Automatic quenching production line

A production line and automatic technology, which is applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problems of leaf spring sheet surface trauma, heat loss, waste of energy, etc., to ensure the quality of the workpiece, improve production efficiency, and facilitate bending and forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

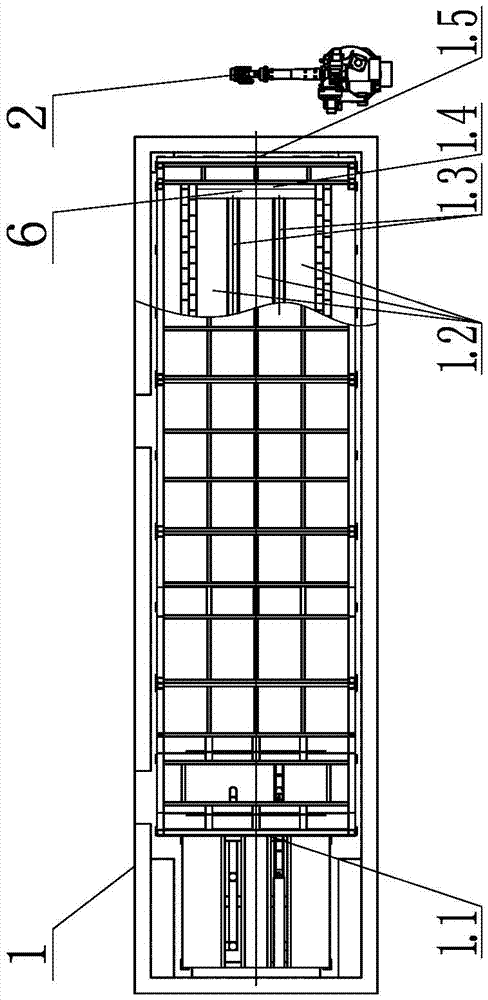

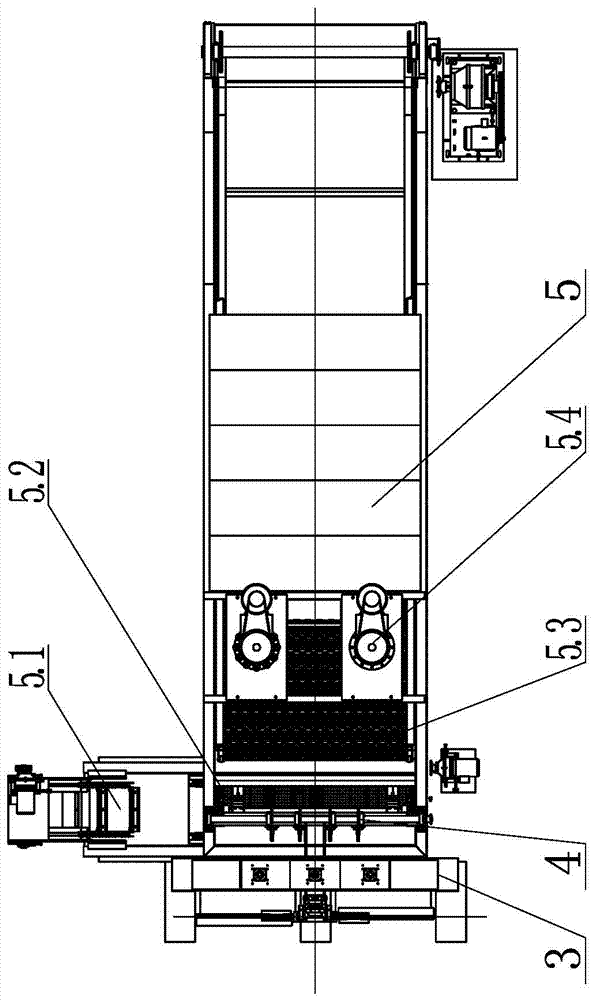

[0049] Such as figure 1 and 2 As shown, the automatic quenching production line of the present invention includes a step-by-step quenching furnace, a leaf spring bending and shaping device, and a quenching pool. The shaping device is connected to the quenching pool through the oil inlet mechanism.

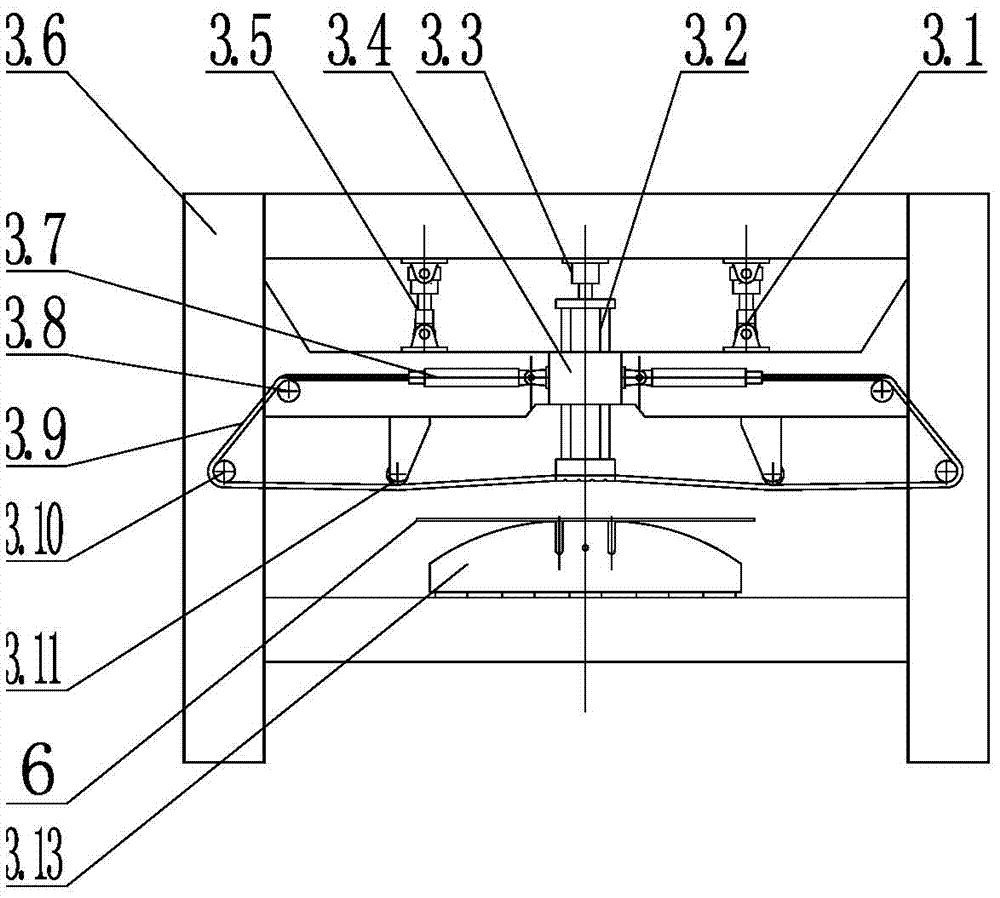

[0050] Such as Figure 3-10 As shown, the leaf spring bending and shaping device includes a shaping frame, a feeding mechanism, a length centering mechanism, a width centering mechanism, a shaping device and a lifting mechanism for supporting materials; the feeding mechanism, the length centering mechanism, and the width centering mechanism Mechanism, sizing device and material lifting mechanism are installed on the sizing frame.

[0051] Such as Figure 3-6 As shown, the sizing device includes a forming hard mold, a forming chain, a chain mounting frame, a guide strut, an intermediate clamping cylinder, two side forming cylinders and two chain tensioning cylinders; the interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com