Processing method of zigzag internal thread

A processing method and internal thread technology, which is applied in the field of zigzag internal thread processing, can solve problems affecting processing quality, cold work hardening, workpiece scrapping, etc., and achieve the effects of improving labor productivity, reducing tool changes, and improving tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

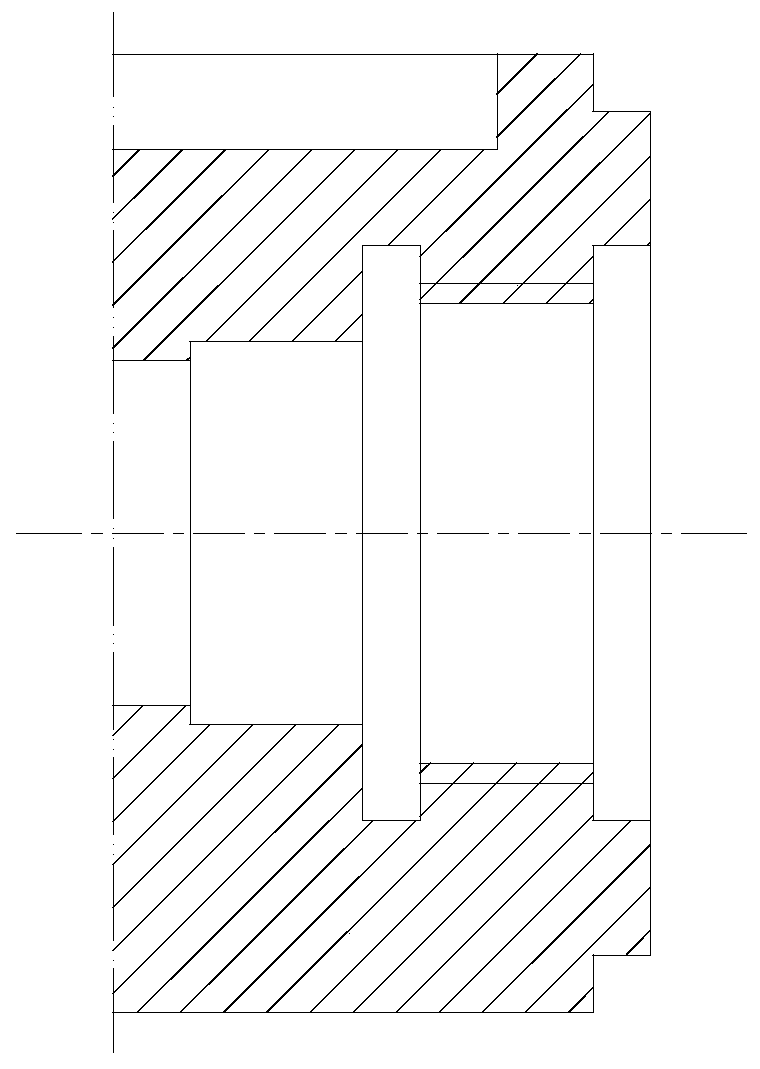

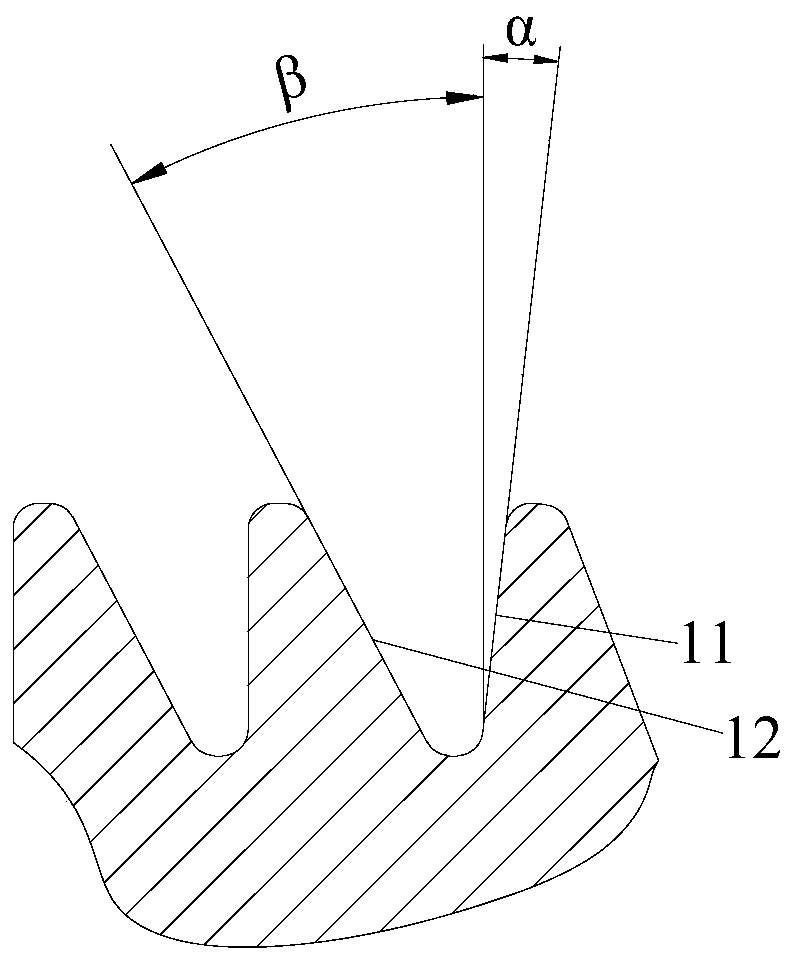

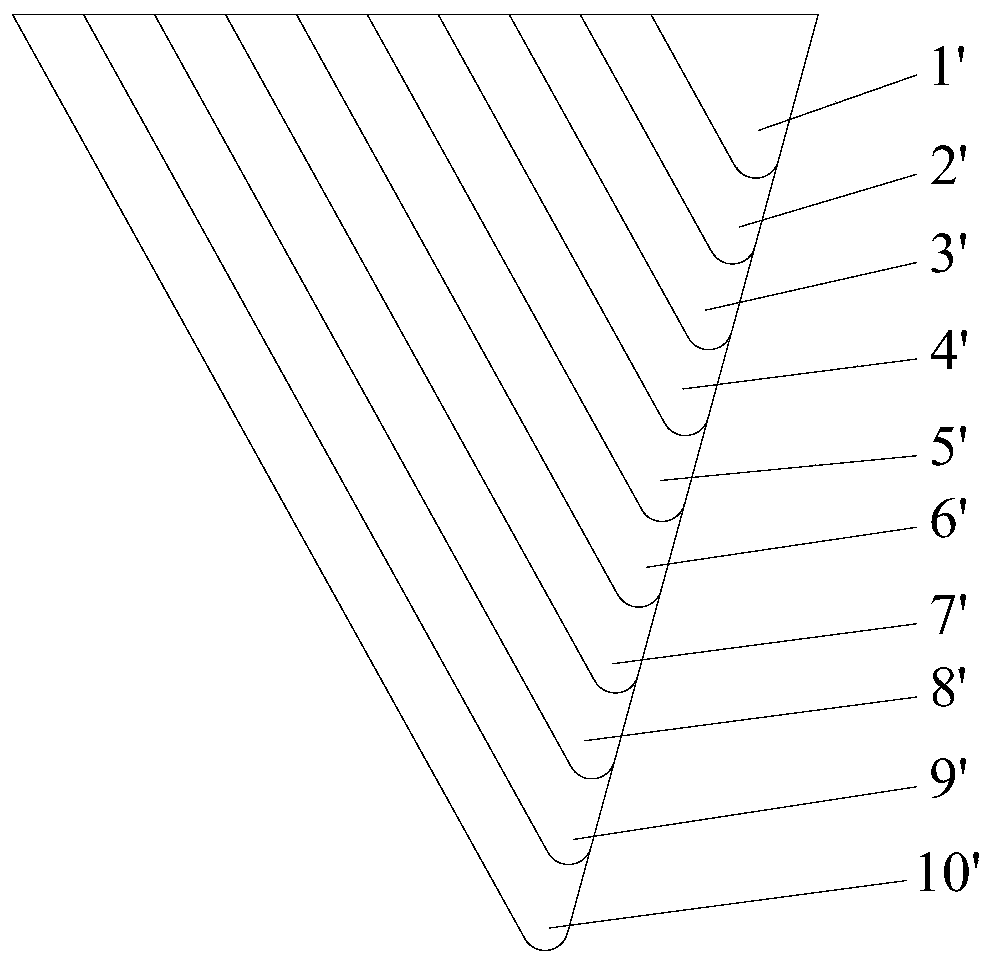

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] Thread cutting generally refers to the method of processing threads on workpieces with forming tools or abrasive tools, mainly including turning, milling, tapping, threading, grinding, grinding and whirlwind cutting. When turning, milling and grinding threads, the transmission chain of the machine tool ensures that the turning tool, milling cutter or grinding wheel moves a pitch (lead) accurately and evenly along the axis of the workpiece every time the workpiece is turned. When tapping or threading, the tool (tap or die) and the workpiece make relative rotational movement, and the tool (or workpiece) is guided to move axially by the thread groove formed first.

[0027] In the thread processing of single piece and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com