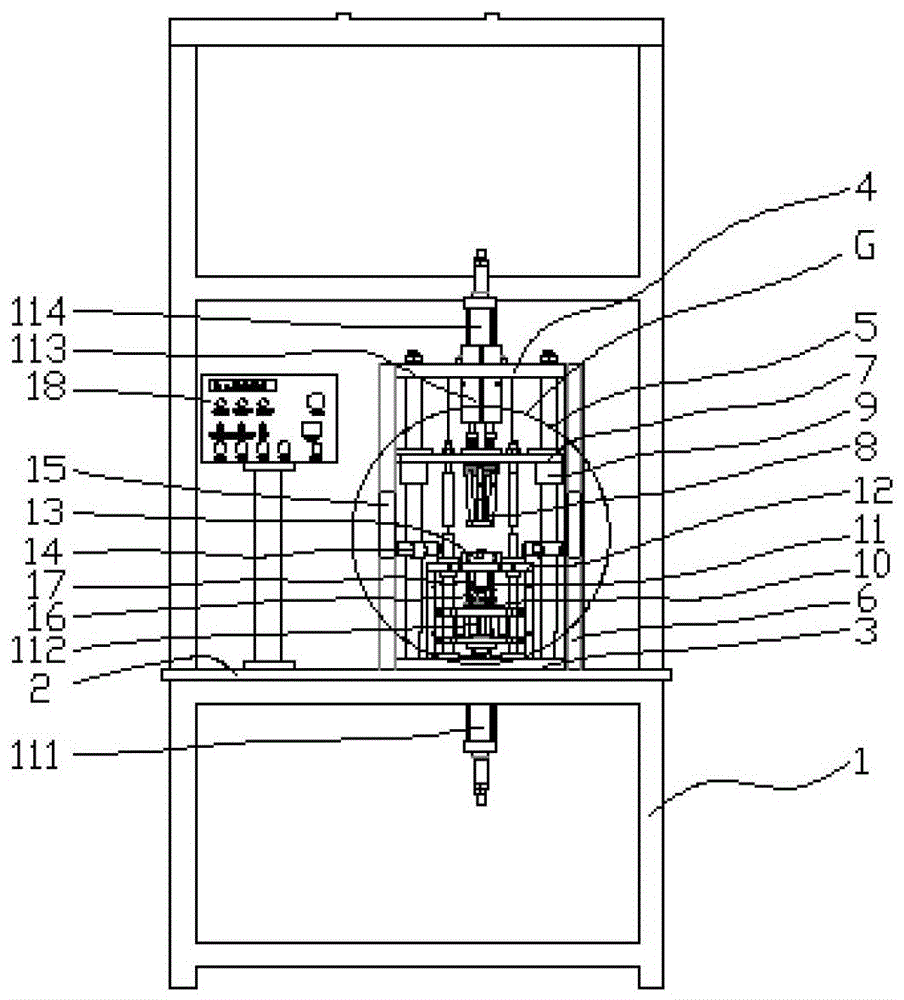

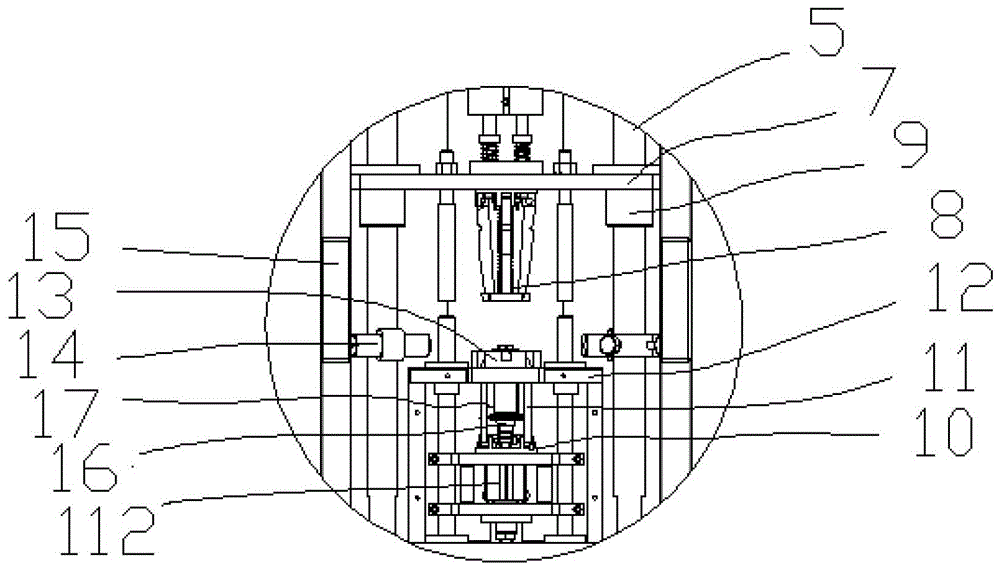

Automatic quenching production line

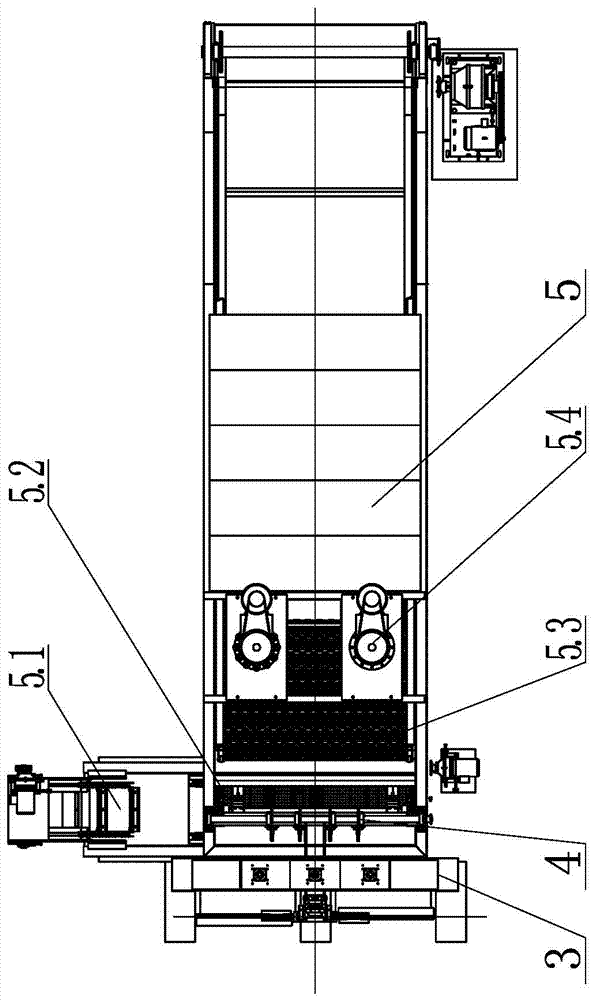

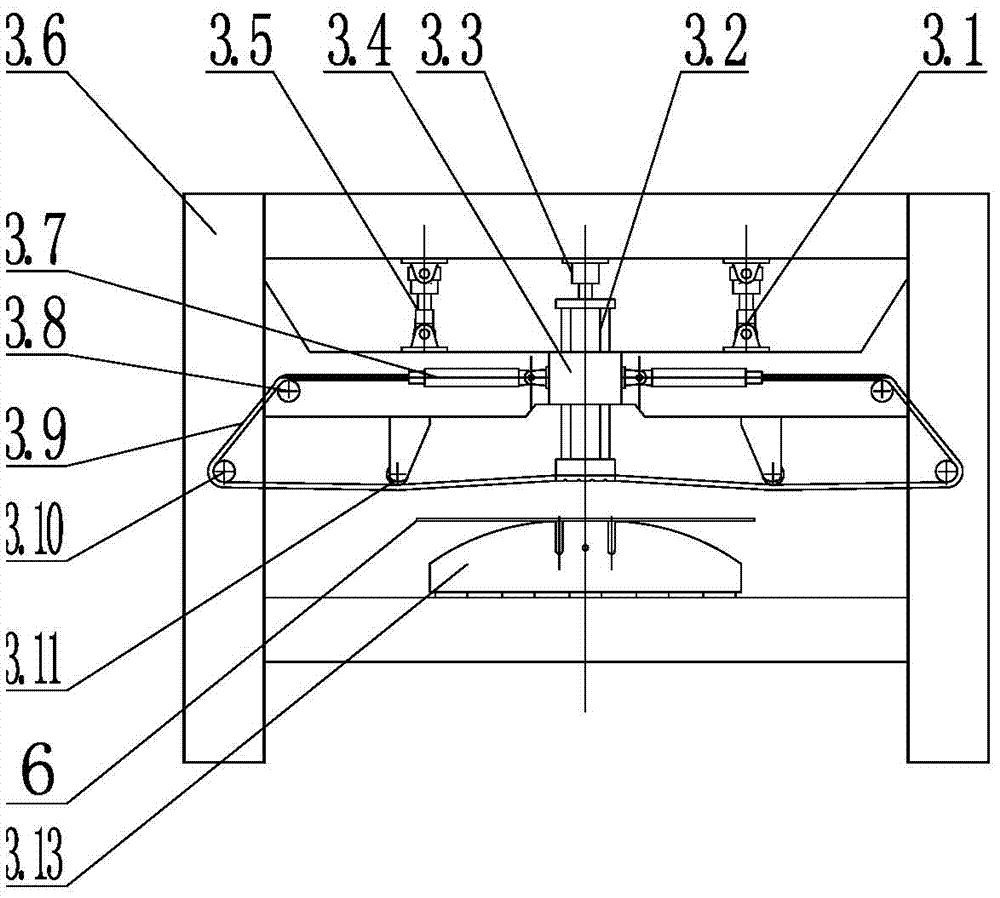

ActiveCN107287396AClosely connectedIncrease productivityFurnace typesHeat treatment furnacesProduction lineManipulator

The invention discloses an automatic quenching production line, and belongs to the field of plate spring shaping and heat treatment equipment. The automatic quenching production line is characterized by comprising a stepping type quenching furnace, a plate spring bending shaping device and a quenching pond. The stepping type quenching furnace is linked with the plate spring bending shaping device through a mechanical hand, and the plate spring bending shaping device is linked with the quenching pond through an oil inlet mechanism. The plate spring bending shaping device comprises a shaping machine frame, a feeding mechanism, a length alignment mechanism, a width alignment mechanism, a shaping device and a material supporting lifting mechanism; the feeding mechanism, the length alignment mechanism, the width alignment mechanism, the shaping device and the material supporting lifting mechanism are installed on the shaping machine frame. Heating, shaping and quenching operation of a plate spring can be automatically implemented, various working procedures are automatically and continuously executed, linage is compact, and the product production efficiency and the output quality are greatly improved.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

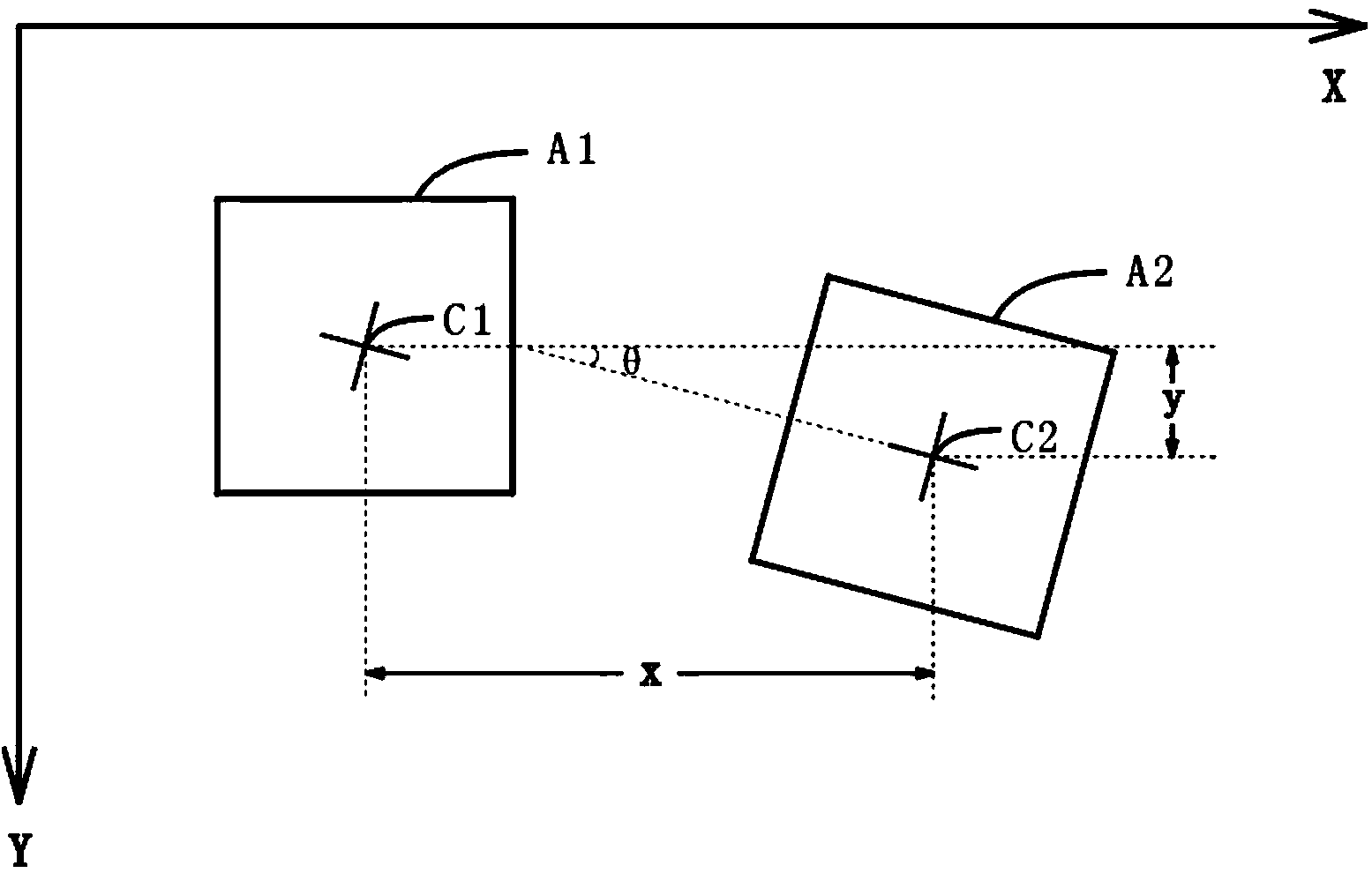

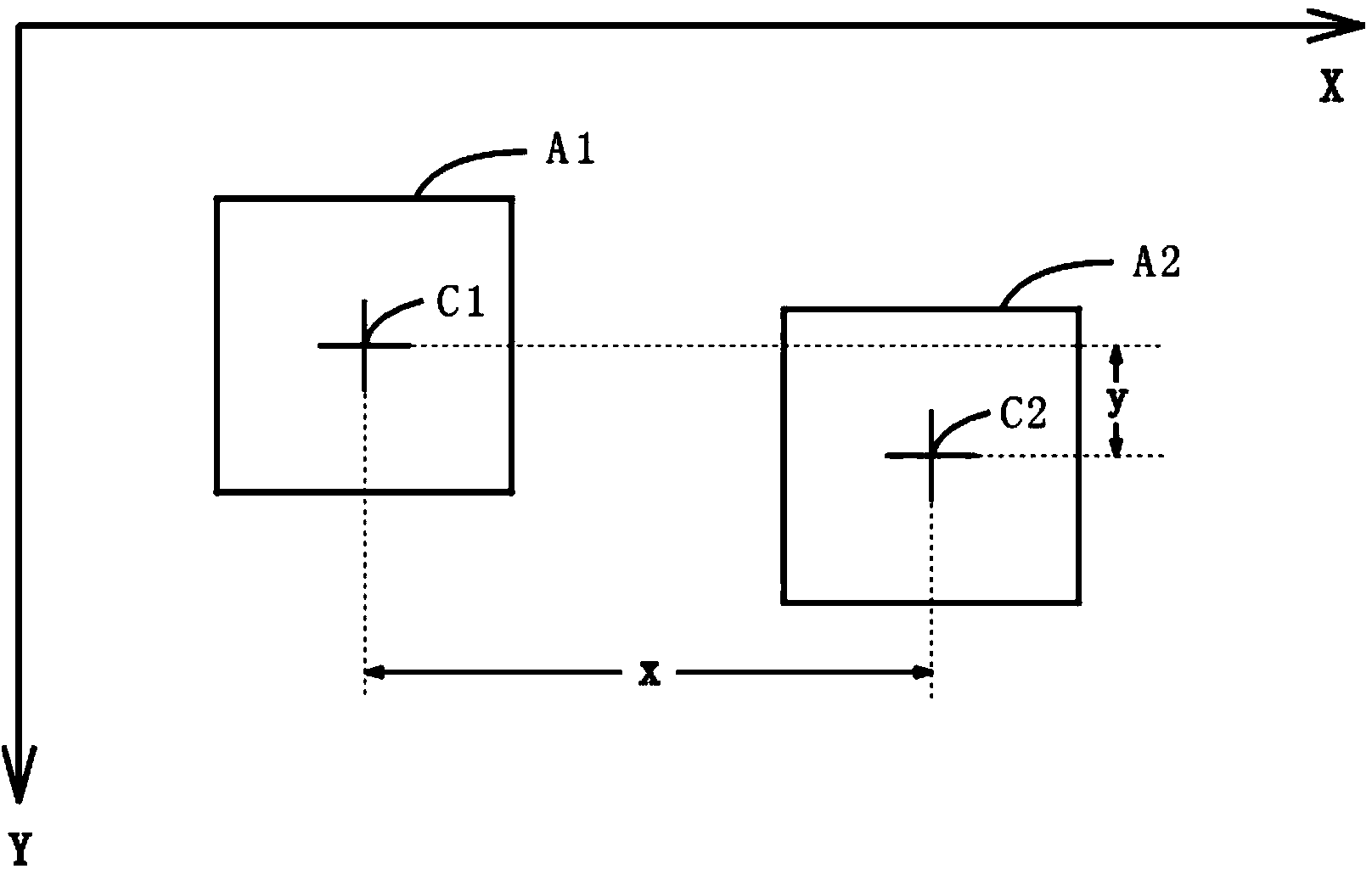

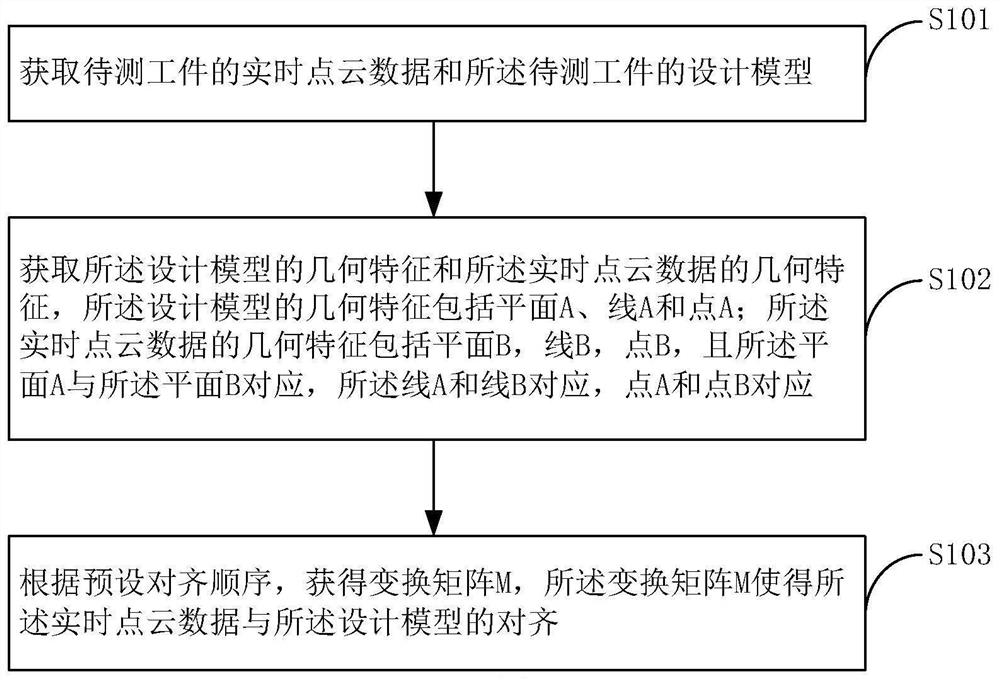

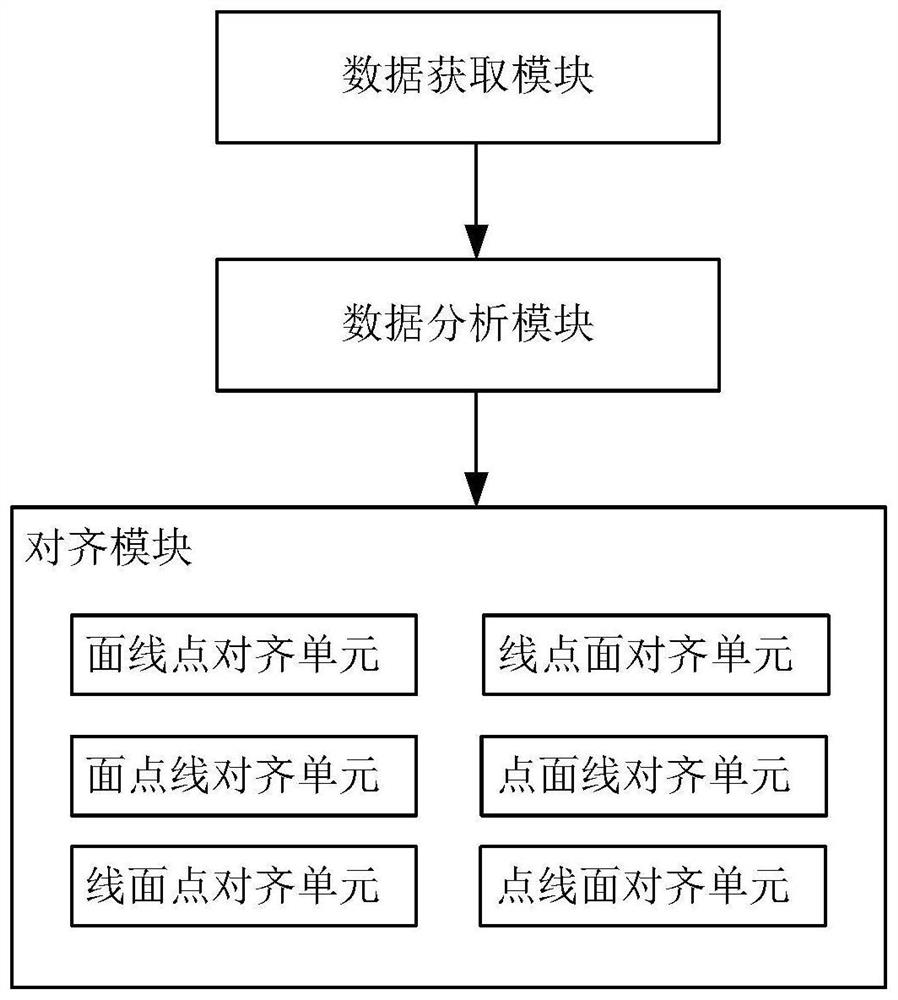

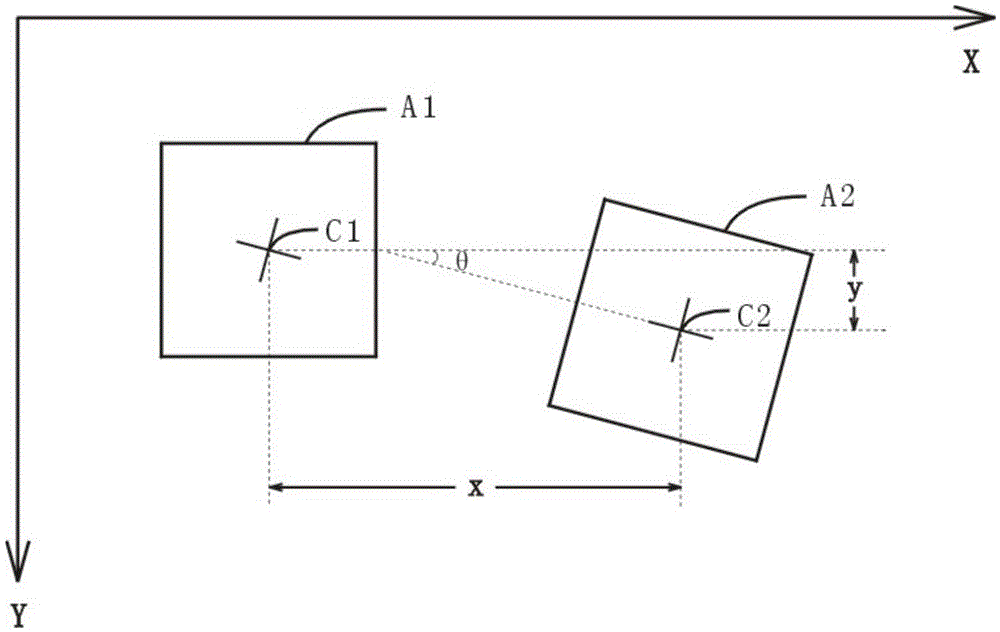

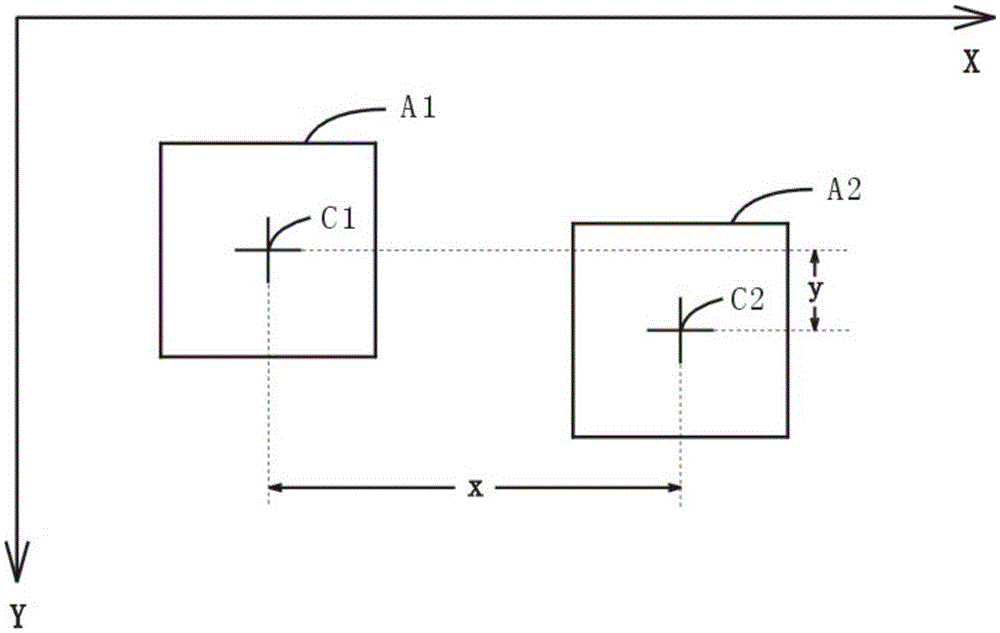

Digital-analog alignment method and device based on geometric features of points, lines and planes

PendingCN114596426AGuarantee the quality of the workpieceImprove detection efficiencyImage enhancementImage analysisTransformation matrixEngineering

The invention provides a digital-analog alignment method and device based on geometric features of points, lines and planes, and the method comprises the steps: obtaining geometric features of a design model of a to-be-measured workpiece and geometric features of real-time point cloud data of the to-be-measured workpiece, the geometric features of the design model comprising a plane A, a line A and a point A; the geometric features of the real-time point cloud data comprise a plane B, a line B and a point B, the plane A corresponds to the plane B, the line A corresponds to the line B, and the point A corresponds to the point B; according to a preset alignment sequence, a transformation matrix M is obtained, and the transformation matrix M enables the real-time point cloud data to be aligned with the design model. For different workpieces to be detected, digital-analog alignment is realized according to a preset alignment sequence, then the workpieces are measured and detected, full-coverage measurement, detection and the like of the workpieces are realized, the quality of the workpieces is ensured, and the detection efficiency is high.

Owner:深圳市凌云视迅科技有限责任公司 +1

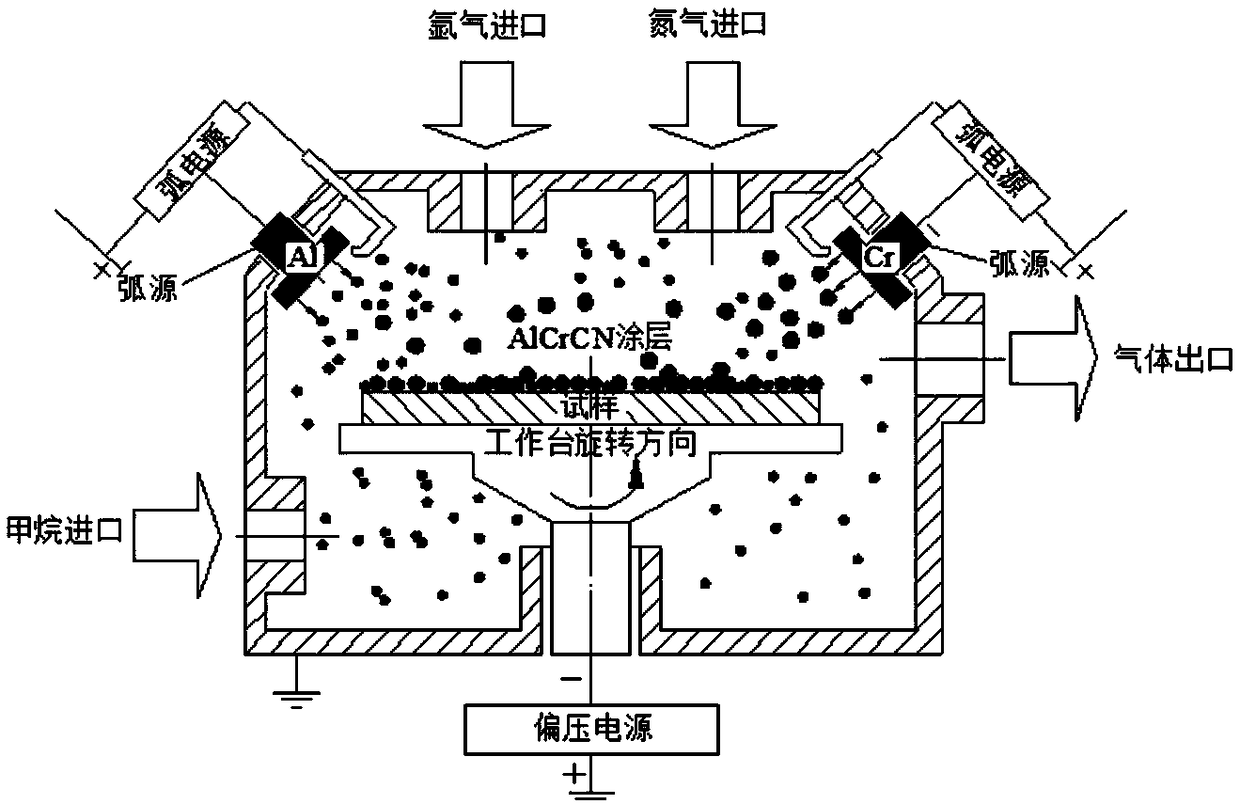

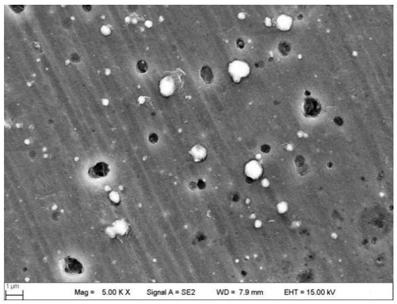

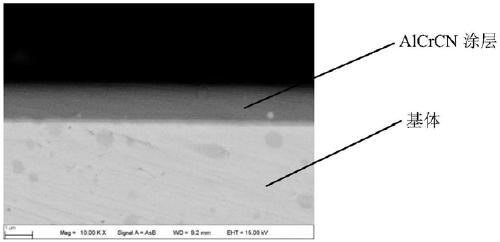

Method for preparing AlCrCN coating on surface of cold working die steel

InactiveCN109252140AClear precisionGood for maintaining accuracyVacuum evaporation coatingSputtering coatingMaterials preparationDeposition temperature

The invention discloses a preparation method for preparing an AlCrCN coating on the surface of a cold working die steel, and belongs to the technical field of material preparation, wherein the methodis scientific, and the preparation principle is clear. According to the present invention, ion plating is performed at a temperature of 500 DEG C, such that the deposition temperature cannot cause mold deformation, and the precision of the mold is easily maintained; the harness of the prepared coating is 3500 HV, such that the surface hardness of the mold is increased, the wear of the mold is reduced, and the quality of the processed work-piece is ensured; the AlCrCN coating and the substrate form the diffusion layer at the interface bonding position, and the elements of the diffusion layer are transitioned into the gradient, such that the bonding of the coating and the substrate is good; the amorphous C-C bond is formed in the AlCrCN coating, such that the self-lubricating effect is achieved so as to effectively reduce the friction factor; and the AlCrCN coating has advantages of ultra-high hardness, low friction factor, wear resistance and the like so as to further improve the surface hardness of the cold working die steel and prolong the service life by 3-5 times.

Owner:YANGZHOU UNIV +1

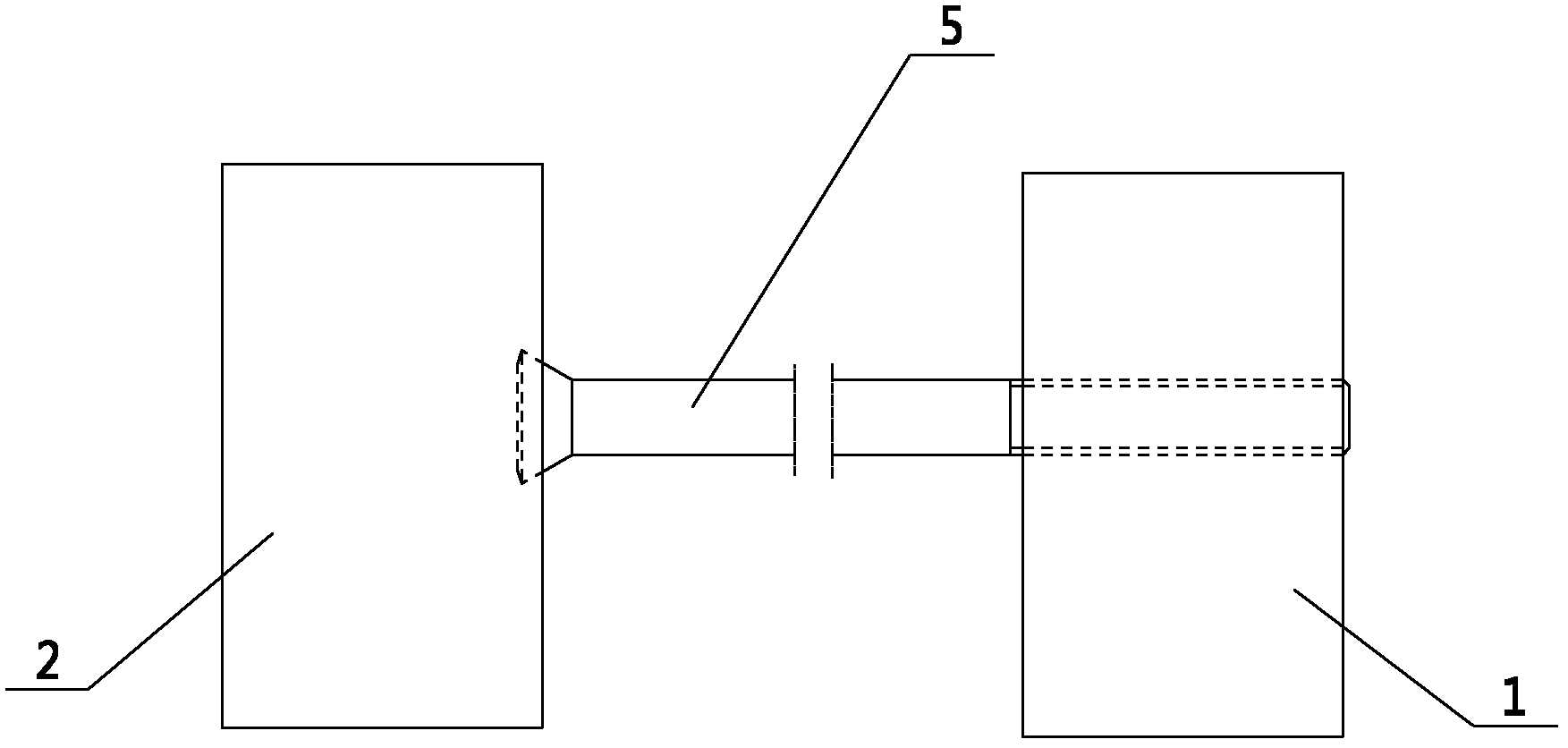

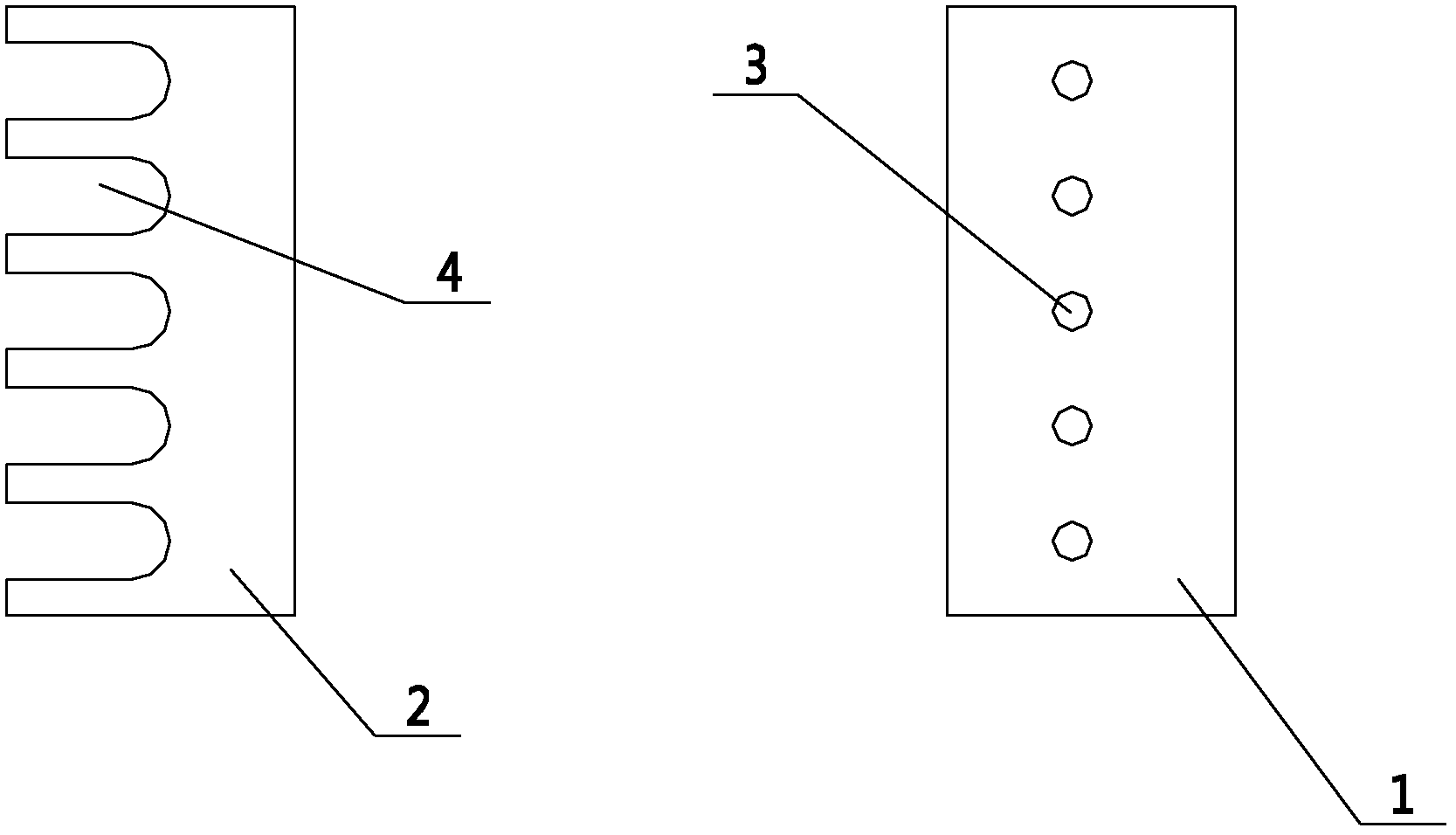

Clamp for machining of electrode and manufacturing method of clamp

InactiveCN102672295AEasy to processEasy to preparePositioning apparatusMetal-working holdersMachiningWorkbench

The invention discloses a clamp for machining of electrodes. The clamp comprises a first clamp body and a second clamp body, which are fixed on a work bench, wherein a plurality of fixation holes are uniformly distributed at equal intervals on the first clamp body, U-shaped slots are formed on the second clamp body and in the positions corresponding to the fixation holes, and the axis of each fixation hole and the axis of the corresponding U-shaped slot are co-linear and are parallel to the work bench. During the fabrication of the clamp, firstly equal division lines are drawn on a blank and cut at a certain depth, and then the blank is cut into two clamp bodies from the middle and the first and the second clamp bodies are machined respectively according to the equal division lines after cutting. When the clamp for machining of electrodes is used, the clamp effectively ensures the coaxiality and consistency of work pieces to be processed and improves the machining precision of work pieces, can machine multiple work pieces at the same time, and can not only increase the machining efficiency but also ensure the quality of work pieces and exchangeability of multi-cavity moulds. Besides, the clamp for machining of electrodes has a simple machining method, is easy to fabricate and is low in cost.

Owner:SUZHOU YAER PLASTIC TECH

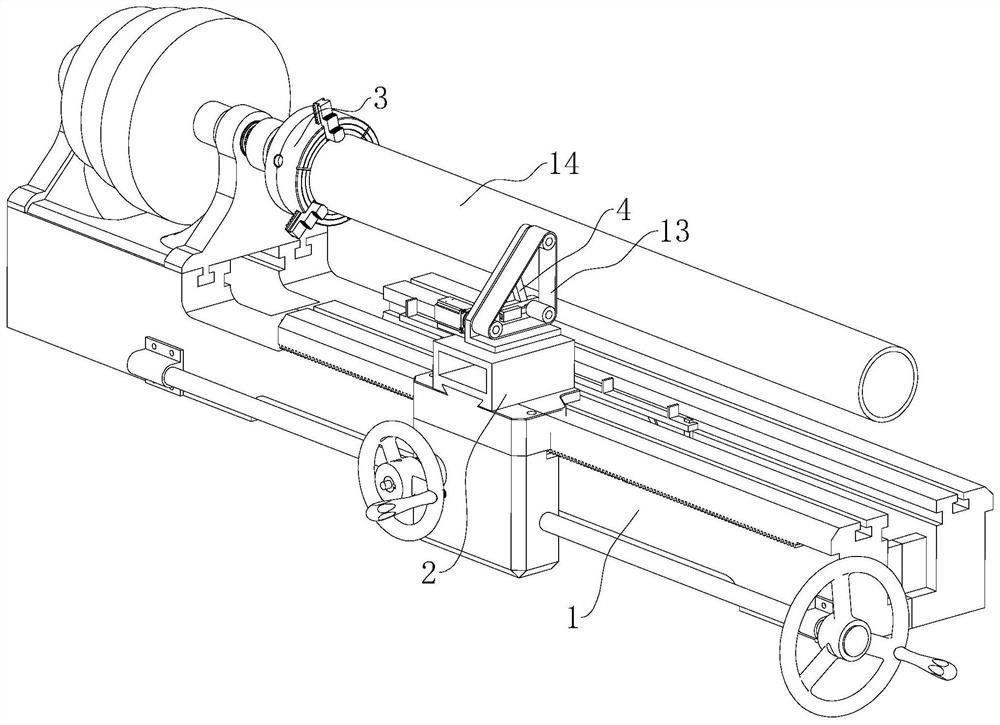

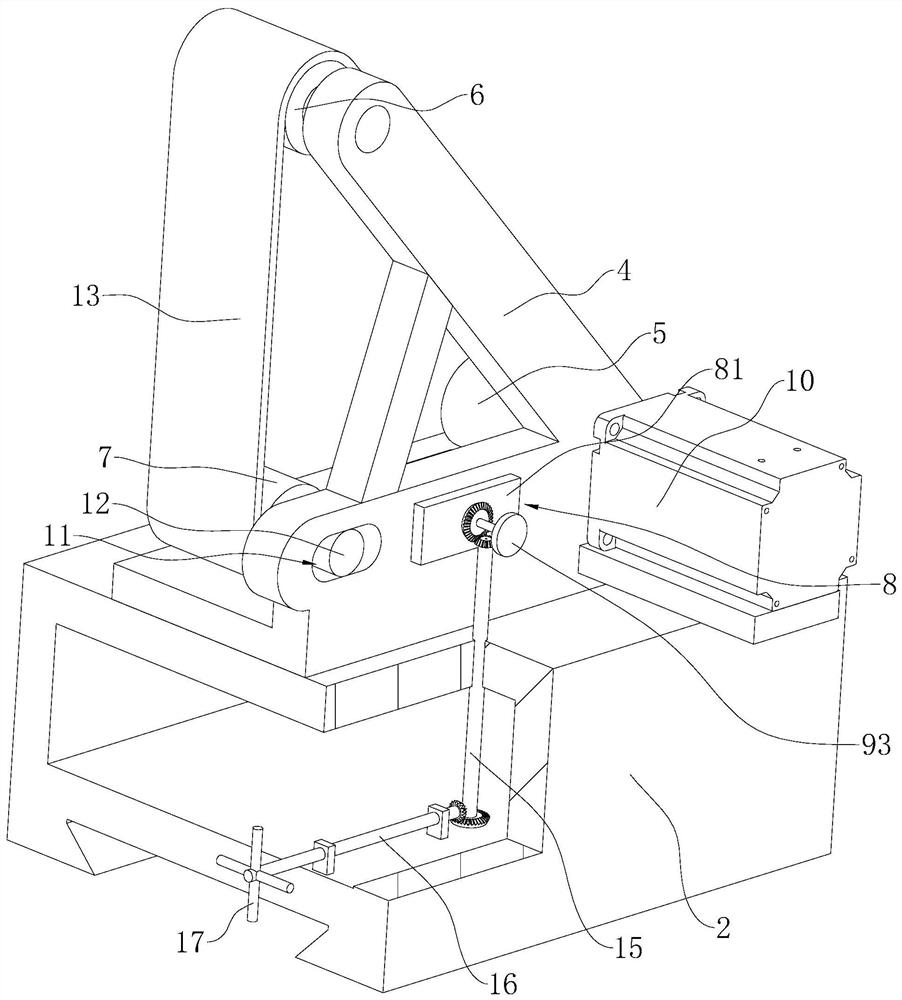

Grinding mechanism of common lathe

The invention relates to a grinding mechanism of a common lathe. The grinding mechanism comprises a support arranged on a cutter pedestal, wherein a driving wheel and a driven wheel are rotationally connected to the support, and a motor connected with the driving wheel is arranged on the support; an abrasive belt is connected to the exterior of the driving wheel and the exterior of the driven wheel in a sleeving mode; a tensioning wheel is rotationally connected to the support, the outer wall of the tensioning wheel abuts against the abrasive belt, and the tensioning wheel is rotationally connected with a rotating shaft; a sliding groove for the rotating shaft to penetrate through and slide is formed in the support; and a transmission piece for driving the rotating shaft to slide is arranged on the support. The grinding mechanism has the effects that the grinding effect on a workpiece is improved, and the quality of the produced workpiece is guaranteed.

Owner:上海易新冶金设备制造有限公司

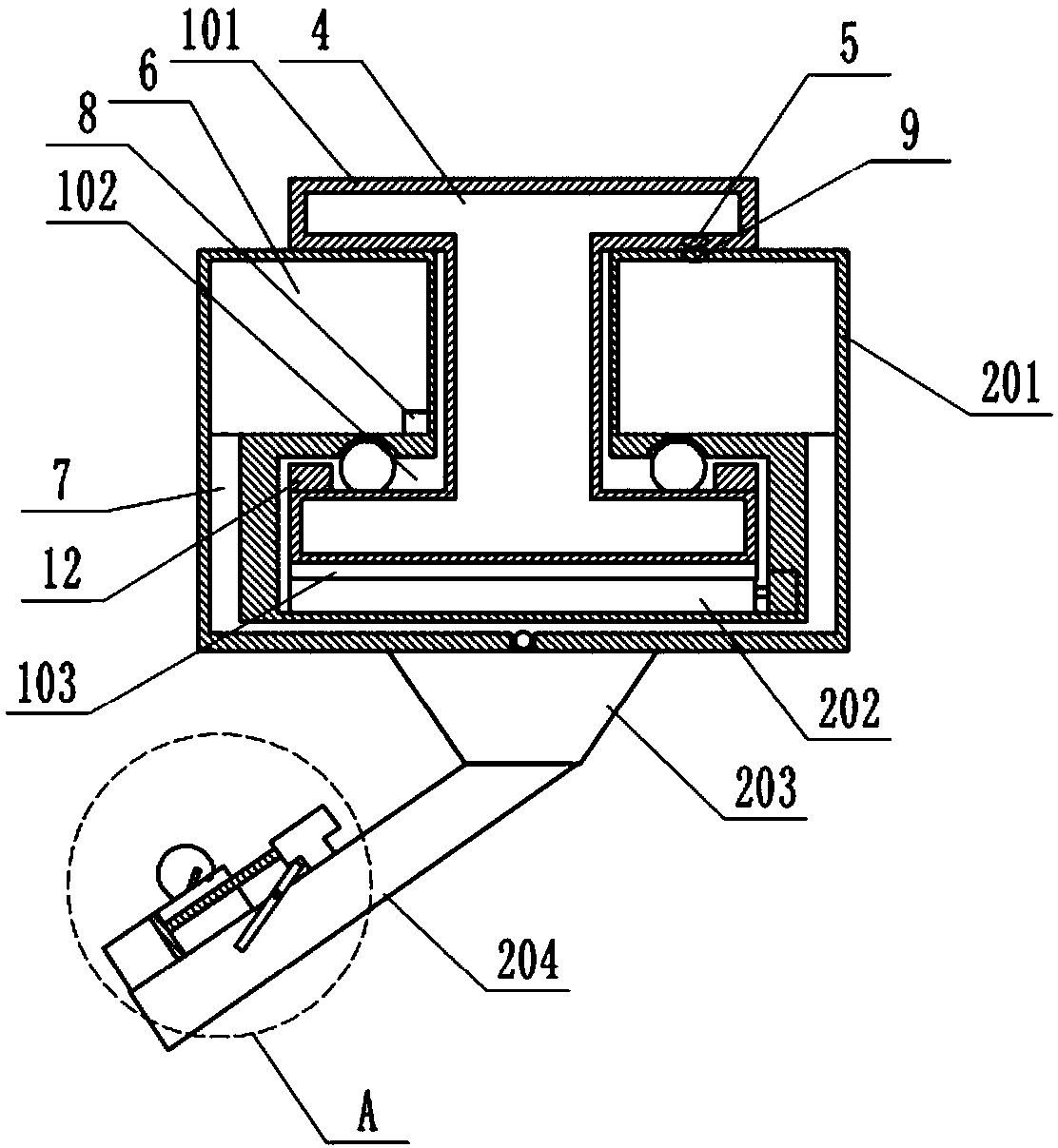

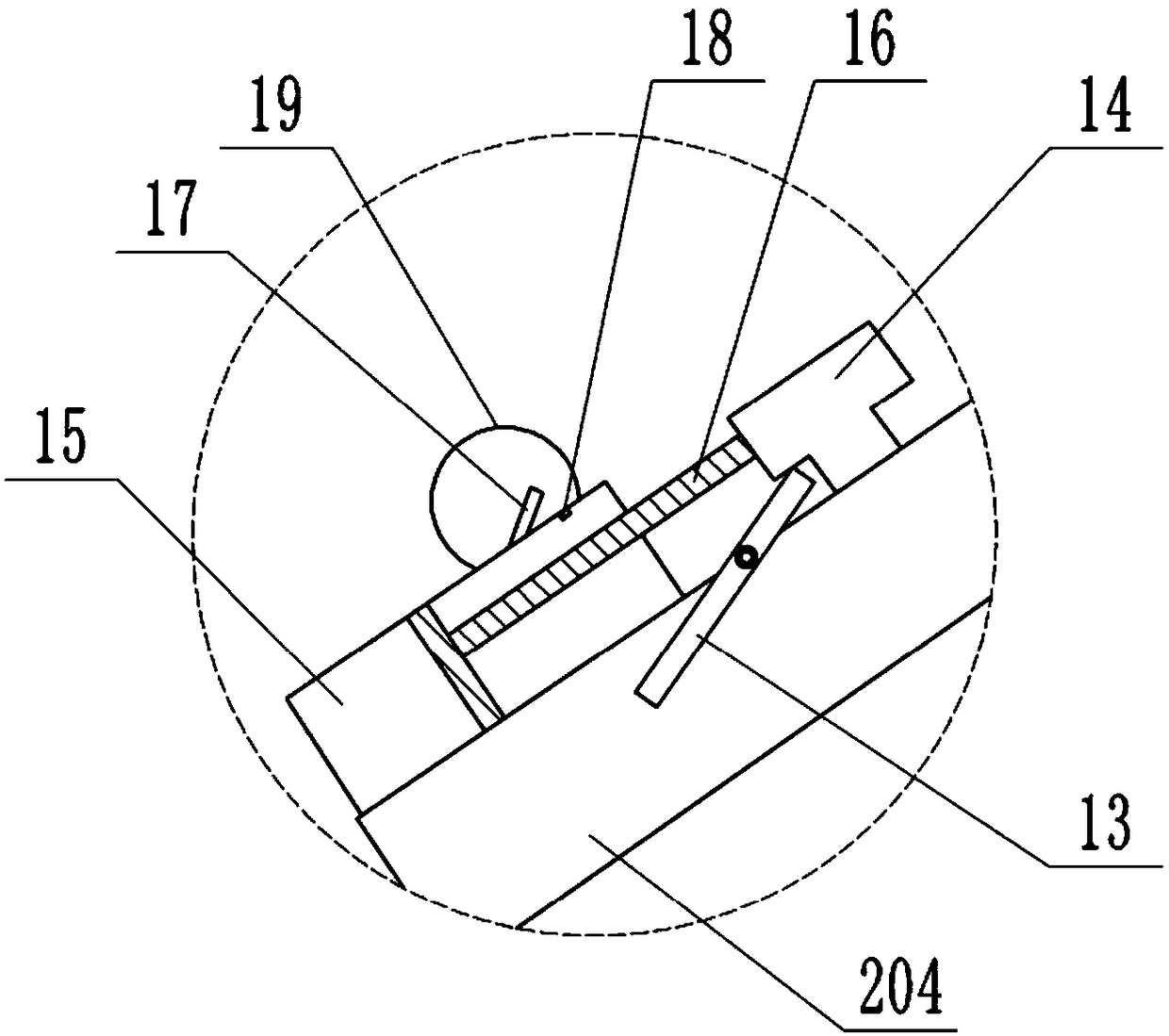

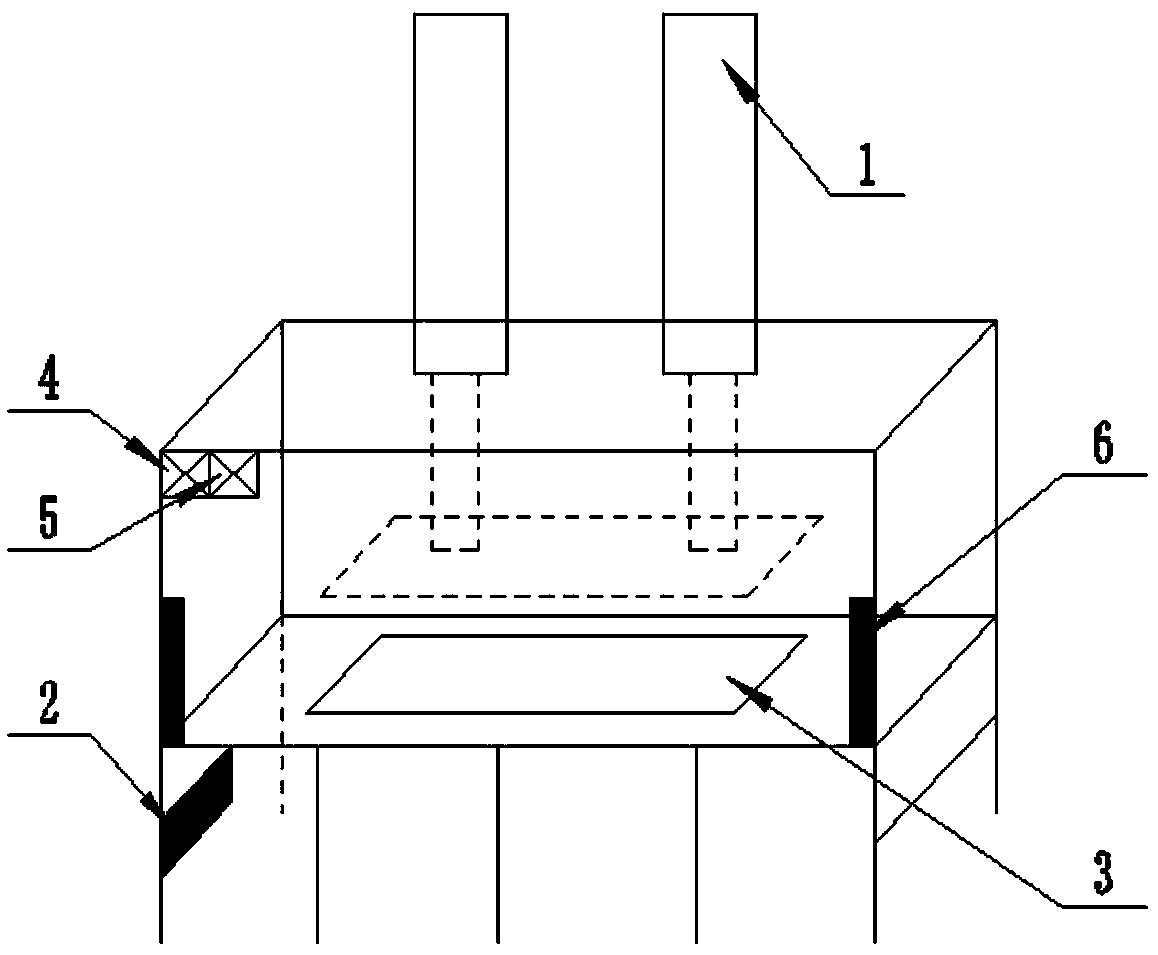

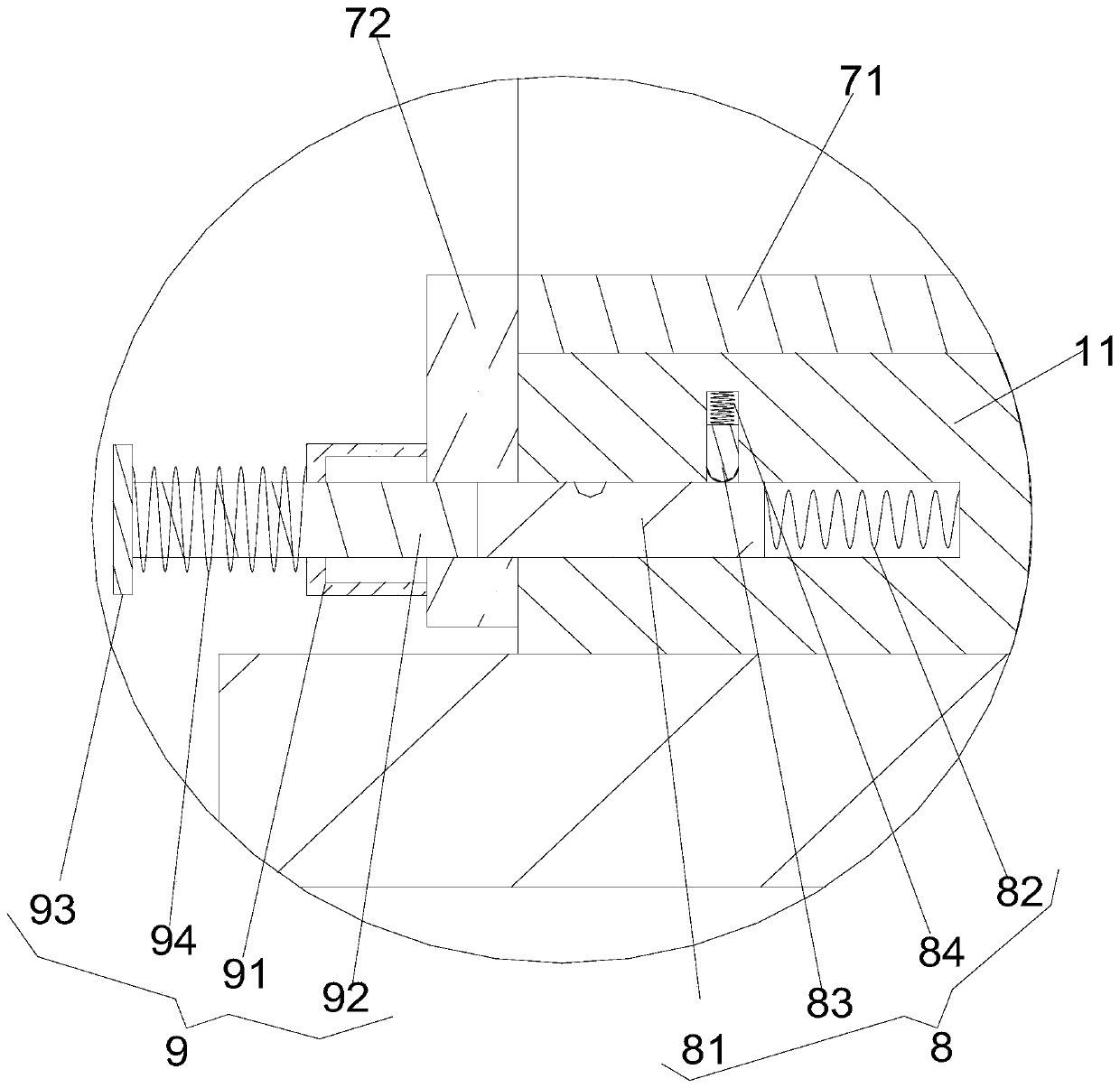

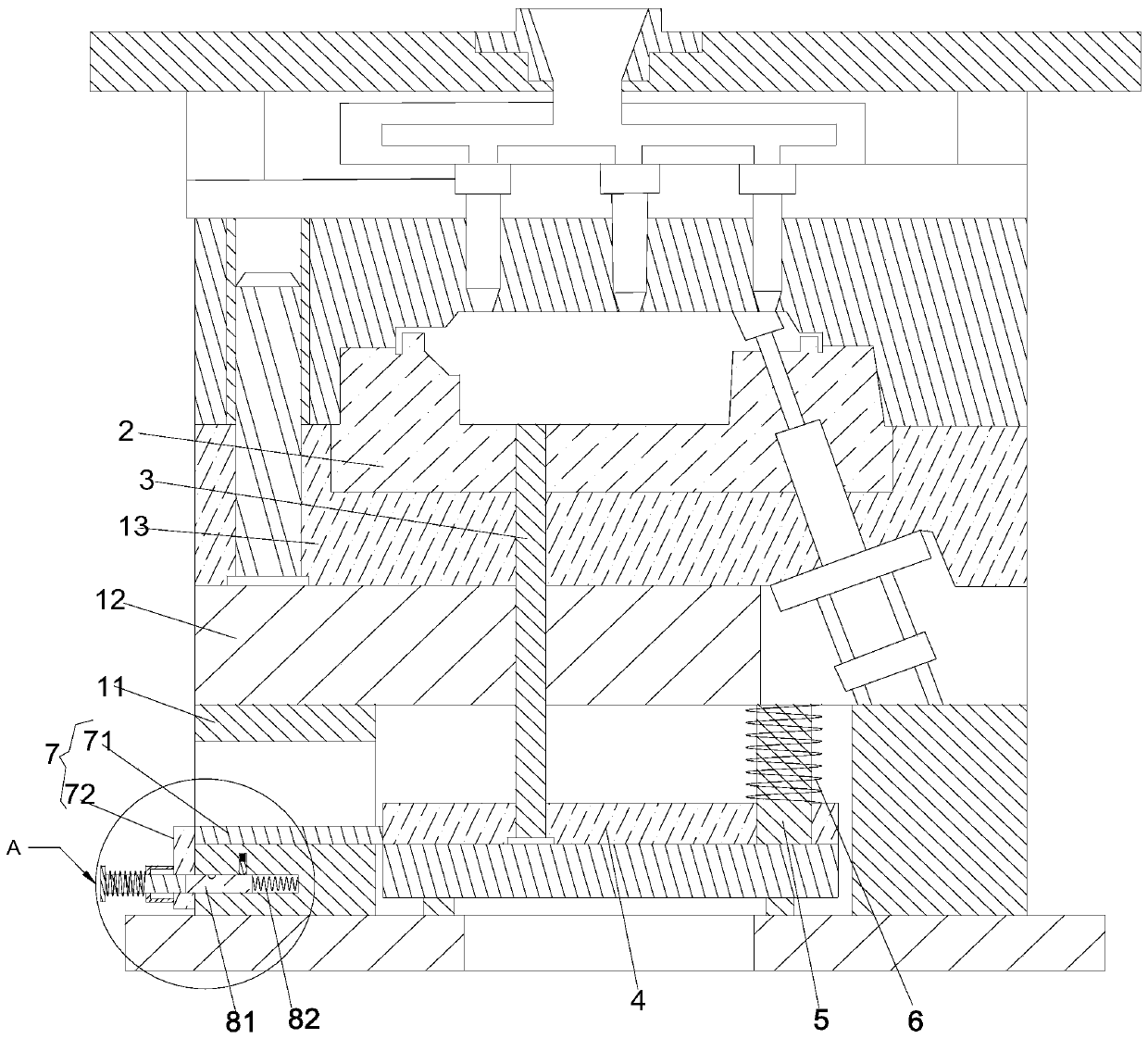

Workpiece detecting mechanism

InactiveCN106824814ARealize detectionGuarantee the quality of the workpieceSortingEngineeringMechanical engineering

The invention relates to a workpiece detection mechanism, which is used to detect the quality of workpieces, which includes a frame body and a first conveyor belt arranged on the frame body, one end of the first conveyor belt is a feed end, and the other end is a discharge end, wherein the first A conveyor belt is provided with a weight sensor near the discharge end. One side of the weight sensor is provided with a push-out device, and the other side is provided with a second conveyor belt. The installation direction of the second conveyor belt is perpendicular to the first conveyor belt. The present invention cooperates with the push-out device and the conveying belt by the weight sensor, conveniently realizes the detection of workpiece quality, can automatically reject unqualified products, and can directly transmit qualified products and unqualified products separately, ensuring the quality of workpieces ,Improved work efficiency.

Owner:雷世英

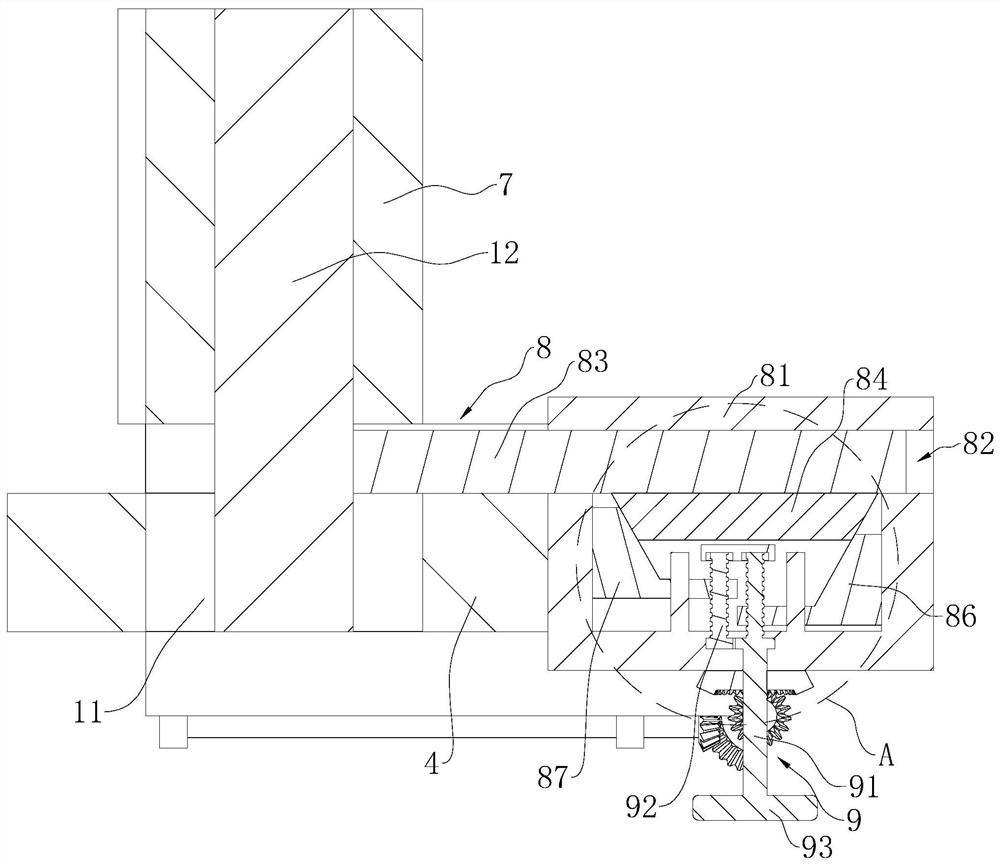

Drilling equipment for drilling lower bracket for reaction rod in dumper bodies

InactiveCN104439421ASimple structureAvoid human errorPositioning apparatusMetal-working holdersHuman errorDrill

The invention discloses drilling equipment for drilling a lower bracket for a reaction rod in dumper bodies. The drilling equipment comprises a drilling rig and a compressing mechanism. The compressing mechanism comprises support bars, compressing plates and screws; the drilling jig comprises a bottom plate, a positioning unit and a supporting unit; the positioning unit comprises positioning support plates, limiting plates and bearers; the positioning support plates are fixed on the bottom plate; the limiting plates are connected with the positioning support plates through connecting plates; each bearer is disposed on the top of each connecting plate; the supporting unit comprises supports and a carrier plate fixed on the supports; a drilling jig plate is mounted at the tops of the supports and is provided with a drilling jig hole; the support bars are disposed on one side of the drill rig; one end of each compressing plate is fixed to the corresponding support bar; the other end of each compressing plate is provided over the corresponding bearer; the compressing plates are connected with the bottom plate through the screws; a compressing nut is disposed over each screw and attaches to the corresponding compressing plate. The drilling equipment is simple in structure and allows drilling to be finished just after manual clamping, human errors are avoided, workpiece quality is guaranteed, and work efficiency is effectively improved.

Owner:LIUZHOU JIELONG AUTO PARTS MFG

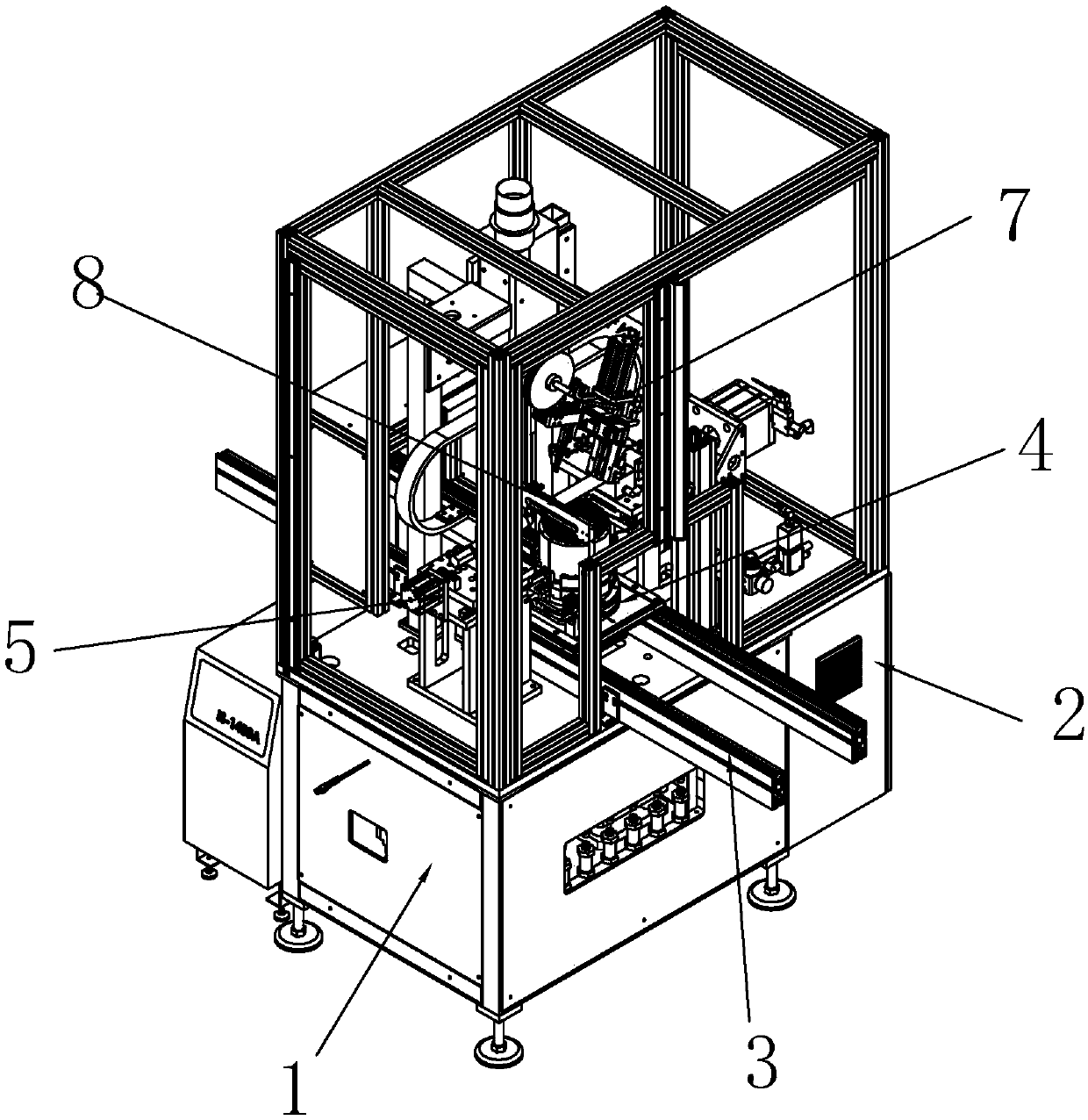

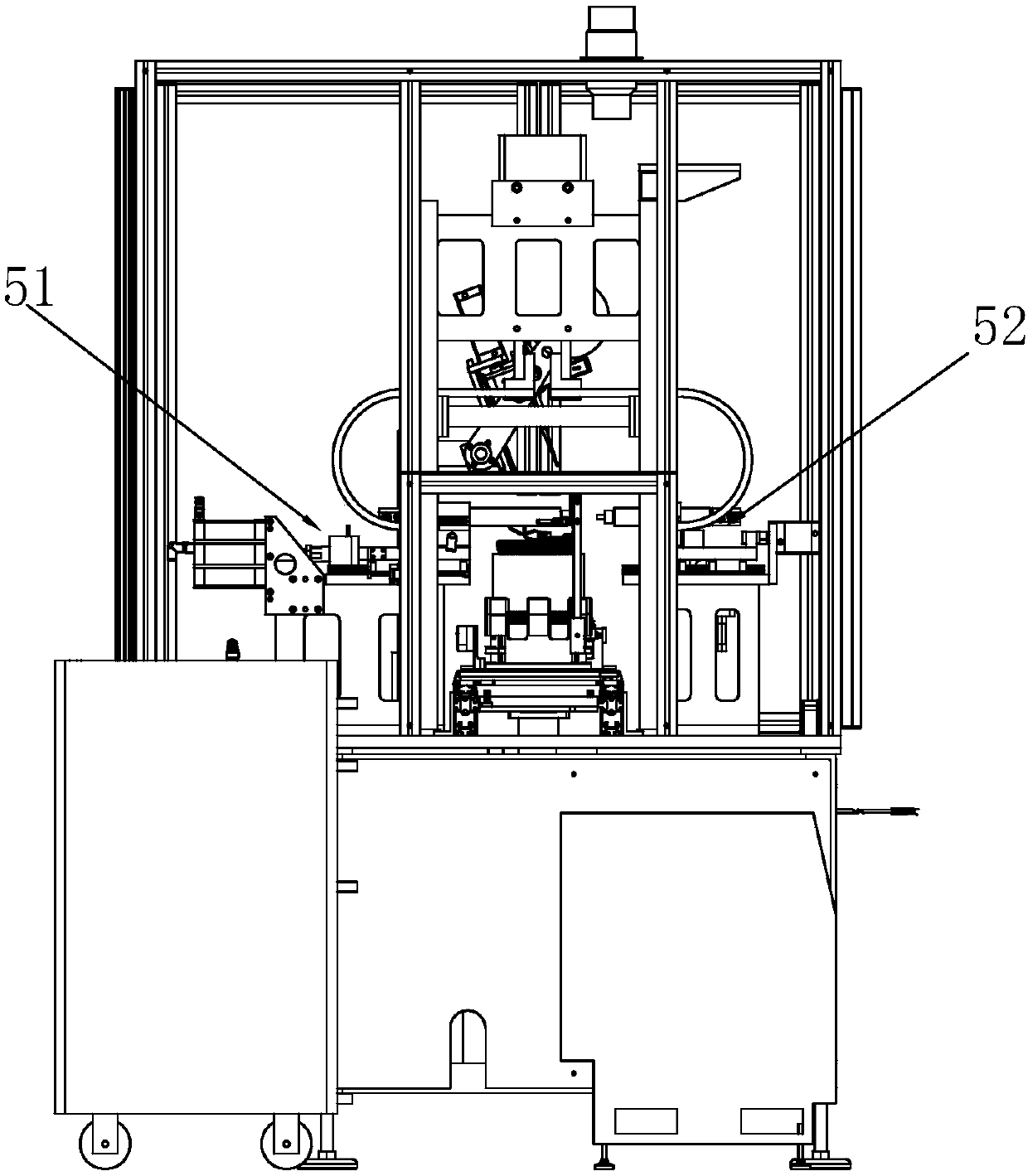

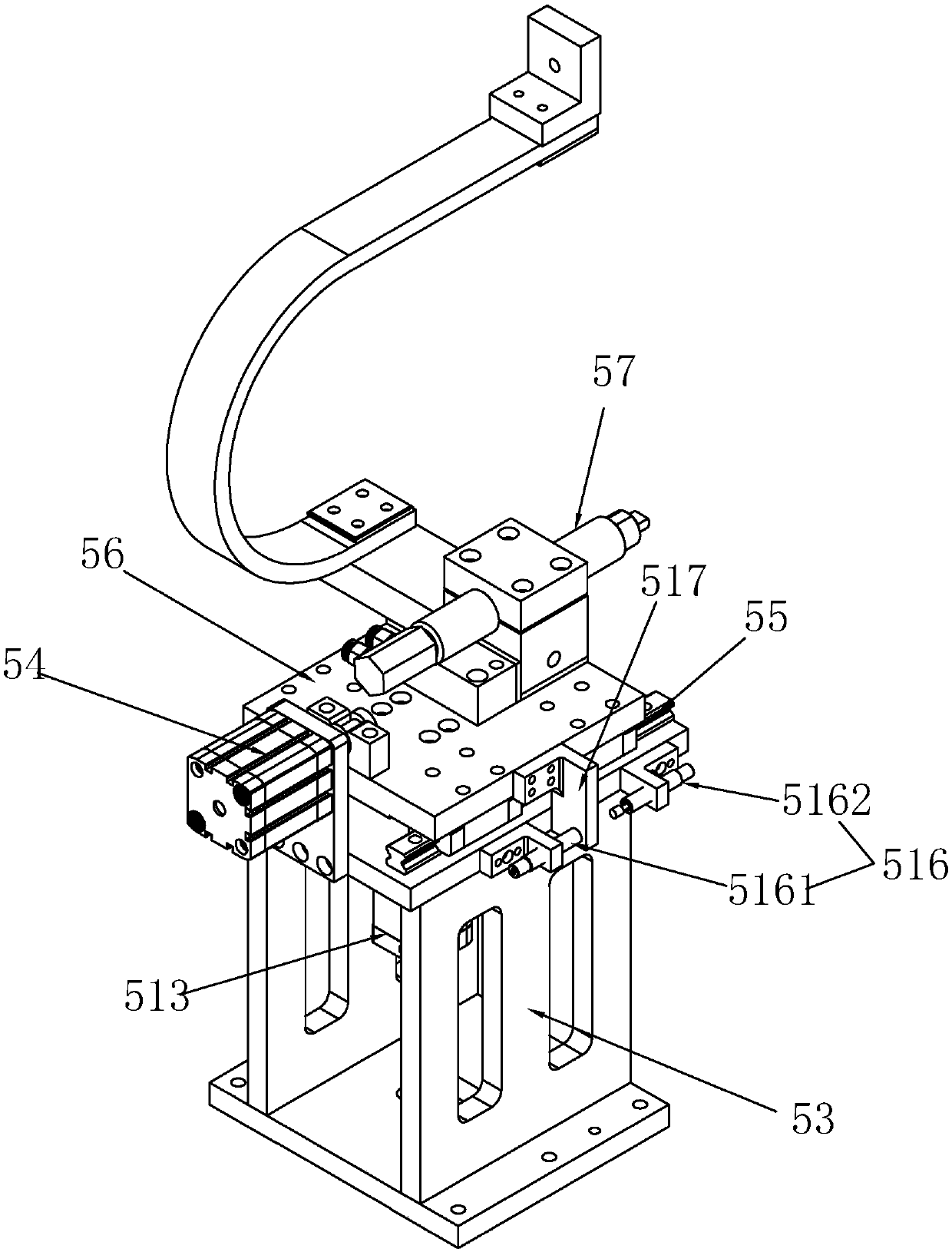

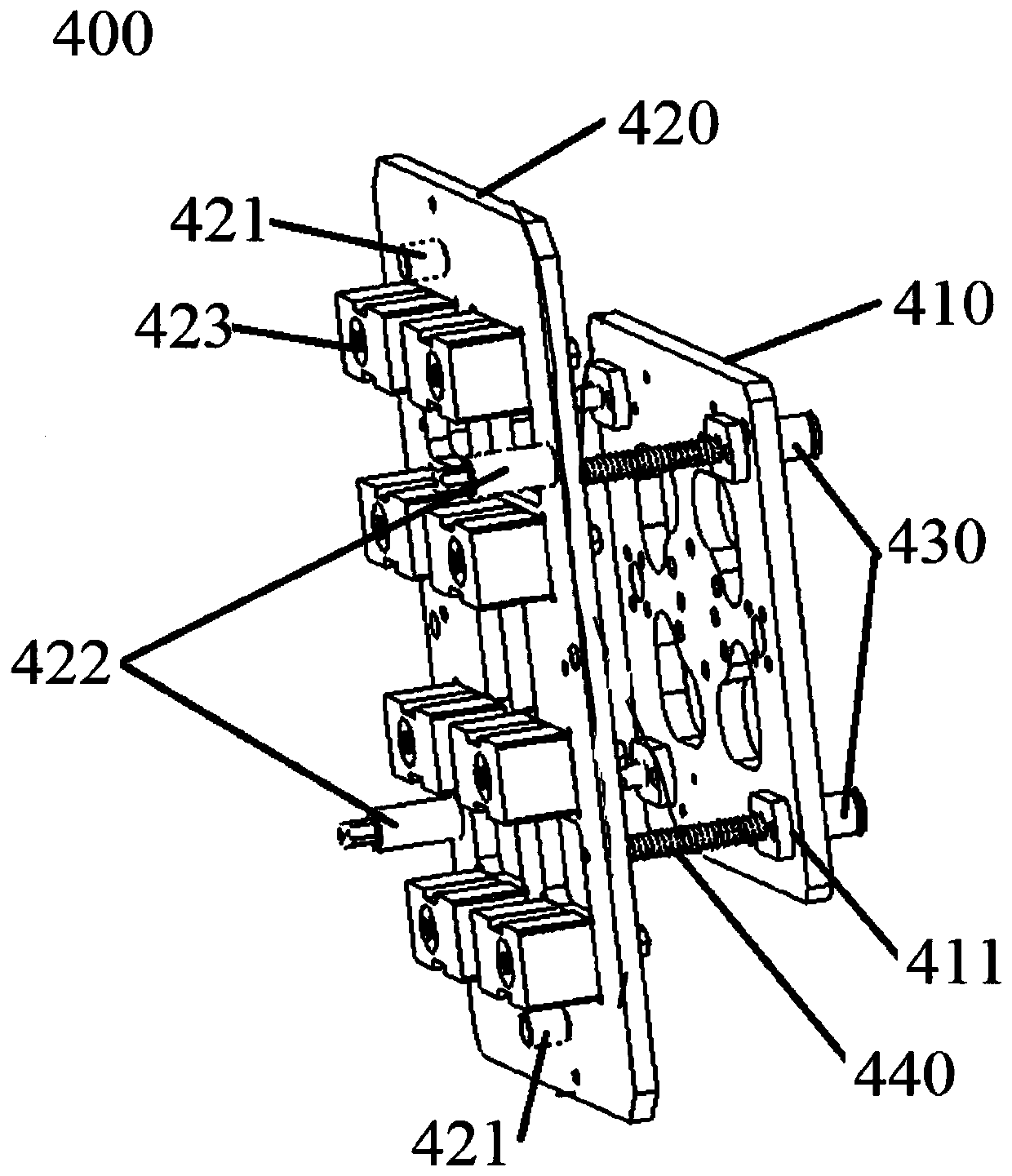

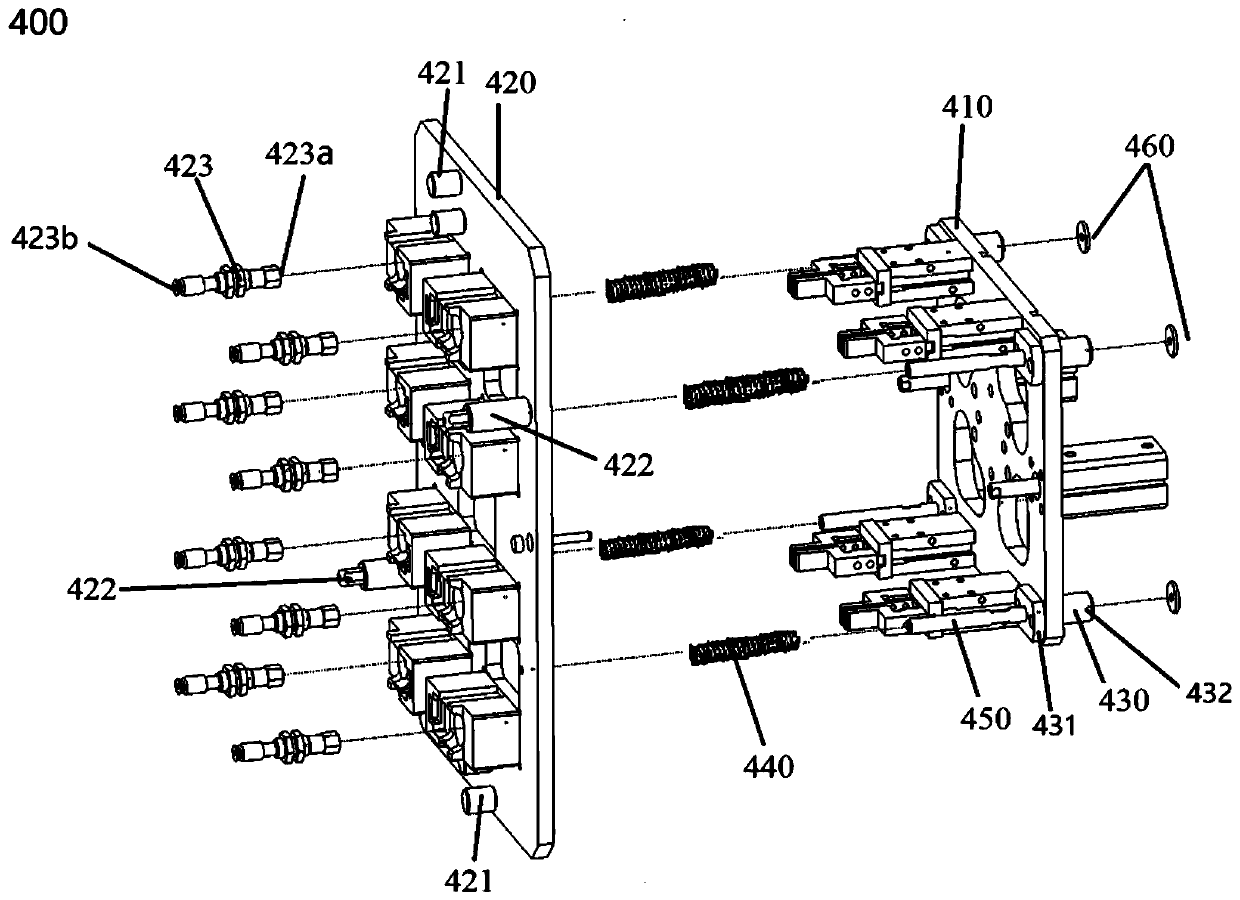

Three-item terminal welding machine

ActiveCN109623078AEasy to operateIncrease productivityMetal working apparatusSoldering auxillary devicesButt jointWelding

The invention provides a three-item terminal welding machine comprising a machine frame, a PLC controller installed on the machine frame, a linear guide rail horizontally laid on the upper surface ofthe machine frame, a tool platform which slides along the linear guide rail, solder welding mechanisms oppositely arranged on the left side and the right side of the tool platform, a jacking displacement mechanism which located below the upper surface of the machine frame and can jack the tool platform and a solder conveying device installed on the machine frame. The tool platform is provided witha locating tool device. The three-item terminal welding machine can automatically achieve butt joint and welding work between a terminal and an outgoing line, is convenient to operate and high in efficiency and guarantees workpiece quality.

Owner:JULI AUTOMATION EQUIP ZHEJIANG CO LTD

Automatic feeding device for lathe

ActiveCN100500344CReduce disturbanceGuaranteed rotation accuracyAutomatic conveying/guiding stockSlide plateEngineering

The present invention provides an automatic feeder device for lathe. Said automatic feeder device is placed by workpiece holder of lathe, and includes the following several portions: material-supporting pipe placed on the machine frame, material-feeding cylinder placed at one side of said material-supporting pipe, slide plate fixedly connected on said material-feeding cylinder and can be axially moved along the material-supporting pipe and two material-feeding devices through which the rod material can be passed are placed on the machine frame. Said two material-feeding devices include one mobile material-feeding device and one fixed material-feeding device. Its operation is convenient, stable and reliable.

Owner:浙江海德曼智能装备股份有限公司

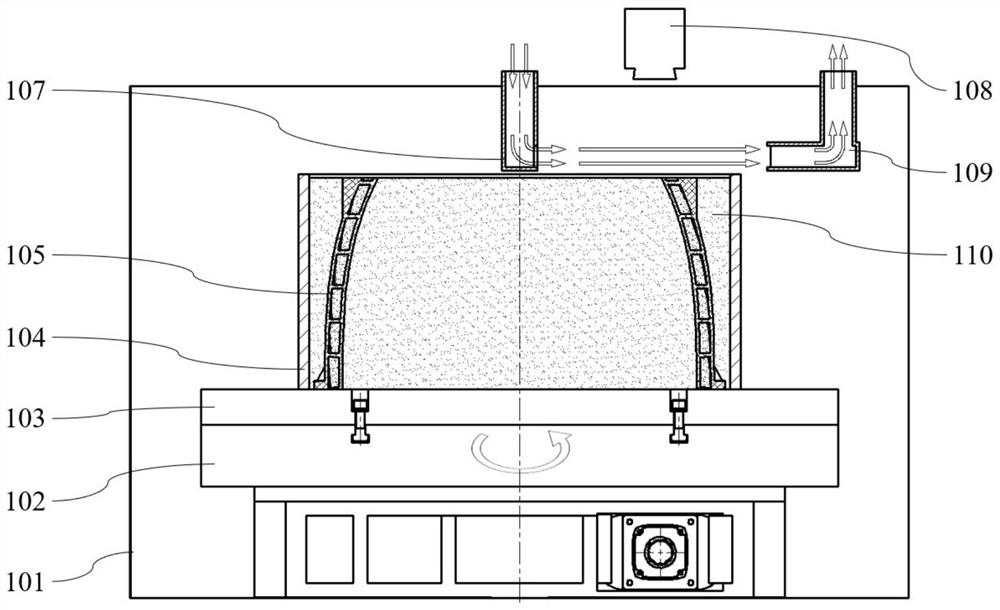

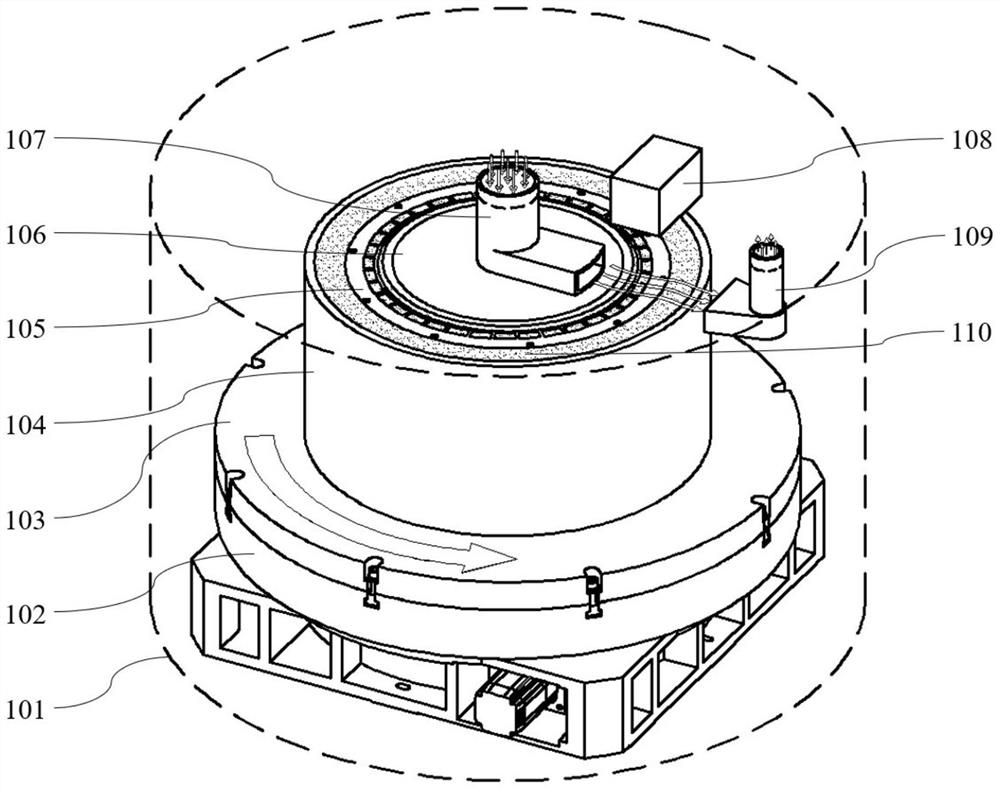

Annular hollow part additive manufacturing smoke-discharging and dust-removing device and method

PendingCN113263188AReduced air flow areaAvoid destructionAdditive manufacturing apparatusProcess engineeringAirflow

The invention discloses an annular hollow part additive manufacturing smoke-discharging and dust-removing device and method. An air blowing device is arranged at the upper end of a forming chamber; an exhaust device is arranged on the side wall of the forming chamber; a connecting line between an air outlet of the air blowing device and an air inlet of the exhaust device is horizontally arranged and located at the upper end of a forming surface; the air blowing device is communicated with an air blowing source or an exhaust port is connected with an exhaust source; the air outlet of the air blowing device and the air inlet of the exhaust device are formed in the two sides of a forming area; an exhaust laminar flow is formed on the forming surface of an annular hollow part; and smoke is blown to the exhaust port through the exhaust device and the air blowing device to be directly exhausted. According to the invention, spreading of smoke generated in the energy beam melting process can be effectively avoided; the exhaust device and the air blowing device are arranged on the two sides of the forming area in the same plane; an airflow flowing area can be reduced; air of an air outlet device can effectively maintain the flow speed at the exhaust port; and damage to the surface of a powder bed can be effectively avoided at the relatively low air speed; and the forming quality is improved.

Owner:XI AN JIAOTONG UNIV

A scraper voltage stabilizing system and its control method

ActiveCN104626584BEfficient removalGuaranteed printing success rateAdditive manufacturing apparatus3D object support structuresSolenoid valveClosed loop

The scraper voltage stabilizing system provided by the present invention includes a scraper and a vacuum box for adjusting the air pressure in the inner cavity of the scraper, a first electromagnetic valve, a second electromagnetic valve, a vacuum pump and a central controller, wherein the central controller is connected with the inner cavity of the scraper respectively. connected to the pressure sensor, the first solenoid valve and the second solenoid valve, which includes a data processing module and a sending instruction module, and can control the first solenoid valve and the second solenoid valve according to the air pressure value measured by the pressure sensor. The solenoid valve is adjusted to control the air pressure in the inner cavity of the scraper to maintain a stable value. The present invention maintains the constant pressure of the inner chamber of the scraper through the above-mentioned closed-loop voltage stabilization control, further realizes the stability of the resin liquid level in the inner chamber of the scraper and the effective removal of air bubbles, and guarantees the laser light curing molding printer using the doctor blade voltage stabilization system The printing success rate and the quality of the printed workpiece during printing.

Owner:SHINING 3D TECH CO LTD

An automatic quenching production line

ActiveCN107287396BClosely connectedIncrease productivityFurnace typesHeat treatment furnacesProduction lineManipulator

The invention discloses an automatic quenching production line, and belongs to the field of plate spring shaping and heat treatment equipment. The automatic quenching production line is characterized by comprising a stepping type quenching furnace, a plate spring bending shaping device and a quenching pond. The stepping type quenching furnace is linked with the plate spring bending shaping device through a mechanical hand, and the plate spring bending shaping device is linked with the quenching pond through an oil inlet mechanism. The plate spring bending shaping device comprises a shaping machine frame, a feeding mechanism, a length alignment mechanism, a width alignment mechanism, a shaping device and a material supporting lifting mechanism; the feeding mechanism, the length alignment mechanism, the width alignment mechanism, the shaping device and the material supporting lifting mechanism are installed on the shaping machine frame. Heating, shaping and quenching operation of a plate spring can be automatically implemented, various working procedures are automatically and continuously executed, linage is compact, and the product production efficiency and the output quality are greatly improved.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

A cutting machine tool for crankshaft connecting rod production

ActiveCN106392185BRealize clamping and fixingReduce labor intensityMetal sawing devicesNumerical controlEngineering

Owner:重庆昌跃机电制造有限公司

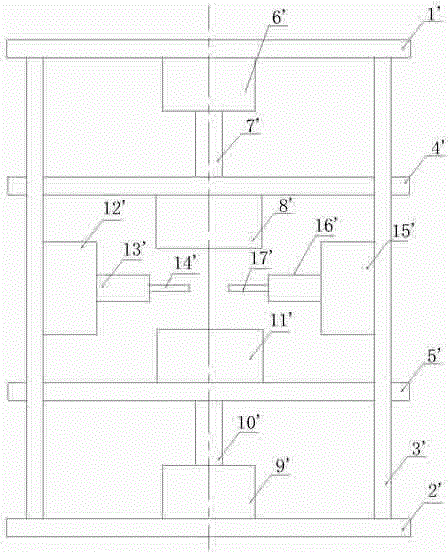

Combined press

PendingCN109434468AIncrease tonnageCompact structureOther manufacturing equipments/toolsPunchingEngineering

The invention discloses a combined press. The combined press comprises an upper transverse beam, a lower transverse beam, vertical columns, a main cylinder, a punching slide block and a lower die; theupper transverse beam, the lower transverse beam and the vertical columns are combined to form a rack, a double-station sliding table is slidably arranged at the lower end of the punching slide block, the sliding table is provided with a punching punch and an upsetting punch, a pulling-extending device is arranged on one side of the rack, and the pulling-extending device comprises a pulling-extending punch, a pulling-extending slide block and a pushing cylinder; and the pulling-extending punch is longitudinally and fixedly mounted on the outer side of the upper transverse beam, the pulling-extending slide block is arranged under the pulling-extending punch, longitudinal guide rails are arrange on the two adjacent vertical columns on the corresponding sides, the two ends of the pulling-extending slide block are arranged on the vertical columns in limiting and sliding modes through the two corresponding sliding rails correspondingly, the lower end of the pulling-extending slide block isfixedly connected with the pushing cylinder, and the pushing cylinder is longitudinally mounted on the lower transverse beam. The combined press can complete three processes of upsetting, punching and pulling-extending, a mechanism is simplified, the cost is saved, the transferring distance is greatly shortened, and the occupied area of the equipment is decreased.

Owner:CHONGQING JIANGDONG MACHINERY

Press fit tool

The invention discloses a press fit tool. The press fit tool comprises air cylinders, a controller, a detecting device and a timer, the controller is used for controlling the air cylinders to extend and retract to enable the air cylinder to be press fit with a workpiece or be separated from the workpiece, the detecting device is used for detecting the input air pressure of the air cylinders, and the timer is used for timing the time of the air cylinders performing press fit on the workpiece. The timer can be connected with the controller and the detecting device in a communication mode, and when the timing time of the timer achieves a preset time, the controller controls the air cylinders to be separated from the working piece; and when the input air pressure of the air cylindersdetected by the detecting device is smaller than a preset pressure value, the timer stops timing, and when the input air pressure of the air cylinders detected by the detecting device is larger than or equal tothe preset pressure value, the timer keeps timing. Through the arrangement, the condition that during the press fit process of the air cylinders and the workpiece, the pressure applied to the workpiece and the applied time meet the technology requirements constantly is ensured, the quality of the workpiece is ensured, and the problem existing in the prior art that when the air cylinders perform press fit with the workpiece, the air pressure fluctuation has influence on the quality of the workpiece is solved.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

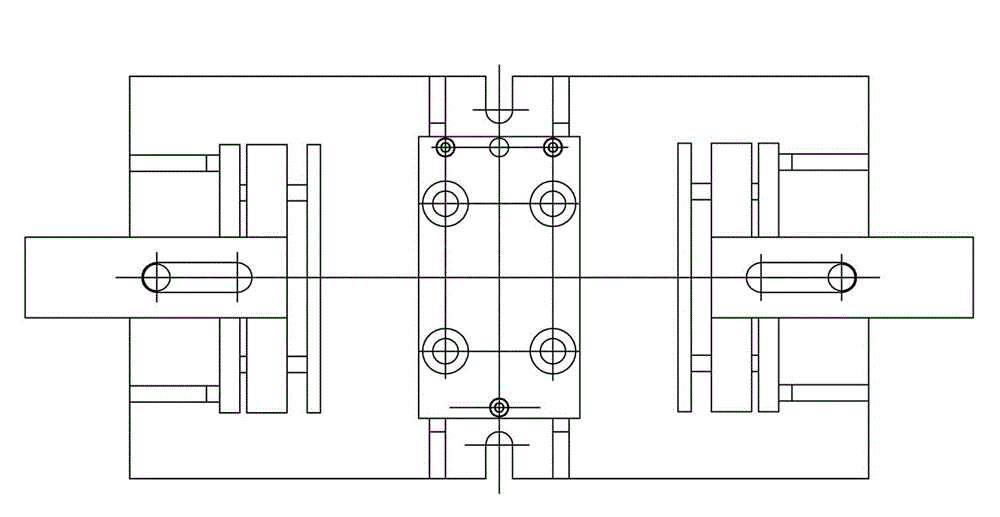

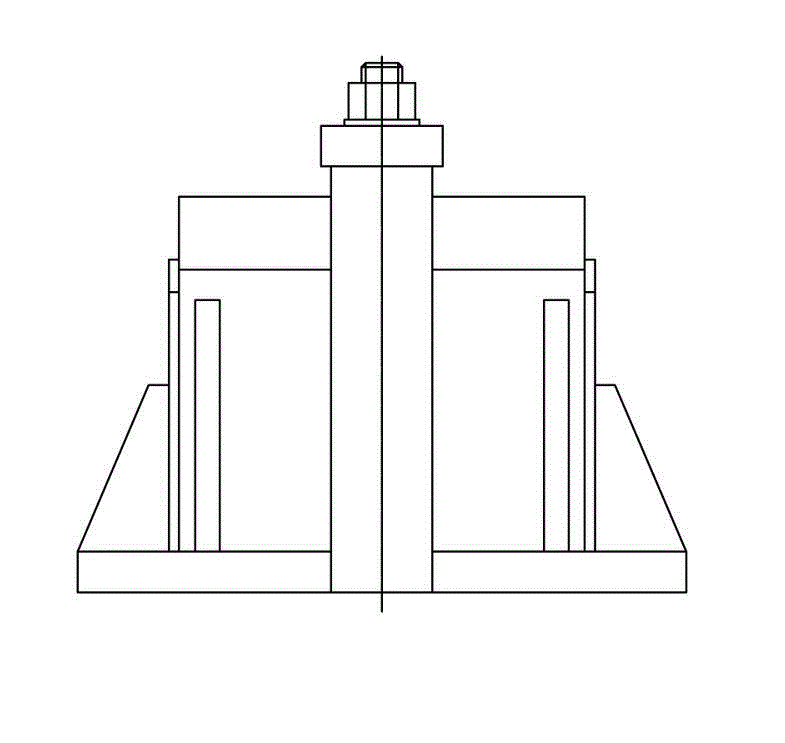

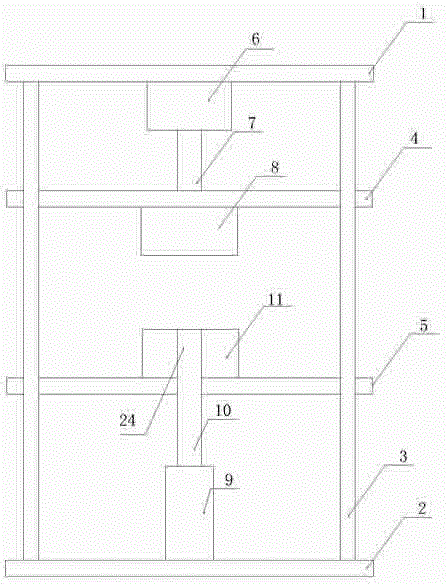

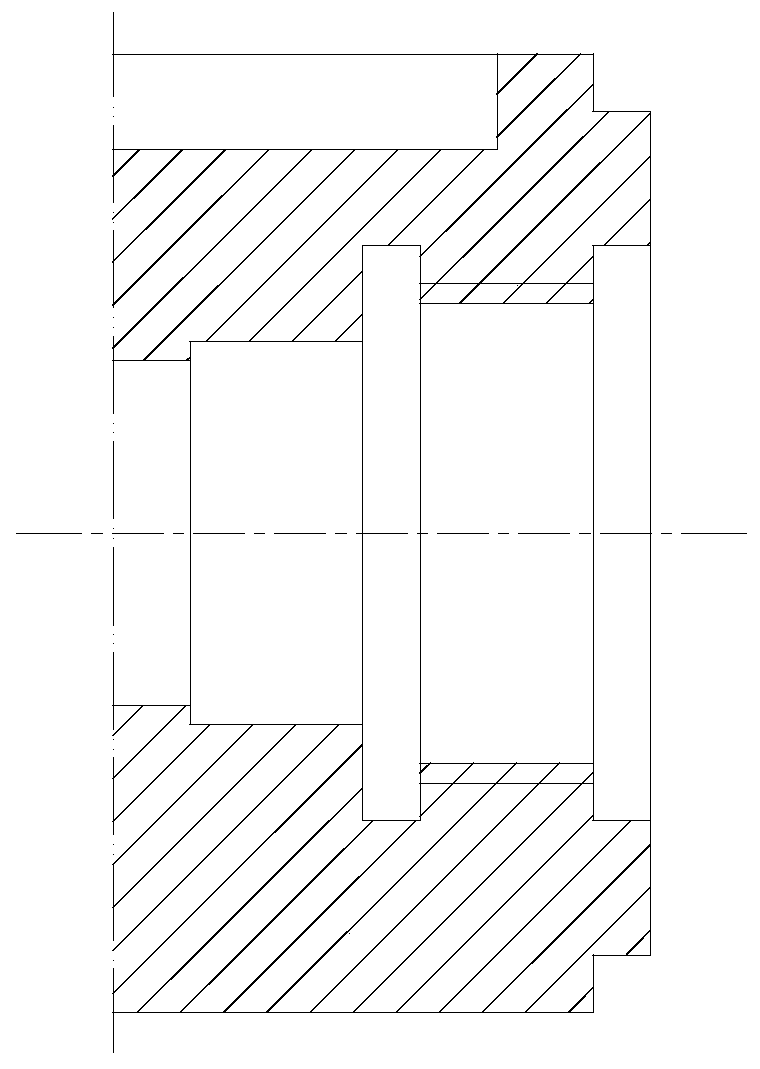

Sealed forging device

ActiveCN102794382AImprove stabilityPracticalForging/hammering/pressing machinesStructural engineeringClassical mechanics

The invention relates to a sealed forging device, wherein two ends of an upper die fixing plate and a lower die fixing plate are respectively connected with a vertical column and are arranged between a die frame upper plate and a die frame lower plate; two ends of the upper die fixing plate are movably connected with the vertical column; two ends of the lower die fixing plate are fixedly connected with the vertical column; an upper cylinder fixed at the die frame upper plate is arranged between the die frame upper plate and the upper die fixing plate; an upper cylinder piston rod connected with the upper die fixing plate is fixedly arranged on the upper cylinder; a material jacking device which is matched with a lower die is arranged between the die frame lower plate and the lower die fixing plate; and a die punching device is further fixedly arranged on the lower die fixing plate. When the vertical column on the die frame is mainly stressed, only the upper die fixing plate is moved but the lower die fixing plate is arranged on the vertical column and is not moved; left and right punching heads are also fixed through a left baffle plate and a moving baffle plate and are moved through a slide rod; according to the structure, a bending force implemented on the vertical column on the die frame is completely canceled, so that the whole device is higher in stability and stronger inpracticability, and moreover the machining precision and the quality of a workpiece are ensured.

Owner:ZHANGJIAGANG CHUANJUN VEHICLE IND CO LTD

Sealed forging device

ActiveCN102794382BImprove stabilityPracticalForging/hammering/pressing machinesPunchingClassical mechanics

The invention relates to a sealed forging device, wherein two ends of an upper die fixing plate and a lower die fixing plate are respectively connected with a vertical column and are arranged between a die frame upper plate and a die frame lower plate; two ends of the upper die fixing plate are movably connected with the vertical column; two ends of the lower die fixing plate are fixedly connected with the vertical column; an upper cylinder fixed at the die frame upper plate is arranged between the die frame upper plate and the upper die fixing plate; an upper cylinder piston rod connected with the upper die fixing plate is fixedly arranged on the upper cylinder; a material jacking device which is matched with a lower die is arranged between the die frame lower plate and the lower die fixing plate; and a die punching device is further fixedly arranged on the lower die fixing plate. When the vertical column on the die frame is mainly stressed, only the upper die fixing plate is moved but the lower die fixing plate is arranged on the vertical column and is not moved; left and right punching heads are also fixed through a left baffle plate and a moving baffle plate and are moved through a slide rod; according to the structure, a bending force implemented on the vertical column on the die frame is completely canceled, so that the whole device is higher in stability and stronger inpracticability, and moreover the machining precision and the quality of a workpiece are ensured.

Owner:张家港爱斯诺机械密封有限公司

Ejecting type jig for grabbing workpiece

PendingCN110480962AThe process of taking workpieces is stableGuarantee the quality of the workpieceDomestic articlesEngineeringMechanical engineering

Owner:SUZHOU CM TECH CO LTD

Iron chip cleaning equipment for mechanical processing

The invention discloses an iron filings cleaning device for mechanical processing, which comprises a frame, a hopper, a screening mechanism, an oil guide plate, an iron filings collection mechanism and a screw baffle; the hopper is erected on the frame, and a screening groove is set at the center of the hopper ;The screening mechanism is arranged on the lower side of the screening tank, and the bottom of the screening mechanism is provided with an oil guide plate and a blanking guide plate. On the contrary; the chip collecting mechanism is detachably connected with the oil deflecting plate, and the lower end of the oil guiding plate faces the feeding port of the chip collecting mechanism. In the present invention, the processed workpiece falls into the hopper and falls into the screening mechanism from the screening trough, and the iron filings on the surface of the workpiece are shaken off and separated with the operation of the screening mechanism to complete the cleaning of the workpiece surface and ensure the quality of the workpiece; After being transported to the blanking guide plate, the iron chips and cooling oil slide down from the oil guide plate into the iron filings collection mechanism, and the cooling oil is recycled to avoid environmental pollution and waste of resources.

Owner:殷彩红

Aerostatic electric spindle and cooling device thereof

ActiveCN102476194BPrevent thermal deformationAvoid precisionMaintainance and safety accessoriesThermal deformationEngineering

The invention discloses an aerostatic electric spindle and a cooling device thereof. The aerostatic electric spindle comprises a shell, a sleeve, a radial bearing, a revolving shaft, a rotor and the like, wherein the inner wall of the shell is provided with at least one groove; the groove axially extends on the inner wall of the shell; the outer wall of the sleeve and the inner wall of the shell are fixed and bound; the groove forms a path for containing a coolant; the inner wall of the sleeve and the outer wall of a radial bearing are bound; the radial bearing is cylindrical; the revolving shaft is contained in the radial bearing; the radial bearing is used for forming an air film between the inner wall of the radial bearing and the revolving shaft; the revolving shaft is supported by the air film; and in addition, one end of the revolving shaft is fixedly connected with the rotor. According to the invention, the radial bearing, the revolving shaft and other components can be effectively cooled so as to avoid the problem that the precision is affected because components such as the revolving shaft and the like in the aerostatic electric spindle are subjected to thermal deformation because of lacking of the heat radiation measures to the radial bearing part.

Owner:CETC BEIJING ELECTRONICS EQUIP

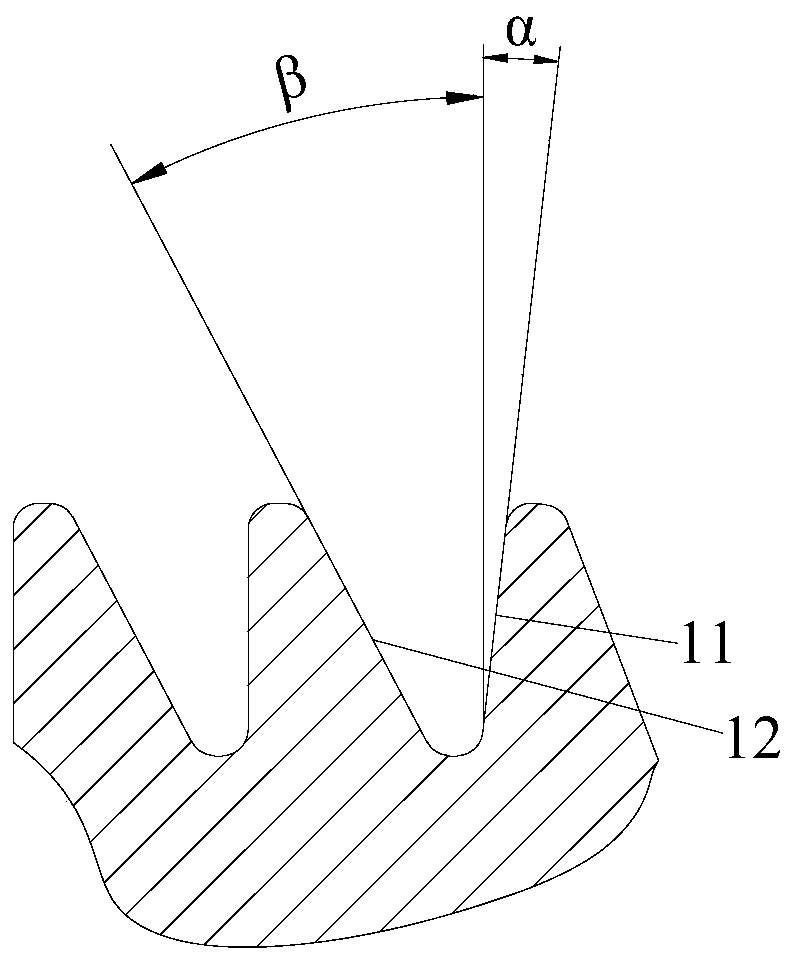

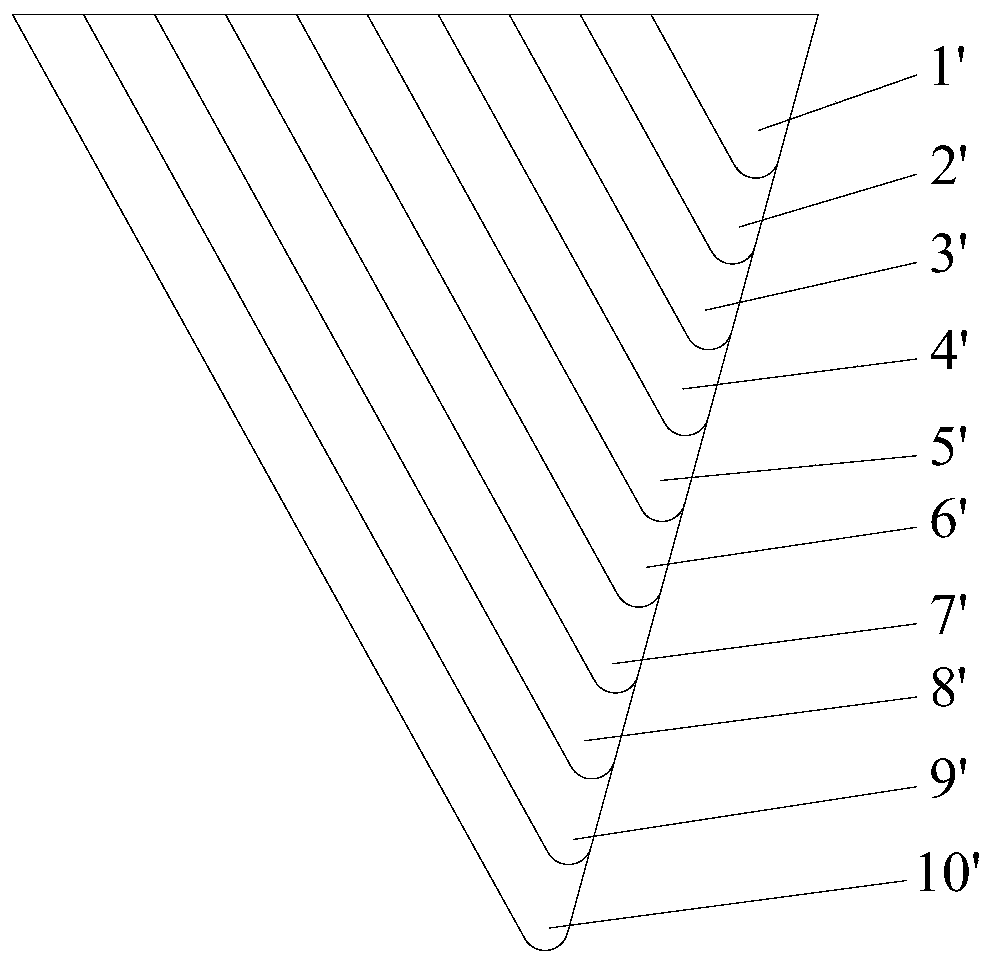

Processing method of zigzag internal thread

ActiveCN108672842BSolve crackingReduce surface roughnessThread cutting machinesEngineeringScrew thread

The invention relates to a method for processing a zigzag internal thread. The flank angle of the working surface of the zigzag internal thread is 3 degrees, and the flank angle of the non-working surface of the zigzag internal thread is 30 degrees. The method comprises the steps that firstly radial feed is performed twice, then axial feed matched with the radial feed is carried out on the non-working surface for three times, then radial feed is carried out once, the axial feed matched with the radial feed is carried out on the working surface twice, then the radial feed is carried out once, and finally the axial feed matched with the radial feed is carried out on the working surface once. The processing method adopts a positive and negative cutting method, and after ten times of cutting,it is ensured that cutting chippings can be cut from both the non-working surface and the working surface, and the chipping shape is a V shape, so that the problem of the crack of the working surfacewhen the zigzag thread is processed is solved effectively.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Barbell hexagonal frame rod blanking device

ActiveCN113245426AGuarantee the quality of the workpieceRealize automatic blankingShaping toolsEjection devicesStructural engineeringMachine tool

The invention discloses a barbell hexagonal frame rod blanking device which comprises a machine tool. A lower die and an upper die are arranged on the machine tool, a push-out mechanism is arranged on the lower die, a first telescopic rod and a second telescopic rod are fixedly installed on the machine tool, the driving end of the first telescopic rod is vertically downwards and fixedly connected with the upper side wall of the upper die, and the driving end of the second telescopic rod is connected with the push-out mechanism; and a first right-angle plate and a second right-angle plate are fixed to the lower side wall of the lower die, the end of the first right-angle plate is connected with a vibration mechanism through a driving mechanism, the vibration mechanism comprises a rotary disc, a rotary rod is rotationally connected to the rear side wall of the rotary disc, a vertical rod is slidably inserted into the second right-angle plate, and an impact ball is fixed at the upper end of the vertical rod. According to the barbell hexagonal frame rod blanking device, in the process that a transverse push plate pushes a formed workpiece to be blanked, the impact ball makes contact with and impacts the lower die through rotation of the rotary disc, the connecting position of the lower die and the workpiece is loosened, automatic workpiece blanking is achieved in combination with movement of the transverse push plate, and the workpiece quality is guaranteed.

Owner:南通市力行机械制造有限公司

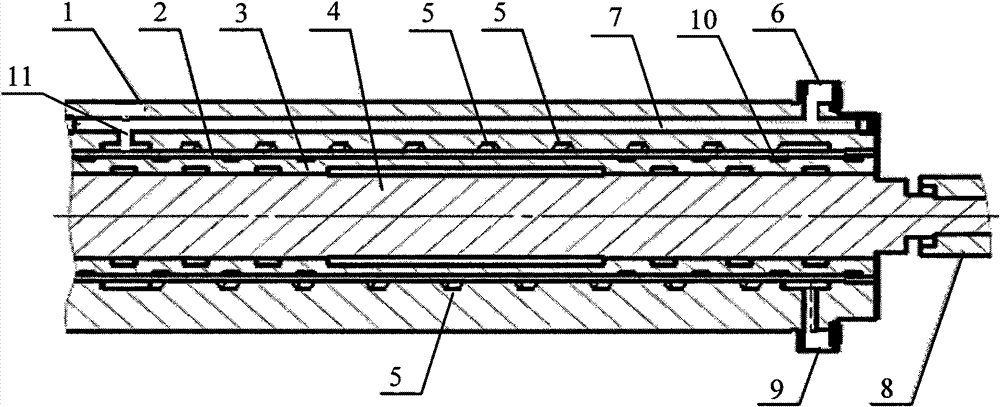

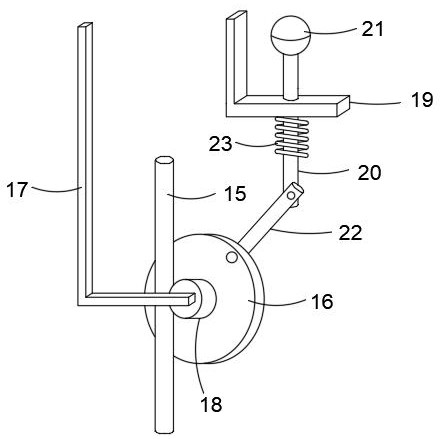

Dust cover assembly machine

InactiveCN102886670BEasy to operateLabor savingMetal working apparatusReciprocating motionAgricultural engineering

The invention relates to an assembling tool, particularly relates to a dustproof cover assembling machine, and belongs to the technical field of machinery. The invention mainly solves the problems that the existing dust cover needs labor assembly, so that the operating procedure is complex, the labor is wasted, the assembling efficiency is low, the insecurity is caused and the qualification rate is low. The dustproof cover assembling machine comprises a rack and a working platform, wherein the working platform is horizontally arranged on the rack and is provided with a lower bottom plate; the lower bottom plate is provided with a positioning device; an upper top plate is arranged above the positioning device and is provided with a jacking device; the jacking device and the positioning device are vertical to the working platform and do reciprocating movement in a matching manner; a guide rod is fixedly arranged between the lower bottom plate and the upper top plate at the two sides of the jacking device and the positioning device; and the upper top plate and the lower bottom plate are connected by a supporting rod. The dustproof cover assembling machine has the advantages of simple operating procedure, labor-saving effect, high assembling efficiency, safety, reliability and high qualification rate.

Owner:ZHEJIANG TONGSHI AUTO PARTS

A laser deburring system and method

ActiveCN103639599BImprove efficiencyGuarantee the quality of the workpieceLaser beam welding apparatusComputer scienceLaser

The invention relates to the technical field of laser machining and provides a laser deburring method which comprises the following steps of: acquiring an actual outline of a workpiece and a burr outline through a workpiece image, determining a start point coordinate and an end point coordinate according to a distance between the actual outline of the workpiece and the burr outline, and cutting the burr according to the start point coordinate and the end point coordinate of the burr of the workpiece. With the adoption of the method, a part with the burr is only required to be cut, and deburring treatment is not required to be performed on the whole outline of an object, so that the deburring efficiency is improved. Simultaneously, the workpiece quality is ensured since parts without the burrs on the workpiece are not influenced by laser heat.

Owner:HANS LASER TECH IND GRP CO LTD +1

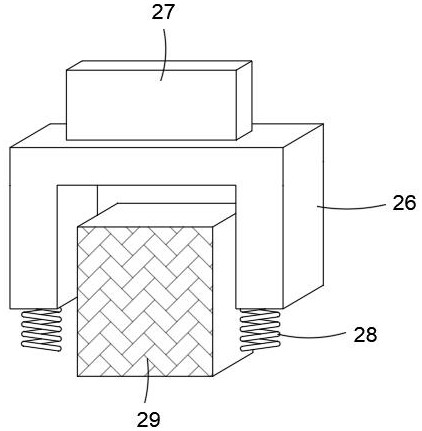

Evaporator shell casting die

The invention provides an evaporator shell casting die. The evaporator shell casting die comprises a support seat, a support plate, a fixing plate, a core, a push rod, a guide plate, a guide rod, a first spring, a pull-assisting mechanism and a clamping mechanism, wherein the support plate is supported on the support seat; the core is installed on the support plate through the fixing plate; the push rod penetrates through the support plate, the fixing plate and the core; the end, below the support plate, of the push rod is fixed to the guide plate; the push rod can move in the vertical direction relative to the support plate, the fixing plate and the core; the guide rod penetrates through the guide plate, and one end of the guide rod is fixed to the support plate; and one end of the firstspring is fixed to the support plate, and the other end of the first spring is fixed to the guide plate. The evaporator shell casting die solves the problem of troublesome operation caused by the factthat a push plate and a push rod need to be pushed manually in the prior art, and simultaneously solves the problem that the push rod is prone to extending into a die cavity after a spring is damagedand consequently forming of a workpiece is blocked.

Owner:湖南省诚信苏南制冷设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com