Clamp for machining of electrode and manufacturing method of clamp

An electrode processing and fixture technology, which is applied in the field of tooling and fixtures, can solve the problems of increasing the cost of mold manufacturing and maintenance, the service life of the workpiece is not long, and the processing has errors, and achieves the effect of simple manufacturing method, easy processing, and improved processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described below in conjunction with accompanying drawing.

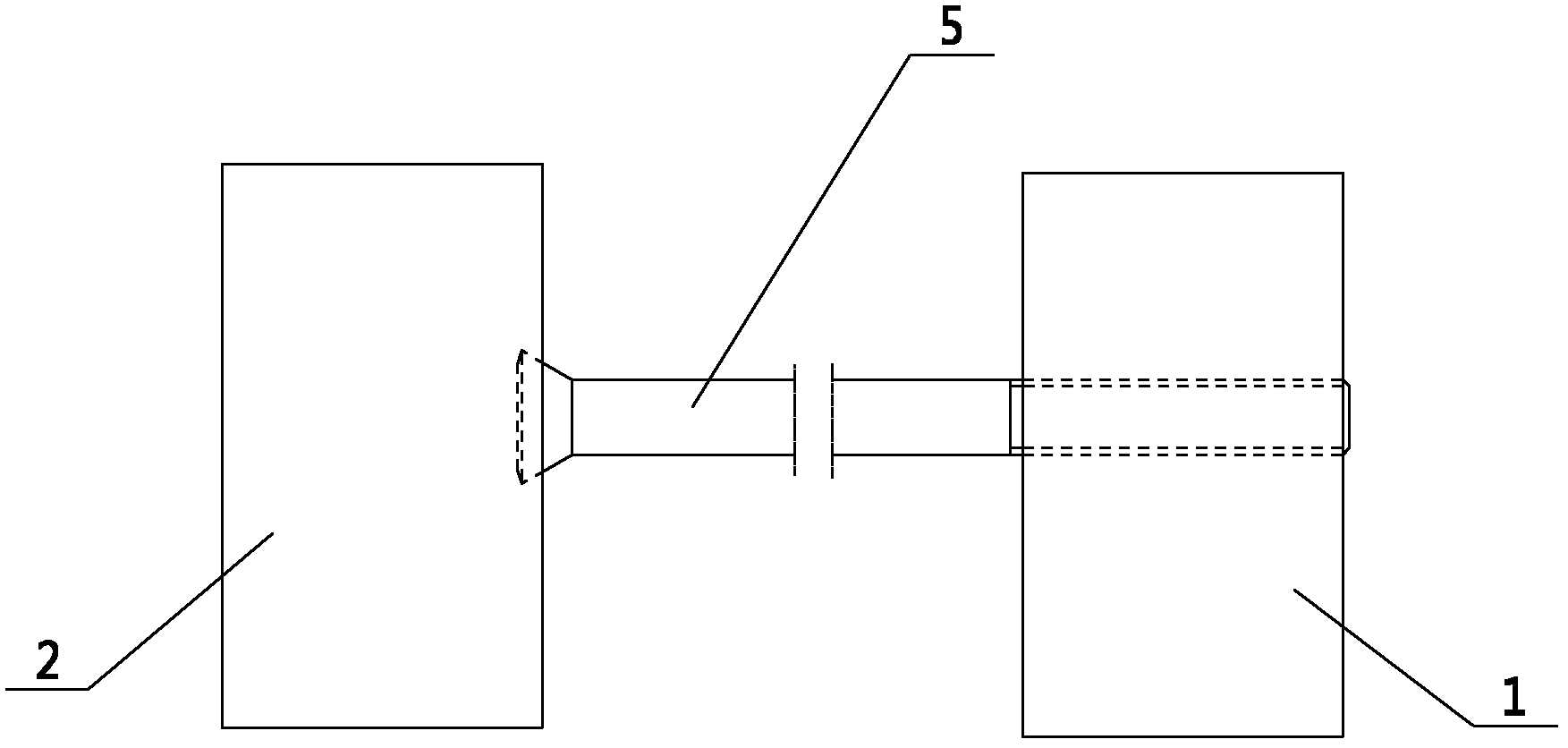

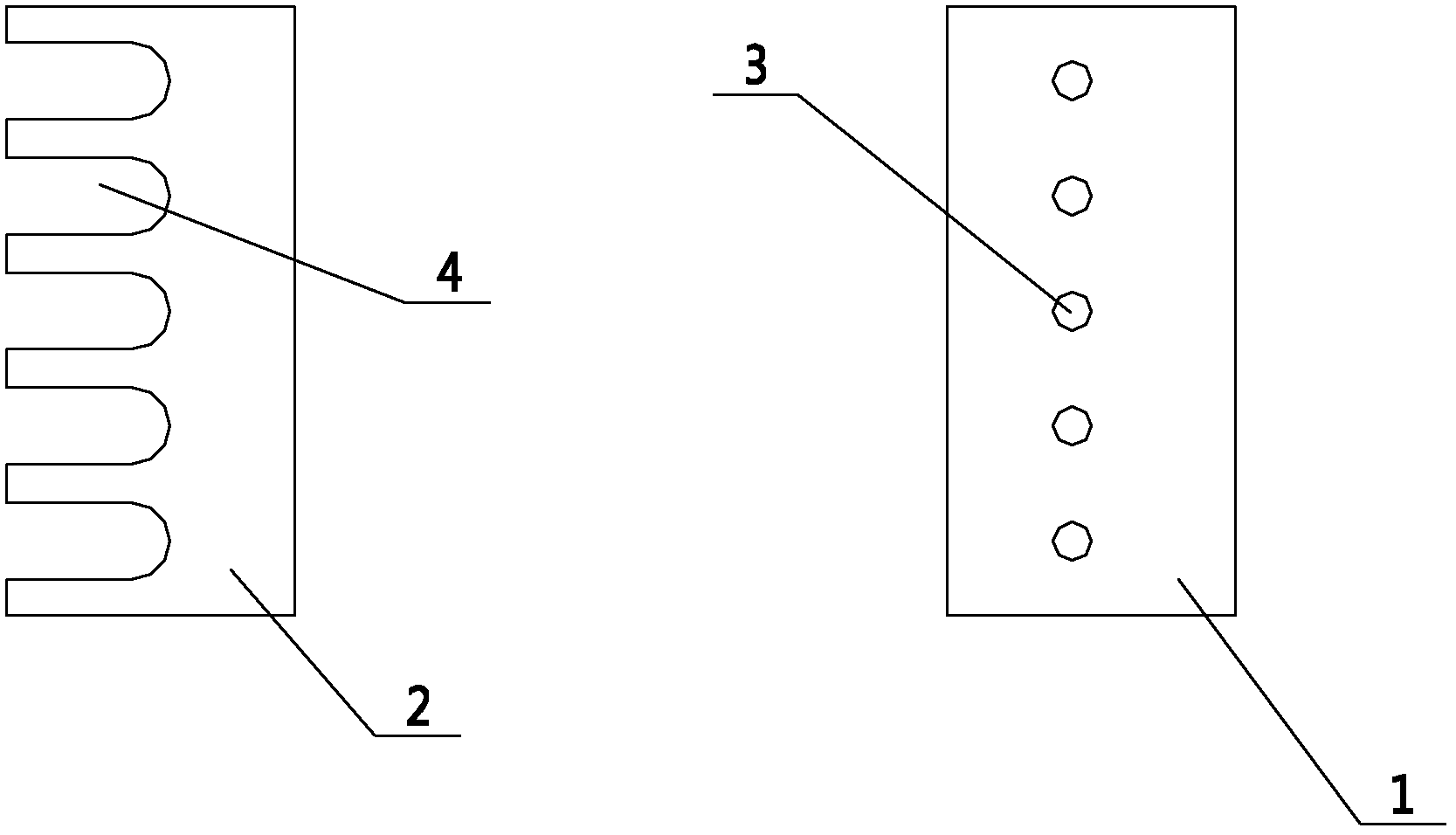

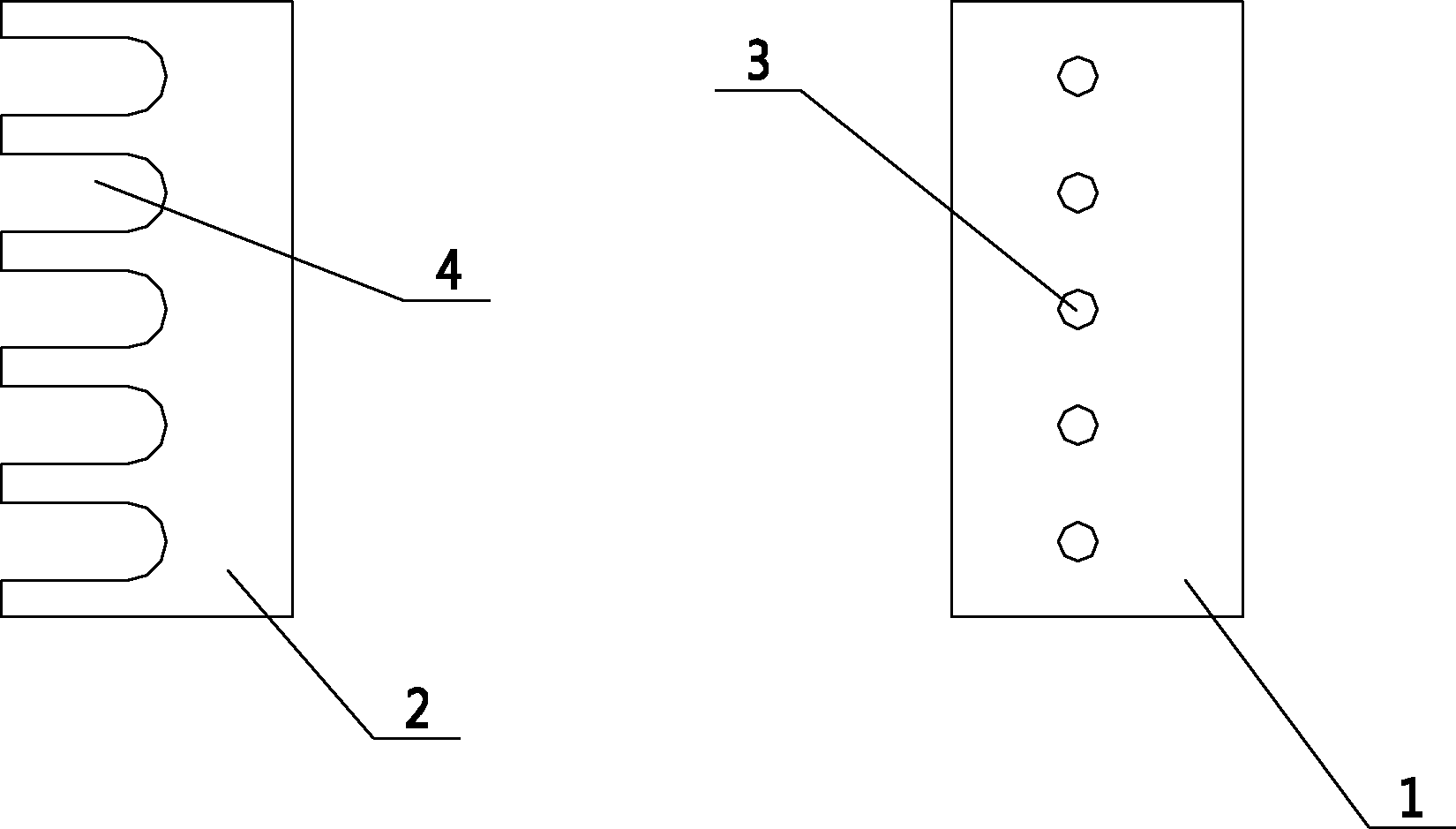

[0020] as attached figure 2 Shown is a jig for electrode processing according to the present invention, including a first clamp body 1 and a second clamp body 2 fixed on the workbench by adsorption; the first clamp body 1 and the second clamp body 2 are shaped, Cuboids with the same size; five fixing holes 3 are evenly distributed and spaced on the first clamping body 1; five U-shaped grooves 4 are opened on the second clamping body 2 relative to the fixing holes 3 ; The axis of each fixing hole 3 is collinear with the axis of the corresponding U-shaped groove 4 and is parallel to the workbench.

[0021] When clamping the workpiece, the first clamping body 1 fixes one end of the workpiece 5 to be processed through the fixing hole 3; the other end of the workpiece 5 to be processed is fixed in the U-shaped groove 4 of the second clamping body 2. , the workpiece 5 to be processed is par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com