Grinding mechanism of common lathe

A technology of grinding mechanism and common lathe, applied in grinding machine, abrasive belt grinder, grinding/polishing equipment, etc., can solve the problems of reduced abrasive belt grinding effect, difficulty in guaranteeing workpiece grinding effect, etc., and achieve the effect of guaranteeing the limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

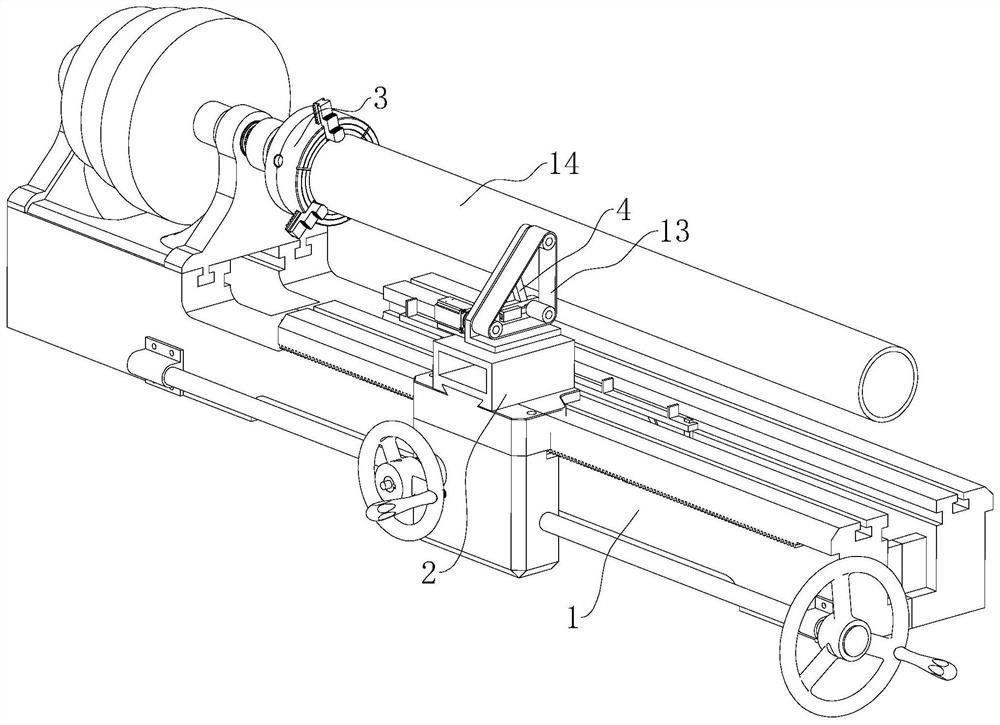

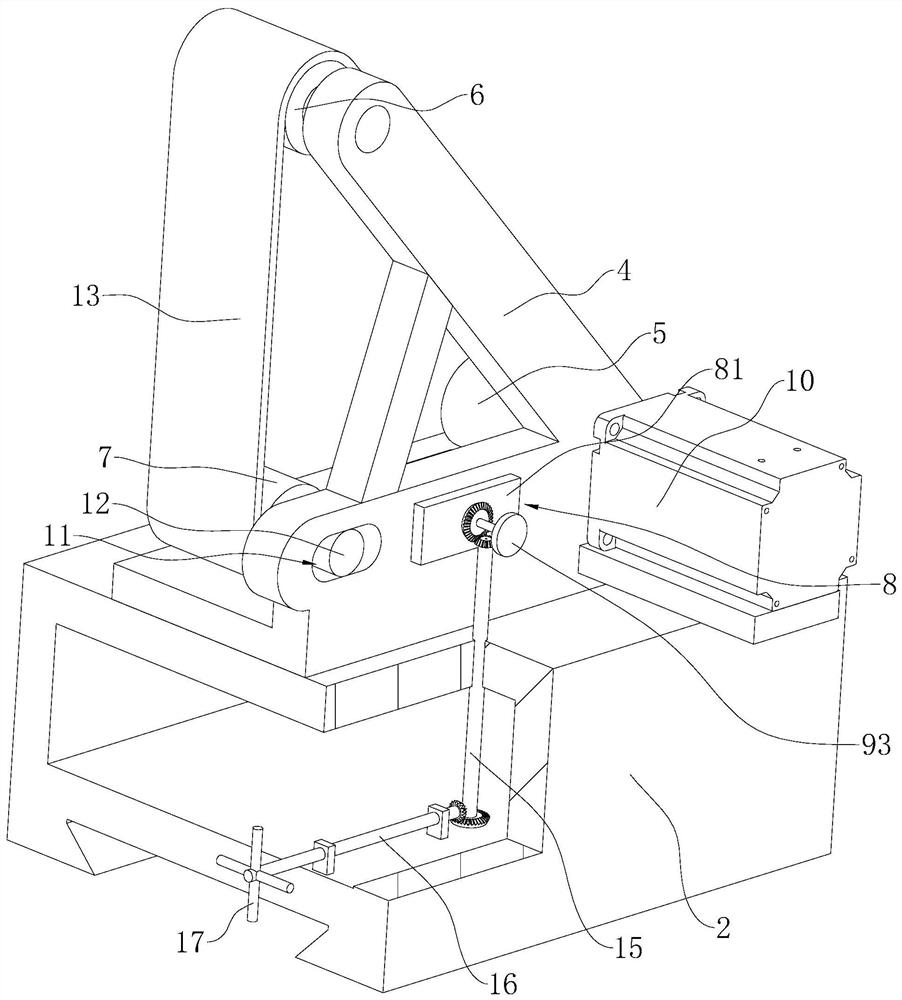

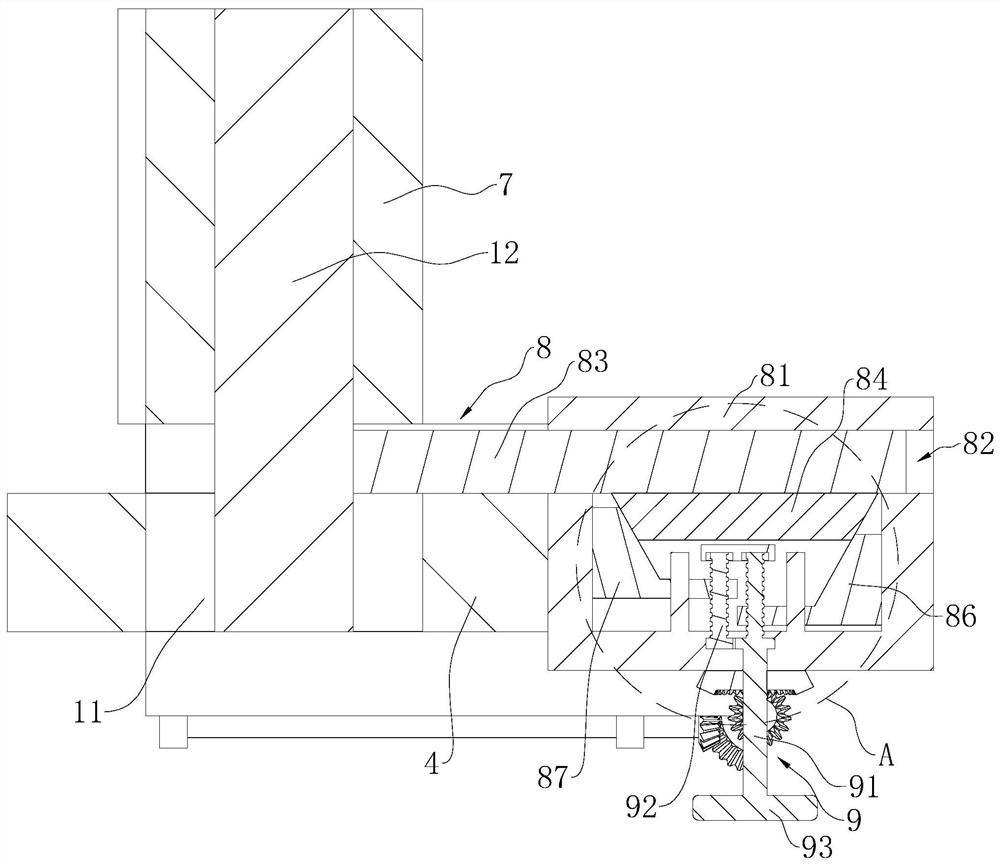

[0036] The embodiment of the present application discloses a grinding mechanism of an ordinary lathe, referring to figure 1 and 2, comprising a bracket 4 installed on the tool table seat 2, the bracket 4 is arranged in a triangle, and one end facing the workpiece 14 is an opening; the three corners of the bracket 4 are respectively rotated to connect the driving wheel 5, the driven wheel 6, and the tensioning wheel 7. The driving wheel 5 is set on the side away from the opening of the support 4; the driving wheel 5, the driven wheel 6 and the tension wheel 7 are covered with the same abrasive belt 13; the support 4 is also fixed with a motor 10, and the output shaft of the motor 10 is connected to the The driving wheel 5 is coaxially fixed and communicated with an external power supply through a power cord. In the present embodiment, it is mainly used for grinding the slender shaft workpiece 14; the workpiece 14 is fixed on the clamping mechanism 3 of the lathe and rotates, t...

Embodiment 2

[0043] refer to figure 1 with 5 , the difference from Embodiment 1 is that the lathe base 1 is provided with a guide mechanism 18 along its length direction and below the workpiece 14; refer to figure 2 with 5 : Simultaneously screw rod one 91 is in one section outside mounting seat 81 and is connected with connecting shaft mechanism; Connecting rod mechanism comprises connecting rod one 15 and connecting rod two 16, and connecting rod one 15 is vertically arranged, and bevel gear one is fixed on the upper end, and screw Rod one 91 is coaxially fixed with bevel gear two meshing with bevel gear one to realize the transmission between connecting rod one 15 and screw mandrel one 91; the other end of connecting rod one 15 is coaxially fixed with bevel gear three and connecting rod two 16 One end is fixed with the bevel gear 4 meshing with the bevel gear 3, and the connecting rod 2 16 is arranged vertically to the moving direction of the tool pedestal 2, and the connecting rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com